Equipment for detailed processing of products

All this is special equipment for manual sharpening and finishing of various types of tools:

- The floor-standing grinding and grinding machine model 3K634 is equipped with two grinding wheels, type PP 400×50×203, PV 400×50×203.

- With a diameter from 110 to 450 mm or more, depending on the type of equipment and manufacturer.

- The height of the incisors to be sharpened should be in the range of 6–100.

- The permissible sharpening angle of the drill is from 70 to 140 degrees.

- Parts are processed with a universal wheel for detailed polishing of products H – 55 mm, D – 400 mm, Dpos – 50 mm.

- The spindle operates at a maximum speed of 30 m/min and a permissible rotation speed of 1.44 thousand revolutions per minute.

- Machine dimensions – 1000×665×1230 mm.

- The weight of the machine reaches 425 kg depending on the type of unit.

The equipment is mainly used for processing certain batches of parts; manipulations are carried out for finishing and repairing products for subsequent full-fledged work.

Technical characteristics of the grinding machine 3K634

| Parameter name | 3B634 | 3K634 | TS-3 |

| Grinding wheel | |||

| Number of grinding wheels | 2 | 2 | 2 |

| Type of grinding wheels | PP 400x50x203 PV 400x50x203 | 1-400x50x203 5-400x50x203 | GOST 2424-83 |

| Outer diameter of the circle, mm | 400 | 400 | 400 |

| Circle height, mm | 50 | 50 | 50 |

| Wheel diameter, mm | 203 | 203 | 127 |

| Diameter of worn circle, mm | 240 | ||

| Unbalance class | 1, 2 | ||

| Height of centers from base, mm | 900 | 900 | 950 |

| Recommended height of sharpened cutters, mm | 6-100 | 6-100 | |

| Diameter of sharpened drills, mm | 6-60 | 6-60 | |

| Drill tip angle, degrees | 70-140 | 70-140 | |

| Rear angle, degrees | up to 20 | up to 20 | |

| Rotation angle, degrees | +20..-1 | +20..-1 | |

| Contact roller diameter, mm | 400 | 400 | |

| Sanding belt width, mm | 80 | 80 | |

| Sanding belt length, mm | 3000 | 3000 | |

| Sanding belt tension force, N | up to 1000 | up to 1000 | |

| The largest diameter of the polishing wheel, mm | 400 | 400 | |

| Maximum height of the polishing wheel, mm | 55 | 55 | |

| Polishing wheel hole diameter, mm | 50 | 50 | |

| Spidel | |||

| Rotation speed, 1/min | 720/ 1440 | 1440 | 950 |

| Maximum cutting speed, m/s | 15/ 30 | 30 | 20 |

| Grinding spindle end (diameter/length), mm | 40/ 40 | 40/ 40 | |

| Electrical equipment | |||

| Drive electric motor, kW | 3,2/ 5,3 | 4 | 3,0 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 1000 x 665 x 1230 | 1000 x 680 x 1230 | 660 x 600 x 1670 |

| Machine weight, kg | 425 | 358 | 220 |

- Dibner L.G., Tsofin E.E. Sharpening machines and semi-automatic machines, 1978

- Demyanovsky K.I., Dunaev V.D. Sharpening wood cutting tools, 1965

- Kudryashov A.A. Tool production machines, 1968

- Lisova A.I. Design, adjustment and operation of metal-cutting machines, 1971

- Menitsky I.D. Universal sharpening machines, 1968

- Paley M. M. Technology of production of metal-cutting tools, 1982

- Rozhkov D.S. Design, setup and operation of equipment for sharpening wood-cutting tools, 1978

Bibliography:

Related Links. Additional Information

- Classification and main characteristics of the grinding group

- Repair, restoration and modernization of grinding machines: the American approach

- Cylindrical grinding. Processing on cylindrical grinding machines. Grinding Methods

- Setting up a cylindrical grinding machine when installing parts in centers

- CNC grinding machines

- Marking of grinding wheels

- Testing and checking metal-cutting machines for accuracy

- Grinding machines. Market of grinding machines in Russia

- Directory of grinding machine manufacturers

- Directory of factories producing metal-cutting machines

- Directory of surface grinding machines

- Articles on the topic

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Unit design

The 3M634 grinding machine has a very simple design that does not require complex maintenance; it is enough to carry out a certain list of operations. All technical characteristics are included in the passport.

The equipment consists of the following components and parts:

- power electric motor 380 V;

- floor stand – 358 kg;

- start and stop control buttons;

- two abrasive wheels and their protection;

- protective casing for the housing;

- lighting elements.

Main mechanisms of the unit:

- rotor;

- starter.

A modern 3K634 machine has a main unit responsible for the rotation of roughening, grinding and grinding wheels - a head with a two-speed electric motor. The housing with two covers houses the rotor, fan, stator and motor shaft; it replaces the spindle.

The fan is protected by a special casing to ensure safe operation; the cover is hinged to facilitate repairs or access to the object.

The 3K634 machine is equipped with a spindle support, due to which the wheels rotate accurately. Additionally, this element is responsible for the strength and reliability of the equipment of the entire unit. The supports have fatty grooves on the inside and axial labyrinth elements on the outside.

Since the engine heats up during operation, the manufacturer provides a fan that effectively cools it with circulating air flows inside the head and frame.

Unit features

The bed is made of cast iron. All important elements are located inside the part. Access is provided through a special window in the front part, which is closed with a special lid.

To fix the wheels on the spindle, adapter flanges with three crackers on the outside are used, which help with balancing.

The instruction manual prohibits operating the machine without protective covers made of steel.

The casing is equipped with two visors made of organic glass. To collect dust that is generated during the processing process, retractable dampers and dust collectors connected to the hood are used. This helps reduce dust accumulation by up to 40% during roughing and grinding work.

Transparent screens with protective functions are equipped with lighting using a lamp. The passport recommends using 41.6 W lamps in this case.

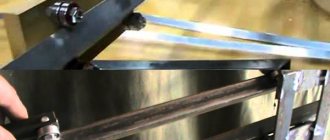

To change the circles, no additional effort is required; you just need to fold back the side of the metal protection.

The set of the grinding and grinding machine model 3K634 includes:

- turntable;

- handyman

These elements allow sharpening of turning cutters up to 100 mm high. During operation of the 3K634, strong vibration occurs, which requires specialists to be fully aware of the load-bearing capacity and strength of the floor covering. Before installation, a proper installation plan must be developed.

Application of grinding machines

A sharpening and grinding machine can be called differently: an electric sharpener, an emery machine, a grinding machine, or, according to the international classification, a Grinding machine. Each of these names refers to equipment that is used to manually sharpen and fine-tune tools for various purposes.

Using such machines, the working part of which is an abrasive, diamond or CBN wheel, you can sharpen and finish tools used for processing metal and wooden workpieces. Machines of the sharpening and grinding group are also successfully used for chamfering and deburring, manual grinding, cleaning and stripping parts made of metal, wood and other materials.

Sharpening a countersink on a grinding machine

Based on criteria such as purpose, several categories of sharpening and grinding machines are distinguished.

Small-sized tabletop sharpening and grinding equipment

Such devices, used for sharpening and grinding small tools, can be equipped with working wheels with a diameter of 100–175 mm.

Mid-range floor equipment

The wheels installed on such sharpening and grinding machines must have a diameter of 200–350 mm. These machines are used primarily for sharpening common types of turning tools in manufacturing plants.

Large grinding machines

These devices can accommodate machining wheels with a diameter of more than 400 mm. Large manufacturing enterprises are equipped with such equipment. Using sharpening and grinding machines of this category, you can effectively perform roughing, cleaning and grinding.

The technical capabilities of these devices make it possible to additionally equip them with devices that make it possible to perform such technological operations as sharpening drills, dressing wheels, belt grinding and polishing. The grinding wheel on such equipment can be replaced with a polishing washer, which allows polishing operations to be performed with high efficiency.

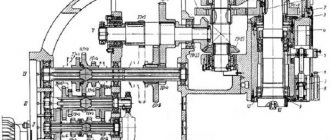

Installation diagram of the 3K634 machine

Advantages

The 3K634 sharpening and grinding machine has the following advantages:

- simplicity of design;

- multifunctionality;

- versatility;

- quality of equipment and its components;

- ease of installation and operation;

- accuracy of work;

- safety;

- attractive price;

- reliability and strength;

- long service life.

Operating rules

Before using the machine, you must perform the following steps:

- Install the equipment on a level surface, without additional elevation.

- Provide the room with a 380 V electrical network; it is operational for 3K634.

- Take care of forced ventilation.

- When connecting, check the correct rotation.

- Check the functionality of the circuit breaker, which provides overload protection.

Before operating the machine, the operator must undergo appropriate training. Since the electrical part wears out during long-term operation, personnel must periodically check these elements of the machine.

When starting up new equipment for the first time, wipe it with a rag soaked in acetone or gasoline to remove the anti-corrosion coating. After checking the serviceability of all elements, specialists launch it.

It is imperative to balance the abrasive wheels, which, when rotating, should not create a feeling of beating.

Preparing for the first launch

When installing a new model, before use, it is necessary to wash off the anti-corrosion coating with a rag soaked in gasoline or acetone. The electrical and mechanical components of the machine are then checked. After this, you can carry out the first test run.

Don't miss: Metal grinding machines: design, purpose, application

A prerequisite is the balancing of abrasive wheels. There should be no beats during their rotation. This is checked manually by turning the pulley rotor and visually observing a possible change in the gap between the wheel and the protective casing.

To control the correct operation of the sharpening and grinding machine, idle running is performed for 10 minutes. If no external changes or defects have been recorded, proceed to processing of tools, parts or workpieces.

The video describes in detail the design of grinding machines of this type and the parameters for choosing abrasive wheels:

Safety precautions

To safely use the 3K634 roughening, grinding and grinding machine, the following rules must be observed:

- Installation of equipment is carried out only on a level basis.

- The place where the machine works must be equipped with forced ventilation.

- The unit must be grounded.

- The machine must not be left unattended while the engine is running.

- You should leave the room only after the engine has completely stopped.

- Periodically, all equipment mechanisms are cleaned of abrasive dust.

Reviews from masters

Alexander, Novgorod: “The 3K634 sharpening and grinding machine is Soviet quality and reliability, with no plastic parts, since the body is made of cast iron. The equipment is convenient to use not only for industrial needs, but also in small workshops or workshops.”

Zakhar, Samara: “Accuracy of operation, ease of operation and reasonable price make the machine attractive to many specialists in the country. I have a small workshop, which is equipped with a number of necessary machines and tools, including 3K634, it makes work more productive and uninterrupted. A really good unit that has never let us down.”

Igor, Pskov: “The 3K634 machine is an excellent assistant, the unit is distinguished by high quality and excellent technical characteristics, as well as an affordable price. We have been using the equipment for several years and have had no complaints. Accurate operation, many useful functions. No plastic, only durable and reliable metal. It is worth emphasizing that the machine is produced by a plant with years of accumulated traditions.”

Design features of the machine

Appearance

After an initial analysis, you can notice that the equipment differs from similar models in its simplicity of design and minimal operating requirements. The circuit of the 3K634 grinding and grinding machine consists of a vertical frame on which an electric motor is installed.

The power unit is built into the equipment head. The shaft of a two-speed electric motor simultaneously functions as a double-sided spindle. Abrasive wheels with different grain sizes and overall dimensions are installed on it. The main part of the electrical equipment (rotor, fan impeller and stator) is located in a closed unit. To access these elements, a cover is provided in the design.

Additionally, it is necessary to highlight the following design features of the 3K634 machine:

- ball bearing supports. They have a radial contact shape, which reduces the likelihood of backlash during operation;

- air cooling is carried out using a built-in impeller. The absence of a water system significantly reduces the weight of the machine;

- monolithic frame with control unit. It is made of cast iron with space for installing electrical equipment and controls;

- presence of protective covers. They not only increase operational safety, but also regulate the position of the tool relative to the abrasive wheel. For this purpose, at the bottom of the structure there are platforms with adjustment functions.

To increase comfort, transparent protective screens have lighting fixtures. They rotate at a certain angle, the value of which can reach 45°.

The tool rest has two working platforms – flat and curved. The first is used when processing smooth surfaces. If it is necessary to grind a curve, it is recommended to use a different type of working platform.