How to drill a perpendicular and vertical hole

Although it is sometimes necessary to drill at an angle, it is most common to make vertical holes (that is, perpendicular to the surface). In order for drilling to take place strictly at an angle of 90 degrees, it is necessary to use special guides. They will allow you to drill perpendicularly without deviating in any direction.

The simplest guides allow you to make only vertical holes, but there are also more complex designs that allow drilling at certain angles.

Portal about construction

How to drill metal How to drill glass How to drill tiles How to drill concrete How to drill wood and chipboard

Small diameter holes (up to 10-12 mm) in wood and chipboard are most often drilled with ordinary metal drills. They cope with their task quite successfully. But if every millimeter is important for the position of the hole, then you need to use special drills.

When entering wood, a metal drill may deviate slightly to the side, even if a recess is made with an awl at the site of the future hole.

In general, drilling wood can be done even with an ordinary nail or a piece of wire with a flattened end. Special drills for wood have to be resorted to only when it is necessary to drill a hole of large diameter, or when increased demands are placed on surface cleanliness and accuracy. There are several types of such drills:

- spiral (a);

- twisted or single-spiral (it is sometimes also called spiral) (b);

- feather (in);

- annular (crown) (d);

- Forstner cylindrical drill (d).

Drills for drilling wood

Drills for wood are made from tool alloy and tool carbon steels; metal cannot be processed with them.

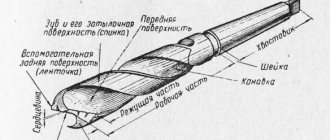

Twist drill

drill holes of small and medium diameter. It can easily be replaced with a metal drill bit, although the hole will be cleaner if you use a wood twist drill bit.

Single twist drill

It has a sharp cutting edge and a screw shape that removes chips well. It is used when you need to get an accurate deep hole with a clean surface of the walls.

Feather drill

They are usually used when drilling holes with a diameter of 10 to 25 mm, although there are drills with a diameter smaller than 10 and larger than 25 mm.

This drill is the simplest in design and the cheapest, so it is reasonable to use it in all cases where high demands are not placed on the quality of the hole. The disadvantages of a feather drill include poor direction, low diameter accuracy, rough surface of the hole walls, and the need to periodically remove chips by stopping drilling and removing the drill from the hole. The advantages are simplicity and low cost. Feather drill

bits

used when drilling large diameter holes - up to 100 mm or more. The kits contain one mandrel with a shank and a centering drill and several bits that are inserted into the mandrel.

Drilling holes with

a Forstner drill

has a centering point and a sharp scorer. Thanks to the latter, it is distinguished by precise cutting geometry. Typically used for drilling blind holes to precise dimensions in softwood, chipboard or laminate for the installation of furniture canopies.

Forstner cylindrical drill

Forstner cylindrical drill

Forstner drill can be short or long pointed.

Forstner drills

It is more difficult to make a blind hole for a hinge in a thin door with a Forstner drill with a long point, since the point can make a through hole. But a drill with a short tip is more prone to moving to the side. In addition to differences in the length of the tip, the Forstner drills shown in the photo above differ in their maximum rotation speed. So a drill with a short tip has welded knives made of high-speed steel and is suitable for working at high speeds, and a drill with a long tip has a maximum rotation speed when working with soft wood equal to 1000 rpm.

There is another device for cutting large holes - this is a ballerina

, designed for cutting large (up to 300 mm) holes in thin pieces of wood, chipboard, fiberboard and other materials.

Ballerina

The ballerina consists of a centering drill and two cutters that are used to cut out a circle. The displacement of the cutters along the guide sets the diameter of the circle being cut. To rotate the ballerina, use a brace or drill with a low speed. You can also rotate it manually.

How to drill wood and chipboard

To prevent the drill from going to the side at the very beginning of drilling, you need to make a small depression in the center of the future hole with an awl. Drilling wood is carried out at low and medium speeds of the drill. The main problem when drilling through holes is chipping at the drill exit. There are two ways to deal with them. First drill a thin hole and drill along it from both sides of the part to the middle with a drill of the final diameter. In this way, it will be possible to avoid chips that occur at the exit. The second method is to firmly press a piece of wood onto the side where the drill comes out, which is removed after drilling.

To make the drill perpendicular, jigs are used. The latter are especially convenient for making holes in cylindrical parts.

Drilling jig

Drilling chipboard requires special attention due to its fragile structure. The presence of laminated or veneer coating complicates the task. To avoid their peeling, use drills with a sharp edge (in particular, a cylindrical Forstner drill) and a backing plate at the exit. To mark holes, be sure to use an awl.

What you need to know about drilling holes in metal

You can secure a metal sheet or part using a variety of fasteners. However, you need to make holes for them. Drilling holes in metal requires a person to use special tools. To carry out the work without difficulty, you need to be able to choose equipment and work with workpieces of different sizes.

Drilling holes in metal

Equipment types

Drilling begins with preparing tools for work. You can make holes using a screwdriver, drill or a special drilling machine.

To make a hole, you need to select the appropriate equipment. For metal workpieces, you need to choose specialized equipment that is suitable specifically for this material. This is due to the fact that equipment for wood, concrete or ceramic tiles have different sharpening and shape. Tooling for metal products is marked with the letters HSS.

The working part of the tool is coated with titanium nitride coating, which increases their strength and wear resistance. For hard steels, a different tooling is used, which is designated P18. The strength of the tool increases when cobalt is added to its composition. An example of marking is P6M5K5.

To drill alloy steel, drills with a tip made of carbide are used. With their help, you can drill any metal workpieces, however, due to the high price, this is not cost-effective.

When the hole is made, you can select a drill for the thread. Its diameter will depend on the previously used equipment. To make holes of different diameters in thin metal sheets, you can use cone drills.

Is it possible to drill with a drill in concrete?

Situations often arise when it is difficult to find a tool for drilling metal products at a construction site, but there is equipment for working with concrete. You cannot make holes of large diameter or in thick metal sheets with concrete drills. Otherwise, you may break the equipment or damage the surface being processed.

How to drill with a step drill?

On sale you can find stepped structures for creating holes in metal of various diameters. Several drills of different diameters are fixed on one axis. They are designed to create holes of various sizes in thin sheet metal. When working, do not rush or put too much pressure on the drill handle.

Is it possible to drill with a Pobedit drill?

Any master of finishing work will tell you that drilling metal with Pobedit equipment is unacceptable. Pobedite drills are designed for hard and, at the same time, brittle materials. These include natural stone, brick, concrete. When it hits metal, the drill will hit the surface and damage it, but there will be no hole.

How to drill large diameter holes?

Drilling large holes in metal requires the use of appropriate equipment. You can do the work in several ways:

- Crown for metal surfaces. It is a circle of the required diameter with sharpened edges. There is a drill in the center that pierces the metal. Next, at low engine speeds, the bit makes a hole of the selected diameter. During work, it is necessary to use forced cooling of the sharp edges of the crown and the surface being treated.

- Multi-stage operation. This implies the use of several metal drills of different diameters. Work begins with equipment of the smallest diameter and increases as drilling progresses.

- Cone-shaped equipment (stepped). Designed for working with thin sheet metal.

Builders recommend using crowns. However, when working with them, it is necessary not to increase the speed and ensure that all the teeth running around the circumference are intact.

How to avoid dulling a tool?

The tool becomes dull because it overheats during use. To maintain sharpness, drilling should be done at low speed. There is no need to press the power button all the way down. When drilling thick workpieces, you need to use coolants or pastes.

If there is no cooling lubricant, machine oil can be used instead. Coolant keeps the tool from overheating and reduces friction.

How to drill metal correctly?

When you turn on the tool, the drill may slide to the side, which makes it difficult to make a hole in the selected location. You can cope with this problem using a core.

It is a metal cylinder with a sharp point at one end. It is necessary to attach the sharp end to the marking and hit the back side of the core with a hammer.

There will be a notch on the metal through which a hole is drilled. DISASSEMBLY 3. Drilling metal

Drilling thick workpieces

Not many novice craftsmen know how to drill a hole in thick metal. Deep drilling is more difficult than usual. In production, it is carried out using lathes. In them, the workpiece is fixed in a movable spindle, which rotates it.

If it is not possible to use industrial equipment, you can drill a deep hole using a drill. To do this, you need to purchase special guides for power tools. Additionally, it is necessary to use machine oil for cooling. During operation, you need to stop periodically to clean out the chips and allow it to cool.

How to drill with a drill?

Drilling metal with a drill requires following some recommendations:

- To make a hole you will need an electric drill, a core punch, a hammer, machine oil and safety glasses.

- Initially make markings.

- Wear safety glasses.

- When the pressure on the drill is low, you need to select the low speed position and start working.

- Don’t forget to water the area being treated with coolant.

If you follow the technology and use high-quality tools, you can make holes of different diameters and depths. To drill straight holes or accurately select the depth, you can use a device called a “depth stop.” It is attached to an electric drill and adjusted to the desired depth.

How to drill with a screwdriver?

You can drill metal workpieces not only using industrial equipment or an electric drill, but also using a cordless screwdriver. This power tool is low power. Because of this, it is suitable for drilling holes of small diameter and depth.

Drilling is performed using industrial equipment and power tools. It is important to choose the right equipment and take into account the depth and diameter of the hole. To ensure that your equipment lasts longer, you should use coolant. You need to drill perpendicularly to avoid damage to the workpiece or tool.

Portal about construction

How to drill metal How to drill glass How to drill tiles How to drill concrete How to drill wood and chipboard

Small diameter holes (up to 10-12 mm) in wood and chipboard are most often drilled with ordinary metal drills. They cope with their task quite successfully. But if every millimeter is important for the position of the hole, then you need to use special drills.

When entering wood, a metal drill may deviate slightly to the side, even if a recess is made with an awl at the site of the future hole.

In general, drilling wood can be done even with an ordinary nail or a piece of wire with a flattened end. Special drills for wood have to be resorted to only when it is necessary to drill a hole of large diameter, or when increased demands are placed on surface cleanliness and accuracy. There are several types of such drills:

- spiral (a);

- twisted or single-spiral (it is sometimes also called spiral) (b);

- feather (in);

- annular (crown) (d);

- Forstner cylindrical drill (d).

Drills for drilling wood

Drills for wood are made from tool alloy and tool carbon steels; metal cannot be processed with them.

Twist drill

drill holes of small and medium diameter. It can easily be replaced with a metal drill bit, although the hole will be cleaner if you use a wood twist drill bit.

Single twist drill

It has a sharp cutting edge and a screw shape that removes chips well. It is used when you need to get an accurate deep hole with a clean surface of the walls.

Feather drill

They are usually used when drilling holes with a diameter of 10 to 25 mm, although there are drills with a diameter smaller than 10 and larger than 25 mm. This drill is the simplest in design and the cheapest, so it is reasonable to use it in all cases where high demands are not placed on the quality of the hole. The disadvantages of a feather drill include poor direction, low diameter accuracy, rough surface of the hole walls, and the need to periodically remove chips by stopping drilling and removing the drill from the hole. The advantages are simplicity and low cost.

Drilling holes in the wall correctly: general rules and recommendations for what to drill

In order to drill

wall, you need to take into account the material from which it is made, based on this you need to select a tool.

- When working, hold the tool correctly. For example, a drill should be held straight in your hands and enter the surface in a vertical direction;

- for convenience, use an additional handle;

- Depending on the surface material, select the necessary drills.

- concrete, stone, brick wall - use a carbide drill, usually a Pobedit one;

- metal – metal drill;

- tiles, ceramic tiles - special drills for these materials, sometimes they can be replaced with a drill for concrete with Pobedit surfacing;

- Chipboard, wood - for holes smaller than 10-12 mm, a metal drill is suitable; for larger ones, special wood drills are used.

How to drill without a drill

When renovating an apartment, attaching shelves, lamps, carpets, paintings and other items to the wall is not an easy task, especially if the walls are made of reinforced concrete blocks or panels. The main difficulty in this case is to punch a hole for a nail or screw.

Previously, 20 years ago, various bolts and drills were used for this. It was a difficult and long process. Today, all this work can be done using special power tools. The depth of the hole depends on its purpose. For fastening heavy objects, a hole with a depth of 5–7 cm is required. For lighter objects – 5 cm.

But what if you need to make a hole, but the electricity has not yet been supplied? The old way will do here. The hole can be punched using a special bolt. The technology is simple. Place the bolt at the point of the future hole and start hitting it with a hammer. After each blow, the bolt must be rotated around its axis. During operation, the bolt must be periodically removed from the hole and cleaned. Long, but effective.

You can punch a hole using a metal dowel. Using strong and sharp blows, we hammer the dowel into the wall 2–3 mm, then loosen it with pliers and remove it from the hole. We repeat these steps until a hole of up to 2 cm is obtained. It is difficult to make a deeper hole using this method. And one more way. This is when a hole is made with a drill inserted into a hand brace. In the absence of a brace, the drill can be used as a punch. In this case, you need to hit the drill sharply, but not too hard.

How to make a hole in metal without a drill

How to drill concrete

wall with a regular drill and hammer drill?

How to drill through a concrete wall with a regular drill? - this is the question that the craftsmen probably asked when they had to hang shelves, cornices and so on.

Concrete is a strong material and therefore can be drilled very poorly. Even how to drill a wall in a panel house seems an unsolvable problem.

Although, if you know certain secrets, this process will be significantly simplified for you.

How to make a hole in a concrete wall without a hammer drill and a hammer TEST!

If you need to attach a baguette in your house, but you don’t have a jack drill

, then the hole can

be made

using a conventional

The eyes are afraid. hands do || How to “drill” a hole in concrete WITHOUT A PERFORATOR

The eyes are afraid. hands do || How to drill a hole in concrete WITHOUT

PERFORATOR My drill does not have a single drill

There are also such bits for drills. But they have a coating of a different nature - from a tungsten-cabrid alloy. They are convenient to use, since you can drill a hole

in a concrete wall and at the same time making a hole in the tiles is quite possible for her. Such crowns are used only with powerful drills.

Drills are another tool for drilling into a concrete wall. Their diameter is varied. In the vast majority of cases, when installing hidden electrical wiring, there is no way to do without such a dirty and noisy procedure as gating. Experienced craftsmen advise making a selection based on the diameter of the dowels.

DIY drill

Small-sized hand drills, the like of which you can make yourself, are best suited for this operation. To do this, two laces and a handle are tied on top to a rigid axis, which can be a steel or wooden rod, and a sharpened nail on the bottom. In the middle of the rod you need to attach a heavy flywheel, which will act as an inertial battery. In order to put this drill into action, the laces are manually wound onto the rod, and then, after installing the nail in the right place, they press the handle. The rod rotates and the nail is drilled, the pressure on the handle is stopped when the laces are completely untwisted. The flywheel rotates by inertia and winds them onto the rod again, and then stops and you need to press the handle again. Viscous wood species may not yield to such a drill, as the drill will get bogged down and slow down its rotation.

DIY screw drill

For the construction of a screw drill, a rotation mechanism from a children's top is well suited. Instead of a cartridge, a pencil holder from a compass works well. When you lower the engine with the same thread by hand, the screw axis of the drill begins to rotate. With this mechanism of action, the drill head must rotate freely on the axis.

If you don’t have a top at hand, you can bend the screw of this action yourself. To do this, you will need a strip of steel, one end of which must be secured in a vice mounted on a machine or on a table, and the other end must be secured in a hand vice. When the hand vise is rotated, the strip is evenly twisted into a screw, onto which a wooden slider with a pre-drilled hole is then mounted. In order to ensure that the engine does not have any difficulties when passing the screw surface of the strip, the strip is heated and, passing through it in this state with the engine, a thread is made on the strip. To make a hat, a small wooden ball with a hole slightly larger in diameter than the diameter of the screw is suitable.

While traveling in Laos I need to drill some holes in the wood of a double door to install a cabinet. The wood is quite hard and I don't have an electric drill (and can't find one).

I only have two small screwdrivers (- and +), a small hammer, but I can find screws, nails and other basic tools. The wood is hard (so much that I can't even get it to fit into a small screw), the screwdrivers aren't very good quality, and the screws are even worse.

Any recommendation on locking the door from the inside would be of interest if this is not possible.

Answers

Make a bow drill:

Take a piece of wood large enough to hold in your hand. Clean out a small hole in the forest. The non-pointed end of the drill fits into this hole. This is called "holding the hand."

You are going to use this block of wood to push the drill bit through the door.

Make a bow from strong wood and strong thread. Wrap the cord around the drill bit, perhaps a couple of times, to get a good grip on it.

A way to make a hole without a drill from the forum

I did this once and it can be done carefully. But it will take all damn day and the workout will work better.

Take a paperclip and straighten part of it. Using steady pressure, press the paperclip point where you want the center of your hole to be. Turn it left and right like a screwdriver/awl. This will drill a tiny hole into the soft plastic.

Once you can fit through the point of the paperclip, take a Phillips screwdriver with a thin enough point and do the same. Once it fits, take an even larger dragonet and do the same thing again.

Eventually you will have a hole large enough to fit the file. I would suggest a round file, but if you can't find one or use a ghetto, use a nail as it has soft plastic in it.

Use a file to enlarge the hole on all sides. It's unlikely that you'll be able to make a perfect circle, so take it a little at a time and keep trying to place the button. Try to write down the minimum minimum size to get the button because if you load too much it will look ugly or the hole will be too big.

Good luck, but this method takes forever. Find a movie to watch while doing this, or just buy a cheap exercise.

Source

What is a wood ballerina

A circular adjustable ballerina drill is a device that is designed for drilling round holes of large diameter. The tool has a simple design. It consists of a shank with a transverse rod on which movable carriages with cutters are attached. The rod has markings according to which you can set the required spread of the cutters relative to the center of the intended hole. A core drill is fixed in the middle of the shank. It serves as a centering element and support when drilling.

In addition to designs with two cutting elements located symmetrically, there are ballerinas with one cutter or even three. In the latter case, they are located on the base in the form of a disk with grooves.

Tool functionality

A high-quality ballerina is made of high-strength steel, which makes it possible to use the device in working with soft and hard wood.

This tool has an adjustable drilling diameter. This allows you to make holes of almost any diameter. The limitation of the drilling range depends on the size of the ballerina. Manufacturers produce devices with the following cutter spread limits:

- from 30 to 120 mm;

- from 40 to 200 mm;

- from 40 to 300 mm;

- from 40 to 400 mm.

The maximum drilling diameter is limited by the rod on which the cutters are mounted. The minimum is the thickness of the shank.

A ballerina drill can be used in any places where using a jigsaw or a hand router would be inconvenient. For example, this may be assembled and installed furniture, in the part of which it is necessary to drill a neat hole, given the limited space. Another example is an uneven (concave or curved) surface. It’s unlikely that you’ll be able to do everything smoothly and neatly with a jigsaw or milling cutter. It will be difficult to control the inclination of the tool relative to the surface. A ballerina can easily cope with this task.

Features of working with the tool

The principle of working with a circular drill is simple. A hole is drilled using a centering drill, and then the cutters are put to work. They gradually make a narrow groove, gradually cutting through the material in a circle to the full depth.

The materials used in working with the ballerina are varied: wood, fiberboard, chipboard, MDF, plasterboard, plastic. One common point is that the thickness of the part should be no more than 15-20 millimeters. This parameter is limited by the length of the incisors. Usually the manufacturer indicates the maximum drilling depth on the packaging. If you try to drill into thicker material, you may experience problems with ragged edges.

The use of a tool with one cutter is characterized by runout. This is caused by a lack of balancing relative to the longitudinal axis of the drill. The beating will be especially noticeable when cutting large diameter holes. Cut holes using a drill at low or medium speed. When working on a drilling machine, such problems do not arise.

Also, a laminated or veneered surface can cause inconvenience when working. After passing through the decorative layer, drilling proceeds without problems.

A feature of the circular drill can be considered the ability to adjust the diameter. The distance between the cutters can be set using a scale on a rod or more accurately using a caliper. This is convenient if you need to make a hole without gaps for a pipe or round part.

The spacing of the cutters relative to the center is adjusted individually. It is necessary to align the cutting parts as accurately as possible. This will eliminate unnecessary effort during operation and extend the life of the tool.

Drilling concrete with a hammer drill

So how to drill

hole in a concrete slab using a hammer drill? The procedure is simple:

- the drill switches to impact mode, after which drilling begins; the tool must be held strictly at a right angle;

- after some time, the drill is moistened with water, this will help avoid overheating;

- after you in drilling a reinforced concrete wall, the drill must be removed without turning off the device itself;

- To clean the resulting hole from dust, a drill is inserted into it several times.

Can't drill

wall? Did the hammer drill hit something hard? This means you need to try making a hole in a different place.

How to choose and what to pay attention to

Choosing a high-quality circular drill is quite easy. The main thing is to know the main points that you should pay attention to first, but also not to lose sight of the little things.

The design is a very important point: a wood ballerina comes with one chisel or two or more. For frequent use, it is better to purchase an option with two or three cutting elements. It is easier to work with such devices and the quality of the processing performed will be at an acceptable level.

It would not be superfluous to be able to replace individual parts. Inexpensive circle drills can have a solid shank with a permanent center drill and rod.

Metal, its quality determines its strength and ability to withstand workloads. High-quality tools are made from high-strength steel or alloys. The shank and cutter holders are shaped using a machine tool. The rod is usually stamped and made of the same metal.

Cheap options often use soft metal or alloys, which can be brittle. Under load, parts may become deformed or break. Such a tool will not last long and it will also be difficult to achieve accuracy from it.

The quality of workmanship, the main feature is the absence of backlashes and distortions. All parts must fit together and be securely fastened with fixing screws.

The markings of a high-quality ballerina's barbell are stamped. Sometimes the divisions are highlighted with bright paint for better visibility.

Cutters and high-quality cutting elements are made from hardened tool steel. They are secured to the holders with rivets or soldering. Solid cutters with holders (made of the same metal) quickly become dull and are not durable.

Manufacturer, when choosing any tool and consumables, preference should be given to well-known and long-proven brands and brands. The most common are Topfix, Stayer, Irwin, Strum.

Purchasing an adjustable circular drill for use at home, or if you need to drill several holes, is completely worth it. This eliminates the need to purchase an expensive tool that may only be needed a few times.

How to drill a straight perpendicular hole with a hand drill

If you don’t have a drilling machine at home or at least a stand for a drill, then drilling an even perpendicular hole is quite a difficult task. To do this, you will need special devices, for example, a jig for drilling holes, but you can’t buy such a device everywhere, or you need to make a vertical hole at 90 degrees urgently. Let's find out how at home you can easily drill a perpendicular hole using a regular hand drill.

The first device for evenly drilling holes is quite simple - it’s a pair of pieces of wood fastened together with a tenon and an iron construction fastening angle glued to the inside, that’s all, I further refined it with stain and varnished it since this is a device I use quite often.

How to drill a straight perpendicular hole with a hand drill

How to drill a straight perpendicular hole with a hand drill

It’s easy to use, we put it on its side, put the drill in the intended place, lean the inner corner of our homemade corner tightly against the drill and drill like that, if the hole should be very deep, and this corner is already in the way, then you can safely remove it and drill further without it , since then the drill itself will go straight.

How to drill a straight perpendicular hole with a hand drill

How to drill a straight perpendicular hole with a hand drill

The second device is a conductor made of a wooden block; using a corner, we mark an even line at 90 degrees on it. Then on a circular saw we set the cutting depth to about 5-7 mm and make cuts with it. Using a utility knife, we make chamfers on the edges of the cut and the jig for drilling vertical holes is ready!

How to drill a straight perpendicular hole with a hand drill

How to drill a straight perpendicular hole with a hand drill

How to drill a straight perpendicular hole with a hand drill

How to drill a straight perpendicular hole with a hand drill

Now we place our jig on the surface that we will drill, bring the guide recess to the drill and drill, pressing the drill to this cut.

How to drill a straight perpendicular hole with a hand drill

If you don’t have time at all to make such devices, you can simply take two slats, move one slat slightly relative to the other to form an angle and tighten them with clamps, then placing the clamp in this corner, you can quickly drill an even perpendicular hole with a drill without using a stand or drilling machine.

How to drill a straight perpendicular hole with a hand drill

Article rating:

How to drill wood without a drillLink to main publication

Related publications

- Hand tools of a professional electrician

How to drill a hole straight

A fairly common problem is that the drill slips off the mark and the hole is not made in the right place. the tree can help combat this.

. Also, sometimes similar difficulties arise if you have to work with an overly thick drill. Then you should first make a recess in the material with a thinner drill, and then drill, resting against the mark you made.

It is important to pay attention to the quality of sharpening. If the edges are not sharp enough or sharpened unevenly, problems with drilling accuracy may occur.

READ How to Make a Hole in Wood Without a Drill