When installing a sewer system, the most questions arise when it comes to the septic tank. In a wastewater network, it is an element of a treatment plant, and therefore requires a competent approach to design. Having properly installed a septic tank with your own hands for your home and dacha, you can easily do without pumping for 10 years.

Work is underway to install a sedimentation tank

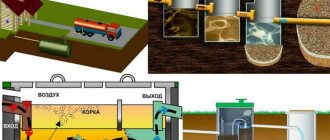

About the working principle

The simplest 2-chamber septic tank is:

- a settling tank in which wastewater is decomposed into solid waste and water (≈3 days);

- a filter well, but without a sealed bottom, into which purified water from the sump tank flows through the overflow, then discharged into the ground.

It is quite possible to build a sequential chain of settling tanks with your own hands. Moreover, the more of the latter, the better the pumping will be and the higher the quality of purification, and therefore cleaning the filtration well will not be required for a long time due to silting.

Even if you install a multi-chamber septic tank, it will not be possible to completely clean the drains. A septic tank designed to hold wastewater in it for three days, regardless of the number of sections, is not capable of providing that degree of purification, or more precisely, the biochemical oxygen demand (BOD) - 2 mg/l or less, which allows water to be discharged further into the reservoir ( option - a ditch for waste disposal). A septic tank designed for 10-day settling gives 25 mg/l of BOD (for a 3-day analogue, purification will not exceed 90–100 mg/l of suspended solids). Therefore, dividing a “3-day” septic tank into sections is ineffective, except for relative comfort - sediment is removed from it more easily. The bulk of the sediment, let us clarify, is collected in the 1st section, the water is not polluted again.

Do-it-yourself sealed septic tank for home and garden: without pumping for 10 years - this is real

Regardless of the container used, a pit will have to be dug in any case. The volume of work associated with excavation is quite large. In order to save money, all operations with land can be carried out manually without the involvement of equipment. The hole should be 30-40 cm larger than the container itself.

Two pits are being prepared at the site

The process of constructing a septic tank from concrete rings with your own hands according to a two-chamber scheme

In many cases, a septic tank made of concrete rings is installed on the site with your own hands. The schemes for its construction are not complicated. Immediately before work, ready-made reinforced concrete elements of the required dimensions are purchased. Typically, a two-chamber design requires six rings and two manhole covers.

Reinforced concrete rings for work

The procedure for construction should be as follows.

- Reinforced concrete elements are placed in the prepared pit. They are installed directly on top of each other.

- The bottom of one well is filled with concrete, and the other is filled with sand and gravel.

- Holes are made in the upper rings for the outlet of sewer pipelines.

- The joints between the structural fragments are sealed with cement-sand mortar.

- Covers with hatches are installed on top, after which the edges of the pit are backfilled with earth.

The following covers should be placed on top

Important! A fairly common option is when the rings are lowered not after digging a pit, but sequentially. Excavation is carried out gradually from the inside until the products are completely embedded in the ground.

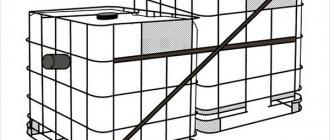

Construction of a settling tank using Eurocubes

For your dacha, you can make a septic tank from Eurocubes with your own hands. Without pumping, it can also last for a long time. Plastic containers, which are three-dimensional cubes, are able to withstand the load from the soil. Their resistance to aggressive substances is very high.

Eurocubes are polymer containers

When installing containers in a pit, it is necessary to carefully seal the drain holes. The containers are connected to each other with polypropylene pipes and fixed with reinforcement or wire. The bottom of the last container is cut out, and a cushion of sand and crushed stone is poured onto the surface of the earth.

To reduce the load on the walls of Eurocubes, you can lay slate around the perimeter

Since there is still a risk of plastic containers being pressed through, you can fence the walls on all sides with old slate. If additional insulation is performed with foam plastic, then there is no need to install asbestos sheets. The load from the ground in this case will be evenly distributed over the entire surface.

Creation of a treatment structure from a concrete composition

When installing septic tanks for a private home with your own hands, the option of filling the walls and floor with a concrete mixture is also considered. However, this method is one of the most labor-intensive, as it requires the preparation of a building composition and its laying in a mold.

Formwork with embedded reinforcement cage for pouring concrete

After digging a pit along the perimeter and in the areas of partitions, formwork is made. To make it, ordinary boards are knocked together in the form of shields. A layer of sand is poured into the inner part and a reinforcement frame is inserted, which is assembled from reinforcing bars. Metal elements are connected with wire.

Holes for pipelines must be made in the formwork itself, after which the concrete mixture is poured. After hardening, the wooden form is disassembled, and then the bottom of one of the chambers is concreted. The filter section is completely filled with sand and gravel so that the lower part does not silt.

Concrete cover with hatches

Both ready-made reinforced concrete slabs and those poured on site can be used as flooring. When making the cover yourself, you should create additional stiffeners from metal corners. Metal hatches are installed on the openings.

Rules for choosing the location of the septic tank

A five-meter sanitary protection area is installed from the septic tank to the structure, as well as to the road. The area from the septic tank to the neighbor’s property must be at least 4 m, because There is always a danger of soil erosion by runoff.

Are you planning to install a sewage treatment plant in your garden yourself? We maintain a distance from trees of 2-4 meters. The roots of the latter can pose a real threat to the structure.

If there is no connection between the filtering layers of soil and the soil layer carrying water, then the standards for the distance from the septic tank to wells and water intake shafts call the control figure 20 m. If the above connection exists, then this distance will be determined by employees of the local hydrogeological service.

Construction materials

In order to build a durable and strong septic tank without pumping with your own hands, you need to choose a material that will be resistant to external pressure, resistant to toxic household waste, salts and alkalis present in the soil.

The following options exist:

- Brick. The masonry is made from clinker blocks, which have sufficient strength and are not destroyed by exposure to dampness. The choice in favor of brick is due to the fact that there is no need to use special equipment. To perform bricklaying, you need to have the skills to do such work. The tank walls are insulated on both sides. A strong concrete base is made for them.

- Reinforced concrete rings. Products with a diameter of 90-120 cm and a height of 90 cm are used. The well consists of 3-4 rings. A special feature of performing such a task is the difficulty of isolating the joints. In addition, there is always a risk of violation of the geometry of the structure due to seasonal soil movement.

- Factory-made containers made of plastic. The polymer, reinforced with steel ribs, is resistant to moisture, chemical and organic compounds. When the soil heaves, it deforms, regaining its shape again after it thaws. The downside is that the products are lightweight; you need to think about how to secure them in the ground. As a rule, a concrete anchor is poured for this.

- Monolithic wells. They are made by continuously pouring concrete into forms filled with reinforcement cages. They are considered the most durable, reliable and durable household septic tanks.

When choosing a building material, you need to take into account not only objective factors, but also your own financial capabilities, skills and abilities, and the availability of the necessary tools and equipment.

Installation of a sump

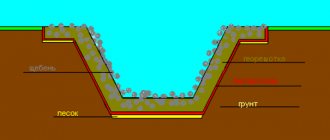

The bottom of the pit is covered with 10-15 cm of sand and filled with water to maximize shrinkage. Next, the joint between the ring and the bottom is waterproofed in order to minimize contamination of the soil with water from drains.

The second ring is installed on the solution (1 part cement + 3 sifted sand + 0.1 liquid glass).

Is there a possibility of ground movement? To further secure the rings, use staples or metal plates.

The hatch with a cover is placed on a bed of standard sand-cement mortar.

1 — rings of the working part; 2 — insulating cover; 3 — neck rings; 4 — hatch body; 5 — hatch cover; 6 — ventilation riser; 7 - floor slab; 8 — bottom plate; 9 — crushed stone cushion; 10 - waterproofing; 11—sediment zone; 12 — running brackets

It is advisable to waterproof a sump tank, unlike a well that filters wastewater, with 2 layers of hot bitumen. Waterproofing is carried out over the primer with a solution of bitumen and gasoline. Coating with water-repellent penetrating compounds is possible. Additionally, the sump tank is insulated from the outside with bitumen roll insulation.

Reinforced concrete rings

You can quickly assemble a septic tank without pumping and electricity from factory-made concrete rings. They are offered fully equipped, with a bottom and a cover. A durable structure, fastened at the joints with cement mortar and treated with waterproofing, ensures high tightness and safety from flooding. Reservoirs made from rings are the same size; they are connected by plastic pipes with a diameter of 110 mm.

Such a septic tank will require labor-intensive excavation work, including digging two or three pits and a trench for a sewer pipe. The depth of the ring wells is 3-4 meters. Tees are installed at the ends of the inlet and outlet pipes to avoid clogging. To access the elements and clean them, use hatches or ventilation holes made directly above the tee. All chambers are covered with slabs with hatches and sealed. When filling up wells, a clay castle is made.

Advice. To equip a drainage well, you can buy a special ring with perforations over the entire surface.

Advantages:

- strength and durability;

- the material is not afraid of soil pressure;

- the structure does not freeze in winter.

Flaws:

- complexity of installation;

- the need for careful waterproofing;

- using a crane.

Installation of a filter well

The parameters of the area used are calculated by the load on S of the bottom filter, which is located inside the well and S of holes in the walls, multiplied by the height of the structure. In sand, the latter are characterized by 100 l/day per 1 m2, and in sandy loam soil 50 l/day.

The limit for the filter base is calculated above the level of existing soil in the strata. water If there is 2 m between the base of the filter well and the level of the latter, then an increase in load by 20% is allowed.

1 — water barrier; 2 — neck rings; 3 — hatch cover; 4 — insulating cover; 5 — hatch body; 6 - floor slab; 7 - ventilation riser; 8 — blind rings; 9 — perforated rings; 10 - filter media; 11 — holes in the rings; 12 — concrete base; 13 - supply pipeline

It is rational to equip the walls of the filter well with rhythmically spaced holes Ø40-60 mm. The total area of the latter should be ≈10% of all walls. This technique can slightly increase the absorbent surface area.

As a bottom, use a filter up to 300 mm thick from any broken stone with fractions of 15-30 mm.

We recommend reading the instructions for building a drainage well.

Tips and tricks

Septic tank ventilation

- As for ventilation, it is best to use an asbestos pipe or a plastic one made of polyvinyl chloride. You can also make a gutter from boards, and the part that will be in the hole should be treated with a special mastic. To make it look nice from the outside, it can be painted and equipped with an umbrella made of galvanized sheet on top.

- The pipe used for ventilation can be equipped for pumping out using the matryoshka principle. A narrower pipe is inserted into the wide ventilation pipe, which will be used for pumping out.

- If your septic tank does not have a concrete bottom, then it should not be located at the same level as groundwater.

- Before starting work on digging a pit, it is necessary to accurately calculate the required volume, which should be 20% more than calculated.

- When planning and purchasing building materials for a septic tank, you should not save. If you buy low-quality material, this may negatively affect the final result, and all your efforts will be reduced to zero.

- Use mixtures and bacterial preparations that will prevent the appearance of unpleasant odors. These bacteria will facilitate the rapid decomposition of waste and the fermentation process.

These are the basic recommendations, adhering to which it will be much easier for you to do the job better. If you have extensive experience in making a septic tank without pumping, then write your recommendations for this article. Perhaps your advice will help those who are experiencing certain difficulties.

About underground filter fields

The main thing for irrigation diversions is that they are laid at a depth of half a meter or one and a half, they must be below the degree of freezing. For the capital, this figure is 1.4 m. The footage from the pipe tray to the ground level established by experts. The water must be at least a meter high.

Filtration fields are either a variant of a similar well or an application to it. The second name for the filter field is the so-called “lying well”. 15 m - this is a typical sanitary area (from the filter field to a residential building).

1 - single-chamber septic tank; 2 - distribution well; 3 - irrigation pipes; 4 - ventilation pipes; 5 - two-chamber septic tank; 6.8 - ventilation risers; 7 - main pipeline

Irrigation pipes are laid from the distribution pipeline. The duration of these branches does not exceed 20 m. A 100 mm pipeline is laid with a bevel of 0.005°. For such systems, non-pressure ones made of asbestos and cement or plastic (plastic) are chosen. Analogues from the latter are both lighter in weight and more comfortable to fit. Inspection wells are installed where branches of irrigation pipes are expected on the distribution system. On them, 30 mm grooves are left in the trays for the control valves. The option without distribution pipes and wells is quite realistic. In such designs, irrigation pipes are placed in a targeted manner, starting from the filter well.

100 mm irrigation pipes (analogues specialized for drainage are also suitable) require holes Ø5 mm. Their orientation to the ground is at an angle of 60°, if we focus on the vertical, and their placement is in a checkerboard 50-mm interval. It is recommended to install bedding under the pipes, with a thickness of at least 200 mm and a width of 250 mm. The pipes literally have to be half recessed into the latter.

30 l/day is the nominal load per meter of sprinkler pipes for soils consisting of sand. For theirs, but sandy loam, this figure is 15 l/day. On loam, it is recommended to increase the gravel layer or add sand to the topping. A good solution is to lengthen the pipes.

At the ends of the irrigation pipes, risers are formed to provide the system with air. The latter, Ø100 mm, are raised to a height of 2 m and are often planted with clematis and other spectacular climbing plants for decoration.

Made of brick

Square brick septic tank

It should be noted that for such a septic tank it is necessary to use only solid brick, since it is the most stable and reliable. So, there are two options for its construction:

- Septic tank without bottom. The bottom of the septic tank is covered with a 25 cm layer of sand or crushed stone. To avoid siltation, experts recommend drilling two or three wells, the diameter of which can be 100 mm. Asbestos or plastic pipes are inserted into these wells and filled with coarse crushed stone. The first chamber is laid out with continuous masonry. As for the second chamber, here the brick is laid in a checkerboard pattern, leaving a gap of 1/3 of the length of the brick. This method allows you to increase the quality of sewage drainage, however, it can negatively affect groundwater if it is nearby.

- Sealed septic tank. This version of the septic tank has a foundation at the bottom, which is necessarily reinforced. Once the concrete has hardened, the brick is laid. The walls of such a septic tank can be 25 cm thick, and between the chambers you need to make a partition 12 cm thick. To increase the tightness, the walls should be treated with mastic.

As for the shape of such a septic tank, it can be rectangular or round.

Round septic tank

How to make a lid for this septic tank will be described below. Some advantages and disadvantages of this design should be taken into account.

Advantages

- Small price.

- Excellent performance and waterproofing.

- Speed of construction.

- Durability.

- Reliability.

Flaws

- There is a high risk of sewage getting into the ground.

- It is mandatory to use high-quality material due to less resistance to aggressive environments.

About sand and gravel filters

Pumping with sand and gravel analogues is quite effective! The components of such devices, used for several buildings at once (this is not one private house), are:

- irrigation system;

- filter-load;

- there is drainage.

1 - supply pipeline; 2 - distribution pipeline; 3 - irrigation pipes; 4 - ventilation riser; 5 — drainage pipes; 6 - collection pipeline; 7 - outlet pipeline; 8 — irrigation zone (crushed stone); 9 - drainage zone (crushed stone); 10 - crushed stone base; 11 — ventilation riser; 12 — ventilation riser of the drainage system; 13 — waterproofing (roofing felt); 14 - clay castle; 15 — insulating coating

The arrangement of this analogue involves laying crushed stone or gravel (15-30 mm) inside the well with a slope of 0.03° to the central part. Next, drainage is placed along the 100 mm substrate. This includes a central pipe, similar drainage pipes Ø100 mm (made of plastic, asbestos-cement), and a collector. Analogues made of asbestos cement have 5 mm side cuts every 10 cm. For plastic pipes, 10 mm side holes are required at the above frequency. The hole arrangement system in any version is checkerboard.

The drainage is covered with a 10 cm layer of slag or any substitutes. The only condition is fractionation - 15-30 mm. Next, the same layer is required, but with only half the coarseness (up to 15 mm). The next 100 mm of the layer involves laying drainage with particles up to 5 mm.

The meter-long filter layer is then filled with coarse-grained sand (up to 2 mm). Then gravel, crushed stone, and maybe old used slag with a particle size of 15-30 mm are poured onto the sand again. The irrigation system is formed similarly to drainage, sprinkled with the same components. Next, everything is covered with roofing felt (an option is waterproofing) and covered with soil.

Filtered S is calculated as follows: taking into account that the distances between irrigation pipes must be at least half a meter. The required length of irrigation and drainage analogues is found at a load of 1 m = 100 l/day. At the beginning and end of the sprinkler collector, risers for ventilation with a diameter of 100 mm are erected, and the height above the surface is set at 700 mm.

At least a meter - this must be taken into account in relation to the distance from the drainage tray to the ground. water Is the latter determined to be high? You will have to install filters in the bedding. For example, analogs under a waterproofing layer are covered with a half-meter slag or gravel layer. The soil with vegetation is also unchanged, at least 0.2 m deep. An eight-meter sanitary zone from such a filter to the house is mandatory and only then is high-quality pumping possible!

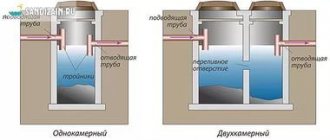

Treatment plant design

The complexity of building a septic tank without pumping depends on its performance, design and selected material. All models of the treatment plant operate on the same principle: wastewater is mechanically separated into fractions, treated with anaerobic bacteria and sent for filtration and discharge.

High efficiency in wastewater treatment can be achieved using a design with a compressor and aerator. The output of such a system is process water suitable for household needs. The biological treatment station has high productivity, it does not require pumping and is environmentally friendly. The main disadvantage of the device is the need to connect to a power supply, so for uninterrupted operation of the sewer system it is better to choose a non-volatile option.

The septic tank provides accumulation and filtration of wastewater. Their purification occurs under the influence of microorganisms. In order for bacteria to have time to effectively disinfect waste before seeping into the soil, it is not enough to install a single-chamber structure. The best option for an autonomous septic tank for a country house would be to build a two or three-chamber treatment plant.

Attention. It will not be possible to completely avoid pumping, but with the correct size of the septic tank, it is performed once every 10 years.

About the filter cassette

The distribution well is equipped with an automated pump (submersible is used). Pumping them and directs the wastewater into the filter cassette. To install such a system, a fertile layer of soil is removed, the perimeter of which is 50 cm larger than the analogue.

Next, a mini pit 30-50 cm deep is filled with sand and thoroughly compacted. Concrete blocks are placed along the perimeter of the site and fastened together. Then fine gravel is poured in and an infiltrator without a bottom is installed, i.e. cassette. A hose or pipe is connected to it for drainage, and a pipe for ventilation is also formed. The cassette is insulated with foam plastic and covered with a 20-centimeter layer of soil.

1 - wastewater supply pipeline; 2 - filter base; 3 - supporting blocks made of concrete or reinforced concrete; 4 - reinforced concrete floor slab; 5 - filtration wells; 6 — ventilation riser; 7 - wooden cover; 8 - drainage tray; 9 — hatch; 10 - waterproofing; 11 - stone blind area; 12 - stone paving; 13 — cast iron hatch; 14 — jet barrier wall

To increase the filtration area, additional wells are provided.

The optimal size of the loading fragment for the base filter is crushed stone with a fine fraction (screening), slag, expanded clay, etc. with a fraction size of 2-10 mm. For paving, we recommend a stone of 60-100 mm.

The jet wall requires a gap of 15-20 mm between the blocks.

How to make septic tanks for a summer house with a high groundwater level

Areas with high moisture are common, which complicates the construction of sewage treatment systems. However, even with a high groundwater level, it is still possible to install a septic tank for a summer residence. It is best to use plastic containers as chambers, as they are completely sealed.

Special container made of durable plastic

It is better to carry out excavation work in the summer, when the groundwater level is slightly lower. If they are too close to the ground surface, drainage can be made from perforated pipes.

Due to the lightness of the plastic, care should be taken to ensure that the body itself does not float when the water level rises. To do this, a reinforced concrete slab is laid in the pit. A polymer container is attached to it using special straps.

Scheme of fixing a container to a reinforced concrete slab using bandage belts

Related article:

Septic tanks for cottages with high groundwater levels. What to do if the problem of high groundwater level is very acute for your area? Read our special publication and the problem will not seem so serious.

Properly constructed do-it-yourself septic tanks for dachas and houses can serve for 10 years without pumping even with elevated groundwater levels. However, in such a situation, they should be additionally protected from soil heaving. A special backfill helps to accomplish this. Five shares of sand are added to one share of binder (cement).

It is not always possible to create a simple filtration field in cases with close groundwater, so it is necessary to install a filter cassette. It is usually located above the level of the septic tank, so an additional booster pump is installed.

Correct filling of a plastic container

About installation of overflows

For the capital region, the minimum depth for laying a pipeline tray is 1.1-1.2 m. It is installed 100 mm from the bottom filter, with the free end of the pipeline placed in the very center of the well.

The overflow is placed with a slope of 2 cm per linear meter in order to minimize blockages.

The 100 mm inlet pipe is placed above the outlet pipe, 50 mm higher. Plastic is not chosen for the external line. To direct the flow of water downward, a tee is used to drain the sewer in a strictly vertical position.

Tees for overflows

About ventilation

The chambers of the septic tank being built must be equipped with ventilation risers Ø100 mm, the height above the surface is calculated to be up to 700 mm. In order to neutralize specific odors, the riser is placed above the roof. But the height of the pipe cannot extend above the latter by more than 0.15-0.3 m (to prevent freezing). For this reason, any deflectors are undesirable.

It is unacceptable to connect the exhaust part of sewer risers with pipes for smoke removal or ventilation systems.

Cross ventilation of septic tank sections requires the presence of holes in the partitions above the drain line, 0.2 m. Their total area must be twice as wide as the cross-section of the exhaust riser.

Second option

In principle, if you have concrete rings, you can use them instead of homemade concrete casting, but two chambers are required. When installing rings, you cannot do without a winch or crane.

Do not place the rings on edge; they may crack, especially if they hit each other. Dig the hole with enough room so that you can easily lower the rings into the hole without touching the walls.

Advice. Very carefully lower the rings into the hole; if the ring gets stuck, it is strictly forbidden to lift the ring with the help of a lift to wedge it out.