Features and Benefits

A variety of utilities are installed in a private house. One of them is the sewerage system. The main element of sewerage in a private house is a well for draining household waste . To construct this well, you can use materials such as brick, concrete or polymer rings. Each of these materials has its own advantages and disadvantages.

Wells made of bricks are less durable in use than sewerage systems for a private house made of concrete rings. In addition, it takes much more time to build a brick well than to install ready-made elements, and deep wells are almost impossible to line with bricks. Their installation, installation price is not much higher compared to the cost of building a brick well. Therefore, concrete products can be considered an ideal option for those who need sewerage in a private home without wasting time and effort.

Wells do not experience any special loads, so the main factor that destroys them is exposure to moisture and an aggressive environment

Advantages of concrete wells:

- can be installed in areas with any soil. Due to their increased strength, concrete rings can withstand pressure created by soil displacements or underground water layers;

- Sewerage in a dacha can be installed with your own hands at high speed;

- the cost of concrete rings for sewerage, the price is more affordable compared to materials such as stone or brick;

- Almost any materials can be used for waterproofing wells;

- the smooth internal surface allows you to quickly and efficiently clean a concrete sewer well, the price of which is quite affordable;

- resistance to various aggressive environments;

- long-term operation without the use of intermediate repairs;

- Concrete rings for sewerage, their sizes and prices allow the construction of wells of any depth.

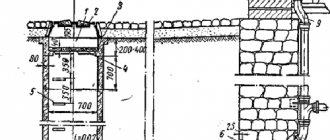

Construction of a differential well for a local sewerage system

Drop well

A drop well is necessary if, due to the natural topography of the site, it is impossible to lay sewer pipes with the required angle of inclination.

As a rule, the design of a sewer drop well differs from the usual one in the presence of a drop.

However, if the height difference between the pipes in such a well is less than 400 meters, then you can do without installing this additional part. You can assemble the lowering for the drop well yourself.

It consists of a straight cross, a pipe and an elbow. If plastic pipes are connected, the elbow should be at 45 degrees; when using cast iron pipes, the required angle is 135 degrees. The lowering is attached to the wall of the well using clamps.

Advice! The presence of a cross in the upper part of the lowering is a prerequisite, since otherwise it will be very difficult to clean in case of blockage.

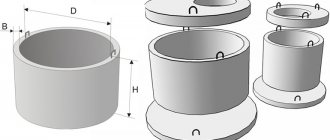

Types of concrete rings

They are products of regular round shape with an internal diameter of 700-2000 mm and a wall thickness of 70-100 mm. For septic tanks and drainage pits, concrete sewer rings are mainly used, the internal diameters of which are 1-1.5 m.

Currently there are the following types of products:

- wall;

- additional ones.

Using wall products, the neck of various wells is formed. Additional manholes have non-standard dimensions and are used when concrete wells for sewerage or other communications have a height that is not a multiple of the standard height. With their help you can adjust the height of any well.

Reinforced concrete products must be manufactured in accordance with GOST 8020-90 . For their manufacture, different grades of concrete and metal reinforcement are used. The presence of metal inside the concrete ensures the reliability and high strength of the rings. Metal reinforcement prevents the entire structure assembled from rings from stretching, and concrete protects the metal from corrosion. In addition, concrete is a very resistant material against compressive deformations. Thus, country sewerage made of concrete has very high strength.

Features of the design

Sewage wells are designed to collect wastewater from domestic use.

There are types of sewerage devices, the type depends on the design:

1.drain pit.

2.storage well.

3.septic tank from several chambers.

All structures vary in shape and size. But they have mandatory design elements, and consist of:

1.neck, which is closed with a hatch or lid.

2.working compartment.

3.drainage or sealed bottom.

Types of concrete rings

Rings are available in different sizes, and for a septic tank the most popular size is: diameter 1500 mm with a height of 900 mm

The following types can be used for sewer installation:

- straight without lock . During installation, such rings are connected using cement mortar or special brackets;

- with ring lock connection . There are special recesses at the bottom of these rings, and protrusions at the top. When installed, they seem to be pushed onto each other, enclosing them in a lock. When used with locks, the elements will not move or move. They will always be in the position in which they were originally installed;

- filtration _ This type has holes evenly spaced over the entire surface. Through these holes, water seeps into the soil, so they are used for filtration sewer wells;

- with a solid bottom . They are necessary for the construction of settling wells. In such wells, silt should gradually accumulate, which is then removed using special equipment. They are an ideal option for arranging such an autonomous structure as an overflow sewer.

Currently, products are produced in various sizes. The designation consists of letters and numbers, for example, KS-20-9. The first number corresponds to the diameter, and the second to the height in decimeters . Therefore, KS-20-9 has a diameter of 2000 mm and a height of 900 mm.

Types of wells for sewer systems

Before you figure out how to make a sewer well, you need to find out what types of these structures will need to be included in the diagram.

The system may include the following types of wells:

- Perepadny;

- Observation;

- Turning;

- Cumulative;

- Filtration.

It often happens that one structure is built to simultaneously perform several functions.

As a rule, the structure of a sewer well consists of a working chamber and a neck covered with a hatch. What design features do certain types of these structures have?

If the sewerage pipeline is long enough, then you cannot do without the installation of inspection wells. Their functions are to provide monitoring of the system and ease of cleaning in case of blockage.

Advice! According to the rules, the distance from the sewer outlet from the house to the first inspection well should not exceed 12 meters. But it should not be placed closer than three meters from the foundation. Subsequent inspection wells are located at a distance of 15 meters from each other.

A rotary well is installed if it is impossible to ensure a straight line arrangement of the pipeline. At the place where the pipe turns, a well is installed that can simultaneously be used as an inspection well.

The main stages of installing a sewer well

To build a sewer system from concrete rings, you need to:

- decide on the scheme;

- calculate the volume of the sewer well;

- choose a place for a septic tank at your summer cottage;

- dig a pit of the required dimensions;

- install concrete rings;

- install external sewerage pipes;

- seal joints and seams;

- fill up the well.

Scheme and calculations

Sewerage from concrete rings, the scheme may include the use of a one-, two- or three-chamber septic tank.

Three-chamber septic tanks are already entire biotechnical complexes that require special costs for their construction and maintenance

If the house has a minimum amount of plumbing equipment installed, then a single-chamber septic tank will be the most optimal solution. The presence of a toilet, bathtub, washing machine and other appliances requires a two-chamber septic tank.

Sewage calculations involve determining the volume of the well, which depends on daily water consumption. On average, one person uses 150-200 liters of water per day. To determine the total volume of the septic tank, you need to multiply the daily consumption by the number of people living in the house.

Choosing a location for a septic tank

When choosing a location for a sewer well, the following requirements must be taken into account:

- the septic tank should be located at least 5-10 meters from the house;

- the distance between the septic tank and any source of drinking water must be at least 50 meters;

- The groundwater level must be below the bottom of the sewer well.

Installation

The pit for the sewer well is dug 20-30 cm larger than the diameter of the rings . Before installing concrete rings for sewerage, you need to make a cushion of crushed stone and sand at the bottom of the pit. A ring with a bottom is installed on top of the pillow, and the required number of wall rings is installed on it. Holes for tees and pipes are punched in the mounted rings.

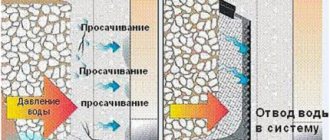

After the drain pipe is inserted into the septic tank, the structure is waterproofed . If this is not done, the wastewater will end up in groundwater, which is not very good. For waterproofing, you can use modern compounds (fused waterproofing materials, liquid glass) or classic cement mortar.

Having completed the waterproofing, they begin to backfill the well. The space between the concrete rings and the walls of the pit is filled with soil, which is compacted every 20-30 cm in height.

Types of sewer pipes

Pipes made of metal (cast iron), concrete and ceramics can be used for sewerage . Classic cast iron pipes are durable and reliable, but have a high cost.

Laying pipes to a septic tank is a separate area that has its own requirements and nuances, without which the entire system will not work

Concrete sewer pipes are very difficult to lay on your own because they are quite bulky and heavy. Their installation requires special equipment, which increases the cost of sewerage installation work. Ceramic pipes are in no way inferior to cast iron pipes in their characteristics, but have a higher degree of chemical resistance.

Schemes of sewer wells ↑

The type of treatment facility is chosen either on the recommendation of the design service, or based on one’s own calculations. Let's consider the most popular schemes of concrete sewer wells, single and assembled into complex two- and three-chamber structures.

Cesspool ↑

An easy way to improve a country house is to assemble a shallow cesspool from 2-3 rings. However, even for this simplest structure a number of conditions will need to be met:

- a plot of free territory 5-10 m from the building;

- suitable soil (sand, sandy loam);

- possibility of delivery of industrial products;

- driveways.

To begin, make a sketch, a pencil sketch, or a drawing made according to all the rules, in which it is advisable to indicate all the components and their dimensions. An approximate diagram of a concrete sewer well looks like this:

Single tank diagram

The diameter of the rings is selected based on the total volume of the container, standard sizes are from 1 m to 2 m. Usually, a neck with a smaller diameter is installed in the upper part. Pay attention to the ventilation outlet - it is mandatory for full operation.

An outlet pipe is necessary if the device involves placing other parts of the structure, for example, an aeration chamber or a filtration field, but for the construction of a simple storage tank, an outlet pipe is not needed.

Layout of the septic tank in the ground

This also applies to the arrangement of the bottom. A blind monolithic slab is installed if regular waste removal is expected (relevant for small summer cottages with clay soils). Sandy soils are an excellent reason to make a drainage cushion, thanks to which the liquid substance will go into the ground for further treatment, and the solid sediment will remain in the tank. Drainage - a dense backfill of gravel or crushed stone at least 0.4 m thick.

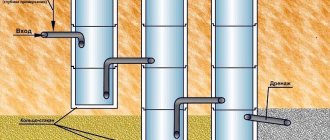

Two-chamber septic tank ↑

The operating principle of a two-stage device differs from the operation of a cesspool. Using two separately located tanks, wastewater is treated more thoroughly. From a residential building, a bathhouse, or a summer kitchen, household waste flows through a pipeline into the first tank, which is a kind of sump. The wastewater breaks down into different fractions: solid substances precipitate to the bottom, and fatty substances float to the surface, eventually forming a crust on the surface. The main part is occupied by water, cloudy from suspended matter dissolved in it.

Scheme of a two-chamber septic tank

The partially clarified liquid flows through the pipe into the second tank – the filter tank. It differs from the first one in its design, since it has an open bottom rather than a solid one. Instead of a slab, a kind of filter is placed on the base - a thick layer of crushed stone and sand. The liquid seeps through the barrier and is cleaned with the help of bacteria settled in the form of sludge on crushed stone, expanded clay or gravel. Additional purification occurs naturally in deep layers of soil.

You should know that a two-stage septic tank does not fully purify wastewater, so discharging water from it into the nearest body of water is strictly prohibited.

Aerobes and anaerobes, actively multiplying in both chambers, cause fermentation processes, which result in the formation of a large amount of emissions hazardous to health. Properly installed ventilation on both tanks prevents the accumulation of gases and helps eliminate the unpleasant odor typical of wastewater treatment plants.

Diagram of a model with a biofilter

When building a two-chamber structure, experts recommend remembering the following nuances:

- accurately maintained slope of sewer pipes (the overflow into the second chamber should be located just below the inlet);

- tightness of all connecting elements;

- optimal (linear) location of all objects (pipelines, septic tank);

- correctly calculated volume of containers (200 liters of wastewater x 3 for each family member).

It is effective to use elements that can be purchased at a factory, for example, a concrete ring with a solid bottom for the first compartment and perforated parts for the second.

Three-stage treatment plant ↑

Concrete rings are also perfect for a more complex device - a three-chamber structure. It differs in the number of compartments and finer cleaning of household waste. It is believed that wastewater that has undergone such thorough filtration can be used in the future for watering the garden, vegetable garden, and flower beds. High-quality sealing, proper installation, rational use of aeration and filtering devices - and your septic tank will not be inferior in performance to its industrial counterparts.

Septic tank of 3 sections

Each of the three sewer wells performs its own function:

- 1 – serves for rough cleaning, accumulates solid waste;

- 2 – filters and purifies liquid waste;

- 3 – performs final cleaning.

There are several options for removing practically clean wastewater from the third reservoir. If free space allows, arrange a filtration field: create an extensive canvas of gravel-sand backfill, install a branched perforated pipeline (drains) onto it, and install ventilation outlets to the surface. If there is a shortage of free territory, clean liquid is redirected to the nearest drainage ditch or reservoir, while part of the water enters the soil through the open bottom.

To increase the cleaning efficiency, additional technical equipment is used (in this case, partial energy dependence appears). For example, a compressor is installed to pump air into the second chamber. They also think about insulating the pipeline and storage tanks - as in the following diagram:

Top thermal insulation diagram

Cost of concrete rings for sewerage

The sewerage system made of concrete rings ensures the arrangement of a drainage system that is environmentally friendly. Such sewerage does not pollute nearby water bodies and does not interfere with tree growth at all. You can buy concrete rings for sewerage, the price of which starts at about 1,000 rubles, in construction stores or on special websites.

The cost of concrete rings from different manufacturers may, although not significantly, still differ. But in any case, the price and quality of these products fully correspond to each other. If you consider how much concrete rings for sewerage cost, then the construction of septic tanks is quite cost-effective.

Concrete rings: sizes and prices:

| Ring designation | Inner diameter, mm | Wall thickness, mm | Height, mm | Cost, rub |

| KS-7-9 | 700 | 70 | 890 | 1200 |

| KS-10-9 | 1000 | 80 | 890 | 1900 |

| KS-15-9 | 1500 | 90 | 890 | 2600 |

| KS-20-9 | 2000 | 100 | 890 | 4400 |

Sewerage made from concrete rings is an affordable and practical option for solving the problem of wastewater in a private home. Rings are convenient due to their versatility. With their help, you can vary the width and depth of the well, which allows you to design a local sewer system based on the needs of a specific family.

How sewerage is made from concrete rings and its diagram is shown in the video:

Scope of application

When it comes to sewer wells, it is worth understanding that they can be of several types. The main types of wells include:

- Inspection (inspection) - located in places where the direction of the external sewerage pipeline changes and every 10 - 15 m if the pipeline is long.

- Control - differs from the previous one in that it is placed at the junction of several pipes into one or when moving from pipes with a larger diameter to pipes with a smaller one.

- Settle – used for purification (settling) of wastewater from solid sediments, the so-called cesspool.

- Special - installed at the point where the autonomous pipeline connects to the central sewer system.

- Differential - serves to reduce the speed of wastewater flow in places with a large slope.

In addition to these options, there are others: flushing, storm, etc.

Video: Installation of a sewer well made of concrete rings

Ready-made plastic wells

The simplest option for arranging a well is to install a ready-made plastic blank . Such wells had not previously been used in Russia, since the plastic could not withstand severe frosts. But with the invention of new types of plastic, this problem was solved.

When choosing this option, the scheme of sewer wells will be extremely simple. Plastic tanks are available in different diameters and with ready-made holes for pipe connections.

The construction of plastic wells is no different from the usual reinforced concrete ones. But installing them is much easier, since they have less weight and ready-made holes for pipes. While in reinforced concrete rings these holes have to be punched using a special tool or manually.

Plastic wells have the following advantages:

- Tightness. This circumstance ensures the environmental safety of using such products;

- Strength and resistance to aggressive environments;

- Ability to withstand temperatures from plus 70 to minus 50;

- Easy to install and install.