We have already done a review about wells and boreholes and told you what their differences, advantages and disadvantages are.

Let us remind you that there are artesian wells (10 meters or more), shallow wells or sand wells (up to 50 meters), Abyssinian wells (16 meters), then there are wells. After talking with engineers who drill artesian wells, my faith in digging a well became stronger. In principle, they do not recognize wells for sand, or they do it with great exception; if you are interested, then find out about karst formations and you will understand everything.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

So, well.

Preparations for the appearance of a well on our site began in the summer. We bought and brought the rings to the site and placed them in a semicircle around an imaginary mine, and in its place they put the first ring.

FIRST JOINT. THEY FORGOT TO PUT BARS UNDER THE RINGS, AND AS A RESULT, THEY HAD TO TEAR THEM FROM THE FROZEN turf AND THEN SPENT TIME CLEANING THE GROOVE.

I’ll say right away that I didn’t go with the vine and frames - a useless idea, it’s like a placebo effect. I chose the location for the well according to SanPi-Nu - 10 meters from the house and more than 25 meters from the discharge of the treatment plant. The future well was placed on a hill to facilitate the drainage of rainwater from the mine.

Neighbors' experience.

Experienced well workers recommend checking out your neighbors' wells to understand how deep the water is in order to order rings correctly. You can also understand the quality of water from your neighbors' wells. And then a catch awaited me. ALL of my neighbors dug wells using an excavator. Cheap, cheerful - the quality of the water is not clear. I'll explain why later.

In general, I ordered 5 rings and a lid. Even in the fall, before the bay of the blind area.

A HDPE pipe was installed around the house in an insulated shaft towards the future well. Before the first frost, the first ring was laid inside with basalt and covered with a shield on top. They began to wait for winter to dig a well.

SECOND JOINT. AS IT TURNS OUT, THE FIRST RING ALSO NEEDED TO BE PUT ON THE BARS AND INSULATED FROM FREEZING OUTSIDE.

Why do you need to dig in winter?

Let me remind you that we have water-saturated soil on the site. During the flood period, the site was partially flooded, but we solve this problem with drainage. In summer and autumn, the high water is already at a meter depth. That is, we need a time of year when there is almost no high water or it is minimal, and we also need to get to the groundwater with normal drinking water. Winter is perfect.

By the way, in the summer I started digging a pond to drain the high water and drain the area, and even on the driest days the high water allowed me to go deeper by 1.2 m. In the fall, the pond was filled to the brim with water, which once again proves the practice of well-dwellers - digging wells in winter.

Economical septic tank made of concrete rings

The linear arrangement of septic tank columns requires a large area, and a large amount of earth has to be removed. Also, each of the columns must be equipped with a neck, which further increases the cost of the structure. There is an interesting option with installing all the columns in a triangle. There is already a saving of space and a reduction in the volume of land work.

Compact septic tank made of concrete rings

The second point of savings is that the inspection entrance can be made one per three rings. Only all overflows must be installed in the area of its accessibility. There are no other features.

Preparing to dig a well

In principle, even a person who is not experienced in these matters can dig a well, but without the necessary tools and mechanisms it will be difficult.

To dig: bayonet shovel, scoop shovel, single-sided pick.

For frozen ground: an axe, a double-sided pick, a crowbar, a sledgehammer.

Remove the soil: a bucket (you can reinforce the place where the handle is attached with a strip), ropes or cables, a wheelbarrow.

Fighting water: a ladle, a submersible pump (it’s better to find a fecal one), a baby hose (buy a normal rubber one, otherwise it will freeze).

For the rings: a large tripod, a winch (we had a frog type).

Well sealing

A big issue for me was the issue of sealing the seams in the well, as well as their fastening together with plates to avoid the ring moving due to soil pressure and hanging in the ground during digging.

Almost all well diggers suggest fastening the rings with plates with anchors, and everything should be fine. But there are counter examples. My neighbor had a crack at the place where the anchor was attached - this is the first disadvantage of this method of tightening the rings. The fact is that the anchor is attached to a particular material due to the fact that the working part expands under the influence of the force of the bolt and is held at the base.

That is, tension is created in the concrete ring, and if you consider that the plates are attached 10-15 cm from the edge of the ring, then it is precisely the edge of the ring that will burst. At least there is a possibility, but I didn’t want to test these probabilities on my well.

The next disadvantage is the iron inside the well. As a rule, the ties are removed after finishing the work, but then there is no point in them - during operation, movements of the pound can also occur, and then what? If we leave the ties, we will get rust in the water. We need another way!

Experienced well workers recommended fastening the rings with reinforcement brackets. The bracket is mounted outside the ring into the shipping holes. After filling the seam with mortar, we insert the ring and hammer in the bracket; it should go in with force, that is, there should be no play in tension. This way we eliminate all negative factors associated with the plates. Our experience has shown that staples do the job perfectly.

The second point is the waterproofing seam between the rings. To prevent water from entering the well shaft, as well as the mounting holes in the walls of the ring, it is necessary to cover it with a solution. It is no secret that for such a solution they use liquid glass (sodium silicate solution, as a rule) and a sand-cement mixture. But what is the recipe? Nowhere and no one in open sources writes the proportions of the solution, so you will have to learn everything experimentally.

Luckily for us, there are some recommendations on the canister of liquid glass, in particular, to seal seams when repairing wells, make a solution in a 1:1:1 ratio. We experimentally derived the following formula.

THIRD CASE. THE FORMULA WAS NOT DELIVERED IMMEDIATELY, AND RINGS 1-2 WERE PLATED IN A SOLUTION WITH A SMALL CONTENT OF LIQUID GLASS. THE SEAM WAS REPAIRED, AND FROM 2-3 EVERYTHING WENT PERFECT.

We need to coat the seam, lower the ring, hammer in the staples and cover the seam outside and inside, and then also brick up the holes - this takes 20-30 minutes in time. Liquid glass upon contact with the solution begins to set quickly - instantly, I would say.

So, we make a solution from sand, cement and water - we made two parts cement and three parts sand, mixed it until it became thick sour cream so that there were no lumps. We collect 250-300 milligrams of liquid glass and go to the ring, so that later we don’t have to run away from home with the thickened solution. Next, pour the liquid mixture into the solution and begin mixing. The first impression will be deceiving, the solution will become liquid and flowing, but literally after a minute it will suddenly begin to thicken. You need to seize the moment. It turned out that the solution became like plasticine and was effectively smeared. When hardened, it formed a strong glassy structure.

Conclusion. Seams and holes in the walls of the ring must be covered immediately,

If we didn’t do this, the high water would flow into the mine from all the cracks. And, for example, I don’t understand how to effectively cover the seam afterwards.

Dimensions of septic tank chambers and their number

For wastewater to be effectively treated, it must remain in the septic tank for at least 3 days. Based on this, the dimensions of the chambers are determined.

Construction of a septic tank from rings

How to determine the volume of a septic tank

According to the standard, the minimum volume of a septic tank chamber is three times the daily water consumption. For one person it is considered 200-250 liters. Total, if you have 4 people in a family, the minimum volume is 3 cubic meters. This is how much storage tanks, that is, the first two chambers, should hold. The third - filter column - in no way belongs to the storage column, therefore it is not taken into account.

This was about the standards that apply in Russia. In Europe, the minimum volume of a septic tank is 6 cubic meters. And many believe that these sizes are more “correct”. Large volumes of wastewater remain in storage tanks longer, which means they are treated better. When using the native standard, if guests arrive, it is easy to “overfill” the standard. As a result, the filtration column will contain untreated wastewater, which will pollute it and the entire surrounding area. Remediation is an expensive and complex procedure.

Even if you decide to adhere to Russian standards, if you have a bathtub, washing machine and dishwasher, you need to increase the volume at least by the size of the salvo discharge of all these devices (bathroom - 300 liters, washing machine and dishwasher 50 and 20 liters, all together - we will assume 400 l or 0.4 cubic meters).

In accordance with the calculated volume, the sizes of the rings and their number are selected. The diameter of a concrete ring can be from 80 to 200 cm, sometimes there are rings with a diameter of 250 cm. Height - from 50 cm to 1 m. The table below shows the dimensions of standard reinforced concrete rings, their markings, weight and volume. In the “dimensions” column, the outer diameter, inner diameter, and height are indicated in fractions. All values are in millimeters.

Dimensions of standard concrete rings and their volume

When making calculations, keep in mind that the actual volume of the column must be higher than the calculated one - the drains are never completely filled, but rise only to the level of the installed overflow pipes. It is up to the level of these pipes that the calculated amount of drains should be placed.

Number of columns

There can be three storage chambers in a septic tank (except for the filter column). Sometimes such a device is more practical - if, for example, it is necessary to install six or more rings in each of the columns. The depth of the pit in this situation is large. It is more convenient/profitable to make three columns of four rings each.

A single-chamber septic tank made of concrete rings is suitable for a small volume of wastewater

The opposite option may also be true - a small volume of septic tank is required. This happens at periodically visited dachas with a small number of summer residents servicing it. In this case, the column can be assembled into one, separating the rings inside with a sealed partition. and making an overflow hole at the required level.

First/fifth.

The most difficult thing in any business is starting it. This is especially true if you have no experience in such matters. After removing the insulation from the first ring, we were happy - the ground was not frozen, but the joy was short-lived, since this area was not so large.

FACT. WE OPEN THE SMART BOOK ON CONSTRUCTION AND LOOK AT THE DEPTH OF SOIL FREEZING IN THE RF. WE ARE IN AN AREA WHERE IT SHOULD FREEZE UP TO 1.5 METERS. AFTER WORKING WITH KYLE AND OTHER CHANCE TOOLS AROUND THE RING, IT FOUND OUT THAT IT WAS ONLY 0.5 METERS FROZEN. AND THE FROST WAS STRONG IN JANUARY.

Sand is easy to dig - that's what can be said about rings No. 1 and 2! The layer cake of Sudogod soil consists of turf in the first meter, then sand of different fractions and colors. The second meter continues the sandy theme, but there are inclusions of white and blue clay.

Sand is easy to dig - that's what can be said about rings No. 1 and 2! The layer cake of Sudogod soil consists of turf in the first meter, then sand of different fractions and colors. The second meter continues the sandy theme, but there are inclusions of white and blue clay.

The third ring greeted us with damp sand and the appearance of stones. The largest stone was the size of a human head. The high water overwhelmed us with regular washes of fine sand and water from under the ring.

And then, in the middle of the fourth ring, we began to enter the clay layer. By the way, based on information from the locals, we managed to find out that there used to be a brick factory not far from us. It became easier to dig than wet sand, and there was a feeling that a layer of groundwater was close, just after the clay.

We rolled the 5th ring and went deeper onto the bayonet. The clay is predominantly red, almost like brick. Springs have appeared! Water began to flow into the mine much faster, it became difficult to stand at the bottom of the well, the clay became soaked under the influence of the springs and turned into a quagmire. During the night the water flow amounted to 2 rings - a good result.

Why are wells dug by hand?

It is worth noting that now there are special drilling rigs that drill a well. But mostly drinking wells are dug by hand, no matter how dangerous it may be.

1. In loose soil, a well is dug in a ring, removing soil from under it. This way we prevent a significant risk of the mine floating or collapsing.

2. By digging with your hands, you do not significantly disturb the soil outside the well shaft, this way the filtration properties of the soil and its tightness from high water will be preserved. By entering the clay layer, you simply cut off the high water.

3. I don’t understand how it’s possible, while digging a well with an excavator, to realize that you’ve reached the springs and see an aquifer.

Bottom line.

We buried 4.5 rings, the ties and the mortar in the seams withstood the pressure and movement of the soil. There are 3 rings of water in the well - and this is in a season with low groundwater level. We are waiting for the fall until the rings finally settle, over the summer the earth around the well will close the cavities, and then we will build a blind area with a roof and bring water supply to the house.

Before you start drinking water from a well, we will take it to the SES for analysis; you need to understand what filters will need to be installed.

Related link: Purifying water from a well or borehole for use instead of tap water

Design and principle of operation

It is best to install a septic tank made of concrete rings on well-draining soils that are not prone to frost heaving. The body of the septic tank consists of several rings stacked on top of each other. Even if they have projections for better fixation, even if they are fastened with staples, frost heaving will move them. The result is a violation of the tightness and expensive repairs. And it’s not a fact that after repair it won’t move again. Therefore, it is recommended to make a septic tank from concrete rings on sandy or sandy loam soils.

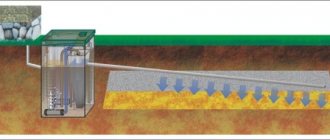

If the soil drains water well and the groundwater level is low, it makes sense to drain water from the septic tank into a drainage column. This device is the most optimal. When the groundwater level is high, treated wastewater is discharged to drainage fields. Their installation requires large areas and an equally substantial amount of excavation work, but sometimes only such a system works.

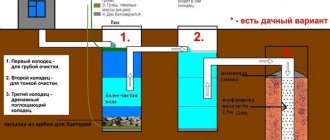

Diagram of a septic tank made of concrete rings

The septic tank diagram is shown in the photo above. It consists of two working chambers connected to each other by an overflow. This is where the cleaning process takes place. The third column is a drainage well (there may be a filtration field instead), through holes in the lower part of which purified water goes into the ground. This is briefly about the construction of a septic tank made of concrete rings. Now about the process itself.

The wastewater enters the first chamber. It is sealed, with the most limited air flow. In conditions of lack of oxygen, the main process of decomposition occurs in it. Organic substances are processed by microorganisms and bacteria. Organic matter breaks down into more or less pure water and insoluble substances, which precipitate and accumulate at the bottom of the chamber.

Through the overflow pipe, water with less contaminants enters the second chamber. The purification process continues in it, but here it occurs with the obligatory participation of oxygen. Therefore, the second chamber is equipped with a ventilation pipe. Here the remaining organic matter decomposes and settles to the bottom. Almost clean water is discharged into the drainage column and goes into the ground, where final purification occurs.

Afterword.

Any business is difficult to accomplish without support, be it moral or physical. But digging a well with only moral support is problematic! Huge gratitude and great human gratitude to my dear uncle Yuliy Ivanovich Karachurin for real physical support in digging a well!

© Author: Evgeny Erofeev Photo: author

TOOLS FOR CRAFTSMAN AND CRAFTSMAN, AND HOUSEHOLD GOODS VERY CHEAP. FREE SHIPPING. THERE ARE REVIEWS.

Below are other entries on the topic “How to do it yourself - for a homeowner!”

- Do-it-yourself repair and insulation of a well HOW I REPAIRED AND INSULATED...

- Decorative well and wattle fence with your own hands How to make a wattle fence and decorative…

- Do-it-yourself well head and its decoration How to make and decorate a canopy...

- Do-it-yourself decorative well - 2 ideas Disguising the pumping station as a decorative...

- Do-it-yourself mini-well (+photo) Do-it-yourself mini-well on the site...

- A well instead of a well in the country (+ drawing) A well in the country - drawings When...

- How to dig a well in your dacha with your own hands A well in your dacha at four...

Subscribe to updates in our groups and share.

Let's be friends!

With your own hands > Wells and wells > Digging a well with your own hands (concrete rings)