The cesspool is still used, despite the emergence and active use of septic tanks and local treatment facilities. This is due to the low cost of arrangement and the possibility of using used materials. Digging a pit is carried out independently or using special equipment. First you need to select the appropriate type of device and ensure the pit is sealed.

A properly equipped cesspool functions for many years without requiring attention.

Types of cesspool installation for a private home

Available options:

- sealed pit (with a bottom);

- cesspool without a bottom.

In the first case, the wastewater ends up in a storage tank, which needs to be cleaned periodically. The pit with the bottom is well protected from leaks. Waste products and contaminated water accumulate inside. When the level of wastewater rises to a critical level, the pit is cleaned using a sewer truck. The frequency of such manipulations depends on the intensity of use of plumbing fixtures (toilet, bathtub, sink).

If the object is small (1-2 people live in the house), purchase a special small-sized container. It is sealed and made of polymer material.

This design is called a drive (available in the form of a plastic container). In properties with permanent residence, it is recommended to drain into a large pit. In this case, the depth of the structure should not exceed 3 m, otherwise it will be difficult to pump out wastewater.

Positive qualities of this type of structure:

Sump pit diagram.

- due to tightness, sanitary safety is ensured: the soil is not contaminated, the likelihood of leaks is reduced, provided that the finishing work is carried out correctly;

- a closed cesspool is installed in different types of soil.

A pit without a bottom has the disadvantage of a high risk of penetration of pathogenic bacteria into the soil and surface groundwater. This may be a consequence of a violation of construction work or operation of the structure.

Features of this version of the sewer system:

- the side walls prevent the penetration of contaminated liquid into the upper layers of the soil;

- instead of the bottom, drainage is installed, which is used as crushed stone or gravel.

The wastewater first goes through a kind of filter of small and medium fractions. Then they fall into the soil, which also traps pollution. Such sewer systems also require periodic cleaning, but they are carried out much less frequently.

It is necessary to install separate pits for wastewater from the sink/bathtub and waste products (from the toilet). This is due to the fact that water containing a minimum amount of insoluble inclusions drains faster through the drainage at the bottom of the pit.

To maintain the conditional cleanliness of such structures, bioactivators are used. They contain bacteria that accelerate the process of decomposition of contaminant fractions. As a result, almost all wastewater leaves through the drainage. Only sediment remains in the pit in the form of sludge containing insoluble particles.

Open drainage structures are not equipped in the following cases:

- clay soil on the site: water will have difficulty draining through such a sewer system, which is due to the high density and fat content of the soil;

- close occurrence of groundwater: sewage does not pass through the soil, but immediately enters the water, polluting the environment.

How to build a drainage hole with your own hands

Let's look at different types and methods of designing drainage systems that you can make with your own hands. They are conventionally divided into permanent and temporary.

From car tires

If you need a flush system for a toilet in a country house at minimal cost, you can make it yourself using old car tires.

This is a quick and budget option for constructing a sewer pit. The design is quite simple. A pit is made where old tires are laid one on top of the other. A layer of crushed stone is poured onto the bottom of the pit; if desired, the tires are sealed with a clay lock.

Advantages:

- if necessary, it can be easily restored;

- durability;

- speed, simplicity and low cost of construction.

Flaws:

- tires rot over time;

- the possibility of a negative impact on the environment due to high load on the structure;

- rapid silting with insufficient cleaning and pumping, resulting in loss of usable area.

Made from concrete rings

This is another way to quickly build a drain system. Its design is similar to a well. The rings are installed on top of each other. The connections between them, if desired, are sealed using a cement screed.

By its design, a sewer pit made of concrete rings is more of a sealed structure. Therefore, you need to pump it out regularly . Although there is an option to install a septic tank made of concrete rings.

Main advantages:

- Convenience of installing a protective cover with a hatch;

- durability;

- possibility of construction with your own hands;

- relatively low cost.

Flaws:

- the possibility of an unpleasant odor coming from ventilation pipes;

- the need for periodic pumping;

- complexity of installation.

Brick drainage pit

This is the most successful and optimal option if you need a drainage system for a toilet or bathhouse in a country house.

Advantages:

- ease of construction - almost any summer resident can handle laying bricks for a drainage pit;

- environmental friendliness - the contents of the drainage structure are periodically pumped out by a sewage disposal machine.

Flaws:

- siltation. Siltation can be prevented by constantly pumping out the liquid in the storage tank;

- relatively short service life (up to 20 years), as a result of brick destruction in unfavorable conditions of the drainage system;

- Occasionally, an unpleasant odor may form. The use of various drugs that accelerate waste decomposition processes and timely pumping of the storage tank can help cope with this.

Types of cesspools

Depending on the design features, the frequency of water use, the location of the facility, etc., there are many types of cesspool design. Each has its own advantages and disadvantages.

For reference! If the cesspool is rarely used, then it is sufficient to use a temporary sump.

Cesspool made of concrete rings

This type of structure does not collapse, does not collapse over time, like a brick pit, where there is a large load on the walls; it looks more aesthetically pleasing, and the installation process takes less time. The only disadvantage of this type of cesspool is that the installation of concrete rings requires special equipment, since the weight of the rings is quite large.

Drainage pit made of concrete rings

Step one. Selection of concrete rings

Concrete rings differ from each other in diameter, which varies from 0.7-2.5 m. When creating a cesspool from concrete rings for an average house, the best option would be to use rings with a diameter of 1 meter, in the amount of 5 pieces. If a large house, more than 200 sq. meters, and there are several shower rooms and toilets, then you need to choose rings with a diameter of more than 1 meter.

Selection of concrete rings

Below is a table of mass-dimensional characteristics of concrete rings:

| Dimensions (inner diameter × outer diameter × height), mm | volume, m3 | Weight, kg |

| 700×800×290 | 0,05 | 130 |

| 700×840×590 | 0,10 | 250 |

| 700×840×890 | 0,15 | 380 |

| 1000×1160×290 | 0,08 | 200 |

| 1000×1160×590 | 0,160 | 400 |

| 1000×1160×890 | 0,24 | 600 |

| 1500×1680×290 | 0,13 | 290 |

| 1500×1680×590 | 0,27 | 660 |

| 1500×1680×890 | 0,40 | 1000 |

| 2000×2200×590 | 0,39 | 980 |

| 2000×2200×890 | 0,59 | 1480 |

Rings, depending on the design, are divided into two large groups:

- with a lock;

- flat.

The name of the group “with a lock” speaks for itself, that is, these rings are equipped with a locking connection, which is very convenient when installing rings. Flat rings have “regular”, flat edges.

Scheme of a cesspool made of concrete rings

To make rings, it is necessary to use a metal frame together with 500-grade cement. It is also worth noting that some products are equipped with a lid and bottom, which facilitates the construction process.

Step two. Construction

First, you need to dig a hole with a diameter 50 cm larger than the diameter of the rings, and a depth of 30-35 cm greater than the total height of all the rings of the cesspool.

Construction process

Next, you need to level and, most importantly, compact the hole so that the rings do not sag after installation; after performing these operations, fill in a layer of 2-3 cm of coarse sand. Fill everything with water, let it absorb and compact the bottom again. Next comes the process of installing the rings. If a ring with a bottom is used, then the installation process will not be difficult, but if the ring does not have a bottom, then it is necessary to create one, that is, fill the bottom of the cesspool with concrete, but before that you need to tie the reinforcement and put it on the bottom. Therefore, before purchasing a ring at the base, decide for yourself which option suits you best.

The mesh of reinforcement should be entirely inside the ring, so if you need to lift it, use bricks.

To create a solution, it is necessary to maintain the appropriate proportion: cement – water – sand – crushed stone 1–0.5–2–3. It is advisable to use cement of 500, but not lower than 400. Next, we begin mixing using a concrete mixer, or manually using a shovel. The bottom must be filled in one stage in order to eliminate seams and joints. After the solution is ready, pour it in, level it, and remember to remove air from the solution by piercing it with a sharp object.

Step three. Installation of rings

As mentioned earlier, concrete rings cannot be installed without special equipment, so we use a truck crane. For this purpose, there are special ears on the rings, to which the cables cling.

Installation of concrete rings

You only need to lift the rings by all the ears, while tensioning the cables evenly. Observe safety precautions when working with a crane and heavy objects.

After installing the first ring, use a level to level it. Then install all the other rings. The joints between them must be filled with cement-based sealant. At the end, install the lid and coat all joints of the structure with bitumen mastic. After this, it is necessary to fill in the voids between the walls of the pit and the finished structure.

Concrete rings with sealant

As a result, we get a high-quality cesspool made of concrete rings. This process is quite labor-intensive and requires the rental of special equipment, but all costs are completely justified.

Finished pit

Video No. 1 – How to make a cesspool with your own hands

Video #2:

Sealed

This cesspool is the safest for the soil and the environment as a whole, but its operation will require fairly frequent pumping of water. Various collectors are also used that allow water to be purified mechanically.

The design of a sealed pit is simple. Its construction will require concrete, from which the bottom and walls are made. The reinforcement included in the structure of the pit allows it to be made not only airtight, but also quite strong.

Fittings for a sealed drain pit

The advantage of this type of cesspool is its ease of manufacture.

The disadvantage is that for its constant operation it is necessary to regularly pump out water.

Without pumping

The construction of this cesspool can be carried out using various methods and technologies, but “without pumping” does not mean a complete absence of maintenance. The operation process includes wastewater processing.

Such a pit is most often used to collect and purify wastewater from showers and baths. It is built on sandy soils to ensure good throughput.

Layout of the drain pit

The advantage is ease of making with your own hands, low maintenance costs.

Disadvantage: high probability of soil contamination.

Made of brick

This object can be made sealed or without a prepared bottom, but with a large drainage layer. It is this type of cesspool that has proven itself in wastewater processing.

Brickwork cesspool

Making a cesspool does not require special preparation or special equipment, and the choice of design depends on the number of water consumers, as well as on the soil.

The advantage is ease of making with your own hands.

Disadvantage: it all depends on the type of pit design.

Construction of a drainage pit made of brickwork

Construction of a brick cesspool - video:

Products from the manufacturer

Septic tanks manufactured at enterprises differ in shape, volume, materials, and have their own design features.

Waste passing through the septic tank is effectively cleaned or disposed of at special points.

Ready-made septic tank

There are septic tanks, the design of which allows, after processing waste, to use water for irrigation or drainage into the ground. For this purpose, microorganisms are used that process the sludge in the cesspool.

The advantage is that you don’t have to build various objects, which sometimes take a lot of time and effort.

The disadvantage is the high cost of the equipment.

Using microorganisms

It is possible to recycle wastewater, as well as the sediment formed in it, using aerobic and anaerobic microorganisms. These bacteria come in a variety of forms, including liquid, powder, and packets that dissolve in wastewater.

Bioactivator for cesspool

In simple septic tanks, anaerobic microorganisms are used, since they contain the necessary enzyme, with the help of which the process of decomposition of organic waste occurs.

The advantage is the effective purification of sewage water, the absence of an unpleasant odor.

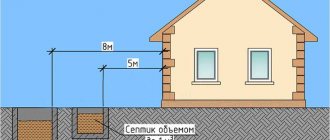

Choosing a location for a sewer pit.

It is important to choose the right place for sewer construction, because its further operation and safety for human health depend on this.

Therefore, this stage must be approached with full responsibility. When choosing a location, the following factors must be considered:

– the possibility of using a special vehicle for pumping wastewater;

– distance from the source of drinking water.

In accordance with sanitary standards, the cesspool must be located at a distance of at least 5 meters from the house. But it is necessary to take into account the type of sewer pit. For example, a sealed pit can be located within 5-7 meters from a living space, but a storage tank without a bottom should be located at a distance of 25-30 meters to avoid unpleasant odors, as well as the entry of various microorganisms into drinking water.

The cesspool must be cleaned periodically, so it is worth taking care of this at the stage of choosing a location.

Technology for constructing drainage pits

Compliance with the technology for constructing a cesspool is the key to high-quality work, which guarantees environmentally friendly drainage of liquid waste, economical use of the tank and its durability. Let's take a closer look at the procedure for creating different types of pits.

Pit without bottom

A cesspool without a bottom is eternal, you just need to properly arrange its bottom and select the appropriate materials for the walls. Following the technology, it is necessary to line the bottom with gravel or other small stones and fill it with sand. The purified drain liquid goes into the ground, and the remaining waste is processed by microorganisms. This is a safe and environmentally friendly method.

The overflow is connected to the sewer system, the waste pipe is inserted into the pit below the freezing level of the soil.

Cesspool without a bottom and with a concrete base - design

We use tires for a cesspool

For decades, used car tires have been used in constructing cesspools with your own hands in summer cottages. Rubber allows you to make an inexpensive, durable and simple structure, the construction of which can be completed even by an inexperienced craftsman. Algorithm of actions when creating a pit:

DIY tire cesspool

- Digging a pit.

- Connecting used tires together with waterproof glue.

- Sealing joints.

- Creating a bottom filter.

- Wheel stowage.

- Sewage pipe supply.

- Making the lid.

Pit made of concrete rings

Creating a pit from concrete rings is a complex and time-consuming process, but the cost of effort and money is fully justified by the durability and reliability of the tank. Technology for creating a pit from rings:

Construction of a pit made of concrete rings

- Preparation of concrete rings (3 pcs.).

- Digging a pit with a depth of 3 meters, a width whose parameters exceed the parameters of the ring by 80 cm.

- Making a concrete screed around the perimeter of the pit (the basis for laying the rings).

- Drilling holes in the lower ring (diameter - 5 cm, distance between holes - 10 cm).

- Laying a filtration layer (1 meter) on the bottom.

- Installation of rings.

- Installation of a plate with holes for the drain pipe and pumping.

Important!

Installation of concrete rings is carried out using a truck crane with a lifting capacity of up to 5 tons. Truck cranes can be rented hourly from specialized organizations.

The use of a truck crane allows you to perform work safely and quickly.

Sealed cesspool

Sealed cesspool made of concrete rings

The sealed design is absolutely safe for the environment and does not allow odors to pass through. When choosing a sealed structure, it is worth considering that its installation is rational only for small amounts of waste; otherwise, the pit will need to be cleaned every week.

Homemade tank. A sealed pit can be lined with concrete rings; you just need to fill the bottom and treat the walls and joints of the rings with sealant (bitumen on the inside and clay on the outside). You can lay the walls out of brick or aerated concrete and then plaster them. This method requires more labor resources and time.

When constructing a sealed cesspool, you must immediately consider the location of the hole for the drain pipe.

Ready container. A device for collecting waste of various capacities can be purchased in specialized stores. Installation of the product involves the following steps:

- Digging a pit.

- Creation of a concrete base.

- Tank installation.

- Connection of waste pipes.

- Burying the container.

Calculation of cesspool volume

The dimensions of the pit are determined taking into account the number of people living in the house. Their age plays a role. For example, it is generally accepted that for 1 adult there is 0.5 m³ of wastewater, for 1 child - 0.25 m³. To find out the daily volume, the indicated values are multiplied by the number of people. For example, if 2 adults and 1 child live in a house, the following is considered sufficient: 2*0.5 + 1*0.25 = 1.25 m³. The resulting value can be rounded up to 1.5 m³.

A more accurate volume can be found by multiplying the resulting value by the number of days before pumping.

For example, if a sewer truck is called once a month, then 37.5 m³ will be sufficient. If you round up, you get a total pit volume of 38 m³. It is necessary to take into account another margin - up to 10% of the obtained value. If the hole is too large, you can make it smaller, but pumping will be done more often.

The depth of the structure should be 2-3 m. Digging a hole less than 2 m is not recommended, since it is necessary to allocate a meter-long space for the release of gaseous substances. In addition, it is important to take into account the likelihood of soil heaving, which can contribute to raising the drainage level and displacing runoff. The width is determined based on the initial volume of the cesspool and its depth.

Standards for placing a cesspool on a personal plot.

Bottom, walls, cesspool cover

First, we cast the bottom of the cesspool with a thickness of 15 cm from concrete. Before pouring concrete, we compact the soil with crushed stone in the place where the concrete is laid. We put a plastic film on the crushed stone, then a reinforcing mesh with 20 cm cells made of smooth wire rod reinforcement 6 mm thick.

To ensure that the mesh is embedded in the thickness of the concrete, we place large pieces of crushed stone under it.

We mix concrete in the “shabby” proportions of 1:2:3. Or for one volumetric part of PC-400 cement, you need two parts of sand and three crushed stones. Water is approximately 0.7 volumes of cement. Let's give the concrete three days to set, and then move on to the walls.

I recommend: Question: What adhesive should I use for tiling walls?

The walls are made of bentonite. These are M150 concrete blocks measuring 19x19x40 cm. Brick (except ceramic), cinder block, aerated concrete, etc. unsuitable for raking.

We lay the masonry in half a block - 20 cm. For strength, every third seam is reinforced with a masonry mesh made of galvanized wire. Carefully fill the seams with mortar and rub (

).

It is best to cover the sump used. reinforced concrete slabs. They are inexpensive and, even taking into account the cost of a crane, the ceiling will cost less than a monolithic one. When buying slabs, do not try to find the exact size. A 230 mm grinder can cut a slab without any problems. We take a four-meter long one, cut it in half and get a finished floor.

Choosing the location of the drain pit

The treatment plant and storage tank are installed on the site taking into account the norms and regulations described in GOST, SNiP.

Basic recommendations:

- a sealed storage tank can be located at a distance of 5 m from a residential building (but this is permissible in extreme cases, when there is not enough space on the site), the drainage well is installed further - from 25 m;

- 10 m are retreated from the neighboring plot to the cesspool;

- the storage tank or drainage well should be located at a distance of 30-50 m from the natural reservoir;

- there should be 15 m to outbuildings;

- the pit is dug at a distance of 2-4 m from the road.

To prevent wastewater from entering the garden plot or vegetable garden, you should retreat at least 5 m and only then proceed to installation.

Construction of an independent sewer system

Diagram of a homemade brick septic tank.

To speed up the work, the option of installing a ready-made storage tank, for example a septic tank made from Eurocubes, is often chosen. However, a structure built with your own hands from brick will be cheaper.

A diagram of such a design:

- digging a hole in the ground;

- the walls and bottom are reinforced with bricks;

- a sewer pipe is installed on the side under the soil layer, it is located at a slight angle to speed up the movement of wastewater;

- the structure is closed with a lid and a hatch is provided for maintenance;

- in the upper part of the pit (in the side wall) there is a hole for connecting the ventilation duct.

A structure with a filter base is built according to the same scheme. However, in this case, a crushed stone cushion is formed at the bottom. There should not be a hard bottom that ensures tightness, as in the first case.

When choosing a finishing material to protect walls from wastewater, you need to take into account the properties and degree of strength of the products.

For example, it is not recommended to use silicate or porous bricks. Such material will absorb moisture, which will not only lead to its destruction, but will also cause the contaminated liquid to spread outside the storage tank.

The best option for a sewer structure is baked brick. It is durable and therefore can withstand the forces of soil heaving. In addition, baked clay brick is not a material with a porous structure. For this reason, it is better resistant to moisture.

If you plan to install drainage at the bottom of the pit, use a multi-layer structure: a layer of soil, sand, gravel or crushed stone. The recommended distance of the filter base from groundwater during the rainy season, when its level rises to its maximum, is 1 m. Sometimes holes are left in the walls of the well during laying, which will improve the filtration properties of the structure.

Digging a pit

Excavation of soil on the site is carried out in accordance with previously made calculations. Moreover, between the outer surface of the brick structure, which will be erected in the future, and the walls of the pit, a gap of up to 50 cm is left on each side.

If this is not done, the storage volume will decrease, since brick walls will have to be moved.

This measure allows for waterproofing on the outer sides of the structure. Even if baked brick is used, the structure is protected from prolonged contact with moisture. This helps to increase its service life.

Preparing the base of the container

The foundation of a sealed structure must be strong. For this reason, reinforcement is performed, and drainage is additionally arranged. If you skip one of the stages, the strength of the cesspool will decrease.

Instructions for making the base:

Installation diagram of a septic tank with a sand and gravel filter.

- A sand and gravel cushion is formed at the bottom of the pit. The total layer thickness is 200 mm. The sand is carefully compacted, which reduces the risk of subsidence of the base during the process of pouring and drying concrete. Gravel should also be compacted whenever possible (it consists of large fractions, so such material is more difficult to compact).

- The base is waterproofed. To do this, roll durable material, such as roofing felt, is placed at the bottom of the pit. It is laid with an overlap. Thanks to this, cement laitance will not get into the ground when filling the hole with mortar.

- A pre-prepared frame of steel rods with a diameter of 8-10 mm is laid on top of the roofing felt. It is recommended to use flexible strong wire for fastening. Welding will cause a deterioration in the properties of the material, resulting in a decrease in the strength of the structure. The cell dimensions of the reinforcing mesh are 100x150 mm.

Concrete bottom casting

To prepare the solution, use cement grade M300 and higher. Due to this, the strength of the structure increases. The prepared multilayer base is poured with a layer of concrete up to 150 mm thick. This is enough for the cesspool to withstand the impact of a large volume of wastewater.

Installation work can continue when the concrete has dried. If there is no time to wait 28 days, they move on to brickwork after 7-10 days.

During this time, the solution will set and harden enough to withstand a significant load without the risk of loss of properties.

Walling

In most cases, load-bearing structures are constructed using half-brick technology. For large pits, more reliable walls are erected: 1 or 1.5 bricks. To strengthen the structure, after completing the construction of the vertical partitions, the space between the storage tank and the walls of the pit is backfilled. A mixture of sand and cement is used.

There is no need to prepare the solution. It is enough to wait until sedimentary moisture begins to release, helping to strengthen the cesspool. The desired result is achieved when the cement-sand mixture is completely moistened. The result is a monolithic structure that will withstand the load exerted by wastewater even when the storage tank is full.

Application of waterproofing

Work to protect brick partitions from moisture is carried out as the masonry is completed. It will not be possible to protect the surfaces after construction is completed due to the small distance between the storage tank and the walls of the pit.

Coating and roll materials are used for waterproofing. Bitumen-based insulation is the most common. They use mastics and roofing felt.

It is recommended to cover the cesspool with coating-type materials. Roofing felt will not last long in direct contact with monolithic walls made of a moistened mixture of cement and sand. It is permissible to combine waterproofing materials, but this will lead to an increase in the cost of the structure. The sand and cement mixture used for backfill does not need protection. On the contrary, it is necessary to ensure access of moisture to this layer of material. Only under such conditions is it possible for the composition to harden.

Finishing the walls of the cesspool from the inside

Waterproofing a brick septic tank must be done using water-repellent materials.

It is recommended to use plaster compositions made from materials with suitable properties. Thus, preference should be given to mixtures with moisture-resistant properties.

But this waterproofing method is not reliable enough, given that the plaster layer will be affected by water in the existing storage tank around the clock.

For this reason, liquid glass is added to the mixture at the preparation stage. A potassium or sodium composition is suitable. This component improves the properties of the plaster.

However, all possible methods should be used to protect the internal walls due to the high humidity inside the drive. For this reason, the surfaces of the structure are additionally ironed with cement.

Covering the drain pit

From above, the pit and brick structure are closed in different ways:

- concrete slab with a hole for a sewer hatch;

- a wooden shield, to protect it from water, it is covered with roofing felt, the surfaces are pre-tarred.

A layer of thermal insulation material helps to reduce the outflow of heat from a structure in the winter season. It is recommended to use polystyrene foam for this purpose.

However, such measures do not always help prevent freezing. It is necessary to additionally use a layer of soil as a thermal insulation material. Soil is laid on top of a concrete slab or wooden panel. The layer thickness should be 150-500 mm.

General information about the cesspool ↑

A cesspool (drain) pit is the simplest anaerobic septic tank. Structurally, it is a pit dug in the ground with walls reinforced with various building materials. It is closed from above with a cap and a lid and sprinkled with earth, and instead of a bottom it has drainage made of gravel and sand.

Over time, any cesspool silts up and overflows with sewage

The organic matter of the wastewater coming from the house is “eaten up” by ordinary bacteria that live in the ground, and the clarified water drains into the soil. As a result, silt gradually builds up on the gravel bottom (a consequence of the activity of microorganisms) and solid waste accumulates. According to the rules, sediments formed on sand and gravel drainage should be regularly eliminated by pumping out with a sludge pump or a sewage pump. However, summer residents often do not do this. The volume of wastewater is small, they simply do not have time to fill the hole to capacity, and calling a sewage truck for a couple of cubes of sewage is too expensive. In fact, the reality is this: the cesspool gradually becomes clogged and at some point stops draining water into the ground. After this, the cesspool is eliminated, and a new one is dug next to the old one for drainage. This is the easiest to implement and cheapest option for installing a sewer system in the country.

Construction of a cesspool without a bottom

Scheme of a cesspool without a bottom.

For a family of 5 or more people, it is recommended to choose another option for arranging the sewer system. In this case, it is advisable to build a cesspool with a drainage base.

The installation principle remains the same as in the case of a sealed drive. However, instead of a solid base, a layer of bulk materials is formed: soil, crushed stone. The technology for constructing walls and their waterproofing is the same.

The brickwork is strengthened with a sand-cement mixture, the structure is covered with a slab on top, and isolated from contact with water.

Waterproofing, backfilling and bunding of the cesspool

Before completing the roofing, we cover the inside of the walls and the bottom of the cesspool with waterproofing made of roofing felt on bitumen mastic.

We coat the outside walls of the cesspool with bitumen mastic. We insulate the ceiling with one layer of roofing felt on bitumen mastic, with an overlap of 10-12 cm on the walls. We also cover the sides of the hatch shaft with roofing felt.

We fill the foundation sinuses with clay and compact it layer by layer with a hand tamper.

I recommend: Question: About building a toilet with a cesspool

We pour a 5-7 cm drainage layer of crushed stone onto the ceiling, put a layer of geotextile on top and pour 15-20 cm of black soil. We sow the black soil with lawn grass and in the spring our cesspool will turn into a nice green mound.

Local sewerage system with wastewater treatment

In this case, ready-made septic tanks are used. They are installed in prepared pits. The main function of such structures is to collect and purify contaminated water.

Septic tanks can be one-, two- and three-chamber. Each of the compartments solves different problems.

The wastewater passing through them is first purified naturally (sediment sinks to the bottom), then goes through the stage of biological treatment, then ends up in a drainage well or filtration fields (equipped according to the principle of drainage). Here the water is purified to 90-97% and can be reused.

Drainage sewer complex

Distribution wells are being installed. Their height does not exceed 400 mm, the diameter varies from 400 to 700 mm depending on the type of material used to construct the walls. To protect the structure from water, the same techniques are used: coating insulation of external surfaces, plaster inside, as well as the ironing method.

The wells are covered with concrete slabs or wooden panels and thermal insulation is provided. It is recommended to equip them with bends. A concrete tray is created at the bottom of the wells; its height corresponds to the diameter of the pipes. Such wells are located away from the septic tank. Communications are diverted from them.

How to clean a cesspool

You can use a special vehicle and do the cleaning quickly. But it is not always possible to take advantage of this. In this case, you must organize cleaning yourself.

Cleaning the cesspool

Cleaning methods:

- using a bucket and rope;

– using a special pump.

The first method is unpleasant and dirty. But the second one is fast and efficient, especially since nowadays there are many models of these pumps with different parameters, as well as prices, so everyone can choose the necessary equipment.

Another important cleaning element is the container into which wastewater will be drained, regardless of the choice of cleaning method. Afterwards, this container is removed and disposed of in specially designated places; waste cannot be dumped somewhere in a field or forest.

The nuances of operating cesspools

In addition to the above measures, it is recommended to make a compost pit. Its walls are protected with a layer of clay (thickness up to 300 mm), then they are concreted. Brick laying is done on top. The walls of the compost pit should rise above ground level. They are subject to ironing. Sludge is dumped here when cleaning a septic tank.

This measure is used to disinfect sewage and convert it into compost. To do this, the sewage is laid out in layers: first peat or soil, then sediment from the septic tank, earth again on top, etc.