Installation of water supply during cottage construction

How to lay water supply pipes in a private house and what pipeline diameters should be used when installing hot and cold water supply systems? What materials can be used for cold water supply and hot water supply? Today we will try to find answers to these and some other questions.

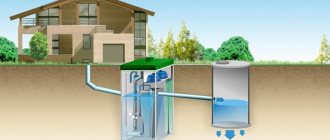

Water supply to a private house: external water supply

The entire water supply system located outside the house is called external water supply. The plumbing inside the house is called internal. Internal and external water supply systems have their own characteristics and installation methods. Since winter external water supply is all-season, and the technology of its construction is more complex, we will pay special attention to it.

The external water supply of a private house delivers water from the water supply source to the house, or rather, to the point of water supply entry into the house. Sometimes water is delivered from the source to the house using a hose deployed around the area. This method is not even slightly stationary, so we will not consider it.

Any stationary external water supply (summer and winter) is laid in the ground. For summer water supply, a trench is dug up to 50 cm deep. For winter water supply, the depth of the water pipe should be 50 cm below the soil freezing level, and each region has its own freezing depth.

Pipe diameter

In order for the pipeline to effectively fulfill its task, before its installation it is necessary to determine the required dimensions of the products used. If you choose a smaller diameter, then due to the low throughput in the network there will always be increased pressure. If the diameter is larger than necessary, then this will, at a minimum, make the pipeline more expensive than usual. Let's look at the sizes for different systems.

For indoor plumbing

To select the correct pipe diameter, it is recommended to invite a specialist who will take into account all the system parameters. You can deal with this issue yourself if you know what to look for.

What factors are taken into account when choosing pipe diameter:

- Water pressure in the system. If the pressure is low, then products are selected with a large diameter.

- Pipeline length: The longer the system, the larger the diameter required. For example, if the length is less than 10 meters, a parameter of 20 mm is suitable. For lengths up to 30 meters – 25 mm diameter.

- Number of turns. If communications are assembled with a large number of turns, the diameter is taken with a margin, since the pressure in the system decreases.

- Number of consumption points.

- Water temperature.

- Pump characteristics.

As an example, let’s take the average speed of water movement in pipes – 0.02 km/s. Accordingly, if the diameter of the system is 25 mm, then the throughput will be 30 l/s, with 32 mm – 50 l/s. In general, it is not recommended to underestimate the diameter, which will affect the efficiency of the system.

To provide water supply outside in a trench

External pipelines are laid from polypropylene, polyethylene, metal-plastic and other types of pipes. For installation in a trench, HDPE products are better suited because they can easily withstand high pressure - up to 10 atm.

Here, the advantage of polyethylene products is that with a diameter of up to 63 mm they are sold in coils of 100 and 200 meters in length. This makes it possible to lay a pipeline through the garden without using connections and without worrying about a leak forming somewhere.

External pipelines from a well or from a central water supply are laid with pipes with a diameter of 32 mm. The internal diameter of such products is 25 mm. Of course, smaller sizes are also used, but this reduces the throughput, that is, there may simply not be enough water. As for large diameters, they are not allowed, since there will not be enough liquid for the rest of the street residents.

Trench for external water supply for year-round use

- In central Russia, the depth of soil freezing is 1000-1200 mm, which means that a winter water supply trench will have to be dug 1600-1800 mm deep.

- A classic trench should have a cross-section in the form of an inverted trapezoid, with the base of the trapezoid at ground levels.

- If you use HDPE (low-density polyethylene) pipe for external water supply, then the evenness of the trench does not matter and it is quite possible, if the landscape so requires, to make a trench with a bend.

Construction of a trench for the external water supply of a house

Read more about the construction of trenches for water supply in the article Laying a trench for the external water supply of a private house. Briefly here: At the bottom of the trench you need to make a sand cushion of 10-20 cm. For clay soil, make a cushion of gravel (crushed stone) under the sand.

Methods for insulating pipes

One of the most important stages when introducing water into a private house is insulating the pipes. If this is not done efficiently, freezing of the water supply and related problems may occur.

There are several methods used to insulate pipes:

- laying the pipeline at a level below soil freezing. This option is not always convenient; it is not suitable for all regions of our country;

- installation of a receiver in the pipeline, which creates high pressure inside the pipes. Due to this, their freezing is prevented;

- pipe heating. It is organized by wrapping them around a cable connected to the electrical network. The inconvenience of this method is the increase in electricity charges and possible problems in the absence of it;

- insulation of the pipe using umbrella-shaped insulation. In this case, the heat from the soil will help prevent the pipes from freezing;

- Another interesting way is to place the pipes that need to be insulated into others of larger diameter filled with thermal insulation material.

Introducing external water supply into the house

There are two ways to introduce water pipes into your home.

- Input of water supply through the foundation. In this case, a hole is drilled in the foundation to insert a water pipe (if such an input is not made in advance when pouring the foundation);

- The entry of water supply into a house on any columnar or pile foundation is carried out between the foundation pillars and is done with insulation of the bend at the entrance to the house.

- Sometimes they install water pipes under the foundation.

Characteristics of water pipes

The design of a water supply system cannot work without pipes, so it would not be a mistake to say that they are the most important element of this system. In construction, plastic, metal-plastic and metal pipes are most often used.

Despite the differences due to different materials of manufacture, all pipes have the same dimensional characteristics, the list of which looks like this:

- Inner diameter, which must be the same at all joints so that the structure is solid;

- Nominal diameter is the nominal value required for the installation of a water supply system;

- Wall thickness;

- Pipe length.

The correct selection of pipes in terms of dimensional characteristics is needed not only for their installation - elements suitable for arranging a water supply system will allow you to create a structure that will not have problems during operation. If the diameter of the plastic water pipe is too small, water turbulence will occur in it, causing the structure to make noise and periodically fail.

Conclusions instead of instructions for installing water supply to the house

Water supply to the house is carried out in stages:

- Mark the route from the water supply source to the water supply entry into the house;

- Dig a trench 50 cm deep above the soil freezing level (about 1500-1800m);

- Make a 20 cm sand cushion at the bottom of the hole;

- Drill a hole in the foundation of the house for the water pipe. Place a sleeve from a piece of steel pipe into the hole;

- Lay an external water supply pipe from an equipped source to the entrance to the house and insert the pipe into the house;

- Insulate the water pipe. The insulation should not come into contact with water. Pay special attention to insulating the place where the pipe exits the well and the exit from the trench into the house (if there is one) and where the pipe passes through the foundation sleeve;

- Connect the external water supply to the source and input (temporarily), and then check it for leaks along the route;

- Cover the external water supply pipe with 20 cm of sand and 30-40 cm of soft soil;

- Without compacting the soil, fill the trench with soil dug out from the trench. Remove boards, roots, and construction waste from the soil.

©Elesant.ru

Other articles of the training course: Water supply at home

- Do-it-yourself water drilling for water supply to a house, cottage, or dacha

- Types and choice of surface pump for a private house

- Choosing polyethylene pipes for external water supply at home

- Choosing a water supply scheme for your home: do-it-yourself water supply for your home

- Choosing a well pump is easy

- Sources of water supply systems for a private home

- How to install a well for a private house

- External and internal water supply of a country house

- Water supply to the house: external water supply of a private house

- Laying a trench for the external water supply of a private house

- Calculation of a surface pump: how to calculate the pressure of a surface pump

- Calculation of a well pump: formula and example of detailed calculation

- Private house water supply systems

- Automatic water supply station: selection and installation of a water supply station

- Insulation of the external water supply of a house: materials and methods of insulation

Why aren't steel pipes used now?

In the absence of an alternative, steel pipes were the only option for constructing water supply systems that were durable, reliable and economical. Until recently, the choice of which pipes were best for water supply in a private home was only between them and copper products, which only wealthy people could afford. But they, not wanting to waste money, often chose the first option.

This is explained by the high strength of steel pipelines, which can withstand both external mechanical loads, excess water pressure, and hydraulic shocks. Such a system could last for several decades, but required constant maintenance and periodic repairs.

In old houses you can still find a working steel water supply system, installed more than half a century ago Source homemasters.ru

Despite all the advantages, steel pipes have many more disadvantages, which have been eliminated in modern materials, which will be discussed below.

- Instability to corrosion.

This is the main disadvantage of such pipes. Corrosion processes affect both their internal and external surfaces. To prevent rusting, the outside of pipes must be painted frequently and regularly. It is impossible to do this inside, so over time the quality of the transported water deteriorates, fistulas and leaks form in the system, requiring repair.

If a leak has formed on the main line leading to the house, it is impossible to detect and eliminate it in time, which leads to serious accidents. Therefore, when choosing which pipe is best to use for underground water supply to the house from a well, the option made of black steel should not even be considered.

- Insufficient smoothness of the inner walls.

They contain roughness invisible to the eye that traps particles of rust, lime and other solid impurities. This process continues continuously; deposits form on the inner walls, narrowing the diameter of the pipe and the water pressure.

Blockages in steel pipes Source tildacdn.com

- Formation of condensation.

When there is a large temperature difference between the pumped water and the surrounding air, steel pipes “cry” - drops of condensate appear on them, which fall to the floor and are another cause of rust.

- Difficult to install.

The large weight of the pipes creates difficulties when fixing them on walls made of cellular materials or drywall. The joints of pipes with each other and shaped elements are carried out by welding, which forces the use of the services of specialists. Assembly on threaded connections is also possible, but they are short-lived, and it is in these places that the risk of leaks is high.

Pipes made of chrome, galvanized or stainless steel resist corrosion quite well, and therefore are free from the disadvantages that arise from it. But they are much more expensive both in themselves and in installation. These materials are less amenable to processing and welding; special consumables are needed to assemble a stainless steel system. You can’t do without highly qualified craftsmen and special equipment.

Stainless steel water supply Source epressi.com

To avoid problems associated with the shortcomings of steel pipes and to save yourself from the need for frequent repairs, it is better to choose other materials for installing the plumbing system.

When deciding which pipes are best for water supply in a private house, you need to take into account the seasonality of its operation, the volume and temperature of the pumped liquid, installation conditions and other factors.

See also: Catalog of companies that specialize in the design and installation of sewerage and water supply

Polyethylene pipes

One of the materials used for the manufacture of plastic pipes is cross-linked polyethylene, which, due to a special production technology, has increased strength characteristics without loss of flexibility and elasticity. There are also low-pressure HDPE pipes, but they are not very suitable for use in apartments.

Pipes made of cross-linked polyethylene are an excellent material for arranging cold and hot water supply in an apartment. This material can operate at temperatures of the transported medium up to +95 degrees, which is quite enough for water supply. Read also: “Which pipes are best for water supply – making the right choice.”

In addition, this value is not limiting - the destruction of polyethylene pipes begins only if the water temperature exceeds +110 degrees.

An important quality of polyethylene pipes is their plasticity. A water pipeline assembled from such pipes does not collapse even when frozen, which is especially important for private homes. In apartments, flexibility is more important, which allows you to give the pipeline the required shape.

Polypropylene pipes

If the budget allocated for construction is not too large, then polypropylene pipes would be a good option for arranging a water supply system. They are cheaper than other polymer products, and in some places they even surpass them in characteristics: the operating temperature of polypropylene is +95 degrees, and the pressure is up to 20 atmospheres. In addition, it is worth noting the service life, which on average is about 50 years.

The disadvantage of polypropylene products is the lack of plasticity, so installation of the pipeline at an angle is possible only with the help of appropriate fittings.

Permanent connections of such pipes are made using a special soldering iron. In any case, before purchasing, you need to carefully understand which propylene pipes are best for water supply, and prepare the equipment necessary for installation.

Low pressure polyethylene pipes

HDPE pipes are used for external laying of water pipes. They are produced in lengths and coils of diameters corresponding to the standard number series.

There are several grades of polyethylene depending on its internal structure; pipes are made from PE-80 and PE-100, the latter being the best.

Unlike polypropylene pipes, the wall thickness of HDPE pipes can vary within wider limits. For them, the dimensional ratio of the outer diameter to the wall thickness SDR is also established, and it can vary in the range from 2.5 to 41.

HDPE pipes are designed to transport water with a temperature not exceeding 40 °C. It is clear that they are used only in cold water supply systems.

As for the pressure characteristics, the pressure that a HDPE pipe can withstand ranges from 2.5 to 25 bar and directly depends on the SDR.

HDPE pipes are connected using external compression couplings, so that their internal diameter remains unchanged throughout the entire pipeline.

Related article:

What is HDPE pipe

A separate article explains what HDPE pipe is - the production process, application, joining methods, installation.

Rice. 4 Installation of polypropylene and polyethylene pipes