Autonomous water supply to the site is not limited to the construction of a well. It is necessary to deliver water to water collection points through pipelines. When the source depth exceeds 7 m, a vibration or centrifugal type submersible pump should be used.

Their design makes it possible to lift water from depths of up to 90 m with the required pressure, while energy consumption is significantly lower than that of surface units. The advantage of submersible pumps is relative silence during operation, since water serves as a natural sound insulator. You can only hear the relay clicking.

The photo shows installation of a pump in a well.

In addition, such equipment is protected from frost and can demonstrate stable and well-functioning operation at any time of the year. The main issue when operating a submersible pump for a well is the correct choice of model for your needs, as well as the correct installation of the pump in the well.

Required materials and tools

In order to quickly install a submersible or surface apparatus in a well, install a water pipeline into the house and install automation for starting and monitoring the water supply, it is necessary to carry out preparatory work.

Purchase materials and equipment that will be needed to install the system:

- submersible or surface pump;

- set of automation equipment with hydraulic accumulator;

- pressure hose;

- distribution tee for submersible version;

- check valve;

- coarse filter for surface version;

- fitting;

- insulation;

- geotextiles;

- stainless steel cable;

- cable for supplying electricity to the pump;

- auxiliary materials for fastening and waterproofing.

To carry out installation work you will need the following tools and equipment:

- Shovels, crowbar.

- Bulgarian.

- welder.

- Electric drill.

- Screwdriver.

- Roulette.

- Set of open end and socket wrenches.

Scope of application

Such units cannot be dispensed with in the following cases:

- when there is a need to pump out water to eliminate the consequences of accidents;

- when flood waters accumulate in basements and on ground floors;

- with a large rise in groundwater levels;

- when performing work on cleaning artificial reservoirs. Often a drainage pump is used to meet the necessary sanitary standards of swimming pools and other artificial reservoirs.

Correct connection

Installation of the submersible apparatus and installation of the surface apparatus are carried out with a connected pressure pipe. Despite the difference in use, both hoses, pressure and suction, in their parameters must meet the requirements:

- rigidity - pressure differences should not affect the shape of the pipe;

- wear resistance - abrasive elements in water should not damage it;

- frost resistance – not to deform during operation at low temperatures;

- environmental safety - the drinking hose must be made of materials that do not emit toxic substances;

- operating temperature range from +1 °C to +40 °C.

Products made of polyvinyl chloride (metal-plastic and polypropylene) shown in advertising photos meet these requirements. Hoses are used to lift water and move it into a house or storage tank in the country, and they are fixed to the pipes of the pump, tee, or adapter using fittings.

Installation of a drainage pump

A drainage pump is used to clean the well. It is distinguished by a particularly durable impeller - it is not afraid of impacts from sand, crushed stone, and solid debris that are found in water. A grill is installed on the suction pipe, which blocks the path of large objects.

Like water pumps, drainage pumps come in submersible and surface pumps. A special feature of deep-well pumps is float-operated automation. It turns the pump on or off without human intervention. Pre-setting is carried out, then the device is lowered into the water. After connecting to the network, it starts working. When the water level drops to a critical level, the automation turns off the pump; when the level rises, it automatically turns on.

Float automatics protect the drainage pump from running dry and failing. During installation, special attention should be paid to fastening the hose: the drainage pump creates high pressure, and if the pipe is poorly secured, it will tear off. Make sure that the pump is located away from the walls and cannot touch them even by accident. A rigid cable mount is required to prevent vibration.

How to hang and secure with your own hands

To prevent the device from ending up at the bottom during operation, it is necessary to securely fasten it with a hose to the wall of the shaft on a metal structure.

- A square-shaped frame with brackets at the corners for fixing to the wall is made from a steel corner using a welding unit.

- Two channels are welded along the diagonals of the square, and a hole is made at their intersection.

- The frame is rigidly fixed on top of the mine casing using brackets.

- A steel cable is passed through the hole in the channel, and a loop is crimped at its end to hold it on the structure.

- The pump is suspended from the safety rope and is used to remove it from the well.

Selecting and installing a pump in a well, video

In special cases, in order to maintain the purity of the water, the pump must be left at the bottom of the well. In this case, once a year it is necessary to lift the pump and clean its filter from contaminants. The practice has become widespread when a well is cleared of blockages once every few years. On average, cleaning takes several days, after which the pump is stored indoors.

When purchasing a drainage pump, it is recommended to focus not only on the technical characteristics, but also on the maintainability of the device. You need to find out whether components for it are on sale, find out the location of the nearest service center. It should also be remembered that models from well-known companies are more reliable and durable.

How to install a submersible machine

At least two people must take part in installing the unit into the source. Installation work of the system from the well to the house is carried out in the following sequence:

- a water supply project is being prepared, taking into account the model of the submersible unit, the automation system, and the required amount of materials for assembling the water pipeline;

- equipment, materials and necessary tools are purchased;

- between the mine and the house we dig a trench under the water pipe, taking into account the cold in your region and 50 cm wide. A layer of coarse sand (20 cm) is poured onto the bottom of the ditch, then a geotextile sheet is spread to protect the pipeline from ground and surface water with abrasive sand;

- On the prepared base, we lay high-pressure pipes made of metal-plastic or polypropylene, which are not susceptible to corrosion, in a trench, having previously been wrapped with heat-insulating material;

- cover the laid lash of the water conduit with a geotextile cloth;

- in the wall of the shaft, at the level of the bottom of the trench, we cut out a hole for the pipe into which we insert the remaining end of the water pipeline; its length should be 30–40 cm. The place where the pipeline enters the well chamber is waterproofed;

- We connect a valve to the submersible electric pump through a fitting, and a high-pressure pipe to it through a coupling. The section of the water pipeline was measured in advance taking into account the depth of the aquifer. We connect a stainless steel safety cable to a special bracket on the pump, and a cable to the electric motor. We secure the wire to the pipe with plastic clamps so that it does not sag;

- above the well we arrange a grid from a metal corner for attaching a safety rope;

- in the shaft, at the end of the water pipe, we fix a tee with a ball valve, which serves for emergency drainage of water. The outlet from the tee, directed into the well, is intended for connecting a pressure pipeline with a pump;

- manually lower the prepared whip with the pump into the source and secure the cable to the bracket. We connect the pipeline from the unit to the tee branch pipe, using plumbing paste to seal it. We lay the cable from the pump along the trench to the house;

- To supply water to the house under the foundation, we install a water pipeline with a cable into the technical room. We connect the hose to the hydraulic accumulator, and connect the cable to the automation;

- We begin commissioning work, start up the unit, and check for leaks. After the test, we dig a trench and begin operating the water supply.

To ensure trouble-free and long-term operation of the system, a PVC hose must be purchased from a specialized store.

Types for water supply of a summer cottage

These devices can be divided into:

- submersible;

- superficial.

How to use submersible pumps

Submersible pumps are designed for operation when partially or completely immersed in water. Depending on the design features of these units, immersion is permissible to a level of up to 300 m under water . Through the holes located in the bottom of the pump, the process of suction of water occurs. The bottom is protected from the ingress of various solid objects by a mesh filter.

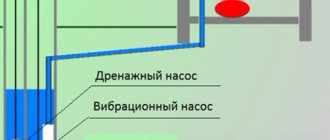

Installation diagram of a submersible pump in a well

Depending on specific conditions, the installation depth of drainage pumps may vary, but it should be remembered that the lower it is installed, the easier it is to work with it, and if necessary, the pump can be quickly removed from the well.

The operation of the device is automatic and begins when a certain volume of liquid accumulates. To prevent possible problems, each model must be equipped with high-quality electrical insulation. One of the main advantages of these pumps is their silent operation.

Submersible pump operating diagram

Based on differences in design, submersible pumps come in the following types:

- Rod Such devices are equipped with an independent motor, which is installed separately;

- Rodless. In such a pump, all elements are assembled in one housing and are completely submerged under water.

Submersible pump installation diagram

Thanks to the special elongated shape of this device, it is possible to install it inside the casing pipe of a well, the dimensions of which, in most cases, reach no more than 200 mm. The technical characteristics of submersible pumps greatly exceed those of other types. Thus, the cheapest models of submersible pumps can produce a pressure of 30-40 meters , while for surface models this is a very good result.

Installation of surface pumps

Installation of surface drainage devices occurs on the surface of the earth. A hose is lowered to the bottom of the tank through which water is pumped out. They are equipped with an inlet pipe, through which water is sucked out of the tank, and an outlet pipe, which is designed to remove liquid beyond its limits. If liquid gets into the pump motor, its breakdown is inevitable, so pumping out water must be faster than raising its level in the tank.

In order to extend the life of the pump, it is recommended to monitor the condition of the filter, which must be cleaned regularly.

Installation of a surface pump

For automatic operation, such pumps are equipped with a float mechanism. After the water rises to a certain level, the process of pumping it out begins. One of the main advantages of surface pumps is their mobility. The equipment can be easily moved to another location.

There are several types of these devices:

- centrifugal;

- vortex;

- screw.

These types of pumps are capable of performing most functions and are the most common. The design of vortex pumps is more complex, which is why their price may be slightly higher.

Connecting a hydraulic accumulator and automation

To ensure an uninterrupted water supply, it is not enough to know how to connect the device; it is important to protect the pump motor from overheating. In an autonomous water supply system, units with built-in automation are protected from voltage surges and dry operation when there is not enough water in the mine. Monitoring the operation of the pump allows you to regulate the pressure and pressure of the liquid in accordance with the parameters specified in the program.

To provide the house with water automatically, two systems are used: hydropneumatic and electronic.

1 ) In a circuit with a hydraulic accumulator, the hydraulic accumulator capacity with a control relay unit, installed in the technical room, ensures pressure regulation in the pipeline:

- The pressure in the system is monitored by a sensor. When the pressure decreases, when the pump stops sucking in water, the well becomes shallow, the electric sensor transmits a signal to the control relay, which works as a switch, and the unit stops pumping.

Choosing a device for a summer residence

Before proceeding with installation, the pump must first be selected. There are two types of devices on the modern market: for wells and borehole devices.

Their design is practically no different. The difference between them is size, shape and price. The well pump has an elongated cylinder shape, which makes it easier to immerse in a narrow well.

Types of well pumps:

- Centrifugal devices pump water using a motor that sucks liquid from the well and pushes it into the pipeline. This type of device must be operated correctly, namely, make sure that the pump does not run dry, that is, does not work without water, otherwise it may burn out. Common models: Pedrollo, ZDS, Grundfos. The average price is 4.8–48 thousand rubles;

Centrifugal pump its description

- A vortex pump is used for watering a vegetable garden. It is shaped like a metal disk with blades. The built-in motor drives the blades, which supply water to the hose under enormous pressure. Popular models: Watomo Mini, Rudes, SPRUT and others. The average cost is 2.5–4.5 thousand rubles;

Vortex pump for watering fruits

- The screw pump is used for pumping water with a large proportion of impurities and large abrasive particles. The external shape of the screw devices resembles a round stainless steel cylinder. Popular models: Sprut 4S QGD, and Sprut QGSa5. Average cost: 15–18 thousand rubles.

Screw pump

- The vibration pump consists of non-rotating elements. This type of device supplies water using an electromagnetic field that opens the stem for a split second. Each movement of the rod creates a slight vibration, which is why the pump got its name. Common models: “Stream”, “Harvest”, “Aquarius”, “Summer resident”. Average price: 3 thousand rubles.

Submersible vibration pump for wells

Features of surface pumps

Surface aggregates have their advantages. Along with them, they also have certain disadvantages. This will be discussed in more detail below.

Advantages

- These installations have great power, so that when used, liquid can be transferred tens of meters.

- Equipment of this type is highly reliable. In addition, when using, there is no need to immerse the pump in a liquid medium.

- A surface pump can be installed in the home. In this case, there is no need to conduct electricity to the well.

- Affordable price.

Flaws

- Such equipment can be used for wells with shallow depths , no more than 9 meters due to the low suction height.

- During operation, they emit a lot of noise, so in order to avoid discomfort during operation, such equipment should be placed in a separate technical room.

- It is necessary to have the skills to properly operate the suction line.

How to choose

To choose the right model, you need to answer several questions.

- How much liquid should be pumped out at a time?

- From what depth should pumping be carried out?

- How often will it work?

- What is the level of water pollution and what is the maximum size of solid particles in it?

- Acceptable price.

The video shows how to choose a drainage pump for a well:

Below are the main models of submersible and surface drainage pumps that have gained popularity in the Russian market.

Gilex Drainer

The Jilex fecal submersible with a grinder is used for cleaning septic tanks, country sewers, and drainage wells. Power – 400 W, productivity – 9 cubic meters. per hour, the maximum permissible size of solid particles is 35 mm. Price – 3,400 rubles.

Vortex

Power – 900 W, productivity – 16 cubic meters. at one o'clock. Price – 4,000 rubles.

MAKITA PF0403

Submersible for lightly contaminated water. Power – 400 W, productivity – 4,000 l/hour. Price – 5,000 rub.

GRUNDFOS

The company produces various models of submersible drainage and sewage pumps. The average price for models with a power of 300-500 W and a capacity of 5-10 cubic meters. per hour starts from 10 thousand rubles. The pumps are equipped with a built-in float sensor and dry-running protection.

Cleaning methods.

The well can be cleaned manually or automatically.

The manual cleaning process is considered complex and consumes human physical resources. After direct pumping, using brushes and products, clean the dirt from the walls. Next, the walls are disinfected with water and bleach. After 10 hours, the bleach is washed off with running water.

The automated method is considered the best option, using a drainage pump.

Types of pumps used to clean a well with your own hands.

Wells are cleaned using different types of pumps:

1.submersible

2.superficial.

The submersible type of pump is completely lowered into the well.

The equipment has its own positive features:

1.high level of performance.

2.Long service life.

3.compact dimensions.

4.light weight.

5.The device is universal because it can pump out both dirty and clean water.

6. Has a float to protect equipment.

The disadvantages of a submersible pump are:

1.water can be pumped out at a depth not exceeding twenty meters.

2.low pressure of the water jet.

3.there is no function that purifies the water.

The surface type of pump has its advantages:

1.presence of powerful pressure.

2.high reliability because it does not come into contact with water.

3.works all day without interruption.

4.can be installed wherever needed.

5.inexpensive price.

Negative characteristics of a surface type pump:

1.the presence of a lot of noise during operation.

2.water can be pumped out no deeper than eight meters.

3. To use the device, you must have the skills to correctly assemble the pipes and inspect the engine.