The operation of any well is accompanied by wear and tear of the structure. It loses its tightness, which is fraught with the risk of unwanted impurities getting into drinking water along with surface and groundwater.

Therefore, in case of wear, you definitely need a hydraulic seal for a well - a modern method of sealing a well shaft, which allows you to quickly and efficiently eliminate cracks, as well as repair damaged joints between concrete rings and in places where technical communications cut into the shaft.

Read below about the types of hydroseals, famous brands of such sealants and methods of using them. And also find out whether you can make a hydraulic seal with your own hands.

Types of seals for hydraulic structures

Depending on the purpose of the waterproofing, the conditions for performing the work and the task at hand, hydraulic seals are divided into 2 main types:

- Pressure. Used to eliminate active leaks. The setting time of such compositions is 30-50 seconds. After gaining strength, the applied coating not only seals the hole, but also resists soil pressure, as well as the constant influence of groundwater.

- Non-pressure repair mixtures are intended for sealing seams, minor defects, and cracks in operating above-ground structures. The setting time of such solutions is 3-5 minutes.

The category of non-pressure waterproofing materials includes gel sealants, which, like dry mixtures, serve to seal seams and eliminate coating breaks:

- rubber;

- acrylic;

- polyurethane;

- silicone.

Such materials are produced in plastic tubes, and their use requires a special compression tool.

Areas of application of blitz trains

If you understand what a hydraulic seal is, it was not difficult, then you can move on - find out what the areas of application of repair compounds are. Their main “line of business” is eliminating leaks in concrete, brick and stone structures. Moreover, they are used equally often for both old and new structures in which the defect appeared due to violations of waterproofing technology.

The main areas of application of hydroseals:

- Repair of concrete or brick wells. With the help of these compounds, seams between rings are waterproofed and various structural defects are eliminated.

- Elimination of leaks that have appeared in reinforced concrete structures - swimming pools, cesspools, and other reservoirs.

- Emergency assistance in case of water pipe breaks, emergency situations that occur in basements, tunnels, and mines.

- Restoration of foundation waterproofing, elimination of leaks in cold seams, in the joints of walls and floors.

In any of these cases, the use of a hydroseal is recommended. No, more often it remains the only possible material. The composition allows you to almost instantly create a waterproof barrier that can withstand even the strongest, almost record-breaking water pressure: blitz cement can withstand pressure of 7 atmospheres.

Technology of using ready-made compounds

Ready-made waterproofing seals are most often used to seal leaks when the water that leaks or leaks can cause serious damage.

When using ready-made hydraulic seals, it is necessary to strictly follow the work technology:

- Surface preparation. At this stage, using a perforator or hammer, it is necessary to clean the surface of the well from exfoliated concrete. However, first the surface must be cleaned of dust, dirt, and mold.

- Expansion of the repaired area. It is necessary to widen the hole by 20-30 mm and deepen the hole by 30-50 mm. This is done in order to “refresh” the edges of the hole. In this case, you should try to give the sealed crack the shape of a funnel. When sealing a seam, it is necessary to strip it and deepen it by 5-10 mm. To expand, it is best to use a wide spatula, working the damaged area from top to bottom. Small cracks and holes can be expanded in any direction as convenient for the repairman.

- Preparation of the solution. The solution is prepared no later than 2 minutes before use. Recommendations for preparation, proportions, optimal water temperature - all this must be studied before preparing the waterproofing mixture. To dilute the mixture, use a clean metal (not aluminum!) container.

- Filling the crack. We fill no more than 50-70%. This is necessary so that the waterproofing solution, which expands during the hardening process, does not damage the walls of the well.

- Stabilization of the filling. Press the finished filling with your hands for 3-5 seconds to several minutes (indicated in the instructions for use).

- Care. Depending on the mixture used, it may be necessary to periodically wet the seal over a period of 12-24 hours. If the instructions do not provide for this, then there is no need to do this.

- Treating the seal with a waterproofing compound. At this stage, a penetrating waterproofing material is used, which will protect the concrete wall of the well and the installed hydraulic seal from further destruction. From ready-made waterproofing mixtures you can choose: “Osmosil”, “Hydrotex”. Waterproofing can be applied only after the filling has completely hardened, unless otherwise provided by the manufacturer.

When diluting the solution, strictly follow the proportions specified by the manufacturer. You should not skimp and try to dilute the mixture thinner or, in an effort to increase its effectiveness, make it too thick. In both cases, the waterproofing properties of the seal will be impaired.

Installation of the hydraulic seal should be carried out quickly; it is advisable to do this with an assistant who will dilute the mixture while you prepare the hole for sealing

Often, along with sealing cracks, more serious damage is revealed that requires major repairs of the well. We recommend reading information about their elimination methods.

WHY DO YOU NEED A HYDROSEAL? INSTRUCTIONS FOR USE, WHICH TO CHOOSE, WHAT TO PAY ATTENTION TO

When leaks occur, one of the most difficult tasks is stopping the flow of water.

For this purpose, special compounds are used - hydroseals.

These compositions have a short setting time, rapid development of strength characteristics, and good adhesion, which makes it possible to isolate pressure leaks for further treatment with waterproofing compounds.

A hydraulic seal is not so much a repair material as a “first aid” when a leak is detected.

WHY IS HYDROSEAL USED?

As mentioned above, a water seal is a “patch” to eliminate a leak, which will then be covered with the main waterproofing layer.

Hydroseals are used on foundations made of concrete, stone, brick.

Compositions are used:

- To prevent water from seeping through pores, voids, cracks or other openings.

- To block an active leak when water enters under pressure (it can be significant).

COMPOSITION AND ADVANTAGES OF HYDROSEALS

Hydroseal is a rather conventional name that combines a variety of materials. Moreover, most of them have a fairly similar structure, i.e. they operate on a similar principle.

Material include:

- The binder is usually high-quality Portland cement, although polymer compositions are sometimes used.

- The filler is fine-grained inclusions, which, after polymerization of the composition, provide its mechanical strength (quartz/sand).

- Additives – activators, hardeners, etc. It is thanks to them that the composition firmly adheres even to a wet surface and quickly hardens, stopping the leak in the problem area.

The possibility of using hydraulic seals for emergency repairs of structures and concrete, reinforced concrete, brick, stone is due to a number of features of such compositions.

Properties of ready-mixes:

Fast setting . After mixing and applying to the base, the composition hardens within 30-100 seconds. This allows you to hold the composition at the site of the leak and, after a minute or a minute and a half, ensure that the leak is eliminated.

Rapid strength gain . The action of hydroseals is based on their ability to quickly set (some seals expand under the influence of water), which makes it possible to isolate pressure leaks for further treatment of concrete with waterproofing compounds.

Good adhesion . The solution for hydrosealing, prepared in accordance with the instructions from the manufacturer, is securely fixed to the base even if it is completely covered with water. This is one of the important differences from more common sealants, which are fixed only to a dry surface.

CHOOSING A QUALITY HYDROSEAL

Hydroseal is a composition that it is advisable to have on hand. The presence of a hydraulic seal is especially important if you are in charge of hydraulic structures or similar objects where leakage may occur.

When choosing compositions you need to pay attention to:

- The material for which the filling is intended.

- Setting time (the best samples set in less than a minute, which allows you to quickly eliminate leaks).

- Chloride content (they can cause corrosion of the metal at the point of contact).

Optimal performance:

- Adhesion - 2MPa or more.

- Water resistance - W10 or more.

- Strength - tensile strength from 5 MPa, compressive strength from 40 MPa.

HYDROSEAL FOR WELLS

If you have to seal a tank or pipe with drinking water, or, for example, a well, then you should use only special compounds that have been certified for this.

Practice shows that the best results are achieved by using hydraulic seals from world-famous and reputable manufacturers (KEMA, ISOMAT and analogues). They are characterized by consistent quality, and the higher price is usually offset by greater efficiency and safety.

WHAT SHOULD YOU CAUTION WHEN CHOOSING HYDROSEALS?

Separately, it is worth warning against the use of “network” hydraulic seals - miracle compounds that are actively advertised on the Internet. If you believe the videos, such products almost instantly stop any leak and can be used even without subsequent waterproofing.

In fact, everything is not so rosy: the setting time of the binder for such hydroseals is unpredictable. In addition, sometimes they may not work at all, so the leak will persist or quickly resume.

INSTRUCTIONS FOR USE OF HYDROSEAL

Along with the correct choice of hydraulic seal, it is also important to apply it correctly. Here are some recommendations for using such formulations:

- The composition is prepared only in small portions. There is no point in making the material in excess to seal several leaks - it will simply set and petrify.

- All work with hydraulic seals is carried out only with gloves. Contact with exposed skin is almost guaranteed to cause a chemical burn.

- Seal leaks from top to bottom. When sealing, part of the material is applied to undamaged areas around the perimeter of the leak.

- The setting time of some compositions depends both on the temperature and composition of the water added to the solution, and on the ambient temperature. If you need the waterproofing concrete to set faster, warm up the treated area (for example, with a hair dryer).

Despite all the advantages of hydroseals, this is still a solution to an emergency problem. After the leak is stopped, it is worth taking care of reliable waterproofing.

Source: xn--1-etbdejebb0alkhcdwk0hvhc.xn--p1ai

Review of famous brands

The modern construction market contains a lot of offers from various companies. Despite the fact that the technologies for using hydroseals are similar, the effectiveness and quality are different. Therefore, it is recommended to opt for products from the world’s leading brands that have proven themselves among specialists who deal with shotcrete professionally.

Waterplug

This is a dry mixture that is packaged in a plastic container. Before use, it is necessary to prepare an aqueous solution in accordance with the attached instructions. The composition includes quartz sand, and special hydraulic cement is used as a binder.

The peculiarity of this mixture is that it is possible to seal the holes through which water rushes out under pressure. Three minutes is enough for the solution to harden. The effectiveness of waterproofing concrete wells is achieved due to the ability to expand when hardening, which fills the pores and ensures a strong, airtight connection.

Peneplug

This is a similar composition to the dry mixture, but the aqueous solution has a faster setting time. 40 seconds to a minute is enough to eliminate a leak under pressure. Sealing is achieved due to the ability of the mixture to expand as it hardens.

The advantages of this hydraulic seal include:

- Fast setting, effective sealing, durable.

- It can be used at temperatures from 5 degrees Celsius.

- Resistance to water and aggressive environments.

To prevent the hydroseal from cracking, it must be moistened for the first 3 days. In a well, this problem does not arise if it is covered. This composition has one drawback - a fairly high (twice as high) price.

Puder Ex

The quick-setting material allows you to seal holes under pressure. The composition is resistant not only to water pressure, but also to the capillary action of moisture. In a well, dry joints are sealed in 7 seconds. This is exactly how much water sealing is needed to make the concrete structure airtight again.

Despite the high performance and advantages, the price of this dry mixture is low. German quality and reasonable cost have made it popular among builders of hydraulic structures and workers of specialized teams performing their repair and maintenance. The maximum water pressure withstand is up to 7 atmospheres, which means that this hydraulic seal will be able to eliminate any leak.

TYPES OF HYDROSEALS AND PROCEDURE FOR WORKING WITH THEM

Drinking wells are filled with water through an open bottom. There is a combined method, when the bottom ring is additionally perforated so that moisture flows through the side walls. When digging, several layers of soil with different compositions and densities pass through, filtering surface water as it soaks down. They should not enter the well directly.

Lining the mine with pipes or concrete rings protects clean water from the ingress of high water and runoff. Sometimes when digging, several aquifers are passed through. Their streams are blocked, and the gaps between the rings are sealed with waterproofing. Usually these are cement-based solutions, liquid glass, and there are tips for sealing joints using tarred hemp (not recommended).

High-quality sealed joints do not allow water to pass through, no wet streaks or streams are visible on the walls of the well, and there are no pockets of growth of moisture-loving vegetation. If a routine inspection of the shaft reveals damage to the waterproofing or cracking of the rings, urgent repairs are required. Waiting will turn drinking water into technical water, suitable only for irrigation.

Reasons for the formation of holes in waterproofing

The integrity of the seams between the rings is broken over time. They are covered with growths, the roots of which slowly penetrate deep into the monolith. The larger the gap, the faster it grows. Chips and crumbling of the putty and reinforced concrete itself occur due to non-compliance with construction and production technologies. It is imperative to check each ring upon purchase, transport and unload it with the utmost care.

Rings may break due to improper installation. There are craftsmen who simply throw them into the shaft when they need to be lowered gradually with a winch or crane. This method not only leads to deformation of the ring, but the force of the impact during a fall can disrupt the position or provoke a complete collapse of the shaft.

Particular care must be taken to seal technical openings in wells intended for introducing pipes, electrical cables and cables for the organization of individual water supply

When restoring and putting abandoned sources into reuse, the seams between the rings need to be completely cleaned and sealed with mortar. In old wells there is no waterproofing as such, or something like oakum or wooden plugs are used, which swelled and did not allow water to pass through. The disadvantage of the old methods is that the materials began to rot, releasing harmful substances and coloring the water.

Repair with cement mixtures is suitable for dry surfaces; if water flows through the cracks, the grout simply will not have time to harden or will soon fall off. Previously, such damage had to be cleaned out, filled with clay and only then covered with cement. Now a new product has appeared on the market - a hydraulic seal for drinking wells.

Composition and effect of hydroseal

This is a special mixture that sets very quickly and stops pressure leaks in a matter of minutes. The composition includes components that are resistant to water. Upon contact with a cleaned concrete surface, the hydroseal penetrates as much as possible into the pores of the material, ensures a high degree of adhesion and reliably eliminates damage. The quality of repairs and the service life of the restored area increases, and time costs are significantly reduced.

Based on the curing time of the prepared solution, hydroseals are divided into:

- Non-pressure – hardening period up to 10 minutes.

- Pressure - it takes no more than 60 seconds to harden.

The first type is used for routine preventive maintenance of a well. Immediately after hardening, they are ready for use. Instant hardening hydraulic seals are an express aid for emergency perforation of well walls, when you need to immediately stop the flow of contaminated water. After sealing the leak, the seal is duplicated with a waterproofing repair compound. Their advantage is that it takes up to one minute to eliminate a jet with a pressure of up to 7 atmospheres.

When purchasing a hydroseal mixture, you need to carefully read the instructions, especially the paragraph that indicates whether the composition is allowed to come into contact with drinking water. You need to choose a material that has a certificate confirming the harmlessness of the components

Using a hydraulic seal for wells greatly simplifies repair work, but it is imperative to follow the technology for preparing and using the mixture. Otherwise, even the most expensive hydroseal will not give the promised result.

How to use a hydraulic seal correctly

In order for the material to hold securely, the working area must be carefully prepared for embedding, and only then begin mixing the solution. If you delay, the setting speed of the hydraulic seal will work against you.

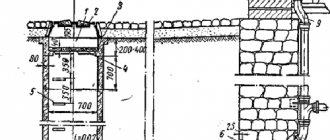

All identified holes must first be cleaned of chipped edges, widened and deepened to an undamaged layer. The cavity is processed with a hammer or perforator (when working with electrical appliances in a damp environment, strictly follow safety rules). Small recesses and holes are widened and deepened for easy loading of the finished paste. The optimal width is at least 25 mm, depth is 55-60 mm. The working hole is given a conical shape.

After preparation, the approximate required volume of hydraulic seal to repair one cavity is determined. Due to rapid hardening, you need to prepare a single portion of the mass. For kneading, water at a temperature of 20 C is used. The components are quickly mixed with a spatula or by hand. From pouring to the start of bookmarking, no more than 2 minutes should pass.

The finished mass resembles wet clay or plasticine . For simple well repairs, a hydraulic seal is prepared at the rate of 1 kilogram of dry mixture per 150 grams of water.

Approximate proportion: 1 part water mixed with 5 parts powder. Pressure leaks are sealed with a solution of high concentration, prepared in a ratio of 1:7.

Minor damage is repaired in one pass. After filling the recess, the repair mass is pressed and held by hand until initial setting. To speed up the process, the solution is mixed with water at a higher temperature. Vertical cracks are filled gradually from bottom to top. As the mass dries, it increases in volume, so when sealing seams in a well, the hydraulic seal is laid in smaller quantities. The finished surface is treated with penetrating waterproofing of the same brand.

The compositions of industrial hydroseals include special types of cement that leave burns on the skin and mucous membranes. You need to wear gloves and goggles when working, and in case of accidental contact, wash off immediately with water.

Comparisons of simple cement putty and hydroseal

The cost of branded powder for preparing a hydraulic seal is higher than the components for traditional cement-based putty, so not every repair team has such material. The standard packaging of hydroseals is plastic buckets of 10 kilograms or more. This volume is enough to repair one well. Leftovers should be stored in a dry place to prevent the mixture from absorbing moisture and spoiling.

The hydraulic seal easily stops the pressure flow of water. The composition is prepared in 1 minute, and the service life is no less than that of cement. The dried surface resembles high-quality concrete in texture and does not crack over time. Simple putty on cement and sand does not give such a result.

Fast setting has disadvantages:

- A separate portion of material is prepared for each crack;

- Limited time of use;

- It is necessary to quickly clean the container and tools so that the composition does not dry out.

When selecting a hydraulic seal for repairing wells, keep in mind that some compounds must be moistened with water after application, otherwise the required strength will not be obtained and all funds will be wasted. Homemade compositions cannot ensure the inertness of the components. Such a “patch” takes a long time to set, and subsequently there is a risk of destruction and getting into drinking water.

A branded hydraulic seal will safely, efficiently and quickly solve the problems of leaks in a drinking well.

Source: rus-kolodez.ru

How to choose the right hydraulic seal

A good dry mixture for preparing hydraulic seals for wells must have a certificate that guarantees the quality of the material. This is the most important detail when choosing putty. This is important not only for the longevity of the well, but also for your health.

The certificate is confirmation of the safety of the material, since it comes into contact with drinking water. Additionally, you should consider the curing time when purchasing putty.

Depending on all these characteristics, the price of a hydraulic seal for wells is determined.

How to eliminate a leak in case of massive damage?

The leak repair technique described above is suitable for small damage. However, if the hole is large, then its elimination is carried out in several steps. If a leak is found in the basement, then first of all you should insert a hose into the resulting hole to divert the flowing water into some suitable container. And only then begin to repair the damage using a special coating waterproofing agent. There is one important nuance here. If the nature of the damage is such that there are separate areas with intense water flows, then it is not worth cementing them immediately. Only after the waterproofing coating has set can a hydroseal be applied. After the latter has cured, you need to again apply a layer of waterproofing agent, covering everything together - both the previous layer of waterproofing and the water seal. If you follow this technique, you will absolutely get a good end result - the basement will be completely dry and will be protected from further water leaks and the appearance of dampness. Large leaks in other places can be sealed in a similar way.

Sealing seams in a well with your own hands

Fixing leaks in wells can be done without the involvement of specialists; any owner can repair a leak with his own hands. To eliminate a leak in a well, first of all, you need to take your time and follow the work technology.

Progress:

- Prepare the surface. Use a jackhammer or hammer drill to remove loose concrete from the walls of the well. Expand the resulting pothole on the sides and in depth by 20-40 mm. Clean from dust.

- Prepare the solution. It is recommended to mix the waterproofing mixture a couple of minutes before application. The finished composition should resemble dry earth. When mixing, strictly adhere to the preparation instructions.

- Seal the crevice. Fill the prepared area with the solution, leaving a quarter of it unfilled. As it hardens, the composition will expand and completely fill the gap.

- Stabilize the filling. Press the filling with your hand or a spatula, as if pressing it inward.

- According to the instructions, you may need to periodically wet the filling a couple of times during the day.

- Treat the filling with a special waterproofing compound - Hydrotex or Osmosil.

After completing all the work, it is recommended to immediately wash the entire tool, otherwise the solution will harden and cleaning it will be problematic.

When working with a hammer drill or jackhammer, you must strictly adhere to the rules for using the tool!

It is better to use ready-made hydraulic seals; a homemade composition does not provide a complete guarantee of quality.

Homemade pressure-free seal

To prepare a waterproofing seal, the following materials are needed: fine-grained, preferably sifted sand, cement of a grade not lower than M300. Proportions – 2 parts sand + 1 part cement. Immediately before use, water is added to the composition.

Water must be added gradually, stirring constantly. The consistency should be thick so that the mixture can be easily formed into a ball that will not spread.

The filling is applied to a large crack by hand, and rubbed into a small crack with a spatula. After the repair is completed, the well section must be covered with an iron plate. After 2-3 days, the iron is removed, and the filling is treated with cement mortar and covered with waterproofing.

This method can only be used to eliminate non-pressure and low-pressure leaks. Under high pressure (over 3 atmospheres), such a homemade composition is quickly washed out.

To seal a deep crack, it is recommended to fill in two layers, and the first filling (bottom layer) should be thicker, almost dry, than the second

Sealing for seams and small cracks

Despite all their shortcomings, homemade hydraulic seals are excellent for sealing seams in concrete wells. They cope with this task “excellently”, while allowing you to save a significant amount on industrially produced products.

Being environmentally friendly and safe, homemade hydraulic seals made of sand and high-quality cement reliably protect well water from the ingress of groundwater, impurities, and soil.

To increase the efficiency of waterproofing the seams of a well, a “liquid glass” composition can be added to the solution of sand and cement. This mixture will make the sealing better and more durable. Proportions 1:1:1 (sand:cement:liquid glass). It is necessary to add “liquid glass” 1 minute before sealing, because The composition hardens very quickly!

- Before applying a hydroseal, it is necessary to prepare the surface: clean it and smooth out problem areas.

- The mixture must be prepared exactly in the proportions indicated by the manufacturer in the product instructions.

- The solution should be mixed so that there are no undissolved lumps left in its mass. The consistency of the hydroseal is indicated in the instructions.

- The repair solution is evenly applied to the problem area of the well wall, then carefully leveled.

The technology for sealing the seams of a concrete well is as follows:

- Surface preparation, which consists of removing exfoliated concrete and remnants of old sealing.

- If necessary, treat the walls of the well with an antibacterial compound to remove/prevent mold.

- Cleaning seams from dust, dirt, and old waterproofing. Expanding the seam by 5-10 mm by gating. The tools used are a perforator, a hammer, a wall chaser.

- Preparation of waterproofing mixture.

- Pre-wetting the seams. The seam should not be wet, but moistened. It is optimal to use a fabric that absorbs water for this procedure.

- Applying the waterproofing mixture using a spatula. Filling cracks and caulking joints.

- Application of a penetrating waterproofing solution.

How often are seam waterproofing works carried out? Waterproofing the seams of a concrete well is carried out on average once every 5 years, provided that the well is operated correctly. Emergency waterproofing is carried out in the event of a leak, deterioration in the quality of well water, or after sudden drainage.

It is best to carry out waterproofing work in the spring, after the snow has completely melted, when the average daily temperature is no lower than +5 degrees.

It is necessary to carry out sealing, moving from bottom to top, simultaneously inspecting the walls of the well, eliminating chips and sealing existing cracks and crevices

Application of a hydraulic seal for a well

To prevent the water in the well from being contaminated by groundwater, which may contain harmful impurities, a variety of waterproofing materials are used. Particularly in need of sealing are the seams between the rings, the places where utilities are inserted into the well shaft, and defects in the body of reinforced concrete products formed as a result of operation.

To quickly eliminate leaks, use a hydraulic seal for a well, which is a quick-hardening material that returns solidity to the structure in a few minutes. When purchasing such material, you must ask for a certificate, which must confirm that the components included in the hydraulic seal are safe for drinking water.

Types of hydraulic seals for wells

This material comes in two types:

- pressure;

- non-pressure.

Pressure ones are characterized by very rapid hardening. This happens within 30 seconds, and the binding qualities remain for many decades. A strengthening solution is applied on top of this material. Pressure hydraulic seals are used in situations where severe leakage occurs.

Non-pressure hydroseals take a little longer to harden. This takes about 5 minutes. This is why water pressure often washes away the solution before it has time to harden and form a filling. This solution is best used in advance to prevent emergency situations, and not to eliminate them.

How to prepare the solution

The hydraulic seal for the well is manufactured in accordance with all the recommendations specified by the manufacturer. To determine the amount of dry mixture, they are guided by how active the flow is. If the pressure is small, then the following proportions are mainly used:

- one part water;

- five parts of the mixture, this is approximately 150 g of water for 1 kg of material.

Strong pressure significantly changes the proportions: for one part of water there are already seven parts of the mixture.

The kneading time is also taken into account. The water used should be about 20 degrees. The solution should be mixed for no more than 30 seconds, and the consistency should be similar to dry earth.

It is undesirable to immediately mix a large amount of solution, because it sets very quickly and then it cannot be used . That is why the hydroseal is prepared in small parts, and each part should be prepared after the previous part has been applied. The mixture is mixed using any tool or with hands, which must be worn with gloves.

Application technique

Quick-hardening mixtures for wells are called hydroseals. Before applying a hydraulic seal for a well, the base is thoroughly cleaned of dirt and dust. If there are weak areas, they should be removed. After this, a small amount of hydroseal is prepared and applied to the damaged area, while pressing it with your hand and holding it until it sets.

Large defects should be processed in several stages. It takes 2-3 minutes for the composition to completely harden. This depends on the ambient temperature, the base, as well as the temperature of the water used and the composition itself. To change the rate of hardening, the temperature of the material and water must be adjusted. If the temperature is high, the material will set faster, and vice versa.

When choosing a hydraulic seal, it is important to take into account such a characteristic as its setting time. Do not forget that the faster the material sets, the more difficult it will be to work with it later. You should also check that the hydraulic seal does not contain chlorides, which, when interacting with metal objects, can cause corrosion. If the hydraulic seal will interact with drinking water, then you must ask for a certificate that will confirm its safety and the possibility of use for these purposes.

Advantages of using a hydraulic seal for a well

The use of this waterproofing material has certain advantages:

- an excellent solution for quickly eliminating or preventing water leaks through joints, crevices, holes, cracks, cavities, seams and other structural defects;

- simple preparation for use and ease of application to a variety of surfaces;

- holds guides and other various auxiliary elements well;

- increased resistance to alkalis, oil and gasoline mixtures, saline solutions, diluted acids;

- is not subject to shrinkage and corrosion;

- environmentally friendly;

- weather resistance;

- frost resistance;

- increased adhesion.

Precautionary measures

The technology for using a hydraulic seal for a well is not very complicated, so it is sometimes done without the involvement of specialists. When working with the solution, your hands should be wearing gloves. After use, the tool must be immediately washed from any remaining mixture, because after final drying it can only be cleaned mechanically.

Conclusion

Using a hydraulic seal for a well helps to efficiently eliminate any leak. This waterproofing material is quite expensive, so not every company that builds and repairs wells uses it.

If there is a need to contact specialized companies, then you should immediately clarify this point, because any other materials are often not effective in combating leaks.

Source: stoki.guru

Safety precautions for working in a well

Work to eliminate a leak or seal a well is a high-risk activity, so it is necessary to strictly follow safety requirements.

At the preparatory stage, you should carefully handle a jackhammer or hammer drill, which is used to clean the surface from peeling concrete and chips.

When mixing the hydroseal, you must protect your hands with thick rubber gloves. The tool used to apply the hydraulic seal must be cleaned immediately after completion of the work of any remaining waterproofing mixture.

When using ready-made hydroseals, make sure that the composition does not get on exposed skin. When diluting the powder, try not to inhale the resulting vapors, as they can harm the mucous membrane.

Preparation

Hydroseals are supplied in hermetically sealed containers and are a dry powder. To prepare a waterproofing composition, you need to take a small amount of this powder, pour it into a rubber or plastic container, and then start adding water. The chemical composition of hydroseals from any manufacturer is toxic and should not come into contact with the skin for a long time. Rubber gloves should be used as protective equipment. If the latter are available, you can mix the powder with water manually or using a spatula. When the mixture is ready for use, it begins to warm up. At this moment, you should quickly seal the hole with a hydraulic seal and wait for the resulting mixture to completely cure. The time period during which the hydroseal hardens can be adjusted by changing the heating or cooling of water and material. When mixing heated ingredients, they set faster. The exact hardening time is determined experimentally and depends on the brand of hydraulic seal purchased.

For reference

Before a hydraulic seal is installed for a well, the composition must be prepared by diluting it with a certain amount of water. The main components of the mixture are cement and quartz sand; with the help of a seal you can stop even a strong leak under pressure. After application, the solution will harden in 3 minutes, and then expand. It is very convenient that work can be carried out at a fairly low temperature, but only if the thermometer has not dropped below +5°. For a 25-kilogram bucket of this mixture, the consumer will have to pay 4,100 rubles.

Selection of the optimal hydraulic seal

Any type of waterproofing seal is designed for the mixture application technology recommended by the manufacturer. The purpose of the solution depends on its chemical composition, which, depending on the set of components, may have different requirements for operating conditions.

Waterproofing wells made from prefabricated concrete rings involves sealing areas of leakage through seams and cracks in the walls of the tank. Filtration of water can occur for many reasons - this is the seepage of liquid into the well from higher-lying horizons (overwater), the release of resource from the reservoir through connecting seams in the event of depressurization of the container, etc.

Restoration measures must be carried out in strict compliance with the technological instructions provided for the selected material and located on the packaging of the purchased product.

Reviews on the method of using the Waterplug/Peneplug hydroseal

Concrete rings can be sealed with these compounds, which are used to restore the integrity of brick, concrete and masonry walls. Such seals are capable of cutting off pressure leaks. The Waterplug composition is used in non-pressure pipelines, while Peneplag can be used to seal strong leaks. The composition is based on aluminate cement, to which quartz sand and chemical elements are added. After connecting with water, the composition sets in a few seconds, gradually expanding in the channel. According to the manufacturer, interaction with the concrete surface is possible at the capillary level. Waterproofing a concrete well, according to consumer recommendations, should be carried out by introducing the material into the groove, and the mixture should be prepared 90 seconds before filling.

Hydraulic seal of the Peneplag brand

If you are installing a hydraulic seal for a well, then you may prefer the Peneplag composition, which is sold in the form of a dry powder and can be used after dissolving in water. It can be used to seal brick and concrete structures. The mixture hardens in 40 minutes, and for the same volume as mentioned above, you will have to pay 8,200 rubles. As practice shows, this solution is one of the fastest in terms of setting time. The remaining application requirements are similar to other hydroseals, for example, application should be carried out under conditions not lower than +5°. After sealing, the treated area must be moistened for 3 days, otherwise the filling will not become resistant to moisture and will quickly become cracked.

Modern method of sealing

Nowadays, tow and wood wedges are a relic of past years, and sealing technologies using this method have become history. Thanks to progress, new methods have emerged for sealing well cracks in concrete and joints between reinforced concrete structures.

A hydraulic seal for a well is an expensive material, and it is not practical to install it as a connecting element when installing rings.

However, sealing holes and cracks in concrete hydraulic structures - the direct purpose of a hydraulic seal - can be afforded by every homeowner whose property has its own source. Among the advantages are durability, not susceptible to moisture, and the ability to be used for drinking water wells.

what it is, purpose and characteristics, reviews + video » SanDizain.ru

A well is an installation required in every yard of a private house. Water is taken from there for domestic needs and for watering the garden plot. But sometimes a well can present such an unpleasant surprise as a crack in the wall. Fortunately, eliminating it is not that difficult. Reviews say that one of the best means for eliminating a leak in a well is a hydraulic seal. Its purpose is to quickly and effectively seal any crack in the well. But, before you buy and use a hydraulic seal, you should find out its characteristics and watch a video on how to fix a leak in a well.

Description and purpose of the hydraulic seal

At its core, a hydroseal is a bulk material that is absolutely waterproof and has the ability to harden instantly. It is this characteristic that is the main indicator of the quality of the composition. The hardening component of the hydroseal, such as quick-hardening cement, ensures hardening. It sets in 30-60 seconds. This forms a plug that does not erode even under water pressure.

There are 2 types of hydraulic seals: pressure and non-pressure. When it comes to quick hardening, this is the first option. Non-pressure hydroseal can harden in up to 5 minutes. When purchasing, you must pay attention to what kind of solution is offered and think about what it will be used for.

Hydroseal

You can eliminate leaks using a hydraulic seal in wells made of stone or concrete. This product is also suitable for repairing basements, tunnels, tanks and swimming pools.

Advice. A hydraulic seal will also help to quickly eliminate a pipe break in an apartment or basement. This will prevent the flood and the waste it brings.

A hydraulic seal is a temporary and emergency measure to eliminate a leak in a well. It is used when there is an urgent need to stop the flow of water. To avoid having to use a water seal, you should carefully consider the initial waterproofing of the structure. Problems arise especially often in areas where groundwater lies close to the surface. A break in the well can also be caused by excess melt water.

Rules for choosing a hydraulic seal

The first thing you need to pay attention to when choosing a hydroseal is its hardening speed. At the same time, material that sets too quickly is difficult to work with. Therefore, the optimal hardening time is about 1 minute.

Experts warn that the hydroseal should not contain chlorides. Otherwise, when it comes into contact with metal elements, corrosion will occur on the latter.

Attention! If the water in the tank that will be repaired with a water seal is used for drinking and cooking, you should request a safety certificate from the seller. The document must indicate that the product can be used for these purposes.

Preparing a hydraulic seal

First of all, when preparing a solution for a hydroseal, you should carefully read the instructions from the manufacturer. However, there are general rules that you can follow.

It is very important to follow the instructions

- The standard portion of the mixture for eliminating leaks in a well is 1 kg of material per 150 ml of water. The more leaks in the tank, the more dry matter should be taken to make a hydraulic seal. Here you can maintain the proportions of dry mixture to water 1:5 or 1:7 with high pressure.

- The water should not be too warm. The optimal temperature for preparing a filling is about 20°C.

- The solution should be mixed as quickly as possible so that it does not have time to harden before starting work. It's best to do this within 30 seconds. A solution that has been mixed correctly should look like dry earth. Under no circumstances should there be any lumps.

Advice. Do not mix too much solution at one time. Otherwise, most of it will be hopelessly damaged. It is better to eliminate the leak in the well using a hydraulic seal in parts.

Hydro seals are not the cheapest means of repair. Therefore, it is very important to use it correctly and not ruin the expensive material due to inappropriate preparation and use.

Rules for eliminating leaks

The base for applying the hydraulic seal must be cleaned of dirt, dust, etc. If we are talking about a leak from any container, the liquid should be drained from there before starting work.

Installing a hydraulic seal for repairing wells and other leaks cannot be called difficult. Even a person who has no knowledge in the field of construction, etc. can carry it out. The main thing is to use rubber gloves to protect your hands. Tools used in the manufacture of a hydraulic seal and its installation should be washed immediately. Otherwise, the solution may harden. Then it will be very difficult to clean the tools from the remaining mixture.

When the solution is mixed, the master must do the following:

- The leak site should be tightly filled with the prepared mixture: after 1 minute. it will set, and after 3 minutes. will completely harden. If the crack is vertical, then it must be sealed with mortar from top to bottom, and not otherwise.

- If the leak is large and the first portion of the solution was not enough, you should mix it again and continue the repair.

- After a few hours, excess material must be removed from the repair site, and its surface can be additionally treated with a special waterproofing compound.

The hydraulic seal allows you to quickly eliminate leaks

Advantages of using a hydroseal

Using a hydraulic seal to repair wells has a number of significant advantages. Among them:

- Economical: Despite the high price, due to its service life, this repair method will save money on repairs in the future.

- Durability: such repairs will last for at least several years.

- Versatility: with the help of a hydraulic sealer you can repair almost any leak in a wide variety of tanks.

The high service life of the hydraulic seal is due to its resistance to diluted acids and alkalis, saline solutions, gasoline and oil mixtures.

A hydraulic seal is an excellent means of repairing leaks, which is useful in every household. It is worth buying it in advance so that the leak does not take you by surprise.

Hydroseal: video

sandizain.ru

Feedback on features of use

At one time, consumers are advised to fill no more than half the volume of the expanded cavity, and the formed plug must be held with your hands for about 2 minutes. If you decide to use the “Waterplug” composition, then penetrating waterproofing should be applied to the surface from the outside, after which the remaining volume of the embroidered crack is filled with the “Pinikrit” composition, the upper part should be leveled with a spatula.

Elimination of leaks

First of all, prepare the leak site. The cavity of the hole or crack is cleared of loose material.

To do this, use a hammer drill or jackhammer.

If the leak size is small, then the hole is widened to 2.5 centimeters and deepened by 5 centimeters, giving the shape of a cone.

The solution is prepared in a clean, dry container. Measure out the dry mixture according to the instructions and combine it with water.

Do you know how to choose the right circulation pump for your heating system? Tips and recommendations from professionals published in this useful article will help you calculate the power of your equipment.

What is an automatic bypass and why is it needed, find out here.

On the page: https://ru-canalizator.com/vodosnabzhenie/truby-i-furnitura/obsadnye.html it is written which casing pipe is best to use for a well.

The formed lump of solution is pressed with a sharp movement into the prepared leak area.

Press and hold the hydraulic seal for 3 minutes. The following portions of the mixture carry out the final repair of the leak.

IMPORTANT! Hydroseals are applied to:

- reinforced concrete structures,

- brick,

- masonry.

The properties of the material will allow you to seal leaks on both horizontal and vertical surfaces.

If it is impossible to eliminate the leak in one go, work is carried out in several stages from top to bottom.

Ready-made waterproofing seals

Dry waterproofing materials are supplied to the retail chain in paper bags or plastic buckets. Methods of using hydroseals depend on the chemical composition and manufacturer of the product.

The best indicators of the effectiveness of waterproofing seals.

Of the waterproof materials presented on the domestic market, the products of the following companies have the best performance indicators:

- Dry mixtures Peneplag and Waterplug (supplier "Penetron"). They are characterized by a short setting time (1.5-5 minutes), instant stoppage of leakage and good expansion ability. They are used in critical cases when other waterproofing materials are ineffective, and are washed off with water at the application stage.

- Mapei Lamposilex is a fast-setting and hardening hydroseal. Designed to eliminate leaks, fistulas in wells and other drinking water reservoirs.

- Bostik Bosco Cem Plug is a fast-hardening composition that has proven itself in underwater work and in conditions of continuous moisture filtration. It has high frost resistance and durability.

- Ceresit CX 1 is a product from a popular manufacturer of waterproofing materials. The CX 1 hydraulic seal is used to stop water leaks in enclosing structures and to seal large diameter holes in underground structures.

Composition and principle of action

The general name “hydraulic seal” refers to dry mixtures that have a similar composition and work on the same principle. Typically, such a mixture consists of the following main ingredients:

- Binder.

Most often, high-quality Portland cement is used as a binder, but there are mixtures in which polymer compositions play the role of a binder. - Filler.

This component is fine particles of quartz or quartz sand, which, after complete polymerization of the mixture, provide high mechanical strength of the filling. - Additives

These can be various catalysts, hardeners and other additives that provide a high degree of adhesion of the composition and a high polymerization rate.

The principle of operation of the hydraulic seal is quite simple. Thanks to the components included in the mixture, it hardens very quickly, which leads to the formation of a strong plug that can withstand even significant pressure. The leak stops and there is time to carry out major waterproofing measures. Let us note once again that the hydraulic seal is a temporary measure and major repairs of the damaged area should not be postponed for a long time.

Using a hydraulic seal of the “Puder Ex” brand

If you need a hydraulic seal for a well, then you can choose the “Powder Ex” product, which is a fast-acting mixture, and after application it sets within 7 seconds. The material is effective against leaks, filtered moisture and pressurized water. A seal can be applied for instant insulation, and you will have to pay RUB 2,500 for a 15-kilogram bucket. If we compare with other materials, the mixture described above is not too expensive, but of high quality. According to the manufacturer: using this hydraulic seal you can seal a leak under a pressure of 7 atm.