Other types of pressure gauges

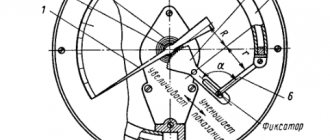

In practice, spring pressure gauges, rather than liquid ones, are used to measure high pressures. They are based on the deformation of a solid body, in this case a spring. Under the influence of pressure, the spring is compressed and, through mechanisms, rotates the arrow of the device. Sometimes, instead of a spring, a metal pipe bent into an arc with a sealed end is used. When pressure is applied to it, it unbends and, through mechanisms, moves the pressure gauge needle.

There are compression pressure gauges. They work on the laws of thermodynamics, in particular on the Boyle-Mariotte law. Such pressure gauges can measure very low pressures.

Liquid pressure gauges

Liquid pressure gauges

designed for measuring pressures, rarefaction and pressure differences of non-aggressive gases.

4.1.

Two-pipe pressure gauge 4.2. Single-pipe pressure gauge In liquid double-pipe pressure gauge

two vertical communicating glass tubes 1 and 2 are fixed to a base 3, to which a scale 4 is attached.

The tubes are filled with working fluid to the zero mark.

The measured pressure is supplied to tube 1, tube 2 communicates with the atmosphere.

The measured pressures are supplied to both tubes when measuring the pressure difference.

To increase the accuracy of reading the level difference, single-pipe (cup) pressure gauges

.

In these devices, one tube is replaced by a wide vessel into which the measured pressure is supplied.

The tube attached to the scale is measuring and communicates with the atmosphere; when measuring the pressure difference, the lower pressure is supplied to it.

A type of single-pipe pressure gauges are micromanometers used to measure pressures and pressure differences up to 3 kPa.

Differential pressure gauge DT-50

(Table 4.1) is intended for measuring the flow of non-aggressive liquids, vapors and gases by determining the pressure drop across the measuring diaphragm or other throttle body; it can also be used as a pressure gauge and vacuum gauge.

For pressure and vacuum gauges MB

static pressure should not exceed the upper limit of measurement.

For differential pressure gauges DT-5

and

differential pressure gauges DT-50,

glass tubes are placed in protective metal frames.

Thrust pressure meter TJ

(Table 4.2) depending on the modification, consists of 1-, 2-, 3-, 4- or 6-cup single-pipe pressure gauges assembled in one housing.

At the pressure gauge TNZH-N

For greater accuracy of readings, the glass tube is installed obliquely.

The design of the multi-limit micromanometer MMN-240

It is possible to install the measuring tube obliquely to the horizon in one of five fixed positions, which correspond to five measurement ranges. This device is portable and is used for periodic accurate measurements.

Pressure and vacuum gauges, differential pressure gauges, thrust and pressure gauges, micromanometers given in Table 4.1 are designed to operate at ambient temperatures of 10–35 °C and relative humidity up to 80%.

Execution: ordinary, export, tropical.

Table 4.1. Technical characteristics of liquid devices

| Device | Type | Design | Static pressure, MPa | Upper limits of measurement, kPa | Aggregate | Indication error | Overall dimensions, mm | Weight, kg |

| Pressure and vacuum gauge | M.B. | Double pipe | — | 1 | Distilled water | ±0.02 kPa | 265×90×25 | 0,15 |

| M.B. | 2,5 | 425×90×25 | 0,3 | |||||

| M.B. | 6 | 795×90×25 | 0,6 | |||||

| Differential pressure gauge | DT-50 | 5 | 93,3 | Mercury | ±0.226 kPa | 1130×290×165 | 11,5 | |

| DT-5 | 0,5 | 2,5 | Distilled water | 635×290×165 | 8,3 | |||

| Thrust gauge | TJ | Monotube | 0,05 | See table 4.2 | Distilled water | ±1,5% | See table 4.2 | |

| TNZh-N | 0,02 | 0,25; 0,4; 0,63; 1; 1,6 | Alcohol with a density of 0.85 g/cm³ | 458×117×46 | 1,84 | |||

| Micromanometer | MMN-240 | 0,01 | 0,6; 0,9; 1,2; 1,8; 2,4 | Alcohol with a density of 0.8095 g/cm³ | ±1 % | 432×207×200 | 2,69 | |

Table 4.2. Technical characteristics of TJ thrust gauges

| Device | Modification | Number of tubes (measuring points) | Measurement limits, kPa | Overall dimensions, mm | Weight, kg |

| Thrust gauge | TJ-1X 160 | 1 | 1,6 | 372 × 138 × 92 | 1,5 |

| Thrust gauge | TJ-1X 250 | 2,5 | 450 × 138 × 92 | 1,9 | |

| Thrust gauge | TJ-1X 400 | 4,0 | 582 × 138 × 92 | 2,7 | |

| Thrust gauge | TJ-1X 630 | 6,3 | 783 × 138 × 92 | 3,6 | |

| Thrust gauge | TJ-2X 160 | 2 | 1,6 | 372 × 162 × 92 | 1,8 |

| Thrust gauge | TJ-2X 250 | 2,5 | 450 × 162 × 92 | 2,5 | |

| Thrust gauge | TJ-2X 400 | 4,0 | 582 × 162 × 92 | 3,7 | |

| Thrust gauge | TJ-2X 630 | 6,3 | 783 × 162 × 92 | 4,0 | |

| Thrust gauge | TJ-3X 160 | 3 | 1,6 | 372 × 202 × 92 | 2,3 |

| Thrust gauge | TJ-3X 250 | 2,5 | 450 × 202 × 92 | 2,8 | |

| Thrust gauge | TJ-3X 400 | 4,0 | 582 × 202 × 92 | 3,7 | |

| Thrust gauge | TJ-3X 630 | 6,3 | 783 × 202 × 92 | 4,2 | |

| Thrust gauge | TJ-4X 160 | 4 | 1,6 | 372 × 242 × 92 | 2,9 |

| Thrust gauge | TJ-4X 250 | 2,5 | 450 × 242 × 92 | 3,4 | |

| Thrust gauge | TJ-4X 400 | 4,0 | 582 × 242 × 92 | 4,5 | |

| Thrust gauge | TJ-4X 630 | 6,3 | 783 × 242 × 92 | 6,2 | |

| Thrust gauge | TJ-5X 160 | 5 | 1,6 | 372 × 322 × 92 | 3,5 |

| Thrust gauge | TJ-5X 250 | 2,5 | 450 × 322 × 92 | 4,4 | |

| Thrust gauge | TJ-5X 400 | 4,0 | 582 × 322 × 92 | 6,0 | |

| Thrust gauge | TJ-5X 630 | 6,3 | 783 × 322 × 92 | 8,3 |

| p·o·r Instruments for measuring and monitoring pressure and pressure difference | |

| Liquid pressure gauges | Liquid pressure gauges |

| Pressure gauges, draft gauges and pressure gauges | Pressure gauges, draft gauges and pressure gauges |

| Pressure gauges without output signals | Pressure gauges, pressure and vacuum gauges and indicating vacuum gauges | Pressure gauges, pressure-vacuum gauges and vacuum gauges |

| Pressure gauges with output signal | with an electrical discrete signal | with pneumatic control device |

| Diaphragm pressure gauges, vacuum gauges and pressure-vacuum gauges | pressure gauges MMP-160-Ks, pressure and vacuum gauges MVMP-160-Ks and vacuum gauges VMP-160-Ks | Pressure indicator ID-1 |

| Pressure transmitters | with electrical output signal | with pneumatic output signal |

| Measuring transducers of the “Sapphire” and “Sapphire-22-Ex” types | Measuring transducers of the “Sapphire” and “Sapphire-22-Ex” types |

| Bellows differential pressure gauges | Bellows differential pressure gauges |

| Bell differential pressure gauges | Bell differential pressure gauges |

| Differential pressure transmitters | with electrical output signal | with pneumatic output signal |

| Membrane separators | type RM |

| p·o·r Instrumentation and automation | |

| Temperature | Technical glass liquid thermometers | Manometric thermometers | Thermoelectric converters | Resistance thermal converters | Measuring (normalizing) converters | Pyrometers | Auxiliary equipment |

| Pressure | Liquid Pressure Gauges | Pressure gauges, draft gauges and pressure gauges | Tubular spring pressure gauges without output signals | Tubular spring pressure gauges with output signal | Diaphragm pressure gauges, vacuum gauges and pressure-vacuum gauges | Pressure transducers | Measuring transducers of the “Sapphire” and “Sapphire-22-Ex” types | Bellows differential pressure gauges | Bell differential pressure gauges | Differential Pressure Transmitters | Membrane separators |

| Consumption | Variable Differential Pressure Flowmeters | Variable Level Flow Meters | Flowmeters | Tachometers and liquid meters | Tachometer flowmeters and gas meters | Electromagnetic flow meters | Ultrasonic Flow Meters | Vortex flowmeters | Heat meters |

| Level | Float level gauges | Displacer level gauges | Acoustic level gauges | Ultrasonic level gauges | Radioisotope level gauges | Capacitive level gauges | Differential pressure level gauges |

| Composition and properties of gases | Gas Composition Measurement | Ambient air analysis | Assistive devices | Hygrometers |

| Composition and properties of liquids | Potentiometric ionomer | Conductometric analyzers | Dielcometric converter | Residual chlorine analyzers | Infrared Liquid Analyzers | Refractometric analyzers | Acoustic analyzers | Nephelometric analyzers-turbidimeters | Analyzers for metal content in solutions | Density meters | Viscometers |

Test on the topic

- Question 1 of 5

The operation of a liquid pressure gauge is based on:

Start test (new tab)

Hall of Fame

To get here, take the test.

-

- Alexander Kotkov

5/5

- Nikita Chervonenko

5/5

- Nikita Karev

5/5

- Alexander Kotkov

5/5

Measuring pressure with a pressure gauge

Headings: Experiments , Crafts , physics , Experiments | Tags: Measuring pressure with a pressure gauge, Experiments, Crafts, physics, experiment | June 20, 2013 | Svetlana

To measure the pressure of air or gas inside a vessel with a pressure gauge, you need to attach its rubber tube to this vessel. Monitor the fluid level in both elbows of the pressure gauge. a) If the liquid is at the same level in both elbows of the pressure gauge, consider the gas pressure inside the vessel to be the same as the ambient air pressure. b) If the liquid level in the short leg of the pressure gauge is lower than in the other, consider the pressure inside the vessel to be greater than the ambient air pressure.

c) If in the short elbow of the pressure gauge the liquid is higher than in the other elbow, assume that the pressure inside the vessel is less than the pressure of the surrounding air.

If there is a difference in liquid levels in the pressure gauge tubes, the difference between atmospheric pressure and pressure in the vessel is calculated using the formula:

You can perform the following experiments using your pressure gauge. Place the end of the rubber tube of the pressure gauge firmly on the glass funnel and tighten its wide opening with rubber film. When the liquid in the pressure gauge has calmed down, lower the funnel into a bucket of water. Monitor how the pressure inside the water changes with the depth of the funnel. Having installed the funnel at a certain depth in the water, turn its hole in different directions, up and down, watching the pressure gauge reading. 2. Open the pipe near the stove that was heated shortly before the experiment. Insert the rubber tube of the pressure gauge into the oven. The water level in the short leg of the pressure gauge rises. Calculate the pressure of warm air in the furnace (during draft). 3. Inflate the rubber bag of the medical heating pad slightly with air and connect it tightly to the rubber tube of the pressure gauge. Lay the bag horizontally and place thick books (weight) on it one after another. The pressure gauge will clearly show the change in air pressure enclosed in the bag. 4. If you get a glass tube with a total length of about 1.7 m, you can make a pressure gauge to measure much greater excess pressure, for example, the highest air pressure when blowing with your mouth. In this way, the “power of the lungs” is controlled. You should not blow in jerks, but gradually increase the pressure.

5. The same device can measure the greatest vacuum created during suction by mouth. In this case, you need to draw air from the upper end of the tube with your mouth. 6. If in the device of the 4th experiment, instead of the short elbow of the tube, you insert a tube drawn to the narrowing, then when you blow into the long elbow, a fountain will flow from the short tube.

E.N. Sokolov “To the Young Physicist”

Range of pressure gauges

Models of meters for determining pressure are universal and specialized. Devices designed for operation in special conditions have a modified housing. In our online store vsemanometri.ru you can buy pressure gauges:

- general technical (universal);

- special;

- exemplary (for checking performance characteristics during operation);

- self-writing;

- vibration-resistant;

- railway;

- ship's

This equipment is designed to monitor the state of liquid or gas in systems where strictly defined boundary indicators are technologically provided. They help prevent tanks or pipelines from bursting due to too much or too little pressure. For operation in aggressive environments, the body and working elements of the device are made of resistant materials.

Barometers. Pressure gauges

Barometers are instruments used to measure atmospheric pressure. A mercury barometer (Fig. 1) consists of a U-shaped glass tube filled with mercury, one end of which is sealed, and at the other there is an open reservoir of mercury. The barometer has a scale with millimeter divisions, which directly measures atmospheric pressure in millimeters of mercury. It is numerically equal to the height of the mercury column between its levels in the closed and open arms of the barometer.

Rice. 1

The advantage of such barometers is their high accuracy of readings. Disadvantages: they are bulky, fragile, and mercury vapor is harmful to human health.

A metal barometer - aneroid (Fig. 2) consists of a cylindrical chamber K, from which air has been evacuated. The chamber is hermetically sealed with a thin corrugated membrane cover M.

Rice. 2

To prevent atmospheric pressure from flattening the membrane, it is connected by means of a rod T to a spring P fixed to the body of the device. An arrow C is attached to the spring, the end of which moves along the scale W. When atmospheric pressure changes, the membrane bends inward or outward and moves the arrow along the scale.

The advantages of aneroids are that they are easy to use, durable, and small in size. The main disadvantage is that they are less accurate than mercury barometers.

Pressure gauges are used to measure pressure greater or less than atmospheric pressure. Pressure gauges are available in liquid and metal types.

A liquid pressure gauge is made in the form of a U-shaped tube with liquid (usually water or mercury), one elbow of which is connected to the vessel in which the pressure is to be measured (Fig. 3, a). The fluid level in this elbow will decrease (if the pressure in the vessel is greater than atmospheric) or increase (if it is less than atmospheric) compared to the liquid level in the second elbow. The measured pressure will be p = pa ± pgh, where pa is atmospheric pressure, pgh is the hydrostatic pressure of the excess liquid column in the pressure gauge elbow.

Rice. 3

To measure the pressure inside the liquid with such a manometer, a flat box is attached to one of its elbows using a rubber tube, one side of which is covered with a rubber film (Fig. 3, b).

The simplest metal pressure gauge is designed as follows (Fig. 3, c). A thin elastic plate M - a membrane - hermetically closes the box K, from which the air has been partially evacuated. A pointer P is attached to the membrane, rotating about the O axis. When the device is immersed in a liquid, the membrane bends under the influence of pressure forces, and its deflection is transferred to the pointer moving along the scale.