Operating principle

The pencil consists of a compressed mixture of aluminum and iron oxide. When such a material ignites, a large amount of heat is released (exothermic reaction). From a chemical point of view, there is a reduction reaction of Fe from the oxide with the participation of Al. When molecular bonds in the oxide are broken, a release of thermal energy is generated.

The temperature of the reagents rises to such an extent that the reduced iron immediately passes into the liquid phase state, or simply melts. This molten metal penetrates and fills holes, crevices and cracks in the parts being joined or repaired.

Oxygen atoms released from the oxide molecules react with aluminum to form aluminum oxide. It plays the role of a flux, preventing re-oxidation of the melt and areas of the product heated to the plasticity temperature.

The welding pencil contains all the necessary components for welding:

- filler metal to form the weld material;

- flux that protects the weld pool from oxygen and nitrogen in the air;

- source of thermal energy for melting metal.

The chemical composition of pencils may vary. Instead of aluminum, magnesium can be used as a reducing agent. The reducing metal is selected depending on what alloys the specific pencil model is intended for welding.

In pencils intended for welding work on thick parts, a metal rod is inserted in the middle - its metal will be used to form the suture material.

Varieties

Manufacturers throw many brands and models of welding sticks into the market. Not all of them are made with sufficient quality; for some, even the chemical composition remains unclear.

Extrapike

It is better not to experiment and stick to products from manufacturers that have proven themselves over many years:

- Thermal pencil for Extrapike welding. Suitable for repairing and welding deep cracks and through holes in steel, aluminum, alloys, and enameled products. Carries out tinning of surfaces, restoration of the enamel layer. The shelf life is practically unlimited, the consumption during operation is quite high.

- Universal pencil Nanopayk. Manufactured using magnesium as a reducing agent. Can work with any metals and alloys. Noticeably more expensive.

- Extreme. With its help, you can repair metal parts, both with and without enamel coating. Affordable. The manufacturer claims that the strength of the weld reaches 70% of that of a weld made by electric welding.

Welding pencil Extreme

There are other brands of pencils on the market that are similar in quality and capabilities.

Comparison of the main characteristics of welding pencils from different manufacturers

Float switch for a pump: principle of operation, advantages

There are welding pencils with completely different characteristics. Each individual manufacturer brings something special to the product:

Oxal. These products boast high efficiency in the absence of any sources of electricity. To get started, all you need is a lighter or any other open flame. Repairs to restore the functionality of materials can be carried out regardless of the ambient temperature.

Nanopike. The welding pencil of this production is famous for its relatively low cost. It is even suitable for repairing heat-resistant plastic and enamel cookware. One rod can be used many times, since the material consumption is very economical.

Welding pencil Extreme. This version of the pencil is also used to restore metals and enamel. Pencil welding "Extremal" in quality gives more than half the strength of conventional contact welding.

Thanks to this universal tool, you can carry out emergency repairs even when you do not have the most necessary materials at hand. With its help, you can not only solder the resulting crack, but also cut the material. You just need to select the required brand of product with the required properties. Thermal pencil is capable of repairing the following surfaces:

- steel;

- cast iron;

- iron;

- brass;

- copper;

- ceramics;

- slate;

- heat-resistant plastic;

- bronze;

- stainless steel and other similar materials.

Technology of use

The process of using a welding pencil is quite simple and can be done by any home craftsman. The sequence of operations is as follows:

- Prepare the surface thoroughly by cleaning it with a wire brush or abrasive paper to remove rust, old paint residue and other contaminants.

- Degrease with gasoline, white spirit or other solvent.

- Remove the packaging from the pencil. Move the metal cover to the other end of the rod - we will hold it by it.

- Don’t forget to wear welder’s goggles (or mask) and thick canvas (split) gloves.

- Use a match or lighter to heat and set the end of the rod on fire.

- Bring the burning end to the starting point of the weld and press it to the surface of the part. Guide the rod along the seam line, holding in one place for at least 3 seconds, so that the welded edges have time to warm up to the melting temperature.

- Welding is carried out without hesitation, if with the right hand, then from right to left. If the welding speed is too high, the welding gap will fill with slag, but not enough melt will get into it to make a reliable connection.

At the end of the welding work, the stub of the rod must be placed on concrete, the ground (without dry grass) and thrown into a bucket of water.

Welding pencil technology

In order to carry out welding or soldering work using a welding pencil, you must follow the instructions, which do not require special professional skills and are extremely simple:

- the control tape on the packaging wrapper breaks; when the tape is torn off, the extreme edge of the pencil is exposed;

- remove the metal cover and place it on the back end of the pencil as a handle when lighting it;

- you need to bring a pencil to the cutting site and light the fuse wick; you can use a lighter to ignite;

- The already burning welder's pencil must be pressed tightly to the place where welding or cutting of the metal surface should begin. It is necessary to wait 3-4 seconds for the metal to warm up, and then, moving the pencil, cut or weld;

- After this, the pencil can be thrown onto a layer of non-flammable material (concrete) or into water. The pencil will burn to the metal handle-cover.

It is also necessary to remember that a pencil for welding metal at a high combustion temperature can burn the surface that needed to be welded.

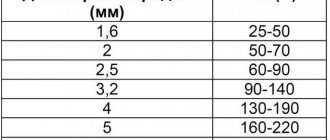

For each surface there are pencils of various diameters with additives that slightly reduce the burning temperature and prevent burning.

The welding stick contains metal oxides, which when burned create a layer of slag over the weld (only in large diameter sticks that are used for welding).

This innovation is used to then protect the melt layer from the surrounding air from the atmosphere.

This is due to the fact that pencil welding can be performed on surfaces where the quality of the seam and its strength are important

The entry of air is unacceptable, as this can destructively change the structure of the metal in the melt.

Advantages and disadvantages of using thermite pencil

The main advantages of a metal welding pencil include:

- Ability to work in the most cramped, hard-to-reach places.

- Energy independence - no sources of electricity or gas are required.

- Small size - fits into a workwear pocket.

- The work does not require long training or special skills.

- Can work both in a workshop and in the field.

- The heat resistance of the seam is up to 180 °C, which makes the device indispensable when repairing household utensils and dishes.

- Cheapness.

Using a Welding Pencil

In addition to the advantages, like any actually used welding method, there are also disadvantages:

- The quality of the seam is lower than with electric or gas welding.

- Not suitable for large volumes of work.

- High material consumption.

The combination of advantages and disadvantages makes the method ideal for minor operational repairs.

What metals can it work with?

Due to their versatility, welding pencils can be used for welding materials such as:

- structural steel alloys;

- galvanized sheet metal;

- cast iron;

- aluminum alloys;

- copper alloys: bronze, brass, etc. ;

- stainless and high-alloy alloys;

- heat-resistant plastics.

Minor repairs with a thermal pencil

Industrial pencils of a special composition are also used for welding other metals, as well as for welding work under water, in a vacuum and other extreme conditions.

Preparing for work

Careful preparation of the workplace and parts to be welded will be the key to high quality and safe welding work.

The workplace must be cleared of flammable materials, fuels and lubricants and other flammable liquids. The parts to be welded must be mechanically cleaned of dirt and degreased.

The parts to be welded must be pressed against each other and securely fixed in a vice, clamps, or other inventory fastening devices.

DIY making

Pencils are freely sold in general construction and specialized welding stores. In addition, they can be made independently.

To begin with, you will need carbon steel alloy wire. The electrode rod is excellent for manual electric welding. The flux coating needs to be removed from it.

Electrodes for manual welding

The composition for its own coating contains:

- one part of aluminum sawdust;

- three parts iron oxide;

- The binder is moment glue or other strong glue.

The preparation of the composition is carried out in a strong and stable container made of glass or clay. The electrode rod (or pieces of wire cut into 15 cm pieces) is dipped into the mixture and layers of the composition are wound onto it by rotating around the axis of the rod.

One end is left clean - it will act as a handle. The other will have the lighter mixture applied to it. It is prepared in a separate container in the following proportion:

- 1 part bertholet salt;

- 2 parts aluminum crushed to sawdust.

After thorough mixing and adding the same glue until a thick viscous mass is formed, small balls are rolled out of it, which are placed on the end of the pencil intended for ignition. Drying time - up to half an hour (or as indicated in the instructions for the glue).

Our welding pencil is ready, we can begin testing and welding training.

Composition and characteristics

A thermal pencil is a cylinder-shaped rod with a diameter of 12–16 mm and a length of 20–25 cm. When it is heated, the mixture under the shell burns and releases an amount of heat sufficient to form a welding seam in any conditions. During the combustion process, a lot of oxygen is also released, which effectively maintains the flame even under water. You can set a pencil on fire with an open flame of three or four simultaneously burning matches or a simple lighter.

The design of a thermal pencil includes a carbon steel core and thermite, which is a flammable composition applied to the core. Thermite itself consists of crushed iron scale and aluminum powder. Nitrocellulose glue is used to give these components a solid form. At the tip of the pencil there is a seed made from aluminum filings and berthollet salt - with its help the product is set on fire.

Don't miss: Welding stainless steel with ferrous metal: technologies

Specifications for thermite pencils may vary depending on the manufacturer. In general, these products have the following characteristics:

- burning time - up to 20–30 seconds;

- combustion temperature - 2300–2900 °C;

- thickness of welded parts - 0.3–6 mm;

- seam length - 8–15 cm, depending on the type and thickness of the material being welded.

Peculiarities

A welding pencil, as already mentioned, is an inferior analogue of welding. It lives up to its name and is an elongated cylindrical stick, 7 to 20 cm long, with one pointed tip. Average weight is about 80 grams (can vary from 70 to 100 g). The diameter of the rod can be from 4 to 16 mm. The outside of the pencil is covered with a protective waterproof shell, and the inside is filled with a special pressed powder mixture.

When burned, this mixture can reach a temperature of 2900 degrees, and, as a result, melts metals well. Therefore, another name for this “gadget” is a thermal pencil. It is also called thermal solder.

Thermal pencil includes a number of components.

- An incendiary mixture, which is located under the “lid” of the pointed tip.

- A cardboard sleeve that is obviously part of the outer shell of a pencil.

- Already the above-mentioned incendiary mixture, but which is located inside the cartridge case.

- The part of the cartridge case that contains nothing. It functions as a handle. Simply put, the cavity of the sleeve is divided into two parts - full and empty.

- On top of the sleeve is an instruction shell.

- On top of the latter there is a moisture-proof coating.

The creator of this thing is the scientist and professor Lebedev.

This item has many advantages that make it a good seller.

- Compactness. The thermal pencil is lightweight and easy to carry.

- Easy to use. It's enough to set it on fire. Does not require special operating conditions.

- Doesn't require a lot of expenses. To use it, you do not need to connect electricity, it does not require refueling.

- Possesses stable combustion.

- Able to reach hard to reach places. Can be used to form inclined, vertical and horizontal seams.

- Suitable for use on a variety of materials.

Such a pencil can burn for about 30 seconds. The price of such products can vary from 50 to 200 rubles.

Areas of application

The scope of application of welding pencils is the widest. They allow you to weld ferrous and non-ferrous metals in any position and in almost any circumstances, from workshop conditions to field and extreme conditions. The product is widely used in the following areas:

- Installation and emergency work in hard-to-reach places and in emergency situations.

- Prompt repair of vehicles (automobile, water, railway) in places where they break down.

- Repair of rail tracks, switches and crossings.

- Soldering copper wires and other electrical components.

- Repair of cracks in heating system components.

- Elimination of leaks in main and distribution pipelines.

- Repair of cast iron and bronze castings for industrial and decorative purposes.

- Repair of construction and agricultural equipment at remote sites.

Soldering pencil instantly

Welding pencils are especially widely used in rail repairs. Their use makes it possible to carry out routine repairs extremely quickly, inexpensively and with minimal delays in train movement.

It is important to remember that the pencil is intended for quick, temporary repairs at a great distance from repair facilities or in emergency circumstances. For continuous operation, high-quality repairs should be carried out using electric or gas welding.

Product reviews

Naturally, before you buy the specified product, you want to know the opinions of other users about it. If you want to use a welding pencil, reviews will help you decide on the manufacturer and consider the properties of the product.

However, the opinions of other users regarding this issue are contradictory: both negative and positive. For example, it is noted that the product emits a fairly strong fire, and that after its use a very unpleasant odor remains. However, a welding pencil should not smell like toilet water. Many people find the product useful enough to keep in their repair backpack. The excellent cutting properties of this product are noted.

However, almost all users note that it is not worth using it everywhere and always. It is best used for partial or temporary repairs. Next, the damaged area must be thoroughly repaired. It is best to use a pencil in truly extreme situations, when there is simply no other way to achieve the desired result. That's all the features of the product. Good luck!

Rules for safe use

Despite the extreme simplicity of their design and use, welding pencils pose a real threat to health, human life and the safety of material assets. To avoid tragic consequences, safety precautions should be strictly observed:

- Carefully prepare the workplace, remove all combustible and flammable substances and materials.

- Securely secure the workpiece or the product being repaired in a vice, clamps, clamp, etc. Cooking by weight is strictly unacceptable.

- Use only non-combustible materials for seam pads and welding shelves.

- It is mandatory to use personal protective equipment: goggles or a welder’s mask, canvas mittens or split-leaf gloves - leggings, thick clothing and durable shoes that do not leave exposed skin.

- When igniting and welding, you should hold the pencil firmly. Move it along the seam line smoothly, without jerking. It is unacceptable to walk around the workshop with a burning pencil.

- When welding on vertical and inclined surfaces, as well as when cutting metal, carefully ensure that the molten metal does not flow towards you or splash around.

- At the end of welding, the cinder should be thrown into a previously prepared bucket of water or sand. As a last resort - on a concrete or earthen floor. Do not leave the workplace without making sure that the cinder has burned completely.

Proper use of an inexpensive and easy-to-use cooking agent will make working with it convenient and safe.

Invention of the pencil

Ultimately, these technologies led to the birth of the idea of a compact welding tool in the shape of a pencil rod.

However, when bringing the idea to life, the “pioneers” faced failure. The fact is that when the mixture cools quickly in the weld pool after the pencil stops burning, the slag and metal mix and the material becomes brittle.

As a result, mixtures based on aluminum thermite did not give a positive result both in the professional environment and in the literature, the “pencil” model was recognized as “not feasible” and for a long time no one dealt with this issue until a professor, Doctor of Technical Sciences appeared, Academician Lebedev Vladimir Georgievich.

Having accidentally become acquainted with the idea, he first calculated a mathematical model, and then implemented a chemical one, based on copper thermite, in which the metal-slag pair is separated in the process of forming a solder-alloy.

Open publications by V.G. Lebedev in Russian publications became the basis for the creation of several welding tools present on the Russian market.

Welding pencils Shkval and Oksal are produced in St. Petersburg and are used for welding, soldering and cutting without the use of any special gas welding or electric welding equipment.

Autonomous mobile welding – pencil SK-1, Moscow