Local wastewater treatment plants (WTP)

designed for country houses without the possibility of connecting to city sewer networks. The drainage enters an autonomous sewer system, is cleaned, and discharged into a filter well or ditch.

Local treatment plants are urban sewerage systems in miniature. In it, wastewater goes through the same stages of purification and is subsequently discharged to filtration fields or to the terrain (depending on the type of treatment plant).

In this article we will consider the following questions:

- Types of local treatment facilities. Septic tanks and biological treatment stations.

- How to install VOC. Why it is not recommended to install sewage treatment plants yourself.

- Maintenance of local sewerage.

- The price of an autonomous sewerage system in a private house.

- Where to buy VOCs with maximum benefit.

The principle of operation of the sewer structure

The sewage system may include a variety of devices. But, despite this, waste treatment is carried out according to a certain algorithm.

First stage

At the first stage, wastewater is purified mechanically. The retention of large contaminants, which are of mineral and organic origin, is carried out by gratings and sieve. Sand traps are used to filter smaller particles - broken glass, sand and slag. The membrane device performs more thorough cleaning. Suspended solids are separated in the settling tank. This removes mineral contaminants.

Second phase

At the next stage, biological agents are used for cleaning. Organic compounds decompose under the influence of particularly active bacteria. The liquid is passed through a biofilter. As a result, sludge and gaseous compounds are formed.

Third stage

At the final stage of wastewater disinfection, additional chemical compounds are used. The resulting liquid can already be used for technical purposes.

The principle of chemical water purification

Types of sewerage treatment facilities

Scheme of wastewater treatment facilities

Cleaning devices are divided into urban and local. The first accept a mixture of household wastewater from city residents, production liquid waste from industrial facilities, as well as rain and melt water.

Local wastewater treatment plants are installed at industrial facilities to purify wastewater from major pollutants before being discharged into the central sewer system or recycled. Local autonomous purifiers are installed in household plots.

The design of sewage treatment plants is varied and depends on the type of wastewater and the degree of its contamination. The complex may consist of the following blocks:

- mechanical components;

- biorefinery installations;

- ion exchange devices;

- oxygen saturating devices;

- adsorption filters;

- equipment for electrochemical and physical-chemical cleaning;

- disinfection installations.

Purification equipment includes containers for accumulating, storing, and processing filtered sludge.

The operating principle of treatment facilities for centralized city sewerage:

- Wastewater treatment is carried out mechanically. Contaminants are retained thanks to special gratings and sand traps.

- The membrane device performs more thorough cleaning. In the settling tank, suspended matter is separated and mineral impurities are removed.

- Biological agents are used for further purification. Under the influence of active bacteria, organic compounds in the contaminated liquid decompose. The wastewater passes through a biological filter. As a result, sludge and gaseous compounds appear.

At the final stage of disinfection, additional chemical reagents are used. The resulting water can be used for technical purposes.

Storm drain

Designed to collect and transport surface water resulting from precipitation. The main task of storm drainage is to remove moisture from the base and walls of houses, green spaces, and road surfaces.

The storm sewer wastewater treatment system includes:

- drainage systems on the roof;

- funnels and gutters that direct and transport moisture to the storm drain;

- a system of pipe sections and trays that transfer water to a storage tank or a nearby ravine.

Sand traps with containers for collecting waste are installed at various parts of the transportation system. They act as a filter and require systematic cleaning.

Local facilities

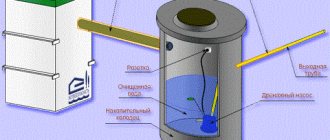

The design is varied: from a cesspool to a deep sewage treatment station. At home, they are most often used:

- Cesspools. These are the simplest VOCs and can be sealed or drainable. Allowed only for small houses and summer cottages.

- Septic tanks are sealed tanks into which sewage is discharged. Anaerobic microorganisms live there, processing sediment and helping to purify the water. Liquids from a septic tank require additional purification, for example, using a biofilter, before being discharged into a reservoir or soil.

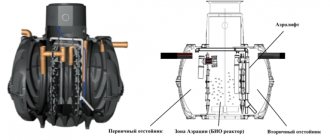

- Aero tanks. These are hermetically sealed installations with forced aeration. To process liquid more efficiently, activated sludge containing the necessary microorganisms is used.

For deep cleaning, sewage stations and bioreactors consisting of blocks and modules are installed. Installations of this type reduce the concentration of sludge in the water after treatment and protect the environment and human health. They bring the purity of waste liquid to 98 percent, which implies its secondary use. The structures are installed in factories or in areas near residential complexes and large cottages.

Installation selection

When choosing a suitable purification system, consider:

- total daily water use;

- type and principle of operation of the sewer installation;

- location of the object.

Some installations can operate in full autonomy mode. Others will require electricity or other types of energy to operate. There are devices the use of which is unacceptable when groundwater is close.

Types of sewer systems

Sewage treatment facilities are designed before the start of construction work. It is important to choose the right sewer design that can solve the waste disposal tasks and have a sufficient level of performance. Today, wastewater treatment can be done using the following devices:

- local cleaning devices;

- individual autonomous structures;

- block systems and modules.

Local cleaning systems

Local treatment facilities are structures that are used to clean and collect waste at facilities of various sizes. They can have household or industrial purposes and are the basis of an autonomous sewage system.

VOC device - local treatment facility

In classical treatment devices, the speed of movement of wastewater decreases with distance from the discharge site. There is a gradual settling of solid particles to the bottom. Removal of other impurities is carried out by post-treatment systems. Classic treatment facilities require sufficiently large containers in which waste is settled. Such a requirement is difficult to implement in individual buildings.

With the help of local treatment systems, wastewater is collected and treated in private homes or small villages where there is no central sewerage system. Let's look at the most common local constructions.

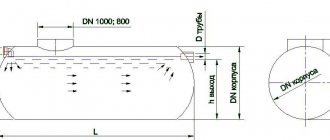

Use of septic tanks

Septic tanks are often used to install an autonomous sewer system in country houses. They usually take the form of plastic containers. Plastic has the necessary performance characteristics:

- it weighs little - the tanks are easy to transport and install;

- the material can withstand exposure to aggressive environments;

- does not rust;

- has sufficient strength.

Each tank contains a different number of sections that perform specific functions. Some act as a settling tank, while others purify wastewater using biologically active microorganisms. Still others are used for filtering.

Septic tanks are widely used in the construction of private treatment structures. They are convenient to use. They have a long service life. The sewer system can be completely autonomous. In order to increase the level of wastewater treatment, the structure is equipped with additional elements - fields that perform filtration and aeration.

The simplest and most effective septic tank

Aero tanks

These treatment devices are an integral part of large sewerage facilities that process wastewater from industrial enterprises. They look like huge tanks. Water and activated sludge are mixed in containers. Oxygen is used to speed up the reaction. Sometimes aeration tanks are used in the construction of autonomous sewage systems in a private house. In this case they have a small volume. They are usually installed in septic tanks. Aerotanks may include special catchers. They remove fat and petroleum products from wastewater.

Aero tanks for wastewater treatment

How does a septic tank work for a private home?

The job of any septic tank is to settle the liquid and gradually filter it. The last task can be performed either naturally or by force. The use of biofilters and bioenzyme preparations is allowed. To understand this, you can consider a conditional diagram broken down into stages.

Primary cleaning

From the house, through a sewer pipe, wastewater enters the system, which gradually fills the first section. Here, rough cleaning of suspended organic inclusions takes place. During this stage, heavy particles (sand, other insoluble debris) gradually settle to the bottom under the influence of gravity. Fats and oils, on the contrary, rise upward, then they flow into the next chamber.

Waste decomposition

Large organic fractions that have sunk to the bottom begin to ferment and gradually decompose. This stage lasts approximately 3 days. The result of the decay of sewage becomes new products - a thick mass, water and carbon dioxide.

To ensure effective wastewater treatment, it is necessary to correctly select the volume of the first tank. The capacity must be sufficient to ensure the preservation of sewage collected over three days. Otherwise, optimal cleaning conditions cannot be guaranteed. The whole process takes about 10 days.

At the bottom of the first compartment, silt gradually accumulates, which must be removed periodically (at least once a year). If we consider the question of how a septic tank works, determining the efficiency of each section, then in the first chamber it is not too large and is only 60%. Therefore, wastewater requires additional treatment.

Re-cleaning

The semi-purified liquid enters the second chamber, where the decomposition of sewage occurs again. Often this compartment is populated with microflora and special preparations, the task of which is to decompose organic and chemical waste (for example, dishwashing detergents, gels, shampoos, etc.). In this case, the cleaning efficiency is already higher: it ranges from 65 to 80%.

Liquid evacuation

In this case, everything depends on the characteristics of a particular system. For example, purified water can be collected in a container intended for watering a garden. If the cleaning quality is insufficient, additional measures are required. These include filtration fields, drainage wells that become third sections, or infiltration.

Storm sewer systems

In local treatment facilities, harmful impurities, inorganic and organic waste are removed from wastewater. The purified liquid is subsequently used to irrigate fields. But in order to collect, transport and purify melt and rainwater, storm sewer treatment facilities are also used. Conventional sewer structures cannot cope with this task.

Drainage and storm sewer system

Stormwater treatment facilities must ensure the safety of the foundation, pavement and lawns surrounding the main structure.

They include pipes, gutters and storm water inlets. Through them, excess water is transported to a common collector.

The system is placed below the soil freezing level. The design contains filters to retain sand and other small particles. Purified liquid must enter the collector.

More refined purification of waste rainwater is carried out using additional devices: a sorption unit and a filter for removing oil products. At the final stage, the purified water is discharged into reservoirs or used to water the garden. It should be taken into account that in this sewer system it is necessary to periodically replace the filtration elements.

Wastewater tertiary treatment

The mechanical and biological stages of purification remove 90% of pollutants, but do not rid the water of microorganisms, which is dangerous for the environment. Therefore, additional purification is necessary.

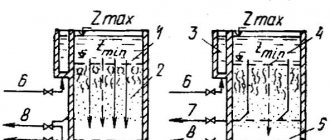

Bioreactors for deep purification

Bioreactors are used to oxidize inorganic substances and convert them into organic ones. Reactions occur on the surface of special disks. Autotrophic microorganisms need oxygen, so aeration of the liquid is activated.

Filters for wastewater treatment

Filtration occurs through sand. Wastewater is supplied from bottom to top. The filters themselves are located below other settings. The contents of the filters are automatically updated.

Ultraviolet water disinfection

Chlorination, ozonation, gamma irradiation, alternating current, ultrasound, and ultraviolet radiation are used to disinfect water.

Ultraviolet irradiation is an effective method that allows you to destroy all pathogens - bacteria, viruses, protozoa, fungi. Turbidity reduces the effectiveness of irradiation, so higher power is required. Gradually, contaminants settle on the UV lamp and it needs to be cleaned.

Types of chlorination: superchlorination, double chlorination, with preliminary ammoniation. Ultraviolet irradiation has an advantage over chlorination - it does not leave an odor, is not harmful to health, and does not pollute the environment.

Ultraviolet water disinfection.

Phosphate removal

Phosphates are found in laundry detergents and other detergents. They pollute the environment, causing water bodies to bloom. To remove phosphoric acid salts, sealants are used before the biological treatment stage and sand filters.

Application of block and modular designs

Block and modular sewerage structures carry out deep wastewater treatment. They are more often used in industrial and manufacturing areas. Using such devices, the following tasks are solved:

- a high level of wastewater treatment is ensured;

- the sludge content in the purified liquid decreases;

- the environment is protected from exposure to harmful substances;

- provides the opportunity to reuse water.

Such systems have increased productivity. They can be used to serve entire areas. Used in wide temperature ranges.

Stages of wastewater treatment

Wastewater from sewer pipes contains many pollutants - fecal matter, surfactants, paper, etc. Therefore, before releasing them into a reservoir, step-by-step cleaning is necessary, including mechanical and biological methods.

Mechanical

Domestic wastewater enters the pumping station and the reservoir. The water enters the mechanical cleaning shop to get rid of large waste - household waste: plastic bags, rags, paper.

There are several water treatment devices available to get rid of contaminants:

- Lattices, sieves. The width of the holes in them does not exceed 1.6 cm, which allows you to catch waste that gets into the sewer - plastic products, cans, bottles. Solid waste is transported for recycling. The gratings are made of metal rods.

- Sand traps. These devices catch smaller debris - sand particles, glass fragments, small stones, which are pumped out and washed.

- Grease traps are capable of filtering out grease, oils, gasoline and hydrocarbons.

- Septic tanks. There are vertical and horizontal settling tanks. They are used to free water from suspended particles and silt. Reagents are used to speed up reactions.

- Other cleaning elements - membranes, septic tanks.

Biological

With the help of special bacteria and algae, wastewater is purified from contaminants.

Aerobic and anaerobic bacteria feed on chemicals, converting them into compounds that are more environmentally friendly.

Biological treatment stages:

- Aerotank. In it, water undergoing purification is mixed with sludge containing microorganisms. If the bacteria are aerobic, then the water is enriched with oxygen for their respiration.

- Air purification workshop.

- Secondary settling tanks. They are necessary for cleaning sludge containing microorganisms. Surface and bottom scraper mechanisms are used to remove sludge from the top and bottom of the settling tank.

- Treatment of sludge sludge. During its fermentation, methane is produced, which can be used for industrial purposes. Sometimes fermentation occurs with the participation of oxygen; this requires a pre-aerator. The fermented sludge is dried using vacuum filters.

It is possible to carry out post-treatment of wastewater.

Modern biofilters containing special bacteria. They may consist of granite chips. Filters are periodically cleaned and their contents replaced.

First, after mechanical treatment, wastewater undergoes filtration and then enters secondary settling tanks. Sludge from the settling tanks is sent to an aeration tank, then it is compacted and dried.

Selection of sewer design

To choose the right cleaning system, you need to consider a number of factors:

- total daily fluid intake;

- preferred type of sewer structure;

- mode of use of the sewer structure;

- location of the object.

Some devices may work offline. Others require electricity or other forms of energy to function. Certain systems cannot be used when groundwater is close to each other.

When arranging a treatment system, you should be guided by existing sanitary standards. If it is necessary to use a sewer truck to remove waste, it is necessary to provide for the possibility of free access to the waste storage site.

Features of design work

When designing sewage treatment facilities, it is necessary to provide for the occurrence of various situations that may subsequently affect the operational characteristics of the system. It is also necessary to take into account the existing legislative framework.

Its basis is security functions to protect the natural environment. The cleaning system must be located in a sanitary protected area. During the design process, you should pay attention to the following indicators:

- dimensions and volume of the sewer structure;

- optimal type of device;

- location of groundwater;

- soil freezing level;

- system performance;

- cleaning method used;

- optimization of the installation of sewerage devices.

Scheme of treatment facilities

To avoid a conflict with sanitary permitting services later, before constructing a sewerage system, it is necessary to prepare a number of documents:

- agreement on ownership or lease of land;

- layout diagram of the location where the treatment structure is supposed to be placed;

- compliance with existing sanitary standards;

- technical conditions for the use of water resources;

- data on the volume of consumed and utilized water;

- general design of the project;

- description of the wastewater filtration and disposal system.

A permit from the sanitary and epidemiological station must be present. It should be remembered that if sanitary standards for locating an object are violated, the owner may be brought to administrative liability.

Design Features

Location of VOCs on the site

When creating a layout plan for treatment facilities, it is necessary to provide for the risks of operating the installation. Each type of treatment design has its own pros and cons. When selecting, you must proceed from the application parameters:

- the likely volume of wastewater that will enter the treatment tank daily;

- use of the structure - on a permanent or seasonal basis, or only on weekends;

- system performance;

- geological conditions of the site location;

- the level of subsoil sources and the freezing point of the soil.

If you plan to build a large house for a large family with several sanitary facilities, it is recommended to build an autonomous sewer system. If you are choosing an installation for a summer house or a small house, an ordinary septic tank will suffice.