A tool known as a counterbore is used to refinish holes in parts that need to fit together precisely. An operation such as counterbore is necessary to form bearing surfaces for various fasteners - bolts, washers, etc. - with a high level of quality and accuracy.

Valve seat counterbore

Scope of application

All types of counterbores, in fact, can be classified as a type of countersink. The latter cannot be used for drilling or deepening holes, although it is intended for processing them. The technological operation performed by counterbore is called counterbore. If, with the help of countersinking, the accuracy of the geometric parameters and the quality of the side surface of the hole are increased, then counterboring is used to form and level the end area around an already formed hole. The following technological operations are performed using counterbores:

- processing of various types of support planes in holes, which are necessary for placing fasteners such as washers, thrust rings, bolts, screws, etc.;

- cleaning the ends of embedded structural elements.

Countered end plate

A counterbore as a cutting tool can be used to work not only with cast iron and steel parts, but also with products made of non-ferrous metals. With the help of counterbores, two important tasks are simultaneously solved: improving the quality of the surface that is being processed, and achieving strict perpendicularity of its location to the axis of the already formed hole.

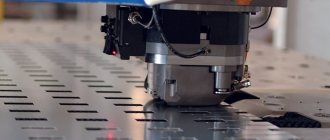

Due to its structural and technological similarity, a counterbore is often called an end countersink. Moreover, it can be installed on drilling, turning and other metal-cutting equipment.

Question answer

How to determine the optimal cutting speed?

The cutting speed is selected taking into account the tool diameter and rotation speed. It is necessary to introduce correction factors. The obtained data can be used to calculate the spindle speed.

How to determine the depth of cut with a counterbore?

This indicator is calculated as half the diameter of the cutting tool minus the diameter of the rough hole.

Is it possible to make custom-made counterbores?

Yes, we will produce tools according to your drawings in a period of 5 to 45 days.

A. The center has a lower smooth guide part that is inserted into the hole around which the processing is performed, which makes it possible to maintain the mutual perpendicularity of the resulting surface and the axis of the hole.

Great Soviet Encyclopedia. - M.: Soviet Encyclopedia. 1969-1978. Synonyms

:

See what “Tsevka” is in other dictionaries:

- Countersink for cleaning end surfaces. Typically, counterbores are made in the form of mounted heads with end teeth. Counters are used to process bosses for washers, thrust rings, and nuts. See also: Cutting tools Financial Dictionary... ... Financial Dictionary

Countersinking, countersinking, countersink Dictionary of Russian synonyms. countersink noun, number of synonyms: 4 countersink (2) countersink ... Dictionary of synonyms

counterbore

- NDP. face countersink face countersink trimming Axial multi-edge tool for processing the cylindrical and (or) end section of a workpiece hole. Inadmissible, not recommended trimming... ... Technical Translator's Guide

counterbore

- tsek ovka, and, genus. p.m. h. wok ... Russian spelling dictionary

Countering

— Countersink for cleaning end surfaces (for example, removing bosses). As a rule, it is made in the form of mounted heads with end teeth ... Builder's Dictionary

Countering, processing around the hole of a part to obtain a plane, conical. or cylindrical recesses for a screw head or nut, Dir. special tool countersink (counterbore) ... Big Encyclopedic Polytechnic Dictionary

Countersink, countersink, countersink Dictionary of Russian synonyms. countersink noun, number of synonyms: 2 tool (541) ... Dictionary of synonyms

A production tool for changing the shape and size of a processed metal workpiece by removing part of the material in the form of chips in order to obtain a finished part or semi-finished product. There are machine and manual M. and. Main parts... ...

Treatment of the surface of a part around a hole (a type of countersinking (See countersinking)), intended to form planes or recesses for a screw head, washer, thrust ring, etc. C. is produced on drilling machines, ... ... Great Soviet Encyclopedia

This article should be Wikified. Please format it according to the article formatting rules. Drilling is a type of mechanical processing of materials by cutting, in which using a special rotating cutting tool (drill ... Wikipedia

A counterbore or countersink is a type of metal-cutting tool designed for making cylindrical holes and chamfering holes. Can be used to work on steels, non-ferrous metals, hard alloys.

Types and design features

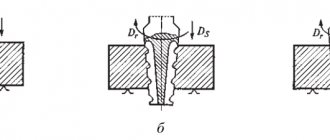

A counterbore is a cylindrical tool of an axial type, the cutting teeth of which are located on its end part. There are grooves on the side surface that serve to remove chips from the cutting area. A special trunnion, which is also located on the end part, is responsible for ensuring the perpendicularity of the plane being processed and the axis of the hole. Such a guide pin is fixed in the hole of the workpiece during processing. Like any other axial type tool (drills, etc.), this device is fixed in the machine using a special shank.

The working part of the counterbore with a permanent guide pin

The regulatory document defining the technology for the production of countersinks is GOST 26258-87. According to the requirements of this standard, counterboring tools are divided into the following categories:

- with a cylindrical shank and a guide pin, which forms a single whole with the counterbore;

- with a conical shank and a trunnion, which can be removed and replaced with another;

- attachment type in the form of a cylindrical cutting head, which is put on a special mandrel with a conical shank (the guide pin is also replaceable and fixed in the same mandrel);

- with a replaceable pin and shank, which is fixed in the pin lock of the equipment.

Types of counterbores (click to enlarge)

The working part of attachment-type counterbores, devices with conical-type shanks and secured in a pin lock, can be produced in two designs:

- entirely made of high-speed steel;

- with hard alloy tips.

GOST 26258-87 establishes that tools with a cylindrical shank are made only from high-speed steel. If we talk about the purpose of tools with a cutting part made of different materials, then those equipped with carbide inserts can be used to work with both cast iron and structural steels, and counterbores with a working surface made of high-speed steel are used exclusively for processing parts made of structural steels.

Reverse counterbore

The number of working blades for different types of counterbores is also different. Thus, the working part of tools with a cylindrical shank can be equipped with two or four blades, for all other categories - only four.

The type of shank the tool is equipped with determines how it is installed on the equipment.

- A counterbore with a cylindrical type shank is installed in the equipment chuck itself.

- To install a tool whose shank has a conical shape, a mounting hole made under a Morse taper is used.

- To install a counterbore fixed in a pin-type lock on the equipment, the machine must have such a lock.

Some of the varieties of bores

Application of scraper conveyors

The scope of application of the mechanism under consideration is very extensive. Often the mechanism is installed in the following cases:

- Transportation of rock. An example is the mining industry, in which it is necessary to transport material over long distances or carry out lifting.

- Acts as a support when moving the plow.

When considering the scope of application of a scraper, do not forget that it is limited. This is due to the fact that the scraper conveyor cannot be used to move fragile materials and parts. This is due to the significant impact that is exerted on the surface.

The difference between counterbore and other metalworking operations

Countering is a finishing operation that follows after countersinking and in most cases before reaming. The process removes minor flaws from the previous treatment. The specialist removes roughness from the surface of the hole and adds the correct geometry to it. When counterbore, cone-shaped and cylindrical recesses are cut out for the heads of the fastening elements and a flat surface emerges for good contact of the part with them.

The lateral surfaces of the cylindrical recesses for bolts must comply with the dimensions and quality requirements established in the drawings. The process of their processing is called reverse counterbore. It uses countersinks with a very decent number of cutting edges, sometimes their number reaches fourteen.

The parameters set on the machine during processing are calculated and determined according to existing industry standards and product drawings. This includes: feed, depth and cutting speed, productive and required power, as well as an indicator of rationality calculated for the selected operating mode.

GOST requirements

In Russia, the procedure for manufacturing counterbores is regulated by the state standard GOST 26258-87, as well as some auxiliary regulatory documents (GOST 1050-74, GOST 19265-73 and some others). In accordance with these documents, the following requirements must be taken into account:

Counters with a small diameter (up to 8 mm) have reduced strength, so they require additional operating rules. For such parts, the tail and the trunnion must be made as a single element (that is, the presence of moving parts is not allowed, and even more so, such parts cannot be made collapsible)

Please note that in the case of such parts, welding is also not allowed, since even the highest quality and precise welded connection does not allow obtaining a high-strength part, so a small welded bore will quickly break, which can lead to a decrease in the quality of processing. This will not benefit the holes, which can create an emergency situation. Counterbodies with a diameter of more than 8 millimeters have increased strength

Therefore, their tail and trunnion must be connected by welding. Special ultra-precision welding is used to connect individual elements to each other. The manufacture of counterbores with movable joints without welding is permitted, but it is associated with limitations. Therefore, in practice they are quite rare.

All parts, according to GOST, must have a uniform, smooth surface without cracks or irregularities. If defects are detected, the part is considered defective and withdrawn from circulation.