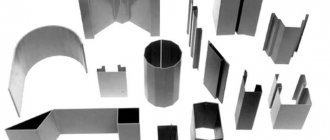

What metal bending services do we offer?

We work using the cold method. As a result, the client receives a solid, aesthetically attractive piece without a single seam.

- Sheet and galvanized metals.

- Aluminum and alloys.

- Stainless steel.

- Pipes.

- Chermet.

- Brass.

- Copper.

The profile of our company is metal bending of any complexity in Moscow.

Equipment used

Bending, straightening and straightening of metal is carried out on CNC bending machines, sheet bending machines, and lasers. We help not only large clients, but also take on small orders for designer decorative elements for apartments, country houses and cottages. Our high-precision equipment and experienced operators guarantee fast, high-quality, highly accurate products for your project.

CNC equipment is in demand in manufacturing and fitting:

- boxes;

- brackets;

- ebb and flow for window structures and building profiles with complex structures;

- racks and shelves;

- corners;

- cassettes for facades and cathedral elements;

- channels.

In addition to standard cutting, we provide the material for the manufacture of the necessary structures and are ready to deliver to an enterprise or private home.

Methods used

The methods that our specialists use when punching and bending metal in Moscow completely preserve its design, while significantly increasing its performance.

We use the following types of bending to order:

We are aware of the latest developments in the world of engineering and use advanced methods of steel processing, which allows us to significantly reduce work completion time with consistently high quality. For each type, we will offer processing options to obtain excellent results. Production is as automated as possible and is under the control of experienced master engineers. Work on modern machines with unique software is carried out in any plane, in several directions and along a variable radius.

Price

The exact price of the service depends on the volume and complexity of metal and stainless steel bending.

Sheet metal.

Sheet metal is a material that is made in the form of a thin sheet. This product is delivered in rolls. Depending on the application, sheet metal can be produced in a specific edge. It has found wide application in various fields of industry, from construction to delicate products.

Each type of sheet metal has a special manufacturing principle. As a rule, the rolling method is used for its production, using cold or hot temperatures. The size of the sheet metal can range from 04 to 4 millimeters. To manufacture such a metal product, low-level alloy steel is used. This type of steel has a high level of strength and is light in weight.

One of the most popular types is a steel product, which has stainless and galvanized characteristics.

Sheet metal is a product that allows you to solve problems associated with complex design problems. It allows the production of bolted and welded structures, chemical equipment, car bodies and ship hulls. The main advantages include a high level of corrosion resistance and a long service life. The companies employ specialists who will give the necessary recommendations on choice, depending on the preferences and wishes of the client.

Basically, sheet metal is used as a basis for the preparation of any parts. The main areas of application of sheet metal include: construction, shipbuilding and automotive industry, production of tableware, furniture, decorative elements and landscape design, electrical energy.

Sheet metal is divided into several main types:

1. Rolled metal, stainless steel.

2. Corrugated rolled metal.

3. Rolled metal produced by cold rolling.

4. Rolled metal produced by hot rolling.

5. Corrugated sheets and galvanized metal products.

Each type has its own classification and characteristics. The class of steel used divides the metal sheet into:

1. Steel, which has a standard level of quality.

2. Low alloy steel sheet.

3. Structural steel sheet.

The cost of the product is affected by the material from which it will be made. Depending on the client's preference, delivery is carried out in rolls or sheets.

Our company offers the widest selection of rolled metal. Environmental safety, resource and energy saving You can buy any metal from us today Safety, resource and energy saving You can buy any metal from us today.

Cargo delivery offers the widest selection of rolled metal products. Environmental safety, resource and energy saving You can buy any metal from us. Ecologist of safety, resource and energy saving You can buy any metal from us.

Production of used sheets

The secondary market for metal products is a real source of cost reduction for such resource-intensive industries as construction, agriculture, production of metal structures, etc. For example, a used steel sheet will reduce the cost of an object by 30%. Such savings in modern crisis conditions mean increased competitiveness, and therefore an increase in the profitability of any activity. LLC "EMG-GROUP" has a developed production infrastructure for the supply of used sheet metal products at the first request of the client.

- used hot-rolled sheet

- production of used sheets

- used sheet in Moscow

- used sheets in the Moscow region

- used steel sheet

- used sheet is made from used pipe

| Used sheet | Price, rub/ton |

| 4 | 35000 |

| 5 | 32000 |

| 6 | 32000 |

| 7 | 32000 |

| 8 | 35000 |

| 9 | 35000 |

| 10 | 35000 |

| 11 | 35000 |

| 12 | 35000 |

| 13 | 35000 |

| 14 | 35000 |

| 16 | 35000 |

| 18 | 35000 |

| 20 | 33000 |

| 22 | 33000 |

| 24 | 33000 |

| 30 | 31500 |

| 34 | 35000 |

| 38 | 35000 |

A used sheet is made from a used pipe using a technology that involves several stages:

- cleaning the surfaces of the source material;

- cutting pipes into pieces;

- metal rolling on special equipment.

The output is an absolutely flat used hot-rolled sheet with dimensions of 1500x3000 mm and 1500x6000. This material is in demand in the manufacture of:

- pit fencing;

- blades of screw piles;

- embedded parts;

- sliding supports;

- flanges;

- stiffeners;

- frame elements;

- construction scarves;

- garbage containers, etc.

The production of used sheets involves the design of the edge at the request of the consumer - edged or unedged. The technical parameters of such material depend on the quality indicators of the source material. The thickness of the sheets can be from 8 to 20 mm.

offers used sheets in Moscow in any quantities at reasonable prices. At the request of the client, it is possible to cut the sheet product to size, join and bend it, and manufacture parts according to the customer’s drawings. We deliver used sheets in the Moscow region cheaply using our own vehicles. Regular customers and wholesale buyers are guaranteed discounts and special terms of cooperation.

How to make a chimney from a steel pipe with your own hands?

Every residential or even country house or bathhouse that is not connected to a central heating system is equipped with a heat-generating device. To remove the products of fuel combustion in the firebox from the interior, a smoke exhaust duct is connected to them. The most affordable option is a galvanized chimney; in construction stores the price of 1 m of pipe made of this material is about 110 rubles. If you add to this the costs of the rotating elements, deflector and brackets, installation will cost a pretty penny. However, in this article we will tell you how to reduce costs by 60% and how to make a chimney from a steel pipe with your own hands.

Making pipes from sheet metal - what you need to do it yourself

Galvanized pipes for construction needs can always be purchased in the store, although they are not so popular lately due to the presence of a large assortment of alternative options. In this article we will talk about how to make a pipe from tin with your own hands, because many owners want to save on repairs and do all the work themselves.

Main settings

The advantage of store-bought models of galvanized steel chimneys is that manufacturers produce a wide range of sizes. In addition, among the factory products you can find double-circuit, thermally insulated, corrugated, with increased flexibility and single-circuit. When making a homemade chimney, you have to limit yourself to only single-circuit pipes. In order for the smoke removal system to work effectively, the following parameters should be taken into account:

- Pipe section size. In order for smoke to come out of the firebox through the chimney, you need to choose the correct pipe diameter. A pipe that is too thin does not provide the required level, which can result in backdraft. A large diameter chimney, on the contrary, releases combustion products into the atmosphere too quickly, therefore increasing fuel consumption and energy losses. The more turns there are in the smoke exhaust duct configuration, the thicker the pipe should be. In most cases, a galvanized steel pipe with a diameter of 100 mm is suitable. Recommended chimney pipe cross-section for boilers of different capacities:

- Material. Chimney pipes are made of sheet metal. This material must be highly resistant to corrosion, moisture and high temperature. Therefore, simple galvanized steel is not enough, since the temperature in the chimney of solid fuel stoves and fireplaces exceeds 500-700 degrees. Therefore, for the manufacture of pipes, metal with increased heat resistance and corrosion resistance is used.

- Wall thickness. The service life of a chimney made of a steel pipe depends on the thickness of the metal used. Sheets of steel with a thickness of 0.25-1.0 mm are used. The higher the temperature of the gases leaving the furnace, the thicker the metal needs to be.

Important! A sheet of galvanized steel measuring 2500x125 mm in construction stores costs about 600 rubles, with proper cutting, one sheet produces 8.75 m of pipe with a diameter of 100 mm, the cost of 1 m is approximately 68 rubles, which gives 60% savings!

Production technologies

Rolled metal manufacturers produce profile pipes in two ways: by rolling a round pipe, when it is converted from regular to profiled, and full-cycle production, which is the production of a profile pipe from sheet material.

Round pipe profile

To make a metal profile from a round pipe, just one rolling machine is enough. The necessary equipment is affordable and compact and is used by both pipe rolling companies and individuals . The technology, called cold deformation, does not require much time and energy.

Production consists of only two stages: procurement of the workpiece and its completion. A welded or seamless pipe is given the desired shape by passing it between the rollers of the machine.

The profiled pipe obtained in this way has sufficient strength for the manufacture of furniture and decorative elements, construction of a gazebo or greenhouse. Such pipes are not suitable for the construction of serious objects requiring high strength.

Full production cycle

For the construction of structures that have high demands on their strength, only profile pipes obtained under full cycle conditions are used.

Such rolled metal is more expensive, but much more reliable than profiled round pipe.

To manufacture a profile pipe, strip is used - sheet material made of low-alloy or carbon steel. A round blank is made from the strip, which is then profiled.

Manufacturing

To make a pipe from a sheet of galvanized steel, you will need a rubber or wooden mallet that is heavy enough to bend the metal . In the process of work, scissors are used for cutting metal, a long ruler, a scriber for marking, a corner and a “gun” for bending. The bending process occurs as follows:

- First of all, the sheet of metal is marked by drawing lines using a scriber. On one side the part is made 340 mm wide, and on the other 330 mm, so that during assembly they can easily fit into each other. If cut correctly, you should get 7 strips 1250 mm long.

- Using a metal corner and a mallet, both edges are bent at an angle of 90 degrees in opposite directions to a width of 0.7 mm. Then the workpieces are turned over and the angle at the edges is adjusted to an angle of 135-145 degrees, gently tapping with a mallet.

Note! The installation of a chimney requires rotating parts, which are made by cutting straight pipes at an angle. If you cut the pipes at an angle of 75 degrees, then when joining, you get a 150-degree turn; if you cut them at an angle of 45 degrees, you get a 90-degree turn. To improve the efficiency of a homemade chimney, it is wrapped in non-flammable thermal insulation material.

Advantages

With the advent of a large number of factory products for assembling galvanized steel chimneys, the need to make pipes with your own hands has decreased. However, homemade pipes allow you to reduce costs and choose the ideal diameter. In addition, they are used to equip drains, so the ability to make pipes with your own hands will be useful in everyday life. Metal chimneys have the following advantages over others:

- A light weight. Smoke exhaust ducts made from homemade galvanized pipes weigh much less than brick or ceramic ones. Therefore, to install this type of chimney, there is no need to equip a foundation, the cost of pouring which exceeds the cost of material and installation work.

- Fire safety. According to building codes, steel chimneys are completely fire safe. High quality metal can withstand heating up to 900 degrees, so it is suitable even for solid fuel stoves and fireplaces.

- Low cost. Chimney pipes made of steel are the most democratic way to organize smoke removal; the cost of installation is several times lower than the installation of brick and ceramic analogues.

- Easy to assemble. You can easily assemble a chimney made of galvanized steel with your own hands according to the instructions, thereby saving money spent on hiring professional workers.

Important! The effectiveness of smoke removal depends on the correct assembly of the chimney. Experienced craftsmen advise choosing a predominantly vertical configuration with the least number of turns. Each rotating element acts as an obstacle to the smoke, reducing the draft force.

Advantages and disadvantages of such a pipe

Galvanization is primarily steel, a material that has many undeniable advantages.

These include:

- Strength;

- Ability to withstand high temperatures;

- Excellent thermal conductivity;

- Low cost compared to other materials.

But without a protective coating, ferrous metal is susceptible to corrosion, quickly rusts and becomes unusable. Galvanizing successfully solved this problem. And, despite the fact that galvanized and steel pipes are the same in shape, the galvanized product has a number of advantages.

Additional advantages of galvanized products:

- Corrosion resistance, the ability to withstand negative environmental influences;

- Increased service life;

- Increased strength;

- Wide operating temperature range;

- High resistance to mechanical stress;

- Galvanized pipe can withstand high internal and external pressure;

- Simplicity and ease of installation;

- High resistance to fire;

- Zinc kills all pathogenic microorganisms;

- Galvanization is practically not inferior in quality to low-alloy stainless steel, but costs an order of magnitude less.

But, like any engineering solution, a galvanized iron pipeline is not ideal.

Disadvantages of the product:

- Not very attractive design;

- Expensive compared to conventional steel;

- Zinc complicates the welding process;

- Unlike plastic, if there are protrusions on the walls, it is almost impossible to ensure a smooth transition into structures made of galvanized pipes.

Assembly Rules

To properly assemble a chimney made of galvanized steel, you must first mark out the layout and laying of the pipe. Using this drawing, you should determine how many pipes are required and cut them into sections of the required length. Assembly is performed as follows:

- First of all, the chimney pipe is connected to the inlet pipe of the heating device using a special adapter. It is important to ensure complete tightness of the connecting seam.

- After the first segment, a tee with a condensate collector and inspection is connected. Each piece of pipe is inserted into the previous one, and the joint is coated with heat-resistant sealant and secured with a steel clamp.

- Where the pipe passes through obstacles in the form of walls or ceilings, holes are cut out and a fire-resistant box made of galvanized steel or asbestos slabs is installed. The space between the walls of the pipe and the box is wrapped with basalt fiber or filled with expanded clay.

Note! The smoke exhaust duct is installed on the roof at a distance of 30-50 cm from the ridge. To ensure the level of draft, the height of the chimney should be 50 cm above the ridge. Incorrect placement on the roof can cause backdraft or wind backlash.

Making a pipe from a steel sheet

A gutter system is essential for every home, but purchasing one is expensive. If you want to save money and get a drain no worse than on the construction market, then make it yourself. Making a drainpipe will not take you much time. Designing a drain starts with pipes.

The materials you will need: a rectangular steel sheet with a smooth surface approximately 0.5 mm thick (can be purchased at https://www.spb.spk.ru/sic/shop/_t_/g=metalloprokat/s=listovoy-prokat/ p=list/), a metal strip for creating a perfectly even seam. You will also need either a table with metal corners or a metal corner one meter long so that it can be attached to the edge of the marking table. If you have a workbench available, secure a corner of the metal to one of its sides .

Working tools you should prepare:

- metal cutting scissors,

- regular or wooden hammer (mallet),

- pliers,

- ruler,

- chalk or sharp object for marking,

- steel meter pipe (“gun”) or a cylindrical pipe template, if available.

Operating procedure

- First, you will need to draw a diagram of the pipe in order to make a pattern based on it. Use chalk, a knife or any sharp object for this. Apply the markings correctly. The width of the workpiece should be equal to the thickness or diameter of the pipe, with another 1.5 cm added for bends. The length should be a little more than a meter. During assembly, one pipe will be inserted into another, so additional centimeters will be needed.

- For a pipe with a diameter of 100 mm, the width of the workpiece at one end should be 340 mm. At the other end of the workpiece, make the width 330 mm. This is done so that the pipe at one end is slightly narrower, and it can be easily inserted into another pipe. It is better to draw patterns in a checkerboard pattern, alternately first on one side of the steel sheet, then on the other. This way you will save material.

- We take scissors and cut the blanks.

- Now we have to make seams to connect the edges of the pipe. We place the blanks one by one on a table with a metal corner. Along the meter edge of each workpiece on both sides we draw a bend line 0.5 - 0.7 cm wide, combine this line with the edge on the corner of the table and use a hammer to bend the edges of the steel sheet. Moreover, we bend one edge in one direction, and the other in the opposite direction. You will get bends around 90 degrees.

An even bend along the entire length of the pipe is achieved by lightly tapping with a hammer, while trying to strike as close to each other as possible.

- For one of the sides you will need to make a bend of approximately 130-150 degrees. Therefore, we turn the sheet over and use a hammer to carefully bend the edge a little more to the steel sheet. Next, we make another bend, the protrusion should be 1 cm. The result will be something like a small hollow in the shape of the letter “G”.

- Wrap the blank around a cylindrical pipe template (mandrel) or any metal pipe.

- We connect the bends to each other, for reliability we press them with pliers.

- We take a hammer, place a metal strip on the seam, lay the edge completely on the sheet, and tap it well. You must work with a hammer or mallet confidently and strike accurately.

The edges of the pipe can also be fastened using staples or metal rivets. But in this case, the seam is not very aesthetic, and the pipe is not so convenient to use. For rivets, you will need to drill holes every three centimeters. Along the edges of the sheet on both sides, bend the edge inward perpendicular to the sheet. Bend the workpiece so that the edge is on the outside. That's it, you can install the rivets.

To ensure a strong connection on the wide side, the pipe can be slightly deformed - flared. You can roll rings in the form of threads on the ends of the pipe. Although in its original form the pipe will hold well at the joints.

A correctly made pipe will easily fit into structures similar to it, as well as with factory products.

Such pipes can be used not only in the construction of drains, but also in chimneys and ventilation systems.

Rules for working with steel in the manufacture of pipes

- To give a sheet of steel the desired shape, it is bent using pliers or a hammer around a cylinder-shaped object.

- You can attach a leather loop to the handle of metal scissors, then it will be more convenient to work.

- To make the edge of the sheet smoother, the cut area is cleaned with a plow. It can be made from an old piece of hacksaw.

- A can opener will help you shape the edge of the drain pipe.

- To make cutting the pipe easier, first cut it with a hacksaw.

Working with metal sheets is not difficult. You should follow safety precautions and be careful, as the metal edges are sharp and you can get hurt on them.

How to make a galvanized pipe with your own hands: step-by-step instructions, calculation according to the diagram and drawing

Good day, dear guest!

The first sheet with galvanic coating came off the assembly line of one of the British factories back in 1867. True, at that time the metal was covered exclusively with gold and silver. But before the First World War, the production of parts with a protective layer of zinc began to be produced, and since then they have been incredibly popular.

This is not surprising - zinc extends the life of iron by 20-30 times. Products made of galvanized steel are durable, do not rust, and behave in everyday life no worse than stainless steel, although they are much cheaper.

In today’s article, I propose to pay more attention to this modest material and tell you how to make a galvanized pipe with your own hands.

Advantages and disadvantages of such a pipe

Galvanization is primarily steel, a material that has many undeniable advantages.

These include:

- Strength;

- Ability to withstand high temperatures;

- Excellent thermal conductivity;

- Low cost compared to other materials.

But without a protective coating, ferrous metal is susceptible to corrosion, quickly rusts and becomes unusable. Galvanizing successfully solved this problem. And, despite the fact that galvanized and steel pipes are the same in shape, the galvanized product has a number of advantages.

Additional advantages of galvanized products:

- Corrosion resistance, the ability to withstand negative environmental influences;

- Increased service life;

- Increased strength;

- Wide operating temperature range;

- High resistance to mechanical stress;

- Galvanized pipe can withstand high internal and external pressure;

- Simplicity and ease of installation;

- High resistance to fire;

- Zinc kills all pathogenic microorganisms;

- Galvanization is practically not inferior in quality to low-alloy stainless steel, but costs an order of magnitude less.

But, like any engineering solution, a galvanized iron pipeline is not ideal.

Disadvantages of the product:

- Not very attractive design;

- Expensive compared to conventional steel;

- Zinc complicates the welding process;

- Unlike plastic, if there are protrusions on the walls, it is almost impossible to ensure a smooth transition into structures made of galvanized pipes.

Make it yourself or order it

What is better, buy a galvanized sheet of the required thickness and bend the pipe yourself, or go to the store and buy a finished product?

Selection tips and approximate price

As usual, let's start with the price. A finished pipe with a diameter of 100 mm and a length of 3 meters will cost you and me about 500 rubles.

The cost of the material in this case is 150 rubles, the rest is labor costs and the seller’s markup.

What if you plan to organize an entire drainage system? You can see for yourself that you will have to overpay for finished products by 2.5-3 times. Making your own pipes will greatly ease the financial burden.

In addition, factory products have strictly defined dimensions, and sometimes it is difficult to choose the right one for your system. And the thickness of the finished pipe usually does not exceed 1 mm.

You should definitely remember that any factory-made product, unlike a home-made one, undergoes strict quality control control, has a perfectly round surface and a precision weld.

Whether a home master will be able to ensure compliance with all these conditions is far from certain.

Which material to choose

If you have decided to make the part yourself, you should start by choosing the material, in our case, a galvanized sheet of the required thickness.

Material characteristics

Thin sheet steel coated with zinc in the factory must comply with GOST 14918-80. Main characteristics that you should pay attention to when choosing:

The most common galvanizing thicknesses are from 0.35 to 3mm. The thinner the sheet, the easier it is to process, which is important for making products at home. But don’t forget – less thickness means less strength.

- Zinc coating thickness

There are 3 classes of material, in accordance with the thickness of the zinc coating layer. Let's summarize the data in a table for convenience.

| Steel class based on zinc layer thickness | Weight of protective layer on both sides (g) | Coating thickness (µm) |

| P (Increased) | 570 — 855 | 40-60 |

| I | 258-570 | 18-40 |

| II | 142.5-258 | 10-18 |

GOST allows some deviations in thickness and the presence of some defects

Marking:

- NR – normal thickness variation;

- UR – reduced thickness variation.

Sheet appearance options:

- KR – With crystallization patterns (some cracks and darkening);

- MT - without patterns.

An important characteristic for the manufacture of pipes is the ability of the metal sheet to be drawn:

- N – normal hood;

- G – deep drawing;

- VG – very deep drawing.

Steels marked VG have the highest ductility, N - correspondingly the lowest.

What you need for work

After purchasing a sheet with the necessary characteristics, you should stock up on the necessary equipment.

Required tools:

- Metal scissors. Choose a convenient tool for cutting a wide sheet of metal;

- A hand jackhammer (also known as a mallet) with a rubber or wooden tip. The mallet should be hard, heavy, but without sharp edges;

- Steel pipe blank for molding the pipe body (“gun”). Its length is at least 1 meter, its diameter depends on the required diameter of the finished product;

- Ruler;

- Tool for marking galvanized steel (sharp metal rod);

- Crafting table. At the corner of the workbench there should be a metal corner, at least 1 m long. It will be used to bend the edges of the pipe, so it must be fastened very securely;

- Pliers.

Size calculation

A standard galvanized sheet sheet has dimensions of 1000x2000mm, or 1250x2500mm, although other cuts can be found.

The width of the workpiece is calculated using the formula:

L (circumference, also known as the width of the workpiece) = 2*3.14*R (R is the required pipe radius, mm).

Thus, to make a pipe with a diameter of 100 mm, you will need a blank with a width

2x3.14x50mm = 314mm.

To the resulting finishing length we add a bend of 15mm and get the required value for cutting -300mm.

An important point is that the width of the workpiece is not a constant value. On one side it is 330mm, on the other 340 (for a pipe with a diameter of 100mm). This is done for the convenience of subsequent installation of pipes with each other or with other elements of the system.

Drawing and diagram

Rice. 1. Pattern of a sheet for a pipe with a diameter of 100 mm.

The fold formation pattern is as follows:

Rice. 2

Cutting out the workpiece

After calculating the required dimensions, a blank for the future product is cut out. For this:

- A sheet of tin is laid out on a horizontal surface, markings are applied in straight lines, strictly according to the dimensions of the semi-finished product.

For a pipe with a diameter of 100 mm, along one edge of the sheet, sections of 340 and 330 mm are measured one after another (see Fig. 1). The same segments, but in the opposite sequence, are marked on the opposite side. All perpendicular lines should be drawn using a square.

Don't forget to add 15-20mm to the width of the product on the bend!

- The tin is cut into rectangles according to the drawing.

Formation of a profile

The resulting rectangular blanks must be “transformed” into a pipe. To do this, we will create her profile.

Stages of profile formation:

- Along the entire length of the workpiece, with an indent of 5 mm on one edge and 10 mm on the other, two lines are drawn. These lines are the boundaries of the folds.

In our case, a seam or a seam lock means a type of connection between the edges of a pipe;

- We bend the edges along the marked line, strictly at an angle of 900. For this we use a metal corner, aligning the fold line with the edge of the corner. We start with pliers, continue with a mallet;

- We pass the hammer along the entire length, gradually forming the future seam;

- On a 10mm wide bend we make another bend in the shape of the letter G. The width of the top bar is 5mm, the location is strictly parallel to the workpiece;

- After forming the folds, we move on to the pipe body. We place the workpiece on the gun and use a hammer to give the sheet a round shape.

Processing the butt seam

The final stage is processing (crimping) the butt seam. To do this, bend the upper part of the L-shaped fold down, wrapping it around the opposite edge. The result is a fold of several layers of metal, which must be pressed against the pipe along its entire length.

In the factory, additional strength is added to the seam using special metal rivets.

For handmade products, no additional processing is required.

manufacturing

Check out useful videos on the topic.

Pipe making:

Inserting a pipe into a plane:

Expert advice

To make it easier to connect the finished pipe with other elements of the system, it is necessary to make a socket at the end of the product.

How to make a socket on a galvanized metal pipe

A bell is a technological extension designed for the convenience of installing communication elements with each other and inserting them into a plane. The socket on the finished pipe is made along a wide edge, using the method of flaring the edge to a depth of 15-20mm. In the factory, a special tool is used for flaring - a rolling cone.

At home, you can expand the edge of the pipe yourself using pliers. Ideally, install special rings—stiffening ribs—at the ends of the workpiece.

Fig.3. Flaring diagram:

Features of working with tin

Galvanized sheet metal is an inexpensive and reliable material. Its main feature is its small thickness (most often at home, a sheet with a thickness of 0.3 to 1 mm is used) and plasticity. Thanks to its softness, it is convenient to work with galvanizing and making the desired product yourself will not present much difficulty even for a novice tinsmith.

At the same time, despite the softness of the steel, the resulting seam seam is very reliable and can withstand significant mechanical stress.