What is the warranty period

Guarantee period

– this is the time period during which the manufacturer ensures the stability of the quality indicators of its products. This term also refers to the officially designated time during which the buyer has the right to file claims against the manufacturer regarding hidden defects discovered during the operation of the product.

The warranty period is individual for each product category. It is installed taking into account the general service life and operating conditions, the complexity of the design or device of the product, etc.

Important: the manufacturer or seller has the right not to establish a warranty period for their products. This is not a mandatory procedure. And they will be responsible for shortcomings or defects in a product for which there is no warranty period only if the buyer conducts an examination and proves that there was a defect before the transaction was completed.

The warranty period begins at the moment the product is transferred to the consumer, unless otherwise specified in the sales contract.

Important: the warranty period must be recorded in writing (coupon, label, receipt, instructions, etc.). Otherwise, the warranty is void.

General rules

The storage of perishable products is strictly regulated by various regulatory documents, primarily SanPiN 2.3.2.1324-03. However, the shelf life of rolled metal according to GOST is not limited

. This means that it does not require special conditions and can be stored for a very long time without significant damage to its properties and characteristics.

Since official requirements for the storage of rolled metal have not been established, each consumer has the right to decide this issue for himself. It is possible to formulate general rules for storing rolled metal products based on the practice of warehousing by enterprises in various industries - metallurgy, mechanical engineering, construction materials production and others.

Regardless of which method of storing metal products you choose, indoors or outdoors, the metal warehouse must meet the following requirements:

- be convenient and safe for loading and unloading operations;

- protect stored products from precipitation;

- provide ventilation or airing of storage areas;

- exclude contact of the rolled product with the surface of the floor or platform.

In other words, the product owner creates his own GOST for storing metal in warehouses, based on specific conditions and capabilities.

What are hidden defects

Hidden defects

– defects that cannot be detected visually, using standard methods, diagnostic and control tools. For example, identifying “hairline” cracks only tens of microns thick inside the metal. This type of defect can only be detected using special diagnostic methods, for example, using a metallographic microscope, or during maintenance.

Hidden defects, depending on the cause of their occurrence, are usually divided into three groups:

- production

– defects, the causes of which were the product’s non-compliance with regulatory and technical documentation for its production: violation of the production process, manufacturing process or restoration of products. For example, in the manufacture of a part, a material was used whose strength is lower than the stated requirements. This could occur due to the use of a steel grade whose chemical composition does not meet the stated technical requirements. Either the part being manufactured did not undergo heat treatment, or the heat treatment was performed poorly. To identify this type of hidden defect, special equipment is required: spectrograph, hardness tester, metallographic microscope, etc.; - structural

– defects caused by design errors: incorrect choice of material for the manufactured product, incorrect dimensions for the product, incorrect heat treatment mode. For example, non-compliance of any part of the product with the design documentation. Most often, such discrepancies amount to fractions of a millimeter and can only be detected using an optical profilometer; - operational

– defects caused by: mechanical damage, wear, fatigue, corrosion, violation of operating rules. For example, exceeding the permissible loads that affected the product, which led to a violation of the integrity of the metal.

Warranty period for metal products

» Internet and law A consumer who has received a poor-quality order only needs to prove that the defect did not occur due to his cause, so that the court will clearly take his arguments as a basis. If the supplier has not indicated a warranty period for the metal structure, one should proceed from the above rule, taking into account the fact that in one case such a product may be classified as a real estate property, but in another not. The legislator approaches this issue as follows: everything that cannot be moved without causing harm is classified as immovable objects.

There are additional signs that allow for more accurate identification:

- high cost and durability;

- satisfies a person's need for living and other space.

- physical connection with the earth;

- unique characteristics;

It is in accordance with this that real estate objects include space objects, sea, river and aircraft, and it can be argued that:

- porch;

- doors;

- balconies;

- gazebos;

- railings,

are inseparable from the house and are subject to a five-year warranty. The manufacturer is obliged to provide a guarantee for this type of product.

If a defect or manufacturing defect is discovered during the warranty period, you can contact the store where the product was purchased and request an exchange or return of the product. In this case, the seller, not you, must prove your non-involvement in the breakdown or defect. To do this, the seller schedules an examination, which you can attend.

If it is proven that you were not involved in the breakdown, the product will be repaired at the store’s expense or your money will be returned. For example, identifying “hairline” cracks only tens of microns thick inside the metal.

This type of defect can only be detected using special diagnostic methods, for example, using a metallographic microscope, or during maintenance.

Hidden defects, depending

Warranty for rolled metal products

In some areas, for example, the production and supply of rolled metal, the manufacturer’s warranty obligations differ from generally accepted rules and have their own nuances:

- The date of transfer and the date of receipt of metal products by the buyer may not coincide. If the contract does not stipulate the obligation to deliver rolled metal to the buyer, the moment of delivery is considered to be the date of shipment of the order from the warehouse of the manufacturer or seller.

- Stainless, ferrous or non-ferrous metal is not a product, but a raw material, the quality and safety of which is regulated by manufacturer certificates. In this regard, there is no warranty period for them as such. This means that rolled metal products may or may not comply with technical documentation.

- In the event that a product, structure, mechanism or equipment made of ferrous, stainless or non-ferrous metal has undergone some kind of deformation and suspicions fall on low-quality metal, the buyer makes an examination that determines the exact cause of the defect: improper operation or low-quality raw materials. Only in the latter case does responsibility fall on the manufacturer/seller.

If it is proven that the manufacturer or seller provided products of inadequate quality, a complaint is filed.

Warranty period for rolled metal according to GOST

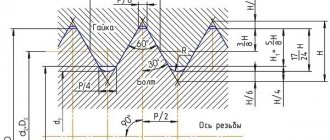

Contents Pallets must have fittings designed for steam supply and condensate removal. The coating of the fittings is Ts6. In this case, the requirements for the protective coating of fittings do not apply to fittings of version 2 according to Appendix 1, welded to the mold.

The design and dimensions of the fittings are shown in the drawing in Appendix 1. Unspecified maximum dimensional deviations: Requirements for frame welding. Symbol of welds - according to GOST 2.

In this case, the reinforcement of the weld seam in places where it contacts the decking, lower cladding and plates for electromagnetic fastening of the forms to the vibrating platform must be removed.

- Requirements for devices for moving and packaging pallets and forms in the process flow;

- The design and dimensions of the fittings are shown in the drawing in Appendix 1;

- From 5 to 7 incl.

We recommend reading: Amounts of insurance payments for a pedestrian injured in an accident

The flooring must be welded to the frame along the contour of the contact using an intermittent seam N1-UP-5-100Z 500 in accordance with GOST 14771, in the corners of the frame - with welds 100 mm long in each direction from the top of the corner.

Local gaps between the flooring and the frame should not be more than 3 mm.

In this case, the total length of the gaps should not exceed 0.5 of the adjacent length. In technically justified cases, it is allowed to reduce the length of the welded section in intermittent seams to 80 mm.

Holes for welding to the frame must be made in the lower skin in the areas adjacent to the internal beams.

The diameter and number of holes are determined by calculation.

- The rules for selecting the composition of concrete are adopted in accordance with GOST 27006;

- The quality of materials used to prepare concrete must ensure compliance with the technical requirements for concrete established by this standard;

- The symbols of the lugs must consist of the type designation, the frame channel number and the designation of this standard;

- Positive values of maximum deviations can be taken greater than those according to Table 3, if this does not lead to a decrease in the required load-bearing capacity of the products;

What is a complaint?

Complaint

– is a written claim presented by one of the parties to a purchase and sale agreement as a result of dissatisfaction with the fulfillment of the terms of the contract by the second party.

The most common reasons for filing a complaint are:

- inconsistency of product quality with relevant standards and regulations;

- discrepancy between the quantity of delivered products and the quantity specified in the contract;

- discrepancy between the initial cost of the product and the final one;

- inconsistency of the configuration with that specified in the product description or terms of the contract.

Each of the above claims must be supported by the conclusion of a special commission, which, through an examination, accurately determined the circumstances of the occurrence of violations. Otherwise, the complaint will be rejected.

Considering all of the above, we advise you to cooperate only with a reliable supplier, distributor, importer or directly with a manufacturer who has proven itself in the rolled metal market, and the rolled metal produced or supplied by him is not in doubt in compliance with technical standards.

Warranty service life of metal products or metal structures

Official terminology ".

from the moment of manufacture or after repair: the period of operation of the metal product during which the manufacturer (performer) fulfills its warranty obligations.” Source: » GOST R 53422-2009. Household services. Repair and production of metal products.

General technical conditions" (approved by Order of Rostekhregulirovaniya dated November 3, 2009 N 494-st) Share on the page - the total calendar duration of storage and transportation of military equipment products in the state of delivery and operation, during which the supplier guarantees that the quality of the products corresponds to the established ones.

Dictionary of military terms - a period of time during which the manufacturer guarantees all performance indicators and consumer properties of products established by standards, provided that the buyer complies with the rules. Commercial power generation. Dictionary-reference book - warranty period 1) the period of time during which the buyer can, having identified hidden defects in the product, present corresponding claims to the supplier.

Encyclopedia of technology - a period, calculated in months or years, during which the construction and installation trust, supplier plant or repair plant guarantees proper operation on the basis of contractual obligations or repair rules. Technical railway dictionary is a period of time during which the manufacturer of a product or its seller guarantees its compliance with the requirements of the contract, quality indicators, and passport data.

Economic Dictionary - “. Official terminology is the period of time during which the debtor ensures to the creditor that the product or work result meets the established quality requirements. Lawyer's Encyclopedia - in civil law, a period of time during which a product must meet the quality requirements under a sales contract, and work and services must retain their consumer properties.

GOST 22352-77 Manufacturer's guarantees.

Establishment and calculation of warranty periods in standards and technical specifications. General provisions

GOST 22352-77 Group T50 Manufacturer's guarantees ESTABLISHMENT AND CALCULATION OF WARRANTY PERIOD IN STANDARDS AND TECHNICAL CONDITIONS General provisions Manufacturer's guarantees. Establishment and calculation of guarantee periods in standards and specifications.

General Date of introduction 1977-07-01 By Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated February 7, 1977 N 208, the introduction date was set from 07/01/77 REISSITION.

July 1990 This standard establishes the types and rules for calculating warranty periods in standards and technical specifications for industrial and technical products and consumer goods (hereinafter referred to as products), as well as the procedure for presenting the section “Manufacturer's Warranties” in these documents. Standard does not establish the types and rules for calculating warranty periods for special-purpose products, as well as rules for calculating warranty periods for products intended for export.1.1. Warranty periods are established in standards and technical specifications in order to ensure the stability of product quality indicators, increase the responsibility of manufacturers and protect the rights of consumers. Establishing a warranty period for a product means that upon delivery or sale of such products, a warranty obligation arises under which the manufacturer (supplier) or seller (retail trade organization) guarantees and ensures compliance with the product quality requirements specified in the standards or technical specifications.1.2. Lists of subclasses, groups, subgroups of products and goods (in accordance with

"Highest classification groups of the all-Union classifier of industrial and agricultural products"

), for which warranty periods must be established in the standards and technical conditions, are determined by the ministry to which these products and goods are assigned, in agreement with the USSR State Committee for Standards. Explanations of the terms adopted in the standard are given in reference appendix 1.2.1 .

warranty period in the contract

#1 Quack Quack –>

lawyer without education

- Old timer

- 1062 messages

- Partner

- 14377 messages

ContactPublications

#2 Tony V Tony V –>

elegantly excused himself (c) thesunbeam

ContactPublications

In principle, there can be no warranty period for such a product.

#3 woo-doo woo-doo –>

In principle, there can be no warranty period for such a product.

#4 Madama Madama –>

Hello! Product – let’s say “metal”. In principle, there cannot be a warranty period for such a product. So, if in the contract for the supply of such goods... a warranty period is still established... can the Buyer refer to it?

#5 Satyr Satyr –>

if the warranty period is not established or has expired

If a warranty period has not been established for the metal by either the seller or the manufacturer, then claims related to defects in the goods may be presented by the buyer to the seller or the organization performing the functions of the seller, provided that the defects were discovered within a reasonable time, but within 6 months from the date of transfer of the goods to the buyer (in relation to real estate - no later than two years from the date of its transfer to the consumer).

When determining the reasonableness of the terms, it is recommended to proceed from the warranty periods established by state standards, and if they are not established, from the indicators of product durability established by regulatory documents on standardization.

You can almost always return an item!

The main thing is to know the procedure and use the law correctly. Get information for free from lawyers via chat (bottom right ↘️) or via this link. return the goods

Acceptance, marking, packaging, transportation and storage of metal products (GOST 7566-94)

Home->Directory->Marking, storage, transportation of rolled metal->Transportation, storage

Acceptance, marking, packaging, transportation and storage of metal products (GOST 7566-94)

Requirements for acceptance, marking, packaging, transportation and storage of blooms, slabs, billets, including cast and forged, long, shaped, calibrated, cold-drawn rolled products, wire, rolled products with special surface finishing, bent profiles, sheet, wide rolled products and strips , must comply with GOST 7566-94.

Acceptance

The definition of the batch and the scope of testing are established in the regulatory documentation (ND) for specific types of metal products. Quality control and acceptance of a batch of metal products is carried out by the manufacturer. Acceptance of a batch, for which control of the surface quality and dimensions of each product included in the batch is provided, can be carried out based on the results of technological and instrumental control during the production process. In case of disagreement between the consumer and the manufacturer, acceptance of metal products is carried out in accordance with the requirements of standards for specific types of metal products.

If defective areas of the surface of rolled products are detected by the consumer and presented to the manufacturer, the manufacturer must compensate the consumer for the same amount of high-quality rolled products.

Each batch is accompanied by a document containing:

— name and (or) trademark of the manufacturer; — name of the consumer; - Order number; — date of execution of the quality document; — steel grade, group or strength class; — heat number and batch number if the heat is divided into batches; - name of the metal product, dimensions, number of pieces, their total weight and, in the case of delivery based on delivery (theoretical) weight, the “TM” sign, conversion factor (for sheet metal, instead of the conversion factor, it is allowed to indicate the theoretical weight of one sheet or 1 m length of rolled steel ), information about groups and categories of rolled products by properties, surface quality, purpose and other requirements provided for in the RD for rolled products; — ND number; — chemical composition of steel according to a ladle sample or in finished rolled products; — results of all tests, including optional indicators at the request of the consumer. It is allowed to indicate instead of the results of all tests: “Metal products comply with ND” or a certificate; — information about the heat treatment regime at the consumer’s request; — stamp of the technical control department.

Marking

Markings are applied directly to metal products if they are not subject to packaging, and on labels if metal products are packaged in bundles, skeins, rolls, bundles of skeins or stacks of rolls.

Marking is carried out by impact - branding (manual or machine), electrography, gluing labels from waterproof film, colored varnish or indelible coloring composition, paint. The standards for specific types of metal products may establish a different method of applying additional color markings.

For metal products that are not subject to packaging, the marking is applied at a distance of no more than 200 mm from the end of each rod, workpiece (all types), strip, sheet or sheet edge, or at the end of the bar, workpiece, sheet or on the outer turn of the roll.

During mechanized in-line marking, it is allowed to apply marking at a different distance from the end of the metal product, from the end or edge of the sheet, but not more than 500 mm.

Metal products bundled in bundles are labeled with two labels, and those in coils and rolls are labeled with one. For metal products tied into bundles or stacks of rolls, one label is placed on one of the coils or rolls and one on the binding of the coils or stack of rolls.

Labels are firmly attached to the harnesses on the side convenient for viewing, or placed in a special pocket. In the case of hanging two labels, the latter are attached to the bindings of the bundle or skein. The material of the labels and their fastening must ensure their safety during transportation and unloading. By agreement between the manufacturer and the consumer, one label is attached to the pack.

When packing sheets and wide strips into bundles, markings are applied to the top sheet or strip of each bundle and markings are applied to the top sheet or strip of each bundle and to a marking card or label firmly attached to the bundle bindings.

When using mechanized marking of thick sheets and strips, it is allowed to apply markings to the side edge of the top sheet and strip of each bundle.

On sheets, and at the request of the consumer on other rental products, the marking area applied by stamping must be outlined with paint, colored varnish or bitumen.

Marking of metal products that are not subject to packaging, as well as metal products bundled in bundles with marking of each product with a size (diameter, square side, thickness, profile number) of 30 mm or more and sheet metal with a thickness of 4 mm or more, must contain:

— name and/or trademark of the manufacturer; — steel grade and its symbol indicating the decoding in the quality document; — heat number or its symbol indicating the interpretation in the quality document; — batch number if the heat is divided into batches; — size (diameter, square side, thickness, length, width, profile number).

The need for piece-by-piece marking of metal products bundled in bundles must be established in the regulatory documentation for metal products of this type. In this case, one label is placed on the pack.

The marking applied to the label (marking card), the top sheet of the bundle, the outer end of the roll must contain: - the name and/or trademark of the manufacturer; — steel grade or its symbol indicating the decoding in the quality document, group or strength class; — batch number, if the melt is divided into batches, size (diameter, square side, thickness, length, width, profile number); — net (actual) weight of a pack, skein, roll or bundle of skeins and a stack of rolls. By agreement with the consumer, the mass is not indicated; — the “TM” sign is indicated when delivering metal products according to delivery (theoretical weight).

It is allowed to establish additional marking details in the RD for specific types of metal products. The weight may be indicated in an additional label.

Transport marking - according to GOST 14192.

For marking, metal, plastic, wooden labels or waterproof film with recommended aspect ratios from 1:1 to 1:2 and an area of at least 24 cm2 are used. By agreement between the manufacturer and the consumer, it is allowed to use labels with a different relationship between the parties.

Markings must be clear, durable and indelible. The numbers and letters of the marking should be 5.0-20.0 mm high and 3.0-12.0 mm wide. On labels, rods with a cross-sectional size of less than 60 mm, and tapes with a width of less than 50 mm, the size of the numbers and letters of the marking should be 2.0-4.0 mm. When marking with paint, it is allowed to increase the height of numbers and letters to 100 mm and the width to 70 mm. The depth of marking (stamping) of metal products is established by agreement between the manufacturer and the consumer.

By agreement between the manufacturer and the consumer, additional color markings are made with paint.

Colored paint markings are applied to the end or end of a bundle of metal products in accordance with the requirements of standards for specific steel grades.

At the consumer's request, metal products are additionally marked at a distance of at least 300-500 mm from the end of a bundle of rolled metal with a longitudinal strip, and with a semi-quiet transverse strip in the color of the steel grade. Strip length 100-150 mm.

Package

Long, shaped, calibrated, cold-drawn rolled products, wire and round rolled products with special surface finishing with cross-sectional dimensions (thickness, diameter, square side, largest size for shaped profiles) up to 50 mm inclusive are bundled into bundles, skeins or bundles of skeins, and over 50 mm and blanks of all types are tied into bundles at the request of the consumer. Bent profiles are tied into bundles.

The cross-section of bundles of long, shaped, calibrated rolled products, wire and round rolled products with special surface finishing, bent profiles, depending on the size and shape of the cross-section, should approach a circle, rectangle or hexagon. By agreement between the manufacturer and the consumer, a different cross-section of the packs is allowed.

When packing metal products of measured length, the ends of the bundle must be aligned on one side, the protruding ends on the other side must not exceed the maximum length deviations established in the regulatory documentation (ND) for specific types of rolled products. By agreement between the manufacturer and the consumer, packaging without trimming is allowed.

Sheets with a thickness of up to 3.9 mm inclusive are bundled into bundles, sheets with a thickness of more than 3.9 mm are bundled into bundles at the request of the consumer.

Each pack or bundle must consist of rolled products from one batch.

The weight of a bundle, roll, as well as the weight of unpackaged rolled products should not exceed: - for manual loading and unloading - 80 kg; — for mechanized loading and unloading in accordance with the order — 5, 10, 15, 20, 25, 30 and 35 tons.

By agreement between the consumer and the manufacturer, a different weight of the bundle, roll, bundle or unpackaged rolled product is established.

Manual unloading is specified in the order.

The rods in the bundle must be tightly laid and firmly tied in the transverse direction every 2 - 3 m, and at the request of consumers - every 1 - 1.5 m.

Rods up to 6 m long inclusive in a bundle must be tied in at least two places.

The skeins should be tied with two diametrically located straps, and the bundles of skeins should be firmly fastened with two or three straps.

The sheets and strips in the bundle must be tightly tied in the longitudinal and transverse directions. In places where the strapping goes around the cut edges of sheets and strips, spacers are placed.

When packing sheets and strips into bundles using bag-knitting machines, as well as into bundles packed in boxes, the gaskets do not need to be placed.

The number of transverse straps, depending on the length of sheets and strips, and longitudinal ones, depending on the width, must correspond to those indicated in the table.

Number of cross straps (GOST 7566-94)

| Length or width of sheet or strip, mm | Minimum number of straps, pcs. | |||

| hot rolled sheet or strip | hot rolled pickled and cold rolled sheet or strip | |||

| longitudinal | transverse | longitudinal | transverse | |

| Up to 800 incl. | 1 | 1 | 1 | 1 |

| St. 800 to 2000 inclusive. | 2 | 2 | 2 | 2 |

| St. 2000 to 4000 inclusive. | 2 | 3 | 3 | 4 |

| St. 4000 to 6000 inclusive. | 2 | 4 | 3 | 6 |

| Up to 6000 | 3 | 5 | 4 | 8 |

Notes.

It is allowed not to tie in the longitudinal direction: - packs of strips less than 0.55 m wide; — wide strip – less than 1.0 m or more than 8 m long; - at the request of the consumer - broadband rolled with a length of more than 4.5 m. Displacement of the strips in the bundle during transportation is not allowed. At the request of the consumer, longitudinal tying is carried out for packs of strips with a length of more than 8 m. With mechanized in-line packaging, it is allowed to tying packs of hot-rolled sheets only with transverse tying in an amount equal to the sum of the longitudinal and transverse tying in accordance with the table.

The strapping distance from the end of a pack of sheets and strips should be up to 0.5 m, and for long and shaped rolled products - from 0.2 to 1.0 m.

Packs of sheets less than 2 mm thick and more than 2 m long must have special wooden (metal) beams or pallets attached to the bottom. For sheets of other sizes, bars or pallets are attached to the stack at the request of the consumer.

The rolls should be tightly wound and tied with one or two circular or two to six radial straps. The rolls are placed on the table with spacers. Rolls of cut tape wound on one winder can be bundled without spacers between the rolls.

The binding of hot-rolled rolls with a thickness of 4 mm or more with a tight fit of the outer end is carried out at the request of the consumer. By agreement between the manufacturer and the consumer, it is allowed to pack rolls by welding the outer ends with electric spot welding without the use of strapping tape.

The number of strappings for hot-rolled rolls with a thickness of less than 4 mm with a tight fit of the outer end may be established by the manufacturer by agreement with the consumer.

For strapping, use metal tape with a thickness of 0.5 to 2.0 mm and a width of up to 30 mm in accordance with GOST 6009 or other ND, wire rod or wire with a diameter of up to 8 mm - in accordance with GOST 3282 or other ND. When tying, the ends of the tape are connected using locks or a double spot weld. The twisting of the ends of the rod or wire must be strong, at least two to three turns.

The use of straps to secure cargo during reloading operations is not allowed.

Depending on the type of metal product, its size and purpose, six types of packaging are used in accordance with the table.

The type of packaging is indicated in the order.

Types of packaging (GOST 7566-94)

| Type of packaging | Name of metal products |

| Piece by piece | Long and shaped rolled products with a cross-sectional size of 200 mm or more, blooms, slabs, billets, and rolled sheets with a thickness of more than 12 mm |

| Harness | Long and shaped rolled products with a cross section size of 100 mm or less, bent profiles, cold-drawn profiles from hot-rolled unetched billets, rolled sheets and strip up to 12 mm thick inclusive |

| Oiling and tying | Bent profiles from cold-rolled and pickled hot-rolled billets, hot-rolled sheets and strip up to 10 mm thick, pickled inclusive |

| Oiling, packaging and tying | Sheet metal and pickled tape |

| Oiling, wrapping in moisture-proof paper, placing in containers and tying | Cold-rolled sheets and strip, hot-rolled sheets and pickled strip, round rolled products with special surface finishing |

| Wrapping in moisture-proof paper, placing in containers and tying | Calibrated, ground and round rolled products with special surface finishing from corrosion-resistant steel grades, hot-rolled sheets up to 6 mm thick inclusive from pickled corrosion-resistant steel, rolled sheets and strips from electrical steel |

Note.

Long and shaped rolled products with cross-sectional dimensions over 100 to 200 mm and shaped rolled products over 200 mm are supplied individually or with strapping.

Metal bags (pallets, boxes) or wooden boxes, container fabric, synthetic films or other materials are used as containers for packaging rolled products. The weight of metal packaging should not exceed 2.5% of the weight of rolled products.

When the weight of a pack of sheets is less than 2 tons and the length of sheets is less than 4 m, the weight of metal packaging is allowed up to 60 kg, and when the length of sheets is from 4 to 6 m - up to 90 kg.

Wooden boxes are made mainly from air-dried softwood. The grain direction in the lumber should be parallel to the edge. It is not allowed to use boards with through cracks or knots that do not sit securely in the nest.

The thickness of the boards must be at least: - 12 mm - with a mass of packaged rolled products up to 0.5 t inclusive; - 18 mm - with a mass of rolled products being packaged over 0.5 to 1.0 tons. - 25 mm - with a mass of rolled products being packaged over 1.0 tons.

The type of design of boxes for cargo weighing up to 0.5 t is in accordance with GOST 2991, for cargo over 0.5 t - in accordance with GOST 10198 and other standards or special technical conditions.

Metal bags used for packaging bundles of rolled sheets consist of lower and upper packaging sheets and channels (packaging sheets bent in the form of channels). The thickness of the packaging sheets is from 0.4 to 1.2 mm.

The channels must cover the side and end edges of the sheets in bundles. The width of the channel shelves must be at least 100 mm.

It is allowed to use a box with a side height of at least 2/3 of the height of the pack instead of the top packing list. At the same time, corners with shelves of at least ¾ of the height and at least 50 mm are installed from the shackles and ends of the pack for hemming under the bottom of the pack. It is allowed to use other packaging methods that ensure the safety of the sheets and the presentation of the product.

When supplying hot-rolled thin-sheet products, it is allowed to use the top and bottom sheets of the bundle as packaging, while the mass of the latter must be excluded from the mass of the product.

Metal bags used for packaging rolled cold-rolled thin-sheet products and tape consist of outer and inner cylinders with dimensions equal to the outer and inner diameters of the roll, respectively, and a height equal to the width of the sheet and two end caps.

Allowed for cold-rolled sheets with a width of St. 500 to 1600 mm and cold-rolled strip in rolls, use containers consisting of an outer cylinder or one or more sheets of packaging metal.

When packing long and shaped steel, wire rod or wire rod with a diameter of 5 to 8 mm is used in two or three turns or in two or three threads with a tight twist.

For tying rods into bundles weighing up to 100 kg, boxes and soft containers, use packing tape with a thickness of 0.5-1.2 mm, wire with a diameter of 2.0-3.0 mm in two or three turns, or with a diameter of 4 mm in one or two turnover. The free ends of the wire after twisting should not be more than 150 mm. The ends of the wire ties are bent to the surface of the bundle or bundle.

When packing bundles of sheets with strapping or with oiling and strapping, protective pads made of rolled sheets with a thickness of 0.5-1.2 mm and a width of 100-150 mm should be placed on the edges of the bundle under the packing tape. When packing rolls, linings are not required.

When packing sheets by mechanization, it is allowed not to install safety linings.

The paper used for wrapping metal products and lining rigid containers must be moisture-proof, durable and neutral (chlorine-free and acid-free) in accordance with GOST 515, GOST 8828, GOST 9569 and other or special technical conditions.

Transportation and storage

Preparation of metal products for transportation must comply with GOST 26653.

Metal products are transported by all modes of transport in accordance with the transportation rules in force for this type of transport and the technical conditions for loading and securing cargo.

Metal products are transported in open and closed cars.

Additional requirements for transportation and storage are established in regulatory documentation (ND) for specific types of metal products.

When transporting metal products by air, it is necessary to take into account the requirements for the permissible specific load on the floor of the cargo compartment of the aircraft.

Rolled products are stored in closed and open warehouses.

Acceptance, marking, packaging, transportation and storage of metal products (GOST 7566-94)

The right of metal structures to a warranty period

» Metal structures for suburban real estate, due to their complexity, are produced and installed by organizations specializing in this.

The law establishes a minimum acceptable warranty period for such products. This allows the consumer to fully protect himself in case of dishonesty of the supplier. Metal structures in the design of a suburban area, despite the high cost, are practical, modern and reliable.

The warranty period is sufficient to identify and eliminate possible defects. This is precisely the chance when the supplier is obliged to compensate for the consumer properties of the product. To take advantage of this right, you need to know what is included in the concepts of “warranty period” and “metal structures”, balancing them with the everyday life of the owner of a country house:

- twisted bars on the windows;

- strict fences,

- openwork gazebos;

- forged gates to order;

- majestic balconies;

and much more that will delight the eye with its unique style for many years.

The warranty period is understood as a set period of time during which the responsible person, in the event of delivery of a product or service of inadequate quality, is obliged to eliminate the identified deficiencies. The consumer has the right to demand compensation for the resulting damage. The warranty period is usually established by the seller or manufacturer in the sales contract or indicated in the warranty card for the product.

The law specifies the minimum warranty period:

- five years when it comes to real estate.

- two years for regular goods and services;

Therefore, attempts by individuals to indicate in the contract a clause on the warranty period for metal structures, or to indicate a short period: six months or a year, are unlawful and do not entail legal consequences. A consumer who has received a defective order only needs to prove that the defect did not occur due to his own cause for the court to clearly take his arguments as a basis.

If the supplier does not indicate a warranty

What goods and work are provided for?

The key point in the determination is the suitability of the goods for the purposes for which goods of that kind are normally used within a reasonable time. This is a very abstract and evaluative definition, from which different people may interpret the words (“goals” and “deadlines”) differently.

To prevent corrosion, the wire is coated with a continuous layer of neutral lubricant, highly soluble in inorganic solvents, or sealed with inhibitor paper.

The warranty (warranty period) is important for the consumer - as the period during which he can contact the seller (or manufacturer).

There may be a difference of 0.1 mm between the left and right edges, which may lead to rapid distortion of the roof deck.