When there is a need to repair or replace hot or cold water pipelines in a country house (apartment), the home owner faces a difficult question: how to choose a ball valve among the huge variety of shut-off equipment? The device is important - the efficiency and safety of utilities, including the water supply system, depends on the quality of the ball valve.

Therefore, this part of the pipeline system is the first to be located at the point of water entry into the building. In the event of an accident or a pipe leak, it is the quality of the tap that determines whether the home will flood and whether large material costs will be avoided. In our article we will look at how to choose a ball valve for water and what you need to pay attention to first.

What is a ball valve and why is it needed?

This is a separate type of pipeline fittings, the main element of which resembles a sphere. The equipment is used to shut off or resume the flow of water, without the possibility of regulating it. Its versatility allows it to be used both for private homes and for industry, for example, transportation of energy resources (oil, gas, etc.).

This equipment has replaced wedge-shaped valves, which have shown to be ineffective. Before purchasing a unit, you need to know which ball valve to choose for your water supply. The main advantage of the mechanism is its simple and reliable design. It is very important during the manufacturing process to obtain a perfectly smooth surface of the shutter, for which manufacturers resort to diamond polishing and chrome plating. After high-quality processing of the ball valve, the likelihood of foreign particles sticking and jamming of device elements is prevented, which generally increases the reliability and service life of the equipment.

Types and design of water taps

When choosing a particular mixer model, you should pay attention to the functionality and design, and only then to the design and cost.

Taps for water supply are installed both at the outlet of the system and in the center of the water supply. In the first case, they are intended for direct collection of water from the pipeline, and are installed in washbasins, baths, kitchens, etc.

Such taps are usually connected to hot and cold water supplies simultaneously, and with their help it is possible to regulate, in addition to the pressure, the temperature of the supplied water. This happens by mixing hot and cold water inside them in different proportions. Therefore, such taps are also called water mixers.

Before dismantling or replacing the unit, the water is first shut off to avoid flooding. These same taps also perform an emergency function - in the event of a leak or rupture of pipes, you can interrupt the water supply to the faulty branch of the water supply with just one turn of the valve. Also, with their help, you can regulate the pressure of water entering the system, increasing or decreasing their throughput by turning the valve. In this sense, taps embedded in the system perform the functions of water shut-off valves (“gate valves”) in main networks.

For example, when a leaky section of a pipeline is replaced in a building, water is supplied to consumers via a reserve branch by switching the valves. Thus, the purpose of the cranes, depending on the type, comes down to the following:

- Adjustment of temperature conditions at the outlet of the system.

- Adjusting the pressure of the supplied water.

- Emergency shutdown of water in a certain section of the pipeline.

- Redistribution of water flows in the system.

Specifications

They are divided according to their capacity into:

- Standard. They dispense no more than 80% of the water flowing in the water supply connected to the tap.

- Full bore. Pass about 100% of the water flow.

- Partial bore. Capable of dispensing approximately 50% water.

According to the maximum operating pressure, they are divided into two classes:

- First class – approx. 1 MPa.

- Second class – less than 0.6 MPa.

Cranes can be made from steel, cast iron, brass, aluminum alloys, and polymer plastics. According to their design, all water taps are divided into two large categories:

The design of a valve-type water tap is fundamentally different from its ball-type counterpart. In this regard, their operational and technical characteristics also differ.

Valve taps

The main working mechanism of a valve-type device is a threaded rod with an elastic gasket at the end. When the valve is turned clockwise or counterclockwise, the rod rises up, freeing the passage for water. By going down, on the contrary, it blocks the flow.

Ball Valves

The ball water valve is based on a ball-shaped control mechanism located inside the body and connected to an external handle. This ball mechanism has a hole designed to allow water to pass through.

By turning the handle, the position of the hole relative to the water flow changes: it is either set parallel to the direction of flow, or perpendicular. In the latter case, the water flow is completely blocked.

Design features of ball valves

In the center of the body, between the PTFE seals (seat), there is a spherical valve mounted on a rotating spindle to allow force transmission from the handle. The wear-resistant and sealed design of the device, quick closing/opening of the passage by turning the shutter by 90° ensures durable and effective use of the locking element.

The principle of operation of the mechanism is as follows: in the initial position, the hole is located at a right angle to the axis of the tap, thereby cutting off the water supply in the water pipeline. When the valve is opened, the inlet hole is in the same axis with the pipe, ensuring free passage of liquid through the shut-off device.

The demand for ball valves in the plumbing equipment market has led to the emergence of a huge range of products, and for most users there is a dilemma: which ball valve is better to choose? In fact, choosing the right product is not easy, due to the variety of taps of low quality and dubious origin. Therefore, it is important to study the technical and physical parameters that determine the functionality, performance of equipment and the piping system as a whole.

Types and differences

When considering the types of such mechanisms, first of all you need to pay attention to their division according to the type of locking mechanism. It is whether we have a ball valve or a shut-off valve in front of us that affects its future use.

So, in a faucet, the shut-off element can be :

In the first case, we are considering a ball valve, the most common and popular in our time. Ball means that the locking element in it is a ball mechanism.

Ball valve design

It is a spherical part with a through hole cut inside. The hole is located on the same spherical plane. Accordingly, the ball mechanism allows water to pass through only in one position.

If we turn it in a different direction, the water will be completely blocked . It is thanks to such a laconic scheme that everything works. In the closed position, the ball mechanism is turned with its blind side towards the flow, eliminating fluid pressure. In the open position, a hole in the ball becomes parallel to the flow, which allows the carrier to be easily transported through the pipes.

The valves are slightly different from the ball samples, because they have a different shut-off element and different functions. The ball valve is best used as a regulator of flow conditions. However, it cannot be installed in an intermediate position. It will be either closed or open, there is no other way.

The situation with valves is different. The locking element in them is a valve, which can be in different positions, from completely open to completely closed. The valve is adjusted by turning the knob, therefore it can be finely adjusted. Gate valves are purchased when you need to not only be able to open or close water, but also regulate its quantity.

Analysis of the properties of a water ball valve (video)

Division by purpose

Also, similar products are divided according to their intended purpose. There are much more differences here and they relate to the basic functionality of this or that part. For example, there are cranes:

- Standard.

- Angular.

- Tees.

- Valves and water folding mechanisms.

The species mentioned above are just the tip of the iceberg, but they are used most often in work, and therefore are best suited as candidates for consideration.

Standard shut-off valves are usually equipped with ball mechanisms and are ordinary bulkheads for isolating individual sectors of water supply systems. They consist of straight couplings, mostly metal. Such products are installed on all heating and water supply systems without exception.

Angular mechanisms are the same as standard ones, only instead of a straight coupling they have a body curved 90 degrees.

Water tap with body in the form of a tee

A tee with a locking mechanism performs slightly different tasks. A tee is a fitting that has not two, like a regular coupling, but three outlets. The tap is placed on the tee mainly in order to be able, if necessary, to redirect the flow from one branch to another.

The tee is used in heating systems, especially modern ones, where temperature sensors constantly monitor the level of the coolant and, if necessary, mix it with heated water.

The water folding mechanism is essentially the same faucet, but with a valve as a regulator. The simplest water folding mechanism is placed on pipes to regulate the flow force. You can see a water tap in any bathroom. It is usually combined with faucets, creating faucets for the sink that are familiar to the eye.

Tips for choosing

When choosing this type of product, you should be guided by the working conditions at your site. There are no universal solutions in plumbing. All of them are good, and all are intended for some specific tasks.

For example, a ball water flow blocker should be used in pipelines for situational isolation of individual branches of the water supply system. You cannot buy it instead of taps with valves. Although they are cheaper, they are not designed to regulate the flow force.

At the same time, valves were designed specifically for regulation. The valve cannot be closed in a split second, but it can be left in the half-closed position for a long time, without any negative impact (the ball mechanism in the half-open position wears out quickly).

Related article: How to install water in a private house

The owner of an expensive water supply system with integrated heating cannot do without tees, and tees with shut-off valves can also be selected automatically. There are taps with electric valves and sensors that can be switched independently using a conventional relay.

I recommend paying attention to the material from which the faucet is made. It must match the pipe material. For metal we take metal, for plastic we take plastic. Of all the different metals, Bugatti brass is the best to buy. It does not conflict with steel and copper, and has excellent characteristics.

Criteria or how to choose a ball valve for hot water

How to choose a ball valve for an apartment? In this case, coupling devices with a threaded connection type are suitable. For one apartment you have to buy on average 5-6 products for piping pumps, collector boilers and other utilities. High demand for products gives rise to the appearance of a large number of taps of dubious quality, which will last a maximum of one or two seasons. Which exit?

To confirm the country of origin and equipment manufacturer, ask the seller to provide a quality certificate and warranty card. Official dealers of famous brands, whom customers trust, can document the originality of the product and dispel all doubts about its quality.

Basic criteria for reliable ball valves for apartments

Housing material

This is one of the main selection criteria.

Ideally, high-quality taps are made from CW617N brass, the high price of which affects the final cost of the finished product. The main component of brass is copper. To reduce costs, some manufacturers use silumin alloys and aluminum-zinc compounds in the technological chain. Ball valves made of silumin are characterized by increased fragility compared to brass products, therefore, answering the question “which valves are better for hot water supply”, silumin is definitely not! They will quickly fail at high temperatures and pressures in the system. Products made from silumin are most often used in the automotive industry, as well as in the serial production of heating and air conditioning equipment.

When the water temperature in the pipe is up to 150 °C and the system pressure is up to 40 bar, brass taps can be used. If water flows in the pipeline at a temperature of 200 °C, and the pressure reaches up to 160 bar, a steel product can be installed. The most optimal solution for installing central heating and cold water supply are cast iron taps.

Product weight and color

The weight of a brass faucet significantly exceeds the similar characteristics of aluminum devices. The weight of the device must correspond to the characteristics stated in the passport and should not differ radically from analogues in weight. In simple terms, choose the one that is heavier among devices with the same markings. Although many manufacturers use a trick, equipping the device with a massive handle, which ultimately affects the overall weight of the mechanism.

Silumin ball valves have a pronounced silver tint, which does not change during oxidation. You can recognize a faucet made of brass in a simple, proven way - remove the top layer of nickel with a sharp object, after which you can observe the characteristic yellowness of the surface.

Ball valve

It is very important that the ball valve has a perfect mirror finish. Branded reliable valves are made of brass, the coating is polished and chrome-plated. Unlike nickel, chromium is not afraid of mechanical stress and boiling of the main parts.

A poor quality mechanism can be easily recognized by its characteristic matte finish with a cloudy tint. You can also take a magnet and check the attraction of the faucet; if it occurs, then the device is made of electrical steel, which is not suitable in terms of performance characteristics for use in water supply systems - the valve will quickly rust and fail when in contact with hot water. Brass is not attracted to a magnet.

Purpose

The definition of “ball valve” is equally applicable to a water tap and a valve. These two types of cranes are distinguished by location and purpose. The water tap is the end point of the water supply; the valve is installed between the elements of the water supply.

Ball valves for water supply are designed to completely shut off the main line or to regulate the flow. In shut-off valves, the design provides for two operating positions “closed” and “open”, excluding intermediate ones. To reduce the water supply, redirect the flow or mix two flows, ball valves of a different design are used, which are specially designed for these purposes.

Note! Operating a shut-off ball valve in a half-closed position will lead to its rapid failure.

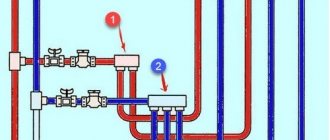

A ball stop valve is installed on water pipes:

- for each branch of wiring to household appliances (water heater, washing machine, dishwasher);

- for each water supply line leading to the sink, bathtub, shower;

- for an individual outlet from the main water supply line (for introducing a water supply system into an apartment or house).

The installation scheme of an internal water supply system with the installation of a shut-off device on each section of the distribution somewhat increases the cost and complicates the installation of communications, but in the long term it is more profitable. In the event of a pipe break or failure of any household appliance, a ball valve allows you to quickly shut off the water supply to the problem area. At the same time, residents still have the opportunity to use running water.

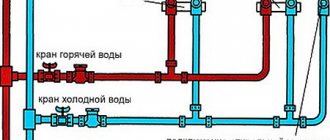

A water-folding ball valve is installed separately for cold or hot water, and is also a common type of mixer. A ball mixer is a valve that is opened and closed not by rotating a knob, but by a lever, turning it left and right to adjust the temperature and up and down to control the flow force.

Note! A regulating ball valve for water supply can be installed to save water consumption for drainage, for example, at a kitchen sink. Here it will combine all the functions: flow reduction, complete overlap, free flow.

Ball valves are used in classic individual heating systems and when installing heated floors. Shut-off valves allow you to isolate individual radiators from the main system, thus regulating the temperature in the room. In the event of a radiator breakdown, this allows you to avoid stopping the heating operation for repairs.

We recommend that you read: Methods and purposes of using a plug for a sewer pipe

The choice of shut-off valves for a heating system is limited by certain requirements for temperature and internal pressure. Not every ball valve is suitable for this due to its operational characteristics.

Type of connection or how to choose a ball valve based on pipe diameter

The type of connection is an important criterion for choosing the desired device model, which determines the features of operation and installation of pipelines. If you choose the wrong faucet according to the type of connection, you will not be able to install it in any other way.

Connection methods:

- Welded. A high-quality ball valve will have high tightness. Due to the complexity of repair or replacement, equipment is usually installed on lines with little wear on the fittings and minimal adjustment of the flow of the transported liquid.

- Flanged. Easy to install and quickly replaced if it fails. This type is used on cranes with DN 15-800 mm. Tightness is achieved by installing a rubber or paronite gasket between the flanges, as well as tight pressing with a bolted connection. The disadvantage of a flange connection is that leaks more often occur due to loosening of the bolt fastening.

- Threaded. Ball valves with a threaded connection type are usually installed on pipelines with low pressure and low temperature of the transported working fluid. Can be used in water supply systems or gas pipelines with a diameter of 8-100 mm in residential premises.

Ball valves are classified by bore diameter:

- Full bore (throughput 90-99%) - the hole in the valve is almost identical in size to the diameter of the pipe. Mounted on pipelines serving intra-house communications.

- Standard bore (throughput 70-90%) - the diameter of the hole in the valve is slightly smaller than the size of the pipe. Installed on utility networks where flow pressure losses are allowed.

- Partial bore (throughput 40-70%) - the diameter of the gate passage is significantly smaller than the diametrical size of the pipeline. Installed to specifically limit the flow of energy resources.

Design and principle of operation

A ball valve is a design similar to a piece of pipe, but with an expanded middle section. This is where the seat made of sealing material is located. There is a shutter inside, which is easy to recognize by its round shape. This is where the shut-off valve got its name – ball valve.

The bolt rotates freely inside the seat. The design may have one, two or three through holes. In regulating models capable of redirecting the flow, there are two of them, if the tap is designed to adjust the pressure of hot or cold water. In faucets, the device is equipped with three holes.

The operating principle of a ball-type valve is based on aligning the axis of the ball hole with the axis of the device body. When the holes coincide, water flows. After turning the shutter 90 degrees, the flow is blocked by the side of the ball where there is no hole.

Design components:

- frame;

- O-rings;

- control lever;

- galvanized steel screw;

- rotating metal sphere with holes;

- stock;

- Teflon valve seals.

The flow intensity is adjusted by rotating the shutter 45 degrees. The hole in the ball is partially blocked, due to which the jet becomes weaker.

The shutter is controlled using a rod that is connected to a lever. The rod is equipped with sealing rings on both sides. For tightness, the hole in the body that allows the rod to pass through also has an O-ring and a washer.

Which taps are best installed on cold water and hot water risers?

Previously, in our article it was already described which valve is better, ball or valve. With the help of the latter, you can not only block, but also regulate the direction of energy flow on the risers. Naturally, it is better to install reliable taps on residential hot water and hot water risers! It’s better to spend money on quality devices than to make repairs for yourself and your neighbors.

|

What types of water taps are there?

An effectively functioning water supply system is a modern system, suitable for expansion and modification. Gone are the days when people made do with a few welded pipelines. Nowadays, in any private home, a plumber cannot do without various fittings, mixing devices and water taps.

Brass water ball valve

In this article we will look at water taps, as one of the most important fittings found almost everywhere, their types and features.

Conclusion

There are many types of water taps. The biggest difference lies in the operating principle of their locking mechanism. It is also important to pay attention to the material of manufacture and throughput.

Water tap 3 4 with internal and external thread

The video in this article will introduce you to additional materials. Make your choice taking into account all the features of the future water supply system.

Did you like the article? Subscribe to our Yandex.Zen channel

Which ball valve is better to choose so that it works for a long time and reliably

Ball valves have long been widely used in pipeline systems due to their simplicity of design and ease of use. However, they must have another valuable quality: reliability. After all, if a crane is made of insufficiently high-quality materials, it may fail prematurely or even cause an accident. There are often cases when, when deciding the question: “which valve to choose?”, in pursuit of savings, buyers purchase ball valves made of cheap aluminum-based alloys, made by some unknown company. And this can result in big troubles and losses - for example, if the tap breaks under the pressure of water, and the apartment of the neighbors below is flooded.

Material of manufacture

As for the material, you should pay attention to the two most commonly used options:

Brass

High resistance to mechanical stress. Withstands any careless handling and survives the most extreme situations.

- High resistance to temperature changes

. Calmly withstands the pressure of hot water and does not deteriorate in the cold. - Ease of installation

. easy to install and dismantle. - No corrosion processes

. Most other metals cannot boast of this property.

Plastic

Polypropylene is a relatively new material, which, despite this, has already managed to take a strong position in the plumbing industry.

Plastic taps boast the following advantages:

- Low cost. Plastic products are always cheap, especially when compared with their metal counterparts.

- Low weight. Due to this, there is no pressure on the pipeline.

- Reliability of joints. The plastic pipeline is installed using a special soldering iron, which guarantees complete tightness. Although it should be taken into account that there are also classic models with threaded connections.

- Neutrality to the aquatic environment - does not rust and does not change the taste of water.

- Durability. Polypropylene decomposes no earlier than after 200 years.

But there are also some difficulties that you need to be aware of when choosing shut-off valves from this material:

- Weak resistance to mechanical stress. The plastic may crack under severe physical stress.

- Fear of high temperatures. Polypropylene begins to deform already at +95 degrees Celsius.

Therefore, depending on the conditions in which your water supply system will serve, choose which material is more suitable.

How to change the inlet tap in an apartment

I will describe a practical version of the stages of replacing the inlet tap in an apartment. The last case is the replacement of an inlet valve by a resident, carried out by an employee of the management company, house series P-44.

Firstly, the shut-off valves were purchased in advance. The choice fell on. They have a nickel-plated brass body and a chrome-plated brass locking ball. One faucet with a handle type, the second with a butterfly handle.

I note that the handle is more convenient than the butterfly handle, but there is often not enough space to turn the “handle,” so they buy valves with a “butterfly” handle.

Read: Preparation, placement and installation of water meters

Secondly. The work was carried out by an employee of the management company, so there was no need to negotiate additionally with him about shutting off the water supply risers.

Thirdly, access to old cranes was provided for the work. Since the toilet, and the risers in the house of the P-44 series are located in the toilet in the plumbing closet, were being renovated, access to them was free. The closet was broken, the toilet was removed. The plumbing cabin was not demolished.

Fourthly, since there was no transfer of risers, replacing the inlet valves took about half an hour. Along with the valves, a bypass was installed on the heated towel rail, so I can’t say exactly the time of work.

What is an entrance tap to an apartment?

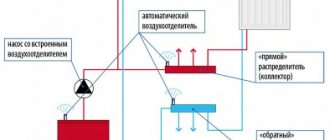

Let me remind you that the internal water supply system of a house consists of: inputs to the building, water metering units, distribution water supply network, water supply risers, connections to plumbing fixtures and installations. As well as water supply, mixing, shut-off and control valves. Read: What is a collector water supply scheme.

As we can see from this regulatory definition, the inlet tap into the apartment belongs to the internal water supply system, namely its utility and drinking part.

Technically, the more correct name for an apartment's inlet tap is a shut-off valve that separates the water supply riser from the apartment's water supply.

It is this boundary location that gives rise to frequent disputes about who should repair it and at whose expense. I will not get involved in this dispute, I will only note that when putting a house into operation, only the installation of inlet shut-off valves is required. Read: Who should check and replace water supply risers

If during the operation of the house the residents do not make other decisions, the water supply riser valve is part of the common property of the apartment building.

Since residents pay for the maintenance and repair of housing, it is quite reasonable to assume that emergency repairs (replacement) of the inlet shut-off valve should be carried out by the building management company or HOA. The same applies to major repairs or planned repairs of the house’s water supply system, and with it the valves.

Read: Water supply riser in an apartment and its replacement

However, it seems to me that if a tenant decides to renovate the bathroom at his own request, replacing the inlet shut-off valve is carried out at his expense.

For example, you decide to replace the water supply risers within the boundaries of your apartment. It is illogical to replace risers at your own expense, and valves at the expense of the repair fund. Although there may be options.