ru.natapa.org

Iron and steel are two substances that are often found in various applications such as cookware, construction, etc. The two substances are often confused as they are similar in color and composition.

Steel is actually made by mixing iron with carbon; therefore, it is a by-product of iron. However, they are still different from each other since iron is also used to make various other alloys. Iron is a chemical element that is found in abundance in the earth's crust. It often makes up the Earth's outer and inner core and is the fourth most abundant element in the crust. It is found on the periodic table of elements under the symbol Fe and atomic number 26. The presence of iron is common on rocky planets such as Earth due to mergers in high-mass stars. Rocky planets typically produce nickel-56 (which decays into the most common isotope of iron) from the latter exothermic nuclear fusion reaction. Iron exists in various oxidation states from -2 to +6, with +2 and +3 being the most common.

Pure iron is a shiny silver-gray, but it is very susceptible to erosion from rust when exposed to moist air. Pure iron is also very soft and malleable, but cannot be obtained by melting. Due to the lack of technology in the old days, copper alloys were widely used in history until this process was created. Iron is often mined from iron ores that are found in the earth's crust. Iron ores undergo an extraction process to extract iron from the rock and other substances. Iron is more commonly found in alloy forms such as steel alloys, raw iron, wrought iron, and cast iron. These alloys are significantly strengthened and hardened by impurities such as carbon. If iron contains carbon in the ratio of 0.2% and 2.1%, it becomes steel, which can be 1000 times heavier compared to pure iron. Crude iron metal is produced in blast furnaces using coke (fuel) to turn the ore into pig iron.

Iron also plays an important role in biology, where it forms complexes with molecular oxygen in hemoglobin and myoglobin and helps transport oxygen and proteins in the body. Pure iron materials have generally not been discovered since ancient times due to the high level of corrosion of iron. The metal balls found in Hertz, Egypt by J. A. Wainwright date back to 3500 BC and also contain about 7.5% nickel, making it an iron alloy. Iron is also known to be used to create forging weapons and tools. It is believed that the first production of iron was in the mid-Bronze Age, when molten iron was found in Mesopotamia between 2700 and 3000 BC. BC. In fact, the Hittites are considered the first people to understand the extraction of iron from its ores and valued it highly in their society. Period between 1500 and 1200 BC was called the Iron Age. Wrought iron and cast iron are most commonly used in various fields such as construction, cutlery, and steel production.

Steel is an alloy, that is, a mixture of two or more metallic elements or one metallic and a non-metallic element. It is most often made by fusing iron and carbon together. Although carbon is the most common alloying material for iron, other materials such as manganese, vanadium, chromium and tungsten can also be used. Carbon acts as a strengthening agent, preventing any dislocations in the crystal lattice of the iron atoms and sliding together, making the steel more durable. By changing the amount of alloying elements and the form of their presence in steel, it is possible to control qualities such as hardness, ductility and tensile strength of steel. Although steel is known to have existed for about 4,000 years, it was not widely produced until the 17th century due to the introduction of the Bessemer process. This process made steel production cheaper, more efficient and easier.

Steel is made by feeding iron into a process known as smelting, in which the iron is extracted from the iron ore, excess oxygen is removed, and the iron is combined with chemical partners such as carbon. Compared to pure iron, steel is more resistant to rust and has better weldability. Other metals are added to the iron-carbon mixture to influence the properties of the steel. Metals such as nickel and manganese increase the tensile strength of steel and make the austenitic form of the iron-carbon solution more chemically stable, while chromium can increase hardness and melting point. Steel is a highly malleable substance and is one of the most commonly used alloys in the modern world. It is found in various applications such as tools, utensils, automobiles, weapons and buildings. It is also the most common alloy, producing nearly 1.3 billion tons annually.

How steel differs from iron: features and differences - Which is better

Steel: types, properties, grades, production

Steel and products made from it have become so firmly established in the life and everyday life of modern people that it is difficult to imagine existence without metal objects. When it comes to dishes, small tools, household appliances and equipment, it is not at all necessary to know the brand, classification of alloys, and their areas of application.

This information is important, rather, for those who have decided to start building their own housing and do not know which metal products are suitable for these purposes. So, what steel is, what types of steel exist, and what properties this alloy, popular today, has, will be discussed in the construction magazine samastroyka.ru.

Steel grades

Despite the fact that steel is clearly recognized as the most popular iron alloy, a unified system for marking its types has not yet been developed. The simplest and most popular is alphanumeric marking.

High-quality carbon steels are marked using the letter “U” and a two-digit numerical value (in hundredths%) of the level of carbon in their composition (U11). In the grade of ordinary carbon steels, the letter is followed by a number indicating the amount of carbon in tenths of% - U8.

Letters are also used in marking alloy steels. They indicate the main element used for alloying. The following figure shows the concentration of this element in the steel composition. The letter is preceded by a number corresponding to the proportion of carbon in the metal in hundredths of a percent.

For example, the letter “A” at the end of a high-quality alloy mark indicates its quality. The same letter in the middle of the mark notifies the main alloying element, in this case it is nitrogen. The letter at the beginning of the stamp indicates that this is automatic steel.

The letter “Ш” at the end of the marking, written through a hyphen, indicates that this is an especially high-quality alloy. High-quality steels are not marked with the letters “A” and “W”. In addition, there are additional markings indicating the special characteristics of steels. For example, magnetic alloys are o, and electrical alloys are “E”.

Alphanumeric marking is perhaps one of the simplest and most understandable for the consumer. Others, more complex, are available only to specialists.

Difference between iron and steel

Iron and steel are two different types of material, but iron is also the main component of steel.

The main difference between iron and steel is iron is an element while steel is an alloy of iron . Both of these materials are widely used in the manufacture of various objects on an industrial scale.

Steel was actually an improvement made to make the use of iron more desirable and durable. The quality of the rust was a key factor that was taken into account here. However, not all types of steel exhibit this quality; steel that displays this property is called "stainless steel".

What is iron

Iron is a popular element as it is found in abundance on earth. In the periodic table it is classified as a ' d block element' because it has its valence electrons in 'd' shells. Therefore, iron is usually called a transition metal.

The atomic number of iron is 26. This means that it is the 26th element in the periodic table by weight. And its electronic configuration is; 1s2 2s2 2p6 3s2 3p6 4s2 3d6, Looking at the electron configuration of iron, it is clear that it has 6 “d” electrons.

When iron forms ions, it settles into two main oxidation states; +2 and +3. Compounds in the +2 oxidation state are called iron compounds, and compounds in the +3 oxidation state are called iron compounds.

This nature of having multiple oxidation states is common among "d" block elements.

When iron forms the +2 oxidation state, it only removes its 4s2 electrons. But when ferric ions are formed, both 4s and 3d electrons are removed.

In general, depending on the final electron configuration, ferric ions are more stable in air than ferrous ions. However, iron is susceptible to rust.

Due to the presence of moisture and oxygen in the air, the iron element is easily oxidized and forms iron oxide, and further oxidation can lead to the formation of iron oxide, which is a dark brown layered substance called "rust".

Iron forms many stable compounds, and the ore of the metal is used for a variety of industrial applications. However, iron is ductile and less durable for some application needs. Thus, improvements in the properties of metal were considered, and Steel was born as a result.

Steel and metal 2021

Steel vs metal

The main difference between steel and metal is that steel is an alloy of metallic iron, while metals are elements naturally present in the earth's crust and are exported from different parts of the world. Metals are non-magnetic, ductile and non-corrosive elements with high resistance to tarnishing. Metals are also safe and hygienic; they are present in the biological system of the human body and are not harmful when implanted.

Steel is made by adding a controlled amount of carbon to iron. Various metals are added to produce nearly sixty grades of steel alloys. For example, chromium is added to steel to make stainless steel. Unlike other metals, steel is known for its strength and fatigue resistance. It can support tons of loads for a long time compared to other metals.

Metal ores must be refined before use. Impurities called slag or other metals are removed. They are then combined with other metals to produce greater strength and quality. Metals are plated to produce more shine and stability, such as nickel-plated brass or gold-plated silver. Steel is a compound of iron and carbon made in furnaces. Steel has toughness and shrinks when cold. In extreme weather conditions, such as cold temperatures, can affect steel to the point of brittleness, but metals can withstand sub-zero temperatures. Metals have attributes of luster, ductility and malleability that make their application in various industries very easy. They are used to make coins, jewelry, weapons, surgical implants, industrial products, household items, engineering and construction, architectural design, and decorative items. Steel is used to make strong structures, tools, automobile bodies and other components, building materials, bridges, ships, guns, etc. Steel is corrosive and can rust if carbon is present in high levels. It is magnetic and not a powerful thermal or electrical conductor like metal. Steel is made hygienic by adding metals such as chromium. Steel is a man-made element and is much cheaper than gold, silver, aluminum or other metals. Metals are expensive, and some of them are considered monetary objects, such as gold and silver.

Metals have high melting or freezing points; this means that the freezing point of a metal is equal to its boiling point. The boiling point of steel is 3000 degrees. In this modern era of technology, almost all metals found are either alloyed or combined with other metals to enhance their strength, hardness and resistance forces. Pure metals cannot be used widely or economically. Steel is economical and is used to determine bearing weight in a variety of ways.

1. Steel is not a metal, but an alloy of iron made in furnaces.

2. Metals exist naturally in the earth's crust and are derived from the earth.

3. Steel is strong and is intended for structures used to build houses, scrapers, ships or tools.

4. Metals are flexible, ductile and are used to make jewelry, decorative items, and surgical implants.

5. Steel can rust and is magnetic. Metals are anti-corrosion and non-magnetic, and are also high thermal and electrical conductors.

How is iron different from steel?

Iron and steel are two different types of material, but iron is also the main component of steel.

The main difference between iron and steel is iron is an element while steel is an alloy of iron . Both of these materials are widely used in the manufacture of various objects on an industrial scale.

Steel was actually an improvement made to make the use of iron more desirable and durable. The quality of the rust was a key factor that was taken into account here. However, not all types of steel exhibit this quality; steel that displays this property is called "stainless steel".

What is steel

Steel differs from iron in that it is an alloy, not an element. An alloy is a mixture of different metals or a metal mixed with another element.

Steel is made by mixing a small percentage of carbon with iron , carbon usually not exceeding 2.1% by weight.

The presence of carbon gives steel more strength than just iron and becomes more usable for a variety of applications. However, the higher the carbon content, the more brittle the steel will be.

Steels also have other alloying elements such as chromium, nickel and manganese. These elements are added to prevent the steel from rusting. What happens here is that instead of oxidizing the iron, chromium, which has a lower oxidation potential, is oxidized, protecting the iron. This way the steel remains shiny for much longer.

Definition

Iron is a pure element.

Steel is an alloy where iron is the main component.

Rust

Iron oxidizes easily to form rust, and the shine does not last long.

Alloying elements in steel protect it from rust; This way the shine lasts longer.

Elemental Composition

Iron is an element in itself.

Steel is mainly composed of iron and carbon and also contains percentages of elements such as chromium, nickel, etc.

properties

Iron is not as strong as steel and is less brittle.

Adding carbon to Steel makes it stronger than Iron. However, this also makes the steel brittle.

Applications

Iron is used for some applications; however, it is not used in finished products and structures where many benefits are required. Therefore, the use of iron as a pure metal has reached its limit.

Much of the use of iron has been replaced by Steel since it has many desirable properties.

Image credit:

Roantrum's Iron Bridge 6 - Flickr.

How cast iron differs from steel: basic properties and distinctive characteristics

Ferrous metallurgy products are widely used in many sectors of the national economy, and ferrous metal is always in demand in construction and mechanical engineering. Metallurgy has been successfully developing for a long time, thanks to its high technical potential. Cast iron and steel products are most often used in production and in everyday life.

Cast iron and steel both belong to the group of ferrous metals; these materials are alloys of iron and carbon that are unique in their properties. What are the differences between steel and cast iron, their main properties and characteristics?

Steel and its main characteristics

Steel is a deformed alloy of iron with carbon , which is always up to a maximum of 2%, as well as other elements.

Carbon is an important component because it gives strength to iron alloys, as well as hardness, thereby reducing softness and ductility.

Alloying elements are often added to the alloy, which ultimately results in alloyed and high-alloy steel, when the composition contains at least 45% iron and no more than 2% carbon, the remaining 53% being additives.

Steel is the most important material in many industries; it is used in construction, and as the technical and economic level of the country grows, the scale of steel production also increases. In ancient times, craftsmen used crucible melting to produce cast steel, and this process was low-productivity and labor-intensive, but the steel was of high quality.

Over time, the processes for producing steel changed; the crucible method was replaced by the Bessemer and open-hearth methods of producing steel, which made it possible to establish mass production of cast steel.

Then they began to smelt steel in electric furnaces, after which the oxygen-converter process was introduced, which made it possible to obtain especially pure metal.

Depending on the number and types of connecting components, steel can be:

- Low alloy

- Medium alloyed

- High alloy

Depending on the carbon content, it is:

- Low carbon

- Medium carbon

- High carbon.

The composition of the metal often includes non-metallic compounds - oxides, phosphides, sulfides; their content differs depending on the quality of the steel; there is a certain classification of quality.

The density of steel is 7700-7900 kg/m3 , and the general characteristics of steel consist of such indicators as strength, hardness, wear resistance and suitability for various types of processing.

Compared to cast iron, steel has greater ductility, strength and hardness.

Due to its ductility, it is easy to process; steel has a higher thermal conductivity, and its quality is improved by hardening.

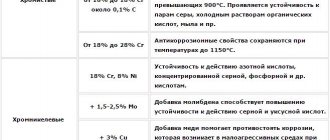

Elements such as nickel, chromium and molybdenum are alloying components, each of which gives steel its own characteristics.

Thanks to chromium, steel becomes stronger and harder, and its wear resistance increases. Nickel also imparts strength, as well as toughness and hardness, and increases its anti-corrosion properties and hardenability.

Silicon reduces viscosity, and manganese improves weldability and hardening properties.

All existing types of steel have a melting point from 1450 to 1520°C and are strong, wear-resistant and deformation-resistant metal alloys.

Cast iron and its main characteristics

The basis for the production of cast iron is also iron and carbon, but unlike steel, it contains more carbon, as well as other impurities in the form of alloying metals. It is fragile and breaks without visible deformation. Carbon here acts as graphite or cementite and, due to the content of other elements, cast iron is divided into the following varieties:

- White - where cementite is in the lead in the majority, this material is white at the fracture. This component is fragile and at the same time hard. It is easy to work, which imparts malleability to cast iron.

- Gray - in this variety, a large proportion is graphite, due to which the cast iron is ductile. Ready cast iron has a low melting point, is soft, and is easier to cut.

- Malleable - achieved by firing white cast iron, it is simmered in special heating furnaces at a temperature of 950-1000 ° C. The inherent hardness and brittleness of white cast iron are reduced; it is not forged, but only becomes more ductile.

- High-strength cast iron alloy - it contains nodular graphite, which is formed during crystallization.

Types and grades of steel

Steel. Types and grades of steel. Their application.

Steel is an alloy of iron and carbon with other elements, the carbon content in it is no more than 2.14%.

The most general characteristic is that steel is classified according to its chemical composition:

carbon steel (Fe – iron, C – carbon, Mn – manganese, Si – silicon, S – sulfur, P – phosphorus). Based on carbon content, it is divided into low-carbon, medium-carbon and high-carbon. Carbon steel is designed for statically loaded tools.

alloy steel - alloying elements are added: nitrogen, boron, aluminum, carbon, phosphorus, cobalt, silicon, vanadium, copper, molybdenum, manganese, titanium, zirconium, chromium, tungsten, nickel, niobium.

According to the production method and impurity content, steel differs:

ordinary quality steel (carbon less than 0.6%) – corresponds to GOST 14637, GOST 380-94. St0, St1, St2, St3, St4, St5, St6. The letters “St” indicate ordinary quality steel, the numbers indicate the marking number depending on the mechanical properties. It is the cheapest steel, but inferior in other qualities.

high-quality steel (carbon or alloy) - GOST 1577, carbon content is indicated in hundredths of % - 08, 10, 25, 40, the degree of deoxidation and the nature of solidification can additionally be indicated. High-quality carbon steel has high ductility and increased weldability.

Low-carbon high-quality structural steels are characterized by low strength and high ductility. Parts for cold stamping are made from sheet steel 08, 10, 08kp. Bolts, screws, nuts, axles, hooks, studs and other parts for non-essential purposes are made from steels 15 and 20.

Medium-carbon quality steels (st. 30, 35, 40, 45, 50, 55) are used after normalization and surface hardening for the manufacture of parts that have high strength and core toughness (axles, screws, bushings, etc.)

Steel 60 - steel 85 have high strength, wear resistance, and elastic properties. Crane wheels, rolling rolls, compressor valves, springs, leaf springs, etc. are made from them.

high quality - complex chemical composition with low phosphorus and sulfur content - according to GOST 19281.

Steel is also divided by application:

a) construction steel - carbon steel of ordinary quality. Has excellent weldability. The number indicates the conditional number of the steel composition according to GOST. The higher the reference number, the higher the carbon content, the higher the strength of the steel and the lower the ductility.

St0-3 - for secondary structural elements and non-critical parts (flooring, railings, lining, washers)

St3 is used for load-bearing and non-load-bearing elements of welded and non-welded structures and parts that operate at positive temperatures. GOST 380-88.

The quality standard provides for steel with an increased amount of manganese (St3Gsp/ps, St5Gsp/ps).

b) structural steel - GOST 1050

Carbon-based high-quality structural steels are used in mechanical engineering, for welded, bolted structures, for roofing work, for the manufacture of rails, railway wheels, shafts, gears and other parts of forklifts. The numbers in the marking indicate the carbon content in tenths of a percent.

St20 - lightly loaded parts, such as rollers, copiers, stops,

St35 - experiencing small stresses (axles, rods, levers, disks, traverses, shafts),

St45 (st40Х) - requiring increased strength (shafts, couplings, axles, racks)

Structural alloy steels are used for tractor tracks, the manufacture of springs, leaf springs, axles, shafts, automobile parts, turbine parts, etc.

c) tool steel - used for cutting tools, high-speed steel for cold and hot deformation of materials, for measuring instruments, for the production of hammers, chisels, chisels, cutters, drills, files, razors, rasps.

U7, U8A (the figure is tenths of a percent in terms of carbon content). Carbon steels are produced in high quality and high quality. The letter "A" stands for high quality carbon tool steel.

d) alloy steel - universal steel containing a special impurity. Silicon content more than 0.5%, manganese more than 1%. GOST 19281-89. If the content of the alloying element exceeds 1 - 1.5%, then it is indicated by a number after the corresponding letter.

low-alloy steel - where alloying elements are up to 2.5% (09G2S, 10HSND, 18KhGT). Low-alloy steel can be used in conditions of the far north, from -70 degrees C. Low-alloy steel is distinguished by greater strength due to a higher yield strength, which is important for critical structures.

medium alloyed (2.5 -10%),

highly alloyed (from 10 to 50%)

Steel 09G2S is used for steam boilers, apparatus and containers operating under pressure and temperatures from minus 70 to plus 450 degrees; it is used for critical sheet welded structures in chemical and petroleum engineering, and shipbuilding.

Steel 10HSND is used for welded structures in chemical engineering, shaped profiles in construction, and carriage building.

18ХГТ is used for parts operating at high speeds under high pressure and shock loads.

e) special purpose steel - steel with special physical properties. It is used in the electrical industry and precision shipbuilding.

The weldability of steel is affected by the degree of its deoxidation. According to the degree of deoxidation, steel is classified:

What's the difference between steel and iron?

Iron and steel are two different types of material, but iron is also the main component of steel.

The main difference between iron and steel is iron is an element while steel is an alloy of iron,

Iron and steel are two different types of material, but iron is also the main component of steel.

The main difference between iron and steel is iron is an element while steel is an alloy of iron . Both of these materials are widely used in the manufacture of various objects on an industrial scale.

Steel was actually an improvement made to make the use of iron more desirable and durable. The quality of the rust was a key factor that was taken into account here. However, not all types of steel exhibit this quality; steel that displays this property is called "stainless steel".

St-3 is the most popular alloy in the world

February 18, 2019

The most popular iron-carbon alloy in the world is steel. Today there are more than 3,500 different grades of steel, which differ in physical and chemical properties.

Moreover, 75% of the total number of modern brands were created over the past 20 years.

Imagine if the Eiffel Tower were built today: its weight would be three times less! And modern cars designed using new brands have become much stronger and at the same time lighter than in the past.

Visitors to the metal warehouse could notice that our assortment is mainly represented by grade 3 steel (also known as St3, structural carbon steel of ordinary quality St3).

This alloy is the very “dough” from which one of the most popular materials for making various metal structures is obtained.

Here you can find other, less popular, types of steel, but about them another time.

Let's talk about the composition

An important component of steel is carbon. Steel 3 contains a small amount of carbon (0.14-0.22%). This is enough to give the alloy strength and hardness, but not to reduce the ductility and toughness of the alloy. After all, the more carbon in the composition, the harder the steel, but the more fragile it is.

Differences between cast iron and steel

| 18.01.2018 18:12 |

Steel and cast iron are some of the most popular types of casting materials used in industry. They are quite similar in their properties; you can understand the difference between steel and cast iron in different ways. Some of the methods can only be used in a factory environment using high-precision equipment, while others are suitable for use at home.

The main difference between cast iron and steel is the composition of the metals. Steel is an alloy of iron (45%) with carbon (no more than 2%) and alloying impurities, which can be substances such as nickel, molybdenum or others. This metal is characterized by high strength, ductility, and ease of processing. Cast iron also contains iron and carbon, but the latter should be 2% or more. Alloying additives are usually silicon, phosphorus, manganese or other components.

History of iron[edit]

The Age Before Metals[edit]

It’s worth touching on that too. The main materials of Cro-Magnon stone tools were flint and quartz. Descendants accumulated vast practical experience in their manufacture and so carefully selected small pebbles with sharp edges, and the craftsmen very carefully chipped larger ones into them that they managed to assemble spearheads, arrowheads, harpoons from them, and a little later - table knives, awls and even needles. According to archaeologists, the best stone knives were not much inferior to modern ones in terms of sharpness and working qualities. In fact, many people still use ceramic knives - this is also stone, but artificial. This required skill and experience in selecting blanks on the verge of HIGH art and a huge amount of time searching for the blanks themselves. Sometimes these craftsmen, while searching, came across pieces of a strange reddish stone with a strange shine...

Copper and bronze[edit]

Copper is the first metal that ranks behind hydrogen in the activity series (that is, it does not lend itself to electrochemical corrosion). Copper salt comes into contact with any base metal (for example, iron) - iron forms salt, copper precipitates. What follows from this? And the fact that, by analogy with gold, there are copper nuggets. This is how forging was invented. Then they came up with the idea of heating copper to get rid of problem areas in nuggets, which resulted in copper smelting - due to its inactivity, copper was the only base metal that can be easily smelted from ores.

Copper made bad tools, but they could be repaired - unlike stone ones, which had to be hewn out again, for a long time and with difficulty. And if things are really bad, you can melt it and re-cast it in the mold. The Copper Age covers approximately the X-IV millennium BC. e.

Then they came up with arsenic bronze, an alloy much stronger than copper, but with three major drawbacks:

- Melting is extremely harmful (remember the lame Hephaestus - he swallowed arsenic vapor).

- Scrap is not recycled - the melting point is lower than that of pure copper, but when melted, arsenic burns and evaporates.

- The alloy is strong but fragile. like tin bronze, the quality of the metal depends greatly on the proportions.

Later, in the first half of the 2nd millennium BC. e., switched to tin or antimony bronze. But there were only one or two deposits of tin and antimony in the ancient world, but the owners of these mines and resellers made wild profits from them.

You can (will) read more about how malleable oxidized ores gave copper to man and how recalcitrant sulfide ores were roasted in the main article.

Meteoric iron[edit]

Black iron stones are quite processed using technologies familiar with copper. Usually meteorites contain admixtures of nickel and precious metals

, giving iron hardness. The weapon turned out to be decent (at the level of modern kitchen knives), but due to its high cost, it ended up in the treasuries of kings rather than participating in battle.

Native iron is also found; the closest deposit now selected to the ancient world was in Germany. Significant deposits of it were and are in Sweden; less significant mines are and have been found throughout the Alpine region.

Cheese furnace and the technologies that arose around it[edit]

The oldest smelted iron began to be obtained along the shores of the Black Sea in the 2nd millennium BC. e. Ferrous sand was burned in a cheese furnace (a pipe built from earth and clay) with charcoal.

2C + O2 = 2CO 3CO + Fe2O3 = 2Fe + 3CO2

It is curious that due to the high melting point of iron (slightly below 1600°), the reduction process took place without melting it, in the solid phase. This prevented the resulting iron from getting rid of inclusions, slag and unreacted ore.

What happened was called kritsa - a mixture of iron and slag. To get rid of slag, the kritsa was forged with a hammer. The iron turned out to be crappy, worse than the bronze of that time. In addition, the cheese furnace was disposable; a new furnace had to be built for a new melt. Through repeated forging, combined with treatment with a good flux, especially advanced craftsmen obtained “white iron” that was almost free of slag - but it cost at least an order of magnitude more than usual.

At the turn of the 1st and 2nd millennia BC, the completely expected happened: the explored tin deposits were worked out, but no new ones were found. Someone began to pass on bronze swords by inheritance, someone switched to “junk metal”... In order to get “Tison, a sword worth a thousand marks”, and not a piece of iron from the Kukuev coat of arms, many problems had to be solved, and they were solved by unknown blacksmiths for a good millennium .

- How to get rid of silicon impurities - for this, flux (limestone) was added along with iron sand.

- How to control carbon content in iron. This was done by blacksmiths literally by eye, according to the color of the heat, and was passed on from one to another. The best products were made from blanks that had lain in the ground or water for a couple of years so that the worst parts would rust.

- Crystalline iron could only be obtained from a melt, and without it there was a choice: a lot of carbon is brittle, a little is ductile. I had to forge packages of blanks with different carbon contents - here you have the famous production technologies of Japanese katanas (although they did this everywhere). Plus hardening the edge of the sword. And if you fold and forge many times, you get damascus (not to be confused with damask steel).

It is not surprising that the blacksmith's profession had a magical touch. They usually forged in pairs: the blacksmith knocked with a small hammer, the big hammer hammer hit this place with a hefty sledgehammer! So the famous Russian toy “man and bear” had a very real prototype.

So the Iron Age crept up unnoticed for more than a millennium: by the 1st millennium BC. e. Basic technologies for iron were obtained; by the 1st millennium, in terms of price/quality ratio, iron surpassed bronze; in the first centuries of our era, mass-produced iron was obtained, superior to any bronze, and this made it possible, for example, to massively build houses from logs. One of the reasons for the emergence of the Middle Ages was iron: the sword, perfected by the 9th century, required iron, and good iron at that. Plus a challenging learning curve. And also armor, also iron. Together with the good nutrition inherent to the landowner, the result was a man-tank, who was difficult to kill, and not profitable to kill: it was better to take prisoner for a ransom. This is how feudalism turned out: we fight (and this business was not as dangerous as it seems), but we receive land for military service.

Iron was expensive, and the carpenter’s advertisement was that he built “without a single nail.” Nails were used in shipbuilding, but more often wooden, less often copper and bronze, because they did not know how to make stainless steel at that time, cast iron was rarely used, and iron and steel instantly corroded at sea. And although metal parts have been used in shipbuilding since antiquity, but exclusively tightening and through connections with their careful coating and protection from air: it was simply impossible to build large ships without the use of metal purely from wood for reasons of strength. Steel, bronze, cast iron so-called. “efficient things” in the form of eyelets, lanyards, carbines, etc. were used even before Columbus, and the ship’s blacksmith was an obligatory member of the crew long before Vasco da Gama’s squadron sailed to India.

But in carts, iron and other nails were used quite widely - all the same, the service life of those parts that were nailed together was lower than the service life of nails, but with iron nails the repair was faster.

Even now scrap metal is not garbage, but scrap, but then they reforged everything that was metal! Blacksmiths instantly appeared at the fire looking for nails. Before wire nailing appeared, forged nails looked like a tetrahedral pyramid - this is how railway crutches still look (because they are huge) and horseshoe nails (it’s more convenient to bend).

Attention, error!

In one of the mobile games I saw a quest: help the gnomes find a coal deposit so that they don’t burn the trees. I don’t remember, for fuel or for iron, I’ll explain both. For fuel: coal has been known since ancient times (no high-tech is needed, remember the Donbass “diggers”), but coal is mined in deposits and consumed everywhere. Only the railway made it possible to transport coal. On iron: Coal contains sulfur, which makes iron brittle. We need not just coal, but coke.

And the second mistake

, which has become a cliche - to draw some cool-looking weapon without thinking about combat techniques and forging technologies.

For the third error

there is a separate article: Cast a sword.

- With a wick - the swords were cast from bronze and copper: it is useless to forge them due to the peculiarities of the crystalline structure, except to beat off the edge in a cold manner for the sake of hardening, and the melting point is quite low for ancient technologies.

Transition to industrial iron processing technologies[edit]

Somewhere in the 1st millennium, the Indians came up with a stukofen, or domnitsa - a permanent furnace for smelting iron with a high (4 m or more) pipe for draft. The bellows were pumped by several people, and even a water engine. In Stukofen, the Indians managed to make damask steel - but this required high-quality ore and graphite instead of charcoal. And the process of carburizing iron itself is not fast. Stukofen was already producing up to 250 kg of kritsa per day - but he converted a lot of ore into cast iron. (According to other sources, the ancient Romans were also able to obtain cast iron). This cast iron had no use and went to waste: it was possible to separate the iron from the slag only by forging, and cast iron cannot be forged.

It is not surprising that stukofen spread when other iron technologies were brought to standard - around the 14th century.

New oven, Blauofen (XV century). We made the pipe even higher and added preheating of the air. Iron became better, there was more cast iron, but it also became better - building blocks and cannonballs could be cast from it.

And then, around the 16th century, they made such a mechanism (a shouting horn). There is coal on the grate and cast iron on it. Under the grille is the air supply. The cast iron melts, flows down, and there the carbon oxidizes. The melting point of iron is higher than cast iron, a piece of iron thickened, they pulled it up with a crowbar - disgusting work, you know. When 50-100 kg of kritsa has accumulated, it is taken out for forging. This turned out to be a revolution: now iron can be made from cast iron (the so-called conversion process)! True, a problem arose - due to contact with burning coal, a lot of sulfur and phosphorus, harmful impurities, passed into the iron. They solved it a little later by creating a reflective forge: the coal burns separately, and the fireplace lies on the hearth separately, and hot air from the firebox passes over it, and the heat is reflected from the curved ceiling (see below about the puddling forge). From a chemist’s point of view, the method is absurd: fuse iron with carbon and then burn the carbon? [1] But there was no other technology. Here they no longer began to waste time on trifles: they blew harder and poured all the metal into the cast iron. What happened was called a blast furnace - from the word “to blow.” Hence “arrogant”, that is, “inflated”.

By the way, another common myth is that krits were folded and forged many times in order to obtain a kind of multi-layered super-duper metal, at the same time so hard that it could cut a falling hair, and so flexible that it could be wrapped around the waist instead of a belt. In fact, when steel is forged, it loses carbon from the surface due to oxidation, and forging of this kind was the only way to remove excess carbon at temperatures available at that time. Such iron was called “welding” (because the layers were welded together by forge welding), which is somewhat counterintuitive for contemporaries. The work was very labor-intensive and unproductive, so when it became possible to maintain iron in a molten state, they abandoned it, crossed themselves and switched to puddling - mixing molten cast iron with a poker with the addition of oxidizing agents.

- Iron was repeatedly welded not in order to burn off carbon - with the help of cheese reduction, obtaining high-carbon steel in sufficient quantities is still a hemorrhage. And in order to even out the chemical composition. In addition, in principle it was possible to increase the amount of carbon in the iron by heating it in the reduction zone of the forge flame.

To this day, cast iron is made in blast furnaces, descendants of the then

, the only fundamentally new ones are coke and operation on natural gas. But the conversion processes today are different, and now the whole history of ferrous metallurgy is about how they began to turn cast iron into iron and steel.

Coke

- almost pure carbon, obtained by burning coal without access to air - was invented by the ancient Chinese. Apparently, at first they used it to heat the houses of nobles, and then they used it in metallurgy. The history of coke in the West is similar: by the 17th century. There was a firewood crisis in England; the smelting of cast iron was banned (it was imported from Russia). But the question arose: how to heat the breweries (coal smoke harmed the booze). In the 17th century Coke was invented, and only by the 18th century. he was loaded into the blast furnace.

A water engine could pump bellows, but to replace a big hammerman with a machine, a steam engine was needed (early 18th century). The result was a forging press.

- Until the middle of the 19th century (or even until the end of it), hammers driven by a water wheel were used in the form of a sort of lever-driven mega-sledgehammer.

At the end of the 18th century. Henry Cort invented the puddling furnace - the main difference from the clarion forge was the insulation of cast iron from the fuel. The iron production process was equally nasty. (The same Cort, by the way, invented the rolling mill.)

Lyrical digression:

One of the attributes of steampunk is a pulley with crooked spokes. By that time, cast iron had become good enough that it was already possible to cast it, for example, into car frames - and these same pulleys. But cast iron remains fragile, it can break even from thermal expansion - therefore, in order to somehow spring back, the knitting needles began to be made crooked. And the number of spokes was made odd - so that when the casting shrinks, the round pulley would not be pulled into a polyhedron (the pressure from each spoke is distributed over two opposing spokes);

In 1856, Henry Bessemer developed the first furnace to produce real steel, the so-called Bessemer converter. This is a pear-shaped vessel with holes at the bottom. The converter is placed on its side, cast iron is poured in, the blast is turned on and the converter is placed vertically. The words “Bessemer steel” became a kind of brand: now what a blacksmith assembled from strips of different types of iron could be made, for example, by casting or rolling, in large quantities and cheaply. And since an ingot, unlike a forging, is quite homogeneous, such steel is convenient to process by cutting.

Modern technological processes of ferrous metallurgy[edit]

In 1865, Pierre and Emile Martin developed the open hearth furnace. It is based on a reflective arch, which reduces the contact of flue gases with metal, and regenerators that preheat the air to a high temperature. The latter made it possible to raise the temperature of the flue gases and melt the steel.

While the Bessemer converter could load scrap metal in very small quantities, the open hearth made scrap metal real scrap again. Open-hearth and Bessemer steel had slightly different properties, but because the open-hearth process was more repeatable, it long became the dominant technology for steelmaking. In 2018, the last open-hearth furnace was closed in Russia, and these furnaces remained only in India and Ukraine. Nowadays steel is melted in oxygen converters and electric furnaces.

Lyrical digression.

People often confuse recycling (using an item several times for the same or a different purpose in its original form), recycling (processing waste into something useful), decontamination (removing waste from harmful properties) and landfill (placing waste where it does not belong). will interfere).

Accordingly, scrap

, or

recyclable materials

, is waste that in a given technical and economic situation can be processed into something useful.

The steel was blown, of course, with air. And it contains 78% nitrogen, and it is harmful. In the 20th century they made cheap oxygen, and they began to put it into the open-hearth (the temperature in the converters developed such that it burned out). In moderate quantities, of course, the refractories melted there too. In 1952, the oxygen-converter process was mastered: oxygen was supplied from above through a pipe, and scrap was constantly added to it for cooling.

Good steel contains many alloying elements. But how can you make sure that they fuse with steel and not oxidize into slag? For this, at the beginning of the 20th century. invented electric furnaces - arc and induction. They can have any atmosphere: even oxidizing, even reducing, even neutral, even completely inert. First, the required amount of carbon was achieved in an oxidizing atmosphere, the slag was removed, ferroalloys with the required elements were added, and heated without access to air. In an arc furnace, an arc was created between cast iron and a graphite electrode, and in an induction furnace, they were heated with a high-frequency current.

Relatively new technologies include vacuum furnaces (reduce the amount of nitrogen and oxygen in steel), electroslag remelting (a method of purifying steel from sulfur and phosphorus) and direct reduction of iron, bypassing cast iron (if there is cheap electricity or large fines for emissions of harmful substances, it can be cheaper) .

[Someone write more about them]

Differences in physicochemical characteristics

The main difference in the qualities of these metals is as follows:

- The hardness of steel is higher than that of cast iron.

- The weight of steel products is less, and the material melts more easily.

- Certain types of processing are available only for steel workpieces (forging, welding), while cast iron products are manufactured only by casting.

- The thermal conductivity of cast iron products is lower than that of their steel counterparts.

- Cast iron does not require mandatory hardening.

The most important metals and alloys

Aluminum . A very light silver-white metal that does not corrode. It is obtained from bauxite by electrolysis. Aluminum is used to make electrical wires, airplanes, ships (see the article “Buoyancy”), cars, beverage cans, and foil for cooking. Aluminum beverage cans are very lightweight and durable.

Brass . Malleable alloy of copper and zinc. Jewelry, ornaments, musical instruments, screws, and buttons for clothes are made from brass.

Bronze . A malleable, corrosion-resistant alloy of copper and tin, known since ancient times.

Calcium . Soft silver-white metal. It is found in limestone and chalk, as well as animal bones and teeth. Calcium in the human body is found in bones and teeth. It is used in the production of cement and high quality steel.

Chrome . Solid gray metal. Used in the production of stainless steel. Chrome is used to coat metal products for protective purposes and to give them a mirror shine.

Copper . Malleable reddish metal. Copper is used to make electrical wires and hot water tanks. Copper is part of brass, bronze, cupronickel.

Cupronickel . Alloy of copper and nickel. Almost all “silver” coins are made from it.

Gold . A soft, inactive bright yellow metal. Used in electronics and jewelry.

Iron . Malleable silvery-white ferromagnet. It is mined mainly from ore in blast furnaces. Used in engineering structures, as well as in the production of steel and alloys. There is iron in our blood too.

Lead . Heavy malleable poisonous bluish-white metal. It is extracted from the mineral galena. Lead is used to make electric batteries, roofs and screens that protect against X-rays.

Magnesium . Lightweight silver-white metal. Burns with a bright white flame. Used for signal lights and fireworks. Part of light alloys. Holiday rockets contain magnesium and other metals.

Mercury . Heavy silvery-white poisonous liquid metal. Used in thermometers, dental amalgam and explosives.

Platinum . Malleable silver-white inactive metal. Used as a catalyst and also in electronics and jewelry production. Platinum does not react. Jewelry is made from it.

Plutonium . Radioactive metal. It is formed in nuclear reactors during the bombardment of uranium and is used in the production of nuclear weapons (see the article “Nuclear energy and radioactivity”).

Potassium . Light silver metal. Very chemically active. Potassium compounds are included in fertilizers.

Silver . Malleable grayish-white metal. Conducts heat and electricity well. It is used to make jewelry and cutlery. It is part of the photographic emulsion (see the article “Photography and Cameras”).

Solder . An alloy of tin and lead. Melts at a relatively low temperature. Used for soldering wires in electronics.

Sodium . A soft, silvery-white, reactive metal. Included in table salt. Used in the production of sodium lamps and in the chemical industry.

Steel . An alloy of iron and carbon. Widely used in industry. Stainless steel, an alloy of steel and chromium, is not subject to corrosion and is used in the aerospace industry (see the article “Rockets and Spacecraft”).

Tin . A soft malleable silvery-white metal. A layer of tin protects the steel from corrosion. Part of alloys such as bronze and solder.

Titan . Durable white malleable metal that does not corrode. Titanium alloys are used to make spacecraft, airplanes, and bicycles.

Tungsten . Hard greyish-white metal. It is used to make filaments of incandescent lamps and parts of electronic devices. Incandescent cutting tools are made from steel with tungsten filament.

Uranus . Silvery-white radioactive metal, source of nuclear energy. Used in the creation of nuclear weapons.

Vanadium . Hard, poisonous white metal. Gives strength to steel alloys. Used as a catalyst in the production of sulfuric acid.

Zinc . Bluish-white metal. It is extracted from zinc blende. Used for galvanizing iron and producing electric batteries. Contains brass.

Metal recycling

Recycling is the reuse of raw materials, a way to conserve natural resources. Metals are easy to recycle because... they can be smelted to produce metal of the same quality as that obtained directly from the ore. Melting steel and aluminum is easy and profitable. Copper, tin, and lead are also melted down. Iron and steel objects can be retrieved from waste heaps using a strong magnet. Most steel for recycling comes from old cars and machine tools, but some is obtained from factory metal filings and even household waste. Scrap steel is mixed with molten iron to create new steel.

Read also: Plywood circular table

Aluminum is not ferromagnetic, but scrap aluminum can be separated from scrap iron using an electromagnet. More than half of beverage cans are made from recycled aluminum. To find out if a jar is made of steel or aluminum, use a magnet. It will stick to a steel can, but not to an aluminum can. Recycling scrap metal requires significantly less energy than extracting metal from ore, and there is less waste during processing. Theoretically, metal can be recycled as many times as desired. Recycling aluminum cans requires 20 times less energy than producing new aluminum.

Many people often use the terms “steel” and “iron” as synonyms in everyday speech. In practice, they differ significantly from each other.

Is it possible to distinguish cast iron from steel visually?

If we are talking about fragments or workpieces, the processing of which will not cause harm, you can look at the visual differences between the metals. When a cast iron product is scrapped, a dark gray matte tint appears; the steel surface is lighter and has a glossy texture. The appearance depends on the content of carbon components; they can be distinguished by the type of cracks: on high-carbon steel surfaces they look like a defect in the form of a split; on a product made of a low-carbon iron alloy, cracks look like a plastic-type rupture.

To the question of whether it is possible to distinguish finished products by shade or texture, one can give a definite answer: objects made of steel are lighter and almost always have a glossy tint, products made of cast iron are dark and matte.

Durable alloys and natural metals

Alloys are combinations of different metals. The need to obtain a variety of qualitative characteristics of metals, including strength, led to the emergence of various alloys. One important alloy in this sense is steel, which is a combination of iron and carbon. So, what metals are considered to be the strongest on Earth?

Since so many factors must be taken into account to determine the strength of a metal, it is difficult to unambiguously order metals from the “strongest” to the “weakest”. Depending on which property is considered the most important in each specific case, the distribution of strength forces among metals will develop.

How to distinguish cast iron from steel?

To distinguish these metals from each other, you can use the following methods:

- Drilling. To do this, you will need to take a nozzle with a small diameter and, having selected a flat area on the workpiece, drill a small hole. If, when processing a material, thin chips are formed, which are formed into a twisted strip longer than the drill used, have tarnish colors along the entire length and bend well enough, the workpiece is made of steel. The cast iron alloy is less ductile, it practically does not form a loach, and the shavings crumble from the slightest mechanical impact: they are easy to grind to a powder state, since the material is more fragile;

- Grinding. For this, an angle grinder is used; for processing, select an area that is not affected by frictional forces, contact with other metal surfaces or parts, otherwise, after grinding, the product may be unsuitable for further use. During the processing process, it is necessary to monitor the color of the spark and its shape. If the alloy is cast iron, the spark will be short, the sprocket will have a reddish tone, and if the part is made of steel, more sparks will fly out, they will have an increased size and an oblong shape. The sparks themselves are yellow or white. The exception is steel alloys with a high carbon content, which produce a short, purple spark with a shortened track and a small sprocket.

Mechanical impact methods can be used in everyday conditions, when you need to determine whether the material in front of you is cast iron or steel, without the use of special equipment. The laboratory can use modern technology, with the help of which spectral or microscopic analysis of the properties of metals is carried out. These methods provide highly accurate results, but are used primarily for industrial purposes, in production and in the scientific and technical industry due to the complexity and high cost of the equipment.

Alloy production

The process of manufacturing the alloy comes down to the processing of cast iron, during which excess impurities are annealed and alloying elements are introduced. Several methods are used for this.

- Open-hearth - molten or solid cast iron with ore is smelted in an open-hearth furnace at 2000 C to anneal off excess carbon. Additives are introduced at the end of the melt. The steel is poured into ladles and transported to the rolling mill.

- Oxygen converter – more productive. Air or a mixture of air and oxygen is blown through the cast iron in the furnace, achieving faster and more complete annealing.

- Electric melting - melting is carried out in a closed furnace at 2200 C, which prevents gases from entering the alloy. An expensive method that only produces high-quality compounds.

- Direct method - in a shaft furnace, pellets obtained from iron ore are blown with combustion products of natural gas - a mixture of oxygen, carbon monoxide, ammonia, at a temperature of 1000 C.

The steel making process does not end there. In cases where it is necessary to obtain the most durable material, additional processing is resorted to.

Thermal method

Thermal methods include:

- annealing – heating and slow cooling of different types and at different speeds;

- hardening - heating above the critical temperature, which causes recrystallization of the alloy, and faster cooling;

- tempering is a procedure carried out after hardening in order to reduce the stress of the metal;

- normalization is the same annealing, but carried out not in an oven, but in air.

Thermo-mechanical method

Thermomechanical methods combine mechanical and thermal effects:

- high-temperature TMT - hardening - hardening, hardening, is carried out immediately after heating, while the alloy retains its austenitic structure. The change due to plastic deformation during rolling or stamping is retained by 70% and after cooling the steel turns out to be stronger;

- for low-temperature TMT – cold-rolled steel. The alloy is heated to achieve an austenitic state, cooled below the recrystallization points to achieve the appearance of a martensitic phase - within 400–600 C. Then hardening is carried out - hardening, rolling. When cooled, the effect is completely preserved.

Thermochemical treatment

Thermochemical treatment is the heating of alloys and holding them in certain chemical environments. The most well-known methods include:

- carburization – saturation of the alloy surface with carbon. In this way a wear-resistant top layer is obtained;

- nitriding – saturation of steel with nitrogen. The goal is the same - to obtain a top wear-resistant layer, but compared to carburization, nitriding provides higher corrosion resistance;

- nitrocarburization and cyanidation - saturation of the surface layer with both carbon and nitrogen. Provides higher speed and productivity of the process.

What is called steel

Steel is one of the most common metal alloys. It is widely used in the production of various machines, mechanisms and devices. Without it, the production of cars and ships, railway cars and locomotives is unthinkable. Steel reinforcement is used in construction; bridges and quickly erected structures are constructed from metal structures. This alloy is created with predetermined properties in order to best suit the quality characteristics of a particular product. Typically, steel is an alloy containing more than 45 percent iron . Carbon and alloying components are added to it for strength and hardness.

High-carbon steel is used to manufacture various power springs and shock absorbers, leaf springs and other elastic parts designed to withstand heavy loads. In the manufacture of high-tech equipment and instruments, suspensions, membranes and many other elements of various shapes and purposes are made from such steel. Parts made of steel with a high carbon content are distinguished by the fact that they can withstand large constant, impact or cyclic loads without permanent deformation. Steels with low carbon content are more ductile and tough. They are conveniently used for the production of stamped parts, for example, in the automotive industry.

For ease of use, steels are classified according to various parameters.

So according to their purpose they can be:

- Structural.

- Stainless.

- Instrumental.

- Heat resistant.

- Frost-resistant.

To assess the chemical composition, they are classified as carbon and alloyed . The former are low, medium and high carbon. Alloy steels are divided according to the same principle, based on their content of alloying components. Steels may differ in other characteristics (specific gravity, density, melting point, content of chromium, molybdenum, tungsten, etc.).