About the composition of the PIC

POS-40 contains 40% tin, and POS-61 contains about 61% tin. Everything else is lead and additional impurities. By appearance you can determine what kind of solder you have in front of you. Matte and dark solder contains more lead. Light and shiny - more tin. This can best be seen in comparison.

The strength of the solder depends, along with the alloying of the alloy, on the metal being soldered. To solder zinc or copper, a little zinc or copper is added to the POS, respectively. This reduces chemical erosion of the metal and increases the surface strength of the joint.

Alloying POS

Solder performance can be improved by doping with the following substances:

- Plasticity and resistance to thermal cycling are improved due to the addition of silver, indium, lithium, manganese, and bismuth.

- corrosion resistance is improved by nickel and copper.

- Cobalt, silicon, zirconium, hafnium, vanadium, tungsten, and niobium contribute to increasing heat resistance

- Solder becomes stronger if you add boron, iron, nickel, cobalt, zinc, and silicon.

- The addition of silver, copper, zinc, cadmium, antimony and aluminum improves adhesion .

Characteristics of POS and POSS

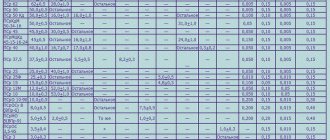

The characteristics of solders of the tin-lead group are shown in the parameters table. Here you can see such characteristics as electrical resistivity, melting point, tensile strength, density, impact strength and Brinell hardness, thermal conductivity, relative elongation of existing varieties of POS and POSSU.

The table shows the lowest melting point solder (cadmium POSK 50-18) with a melting point of 145 °C, and the strongest solder for soldering (POSSu 4-6) with a tensile strength of 6.5 kgf/mm2.

The terrible secret of POS-60 solder

Now the time has come for the terrible secret of POS 60 solder . According to GOST 21930-76 entitled “Tin-lead solders in ingots. Technical specifications" and GOST 21930-76 "Tin-lead solders in products. Technical specifications", solder such as POS-60 simply does not exist. download and view GOST 21930-76 itself . Here is the complete table from this GOST.

So “ POS-60 ” is jargon or a popular designation for “the solder that everyone solders with.” It seems to me that this is due to confusion in the designation of POS-61. Because when the tin content in the solder according to GOST is from 59 to 61%, it is more logical to call it POS-60 rather than POS-61.

Among the solders produced according to international standards there is Sn60Pb40 solder . This is a solder solder containing 60% tin and 40% lead. It could be called POS-60, if at least specifications for it were developed. According to international data describing the characteristics, the melting point of 60/40 solder is 191 degrees Celsius.

The same story with POS-62 type solder . Such lead solder according to GOST has not yet been invented. So, if they ask me “what is the melting temperature of POS-62 solder,” I know that the answer with the figure 184 degrees Celsius must be looked for in the imported solder catalog. For example, you can use the Kester solder catalog.

Characteristics of POS 10

POS 10 has the following chemical composition: 9-10% tin, about 89% lead, 0.2% bismuth, 0.1% antimony and other impurities in small quantities. POS-10 is used for tinning and soldering contact surfaces of electronics. For example, it is used to fill control plugs in radio electronics housings and solder relays.

Soldering temperature POS 10 - 299 °C. The solidus point is 268 °C.

Pros of POS 10

- high melting point is useful when soldering equipment cases.

Cons of POS 10

- high resistivity - 0.2 Ohm•mm2/m;

- high content of lead, which is hazardous to health;

- low strength and tensile strength of about 3.2 kgf/mm2.

Application of POS 60

Due to its properties and low price, POS 60 is widely used both in industry and at home.

It is used for soldering various metal parts, including for sealing holes, cracks, etc.

The low melting point allows the alloy to be melted using a household gas burner, and a variety of fluxes will ensure good adhesion to almost any metal.

Application of POS60 solder

The low melting point is also useful when using POS 60 in radio electronics. Here he found application for tinning and soldering electrical components that should not be overheated. In this case, an ordinary soldering iron is sufficient as a tool, so PIC has become widespread in the manufacture of homemade electronic devices.

If you find an error, please select a piece of text and press Ctrl+Enter.

Greetings to dear readers! In this material I tried to collect all the data about PIC solder. This Tin-Lead Solder is the most popular solder for mounting radio components and is used more often than others in radio engineering. I will try to explain why this is so and tell you about the types and technical characteristics of POS series solders. I’ll also tell you a terrible secret about POS-60 and POS-62 solders. Go!

Characteristics of POS 30

POS 30 is an intermediate link between POS 10 and POS 40. POS 30 consists of: 30% tin and 69.5% lead. The rest is doping and impurities. POS 30 can be replaced without hesitation by POS 40. The melting point (liquidus) is 238 °C, and the plasticity temperature (solidus) is 183 °C. POS 30 is usually used for soldering and tinning of radiators and zinc sheets.

Pros of POS 30

- good adhesion;

- high strength.

Cons of POS 30

- high lead content;

- often produced in rods.

Types of POS solders

First, let's remember what types of solders are made from alloys of the tin-lead group. The most popular are antimony-free solders POS-10, POS-40, POS-61 and POS-90. POS solder containing antimony is called POSSU. Antimony in the solder adds several percent to its strength.

When we talk about melting a mixture of tin and lead, we need to remember the definitions of solidus and liquidus . When any mixture of two or more metals is heated, the melting (transformation from solid to liquid phase) of the lightest particles occurs first. This temperature mark is called the solidus of the alloy.

With a further increase in temperature, more refractory components begin to melt. As soon as they melt, the liquidus . The PIC solder is now completely melted. This process is explained in more detail by a picture taken from a presentation on the topic of alloys.

Between these two points is a state of increased ductility of the solder . In this state, the solder can be pulled and deformed without losing integrity.

There are eutectic alloys - solders, in which the solidus and liquidus points coincide. This is very convenient when soldering and indicates the high quality of the solder.

Characteristics of POS-40

POS 40 consists of 39-41% tin, 59% lead. The remaining impurities are in the same ratio as in POS-10. POS-40 is usually used for soldering and tinning of radio equipment casings made of galvanized iron with galvanized seams.

The soldering temperature of POS-40 solder is 238 °C, and the solidus is 183 °C.

Pros of POS 40

- more resistant to thermal cycling than POS-61;

- good ratio of ductility and melting point.

Cons of POS 40

- elevated liquidus temperature;

- high lead content, which is harmful to health.

Explanation of markings

Solder marking according to GOST consists of two elements. The first element of three letters indicating the chemical composition of the alloy, for example “POS”. The first letter means "Solder". Further, the abbreviation refers to the alloy. In the case of “POS”, you can open it like this: “Tin-Lead”. The rest of the solders have the same markings, for example “PMC” is “Copper-Zinc”, “PSR” is “Silver” and so on. The second element in the designation is the percentage of the first component from the name. In the case of PIC, it is tin, in the case of PMC, it is copper. Thus, POS-60 is a solder consisting of 60 percent tin, and the rest is lead and other impurities.

Characteristics of POS 61

POS-61 is usually used for soldering and tinning of electronic components and printed circuit boards of precision instruments with highly hermetic seams, for which overheating is not allowed.

Composition of POS-61:

- Tin 59 - 61%;

- Antimony - no more than 0.1%;

- Copper - no more than 0.05%;

- Bismuth - no more than 0.02%;

- Arsenic - no more than 0.02%;

- Iron - no more than 0.02%;

- Nickel - no more than 0.02%;

- Sulfur - no more than 0.02%;

- Zinc - no more than 0.002%;

- Aluminum - no more than 0.002%;

- Lead - the rest - about 38.7 - 40.7%.

The soldering temperature of POS-61 solder is 220 °C. Solidus - 183 °C.

Technical characteristics of POS 61 (according to GOST 21931-76):

- Density determines the weight of POS-61 solder and is equal to 8.5 g/cm3;

- The electrical resistivity is 0.139 Ohm•mm2/m;

- Thermal conductivity is 0.12 kcal/cm•s•deg;

- Tensile strength is 4.3 kgf/mm2;

- The relative elongation is 46%.

Pros of POS 61

- good adhesion to metal surfaces;

- universal solder for soldering and most radio installation work;

- the best ratio of melting temperature and strength;

- accessibility and prevalence;

- often produced in the form of wire (POS 61 T2A);

- low cost.

Cons of POS 61

- versatility reduces performance in special cases, for example when soldering zinc;

- melting temperature is not suitable for all devices;

- solder fumes (lead in it) are harmful to health.

Characteristics of POS-63

POS 63 in accordance with GOST and OCT 4G 0.033.200 is an alloy consisting of 63% tin and 37% lead. This is a kind of modernization of POS-61 solder, adjusted to the international standard J-STD 006B. Many high-quality Chinese solders are similarly labeled Sn63Pb37 . These are eutectic alloys with a melting point of 183 °C.

POS-63 is mainly used for soldering and tinning pins of microcircuits and packaged radio components, printed circuit boards, wires and cables. It is the most common of modern solders . The characteristics of POS 63 solder are very similar to POS-61.

Pros of POS 63

- coincidence of solidus and liquidus points;

- the most common POS series solder;

- relatively low melting point;

- low cost;

- supplied in the form of wire filled with flux.

Cons of POS 63

- often counterfeited, especially in China;

- contains lead, which increases the cost of recycling electronic equipment in accordance with modern safety standards.

Release forms

Depending on the scope of application, POS brand solder can have different release forms. So, for example, for tinning large areas, it is most convenient to use it in the form of a flat strip. Special lead-tin rods are produced for soldering various designs. They are convenient to solder with both a soldering iron and a gas torch. In radio electronics, rosin is used as a flux used in the soldering process; for this purpose, solder is produced in the form of a tube filled with rosin. This adds convenience during the installation of radio components as it does not require the application of additional flux.

Solder POS60 in the form of flux paste

Sometimes you can find POS-61 in the form of solder paste. It consists of alloy powder and flux and is used for surface mounting of electronic components using a soldering gun. Rarely used at home (and only by individual craftsmen) due to the need for special equipment.

Characteristics of POSSu-61-0.5

POSSu-61-0.5 designates a type of antimony solder containing 61% tin, up to 0.5% antimony and about 38% lead. It is used for soldering and tinning of printed circuit boards and galvanized radio components with increased operating temperature requirements. The melting point is 189 degrees. Pros of POSSu-61-0.5

- increased adhesion to the metal surface due to the antimony content;

- characteristics are identical to POS-61.

Cons POSSu-61-0.5

- difficult to find on sale;

- increased cost.

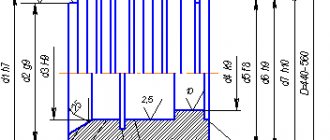

Dimensions

Depending on the scope of application, wire or tube with flux are produced with a diameter of 0.5 to 5 millimeters. As mentioned above, the intended purpose of this form of solder is radio electronics. POS rods are available in four diameters: 8, 10, 12 and 15 mm. They are used when soldering metal structures, for example when installing copper heating pipes, where thin wire will have a high consumption. Tinning tapes also have a certain thickness, depending on the width of the tape. With a width of up to 10 mm, the tape has a thickness of up to 1 mm, and a tape with a width of 10 to 15 mm can have a thickness of up to 5 mm.

Solder POS60 with a diameter of 1 mm

Characteristics of POS-90

POS-90 consists of 90% tin and 10% lead. It also contains about 0.1% antimony and 0.05% copper. Most often used for soldering and tinning internal seams of medical equipment and food utensils . The melting point of POS 90 is 220 degrees.

Pros of POS 90

- low lead content;

- rarely counterfeited;

- low resistance;

- high strength.

Cons of POS 90

- high cost (higher than POS-61);

- low plasticity.

Varieties

Conventionally, solders can be divided into hard and soft. The temperature limit between them is approximately 300 degrees. Soft solders melt at temperatures below this limit, and hard solders, respectively, above. In addition to the melting point, hard and soft solders are distinguished by different strength limits. For soft ones this limit is below 100 MPa, and for hard ones it is higher.

Soft solders are mostly an alloy of lead and tin, depending on the percentage of which the melting point varies. The more tin there is in the alloy, the lower the melting point. Solid ones consist mainly of an alloy of copper and zinc or silver with various additives. Tin-lead solder POS 60 belongs to the category of soft solders.

Increasing environmental standards require the elimination or minimization of the amount of lead in materials used for soldering. Therefore, lead-free solders are entering the market, in which there is no lead at all. It is replaced by other metals such as silver, zinc, indium, copper.

In addition to the high price, such solders have very poor wettability or fluidity, so they have not yet become widespread.

Solder for connoisseurs of high-quality sound

This type of solder is well known to fans of Hi-End electronics . This is solder for soldering audio equipment, produced in the 30s - 50s of the last century. These solders have high purity components, which has a positive effect on the highest quality sound. To hear the effect of such solder, you need both a high-quality sound source, a sound emitter, and excellent hearing. Experts “listen” the solder and formulate their own alloys for better sound transmission. The most famous for music lovers is solder from Kester . It sells for $10 per meter. Every year it becomes less and less. Its composition is close to POS-90. Kester solder is composed of 85.9% tin, 8.5% lead, 3.28% silver, 0.34% copper, 0.79% sodium, 0.55% magnesium and 0.27% mercury.

There is also a solder containing 50% tin and 50% lead Sn50Pb50 .

Buy products based on the article:

- POS 61 —

- POS 60 —

- POS 40 —

- POS 63 —

- ASAHI -

Comments ()

- Nikolay September 26, 2021, 08:14 pm 0

What is the difference between the red and yellow solder you presented?answer

- Manager King September 28, 2021, 1:18 pm 0

Good afternoon! The red spool has solder without rosin, and the yellow spool has solder with rosin. Thank you for your interest in our store.

answer

POS 61 T2A - what characteristic (parameter) is encrypted under the letter “A” in this brand of solder? What is the difference from POS 61 T2?

answer

They are listening to the solder, you say... specialists mean..))) Friends, are you suckers yourself or are you looking for suckers? ))

answer

What types of solders are there and what are their properties?

At the beginning of their amateur radio activities, many novice radio amateurs rarely ask themselves about the types of solders and what their properties are.

To assemble the simplest homemade devices, the most common POS-61 or similar is sufficient. As they say: “If only I had something to solder with...”

You don't even have to buy solder. It is enough to take an old printed circuit board from some electronic device and assemble it with a heated soldering iron tip from the soldered contacts.

This method of “extraction” is especially relevant for those who live far from cities and large populated areas, where there is no opportunity to visit a radio store.

Solder collected from printed circuit boards

But still, solder to solder is different. In his practice, a person dealing with electronics must understand the issue of his choice. Therefore, we will consider in detail what types of solders there are, what they are used for, which one is better to use for installing electronic circuits and repairing household radio equipment.

What types of solders are there?

Solders are divided into soft (low-melting) and hard. For the installation of radio equipment, low-melting ones are used, i.e. such, the melting point of which lies in the range of up to 300 - 450 0 C. Soft solders are inferior in strength to hard solders, but they are used for assembling electronic devices.

Solder is an alloy of metals. For low-melting solders, this is usually an alloy of tin and lead. It is these metals that make up the majority of the alloy. Alloying metals may also be present in it, but their quantity in the composition is small. Impurities of other metals are introduced into the alloy to obtain certain characteristics (melting point, ductility, strength, corrosion resistance).

The most widely used type of solder is POS (Tin-Lead Solder). Next, a brief designation of its brand is followed by a number that shows the percentage of tin in it. So POS-40 contains 40% tin, and POS-60, respectively, 60%.

It happens that solder of an unknown brand comes into use. Its composition can be roughly assessed by indirect signs:

Solders of the tin-lead group have a melting point of 183 – 265 0 C.

If the solder has a bright metallic sheen, then it contains a fairly high tin content (POS-61, POS-90).

And, conversely, if it is dark gray in color and the surface is matte, then this indicates a high lead content. It is lead that gives the surface a peculiar grayish tint.

Solders containing a lot of lead are very ductile.

So, for example, a solder bar with a diameter of 8 mm. with a high lead content (POS-30, POS-40) is easily bent by hand. Tin, unlike lead, gives the alloy strength and rigidity. If there is a lot of tin in the alloy, then it will no longer be possible to bend such a rod easily.

POS-40 (bar)

Let's consider the purposes for which solders of the tin-lead group (POS) are used.

POS-90 (Sn 90%, Pb 10%). Used for repairing food utensils and medical equipment. As you can see, it contains a small lead content (10%), which is quite toxic and its use in things that come into contact with food and water is unacceptable.

POS-40 (Sn 40%, Pb 60%). Mainly used for soldering electrical equipment and parts made of galvanized iron, used for repairing radiators, brass and copper pipelines.

POS-30 (Sn 30%, Pb 70%). It is used in the cable industry, and is also used for tinning and soldering zinc sheets.

And finally, POS-61 (Sn 61%, Pb 39%). Same as POS-60. I don't think there's much difference between them.

POS-61 is used for tinning and soldering printed circuit boards of radio equipment. It is mainly used as a material for assembling electronics. Its melting point starts at 183 0 C, and complete melting is achieved at a temperature of 190 0 C.

Soldering with such solder can be done using a conventional soldering tool without fear of overheating of the radioelements, since its complete melting is achieved already at 190 0 C.

POS-30, POS-40, POS-90 completely melt at temperatures of 220 – 265 0 C. For many radio-electronic components, this temperature is subcritical. Therefore, it is better to use POS-61 for assembling homemade electronic devices.

A foreign analogue of POS-61 can be considered Sn63Pb37 (63% tin, 37% lead). It is also used for soldering radio equipment and for making homemade electronics. Radio amateurs choose it as an alternative to the domestic POS-61.

As a rule, any solder is sold in coils or tubes of 10

100g. The composition of the alloy is indicated on the packaging, for example, like this: Alloy 60/40 (“Alloy 60/40” - also known as POS-60). It has the shape of a wire of different diameters (from 0.25 to 3 mm).

It is also not uncommon that it contains flux (FLUX), which fills the core of the wire. The flux content is indicated as a percentage (usually from 1 to 3.5%). This form factor is very convenient. During operation, there is no need to separately supply flux to the soldering area.

One of the varieties of POS solders is POSSu . Yes, if you say it out loud, it doesn’t sound very presentable. But, despite this, tin-lead solder with antimony (this is how the abbreviated designation stands for) is used in the automotive industry, in refrigeration equipment, for soldering the windings of electrical machines, elements of electrical equipment, winding parts and cable products. Well suited for soldering galvanized parts. In such an alloy, in addition to lead and tin, there is from 0.5% to 2% antimony.

| Solder | Initial melting t 0 (Solidus) | Full meltdown (Liquidus), t 0 |

| POSSu-61-0.5 | 183 | 189 |

| POSSu-40-2 | 185 | 229 |

| POSSu-40-0.5 | 183 | 235 |

| POSSu-30-2 | 185 | 250 |

| POSSu-30-0.5 | 183 | 255 |

As we can see from the table, POSSu-61-0.5 solder is most suitable for replacing POS-61, since it has a complete melting temperature of 189 0 C.

It is worth noting that there is also a completely lead-free tin-antimony solder POSu 95-5 (Sn 95%, Sb 5%). Its melting point is 234 – 240 0 C.

Low temperature solders.

Among the solders, there are also those that are designed specifically for soldering components that are very sensitive to overheating. The most “high-temperature” among low-temperature ones is POSK-50-18 . It has a melting point of 142–145 0 C. In its composition, POSK-50-18 has 50% tin and 18% cadmium. The remaining 32% is lead. The presence of cadmium in the alloy increases corrosion resistance, but also makes it toxic.

Next in decreasing melting temperature is the ROSE alloy (Sn 25%, Pb 25%, Bi 50%). Marked as POSV-50 . Its melting point is lower than the boiling point of water and is 90 – 94 0 C. It is intended for soldering copper and brass. In the composition of the ROSE alloy, tin occupies 25%, lead – 25%, bismuth – 50%. The percentage of metals in the alloy may vary slightly. Usually indicated in the “Composition” column on the packaging.