04/27/2021 Author: VT-METALL

Issues discussed in the material:

- Advantages of metal perforation

- Types of metal perforation depending on the technology used

- Types of metal perforation depending on the shape and location of the holes

- Metals used to make perforated sheets

- Justification of the cost of metal perforation

Types of metal perforation can be very diverse, it all depends on the technology used in the production process and the resulting shape and location of the holes. In fact, there are more than enough options here.

Information about the types of perforation that exist today is very useful and often simply necessary. Thanks to it, the customer can choose the version of the product that is most suitable for his purposes, as well as determine at least the approximate cost of the service.

Advantages of metal perforation

First of all, you need to remember that it is impossible to perform high-quality perforation of metal in artisanal conditions, since this threatens a significant loss of the quality of the material. Even if it is possible to make the most even holes in it, this will still lead to a decrease in the service life of the product, since the surface will be damaged.

What can perforation be used for? The most common material is flat and sheet metal, since making holes in it is, firstly, easier, and secondly, cheaper. This process requires special high-tech machines. With their help, you can make perfectly even holes in the material according to the design.

It should be noted that perforation can also be done in rolled metal with flat edges, such as channels, profile pipes, I-beams - but only if there are special tools for this.

Why is perforation of sheet and other metal so good? To begin with, it must be said that the product thus becomes lighter, but the material retains all its basic properties, with the exception of strength. However, this only applies to those cases when the process is carried out on professional equipment.

It should be noted that the shape of the holes does not have to be round, it all depends on the wishes of the customer. Thus, triangular, square and more complex perforations are often found. Thus, perforated metal has one more property – decorative. Depending on the designer's idea, holes can be used to give the material a completely different look.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Metal sheets after perforation become more transparent and less slippery, so they are often used to make steps on the street or platform as expanded metal.

Another undoubted advantage is durability. Thus, even after a long time, the texture of the perforated material retains its appearance and functional characteristics. Thanks to this, the cost of replacing products or repairs is significantly reduced.

It should also be noted that it is resistant to corrosion, which allows you to keep the surface intact and reliable for a long time. This property is especially pronounced in perforated sheets made of aluminum, stainless steel, painted and hot-dip galvanized.

It is much easier to install and dismantle perforated sheets, without disturbing the geometric harmony of the holes. They can be attached without drilling to guides, any surface, or frame.

Their popularity is also due to the fact that perforated sheets are used in many areas of production.

Perforated sheet metal

Perforated metal sheet is fireproof, it is a non-flammable material, which is very important in our time with increased requirements for fire safety, and at the same time, it is quite durable and at the same time flexible, which allows you to create structures that are unusual in shape and design, and is also valued for its lightness and light transmission. This allows it to be used both as a decorative and structural material, as well as as a material for supporting technological processes, and without a doubt, perforation is a modern high-quality material with enormous potential for use.

Types of metal perforation depending on the technology used

Several technologies can be used to produce perforated sheets. If it is necessary to make holes of large diameter, then a coordinate-punching press is used, which carries out blows with a special tool of a certain size and shape.

Another type involves the use of a cluster, which allows you to make several holes at once, which significantly reduces the number of machines.

Using drilling equipment, it is possible to obtain unique products that fully comply with the customer’s drawings. Most often, this technology is used to produce sheets with a thickness of more than 12 mm, but of small size. It should be noted that this method is not suitable for mass production, since drilling a large number of holes will take a lot of time.

Another method is stamping-cutting. The essence of this method is that a special press (punch) applies high pressure to a sheet of metal. It should be noted that this perforation technology is the most common, since it can be used to produce a large number of sheets in a short time at minimal cost.

Perforated sheets can also be produced using laser burning, but this technology is only suitable for products whose thickness is more than 12 mm. Despite the fact that this method is quite expensive, it is often chosen. This is explained by the fact that using a laser you can create a hole of any shape, regardless of complexity. In addition, the edge does not require additional processing.

Another advantage of this technology is that the processing error in this case is minimal. Thanks to the high speed of work, any number of products can be produced in a short time. It should be noted that laser burning does not provide any restrictions in this regard.

Types of perforation when drilling oil wells

After running the production string in the productive formation interval, it is necessary to create channels - connecting the formation with the internal space of the pipes in the well. This can be done by cutting holes in the column, cement stone and formation rock. Then, through these channels, a product will flow from the formation: oil, gas, gas condensate, water. Perforation is the creation of such channels.

Of the existing types of perforation, oil service companies mainly use these 3 methods of creating a connection between a well and a formation:

- The use of bullets, shaped charges and explosive torpedoes (explosive method);

- Cutting holes using hydro-sandblasting;

- Hydromechanical cutting of a window in a column.

Perforation using explosive energy

Before lowering the production string, the geophysical team conducts GIS (geological research) at the well. On the logging cable, instruments are lowered into the well, which record complete information: the electrical resistance of the formations, the presence and profile of cavities, azimuth and deviation angles, determine the interval of the productive formation, as well as other work to compile an accurate profile of the well.

Re-determination of the perforation interval is carried out after running and cementing the column. Then the well is prepared for perforation. If it is a bush, then the drilling rig is moved to the point of drilling a new well. A mobile self-propelled unit is installed to perform perforation and cause inflow from the formation. The installation has a tower for lowering tubing, a lift and a hydraulic pump.

On a logging cable, a body-shaped cumulative projectile is lowered into the well. The length of the body and the number of holes are selected based on the minimum impact on the casing wall. Rotary hammers are cased PC - reusable, PKO - cased disposable and PKS - charges are located on a tape cassette, each charge is enclosed in a sheath and connected to a logging cable wire.

After installing the tape opposite the formation, an electric charge is applied to the core, which activates the detonator. An explosion occurs, a gas stream burns through the column, cement stone and near-trunk area by 150-300 mm. Channel diameter 8-12 mm. The number of holes is from 100 to 300 per projectile release. Perforation and subsequent injection of inflow are carried out according to the work plan approved by the Customer's chief geologist.

Hydrosandblast perforation

It has an advantage over explosive perforation:

- does not destroy cement stone in the form of vertical cracks, along which flooding of the formation with bottom waters can occur;

- improves formation permeability due to additional channels;

- After perforation, some of the equipment can be used for hydraulic fracturing

A specially equipped pipe with several nozzles (nozzles resistant to abrasive jets) is lowered into the well on the tubing. An abrasive liquid containing sand is supplied to the nozzles through pipes. The pipe at the bottom has a seat for seating the ball. After installing the nozzle at the required interval, a ball is thrown inside the tubing, which, upon reaching the seat, blocks the flow and directs it through the nozzles. The jet cuts the column, cement and formation rock, making channels up to 0.5 meters deep.

Hydromechanical cutting of vertical slots in a column

This method is used for secondary exploitation of deposits. Equipment is lowered into the well along the tubing to cut vertical slots in the column opposite the productive formation. When pressure is created in the pipes, cutting discs are extended and rest against the wall of the column. Performing reciprocating movements up and down, the discs cut slots. Above the disks there are flushing holes with hydraulic monitors; the jet, entering the gap, cuts the cement stone and penetrates deep into the formation. This improves the permeability of the formation and the flow rate of the well.

Hydromechanical perforation includes cutting out a side window:

- A cement bridge is installed in the column.

- After the WCC, the casing string together with the wellhead equipment is pressurized for leak-tightness.

- A high-strength steel wedge is lowered onto the pipes. Using a special device, the wedge is rigidly fixed in the column so that it does not turn.

- The assembly with the cutter (riber) is lowered, and a calibrator is installed above it.

- The column wall is cut with a milling cutter and calibrated. It turns out to be a window.

- The layout is deepened by 5 meters.

Then the assembly is lifted and the BHA with the whipstock is assembled. As a result, an additional trunk is obtained in the productive formation.

These are the main types of well perforations. The method and equipment it will be carried out depends on the specific geological conditions and the work plan approved by the Customer.

We would like to thank a specialist from the

Naftagaz for their assistance in writing this material.

Types of metal perforation depending on the shape and location of the holes

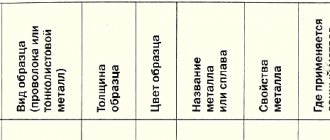

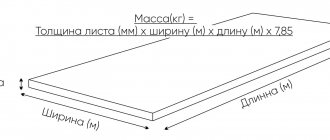

The type of perforation of metal sheets depends on the shape of the holes (round (R), square (Q)), their relative position and center-to-center distance.

In addition, adjacent rows of holes in the perforated sheet can be located in two ways, namely offset relative to each other (v) or directly (g). In this case, the thickness of the sheet and the material from which it is made play an important role.

The recording will be made as follows: perforated sheet Rv 4-6 (0.7x1,000x2,000 mm) art. 08ps, where Rv denotes the type of perforation, 4 is the diameter of the holes in mm, 6 is the distance between the centers of the holes (mm). The numbers (0.7x1,000x2,000 mm) tell you what the thickness of the sheet is and the cutting, and item 08ps indicates the steel grade and sheet material.

Thus, the classification of perforated sheets by type of perforation will look like this:

- round holes arranged in straight rows (Rg);

- round holes with offset rows (Rv);

- square holes arranged in straight rows (Qg);

- square holes arranged in offset rows (Qv);

- square holes that are arranged in mixed diagonal rows (Qd);

- oblong-shaped holes arranged in straight rows (Lgl);

- oblong holes with offset rows (Lvl).

In addition, it is necessary to note the decorative perforation of metal, which involves the production of sheets with holes having a certain location, size and shape.

Often, sheets of metal that have undergone some type of perforation are used as specialized tools, for example, a filter in the mining industry or a screen. However, their parameters are somewhat different, that is, unlike those used in furniture or design, they are thicker. It should be noted that the sheets can be of different sizes, but the thickness for each material is fixed. So, for stainless steel - 0.7-0.8 mm, carbon steel - 0.7-2.0 mm, galvanized - 0.7-3.0 mm.

Torpedo perforation

is carried out by devices lowered on a cable, and differs from bullet perforation in that an explosive projectile equipped with a delayed-action fuse is used to fire the shot. The mass of the internal explosive charge of one projectile is 5 g. The device consists of sections, each of which has two horizontal barrels. The projectile is equipped with a filament-type detonator. When the projectile stops, the internal charge explodes, resulting in cracking of the surrounding rock. The explosive mass of one chamber is 27 g. The depth of the channels, according to test results, is 100-160 mm, the diameter of the channel is 22 mm. Per 1 m of filter length, usually no more than four holes are punched, since torpedo perforation often causes destruction of casing columns.

Metals used to make perforated sheets

Today, perforated sheets are made from various materials. The most popular are steel and aluminum, less common are brass and copper.

- Perforated steel sheets.

In this case, different types of steel can be used as a manufacturing material.

Stainless steel has higher anti-corrosion properties than other types of steel. In addition, it is heat-resistant, durable and tolerates temperature changes well. All these qualities make stainless steel an ideal material for the manufacture of perforated sheets for various fields, for example, the chemical and food industries, as well as technological processes that occur under the influence of aggressive environments.

As for hot-rolled perforated sheets made of structural steel, they are strong, malleable, lightweight, easy to install and process, but at the same time have poor anti-corrosion properties. That is why they are most often used for technical purposes. If decorative use is planned, then the products must be painted to increase their resistance to corrosion.

Sheets made of cold-rolled steel are durable, lightweight and practical in terms of operation, but they also have poor anti-corrosion characteristics. Most often, this type of perforated metal is used in mechanical engineering and industry. If the material is painted, that is, to enhance protection against corrosion, then it can also be used for decorative purposes.

One of the most popular metals is galvanized steel. In addition to all the above advantages, it has excellent anti-corrosion properties, which are provided by the zinc coating. Thanks to this, the scope of application of galvanized perforated sheets is quite wide, including construction, architecture, design, and various industries.

- Aluminum sheets.

As you know, this metal is one of the lightest, it is resistant to corrosion and external factors, and is also ductile. Therefore, aluminum perforated sheets are flexible to any type of processing, and also have high electrical and thermal conductivity. As for the disadvantages of this metal, it is rather low strength. If we talk about the areas of application of perforated aluminum sheets, then these are chemical, food and other types of industries, architecture, mechanical engineering (production of protective covers for machine tools), design.

- Copper sheets.

Perforated copper sheets are quite rare, although they have many advantages. The main thing is high anti-corrosion properties, then strength, ductility, and, of course, aesthetic appearance. If we talk about disadvantages, then copper sheets have only one - their cost, which is much higher than that of other metals. Therefore, they are used mainly in design, small-sized architectural forms, and elements of facade decor.

Perforated metal

Metal perforation (perforated sheet, perforation) is a sheet of rolled metal, the surface area of which has through holes of various shapes and sizes, applied in a certain sequence.

The production of perforated sheets is possible thanks to the use of modern coordinate-punching machines with program control. This allows us to produce perforations according to customer requirements, maintaining dimensional accuracy. Perforated metal sheet is a non-flammable material. It is highly durable and flexible at the same time. All this allows you to create structures that are unusual in design.

Justification of the cost of metal perforation

What influences the cost of work, what factors are involved in pricing, and what significance does each of them have? Here it must be said that the calculation, as a rule, is carried out individually in each case, and much depends on the situation and certain factors.

Nevertheless, the following points are taken into account first:

- whether documentation is available or needs to be developed;

- what are the characteristics of the manufactured products;

- what equipment is used, as well as its energy consumption;

- order volume and complexity.

It should be noted that this is only part of the factors influencing the cost of services; other aspects can be taken into account. Here we cannot help but say that there are different types of metal perforation, as well as the price for each of them. In addition, it is necessary to take into account the urgency of order implementation, since if the deadline is short, then the productivity of the production lines has to be maximized, which increases the client’s costs. But it is also worth noting that today many companies offer good discounts when ordering large volumes of products.

Punch sheet application

Metal perforation (perforated sheet) as a versatile and stylish material is becoming increasingly popular in various areas of everyday life, such as: construction, design, food industry, furniture production, in the production of commercial equipment and many others.

| Construction and architecture: • noise-attenuating and windproof panels • cladding of buildings - facades • decorative facade panels • design of columns, staircase and balcony railings • suspended ceilings • heating radiator screens • lighting, ventilation and air conditioning systems • as finishing, decorative elements of external design of buildings | ||

| Design and interiors: • office furniture • outdoor advertising design elements • creation of fencing • finishing of staircases • furniture decoration • trade and exhibition equipment • information stands • shelving, • bar counters • trash cans | ||

| Food production: • perforated baking trays for baking bread • trays for frying, sautéing, freezing • drums for peeling vegetables | ||

| Landscape design: • street benches for park areas • trash cans • fences for flower beds and lawns | ||

| Allows you to emphasize the individuality of the interior, create unusual decorative elements, thereby making any interior exclusive. | ||

| Industry and chemistry: • air ducts • filters • grilles. | ||

| Mechanical engineering and instrument making: • car bodies • body parts • mufflers • protective covers • conveyor belts • radiator grilles • public transport interior trim | ||

| Electrical: • stainless steel products and galvanized perforated sheets are used to complete electrical cabinets with power equipment, cable channels | ||

Perforated panels in the interior

Today, this problem is especially acute, as the number of different communication and technical solutions for buildings has increased many times over. If previously the problem was exclusively ventilation or plumbing hatches, now in any modern room there are many more different exits and panels. This applies to niches for Internet and telecommunications, control panels such as “smart home”, lighting remote control, etc. Sometimes they are in plain sight and do not fit into the interior at all. That is why decorative grilles have become so widespread.

Decorative grilles for various communications are a continuation of the ancient method of masking interior elements using panels. Previously, and in modern interiors too, such panels were sometimes used to hide entire rooms. Now, with the help of decorative grilles, designers hide ventilation outlets, radiators, space under the bathroom, etc.