Angle grinders (grinders) from Interskol are very reliable and durable. They are distinguished by good performance and high reliability. But improper operation of the tool, untimely replacement of carbon brushes, lubricant and bearings leads to premature failure.

You can also repair the Interskol grinder yourself.

To do this, you need to know the structure of the Interskol angle grinder, the assembly diagram, the procedure for performing technological operations when disassembling and assembling the angle grinder. To properly repair the Interskol angle grinder, it is enough to study the proposed diagram and instructions.

Interskol angle grinders have recently become increasingly popular not only among professionals, but also among DIY enthusiasts.

Tool design features

The Interskol company is a Russian leader in the development, production and sale of various power tools, recognized by world manufacturers. Interskol products are distinguished by ergonomics, simplicity and ease of maintenance, environmental friendliness, and increased power. Interskol grinders are classified by disc diameter: 115,125,150,180,230. Among those who like to make things with their own hands, Interskol grinders of two classes are especially popular: with a disk diameter of 125 mm and 230 mm. In the presented classes, several models are produced, differing in power. In the 125 mm class, 4 (four) Interskol models are produced: angle grinder 125/900, angle grinder 125/1000, angle grinder 125/1100E, angle grinder 125/1400EL. In the 230 mm class, 10 (ten) Interskol models are produced, differing from each other in power. Grinders Interskol class 230 are produced with a power exceeding 2000 W.

The Interskol UShM 230/2300 marking stands for: an angle grinder with a maximum wheel diameter of 230 mm, a power of 2300 W.

For grinders Interskol ushm 125, the driven gears on the spindle are secured using a keyed connection. Grinders Interskol angle grinder 125 are assembled in one body, which serves as a handle.

Grinders Interskol angle grinders 230 have a convenient rear handle on the back of the body. These are powerful professional machines with a two-handed design. For angle grinders of this class, the driven gears are pressed onto the spindle shaft.

In the proposed repair instructions we will consider diagrams of two classes of angle grinders Interskol: angle grinder 125, angle grinder 230.

Necessary tool for repairing an angle grinder Interskol

It is impossible to repair Interskol angle grinders without having a simple, necessary tool. A set of screwdrivers, open-end wrenches, a vice, a hammer, and a press will help you repair the mechanical part of the Interskol angle grinder. To repair electrical circuits, you will need a tester. It’s good if you have the opportunity to use an IK-2 type device to find short-circuited turns in windings. Auxiliary materials you will need are lubricant, wipes, and washing liquid.

To carry out high-quality repairs to an angle grinder of the Interskol family, you need to prepare a workplace and select the right lighting. It is impossible to carry out high-quality repairs on the floor or in a dark room.

To repair an Interskol angle grinder quickly and correctly, you need a diagram of the angle grinder you are planning to repair.

Malfunctions in angle grinders are divided into mechanical and electrical.

Anchor on an angle grinder: how to check the armature of an electric motor at home

If you are absolutely sure that the anchor is broken, then you will need to get the electric motor.

Disassembling the motor should be carried out as carefully as possible. Disconnect all brushes and terminals from power.

Do not forget that before changing the winding, no matter which power tool Bosch, Sparky, Makita, Interskol, you need to manually determine the reasons for the breakdown of the grinding machine. To do this, a winding and gear diagram, as well as a special indicator, will help you. We take out the rotor, and with it the support bearings and the cooling impeller. All this represents a single whole object. If you notice that most of the wiring is damaged and the balance is off, then it is better to replace this component completely. The fact that the balance is disturbed can be indicated by the appearance of hum and vibration in the mechanism.

If the balance of the anchor is not disturbed, and the problem is only in winding, then the anchor must be restored. The work will involve rewinding the coil yourself, everything must be done carefully with patience and accuracy. If the balancing of the angle machine works intermittently, then first you need to check it with a tester. If the groove shows different data, you will not be able to repair the electric motor yourself. But a replacement will help restore it.

In order to replace the rewind in the armature you will need:

- New wires for winding should be copper wires, the diameter of which will correspond to the previous wires;

- Dielectric paper for winding insulation;

- Varnish to fill the coils;

- Soldering iron with solder and rosin.

Before rewinding, you need to count the turns of the wire and apply the same number in the new winding.

Basic electrical faults of the grinder Interskol

As a rule, the most common cause of failure of an angle grinder is an electrical fault. The main percentage of electrical failures of grinders is the failure of carbon brushes.

Repair of control circuits for angle grinders Interskol

The control circuits of grinders of different models are slightly different from each other. It all depends on the power of the tool and the availability of innovative developments. Some angle grinders have a built-in electronic unit that regulates the smooth start.

Wiring diagram of the control circuits of the angle grinder Interskol ushm 125

In Interskol angle grinders 125 angle grinders, electric brushes pos. 55 are mounted in special brush holders pos. 44, which can only be reached by removing the back cover pos. 51 of the stator housing pos. 42.

After removing the cover, you need to unscrew the screws pos. 50 holding the brush holder housing.

Brush wear is determined by their remaining length. The length of working carbon brushes cannot be less than 5 mm.

Power is supplied via cable pos. 53. At the points where the cable enters the angle grinder and into the plug pos. 53, the cable may break off. The malfunction can be resolved by replacing the entire power cord or the failed part. Twists are not allowed.

The power cable supplies voltage to the switch pos. 41, inserted into the housing at pos. 47. To control the switch button there is a lever pos. 46. When performing maintenance, clean the switch lever with silicone grease.

Wiring diagram of the control circuits of the angle grinder Interskol ushm 230

Power is supplied via cord pos. 50 to the switch pos. 46, to which the electronic unit pos. 40 and carbon brushes pos. 38 inserted into brush holders pos. 37 are connected. The electrical part of the angle grinder also includes a stator, pos. 32, and a rotor, pos. 27.

Replacing carbon brushes on angle grinders Interskol USHM 230 does not require removing the back cover. It is enough to unscrew the cap of the brush holder pos. 36 and pull out the brush holder with the carbon brush. But you can replace the switch, electronic unit, capacitor pos. 42 only by disassembling the rear handle pos. 44, 45. To do this, you need to unscrew four 4x16 screws, pos. 44.

How to repair the rotor of an angle grinder Interskol

Rotor failure occurs for the following reasons:

- The carbon brushes have worn out or are faulty;

- Short circuit or breakage of windings;

- The lamellas of the armature commutator have worked:

- The rotor bearings are damaged or jammed.

Rotor repair requires special knowledge, instruments and equipment. It is preferable to buy a new rotor or send it to a specialized service center for repairs. But remember, it costs money. For those especially gifted, we recommend rewinding the rotor with your own hands.

Use a puller to remove the bearings from the armature. But you can also use improvised means. For example, a vice, strips of metal, a hammer, a soft metal attachment.

Dismantling bearings from the armature ushm 125

There are two bearings installed on the rotor, pos. 31: the rear one, near the collector, pos. 32.

Bearing size 608Z.

And on the impeller side there is a bearing, pos. 28, size 6000-2 RS. Russian analogue 180100.

The bearings are removed after removing the rotor from the gearbox housing. To remove the rotor from the gearbox, you need to remove the bevel gear drive, position 26, sitting on the rotor shaft.

To do this, you need to unscrew the M8x3.5 nut, pos. 25, and remove the drive gear Z=12. It is fixed with a key pos. 30. The bearings are removed using a puller.

Dismantling bearings from the armature ushm 230

To remove the bearings from the armature, pos. 27, it is necessary to pull the rotor out of the gearbox housing, pos. 19. Unscrew the M8 nut pos. 20, remove the locking washer pos. 21, remove the drive gear pos. 22. gently rocking, pull the rotor out of the gearbox housing. The bearing will remain in the gear housing. It is closed by a bearing cover, pos. 25, which is attached to the gearbox housing with three M5x8 screws, pos. 26. A bearing of size 6201-2RS is installed in the gearbox housing. Russian analogue 180201.

On the collector side, bearing pos. 28 is removed using a puller. Bearing size 608RT. Russian analogue 180608.

Repair of the stator of the grinder Interskol

Repair of the stator of any angle grinder Interskol is carried out after determining the nature of the malfunction. Most often the stator burns out. This occurs due to overheating of the tool. A malfunction of the stator is indicated by involuntary uncontrolled spinning of the rotor of the angle grinder.

To repair the stator, it is necessary to remove it from the housing. The performance of the stator can be checked without removing it from the housing. But this can only be done in specialized workshops. Or if you have an IK-2 short-circuited turns monitoring device. It is possible to determine a break or short circuit in the stator windings without dismantling the stator. The burnt stator is removed, rewound, or a new one is installed instead.

You can rewind a burnt stator yourself.

The rewind algorithm is as follows:

- Cut the damaged winding from one edge in any way;

- You count the number of turns of the winding, determine the direction of its winding, the percentage of filling of the stator core groove, measure the diameter of the wire;

- After removing the burnt winding, clean the core grooves and check the insulation;

- Using the prepared wire, wind the required number of turns of the stator windings into the prepared grooves;

- Solder the ends of the windings, having first put an insulating wire on them;

- Impregnate the stator windings using alternating current;

- Clean traces of impregnation inside and outside the stator housing;

- Check the free movement of the rotor inside the stator.

DIY video of repairing the stator of an angle grinder Interskol

Video:

Where can I buy

Employees of companies that sell power tools and components for them offer buttons for angle grinders of various types and brands.

So, there is a situation: yesterday, out of the blue, the button on the grinder fell out (ZUBR machine, 1100W, 125 disc). It seems that the device is under warranty (not even a year old) - but I don’t need to wander around to service centers, but to work... so I disassembled it myself... As a result, what we have is a broken plastic thing, which is located in the body of the instrument and to which the main one is attached power button (it’s plastic, shaped like an “G”). This is not available anywhere in the city - not even in the service center... What should I do, what can I replace it with? Or what should we do now?

Mechanical malfunctions of the grinder Interskol

Of the mechanical faults in Interskol angle grinders, the gearbox remains the weak point. The gears used in the gearbox wear out over time, the teeth are destroyed, and backlash appears in the connections.

Repair of the grinder gearbox Interskol ushm 125

In order to repair the Interskol angle grinder gearbox, it is necessary to establish the nature of the malfunction. Most mechanical gearbox malfunctions are determined visually or by ear. Large runout of the spindle shaft, jamming or turning of the gears of the gearbox are determined by a simple inspection of the condition of the spindle shaft. Increased noise during operation of the gearbox, uncharacteristic sounds, and overheating can be detected by ear or by touching the housing with your hand.

To disassemble the gearbox, you need to unscrew (4) four M4x14 screws, pos. 11, remove the DU-1000ER locking washers, pos. 12, and pull out the gearbox cover, pos. 13. The mounted spindle, pos. 10, will remain in it. The spindle is mounted in bearing pos. 14. Bearing size 6201-2RZ. Russian analogue 180201.

To press the spindle out of the bearing housing, you need to use a press. But you can carefully knock it out with a hammer. The main thing is not to damage the gear housing cover.

The bevel gear wheel, pos. 16, is held on a keyed connection and secured with a retaining ring, pos. 17. A ball with a diameter of 3 mm is used as a key in the Interskol angle grinder 125/900. If you remove the retaining ring, removing the gear is not too difficult. In other models of angle grinders Interskol USHM 125, a key is used.

Remove the gears and inspect them for licking teeth, destruction or snagging, or any play in the key joint.

Repair of the grinder gearbox Interskol ushm 230

To disassemble the USHM 230 gearbox, you need to remove the cover pos. 6 by unscrewing 4 (four) screws. The spindle, pos. 8, is held in a bearing, pos. 9, pressed into the cover body, pos. 6. Bearing size 6203zz. Russian analogue 180203.

The gear wheel pos. 11 is pressed onto the spindle with tension. To remove it you will need a press. Craftsmen manage to remove it with a hammer, after heating the gear.

Remove the gears and inspect them for licking teeth or destruction.

Repair of grinder Interskol ushm 230

Video:

Necessary tools for disassembling the angle grinder gearbox

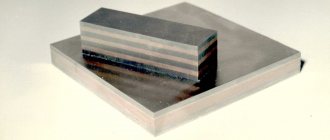

Lubricant for Makita angle grinder gearbox, 30 grams. Photo VseInstruments.ru

Disassembling the grinder gearbox should be done at a prepared workplace , where there are no unnecessary parts. This is necessary so as not to lose small elements of the gearbox design. The workplace must be equipped with the following tools and equipment:

- bench vice;

- a set of wrenches and screwdrivers;

- various types of hammers - from wooden to steel;

- pliers;

- tool for working with retaining rings;

- gas key;

- pullers for bearings and gears pressed onto the shaft;

- for high-quality assembly of bearing assemblies, it is good to have appropriate pressing equipment;

- in its absence, you can use extensions of various designs;

- rags with detergents (kerosene and other similar liquids);

- availability of lubricants.

Assembling an angle grinder Interskol

Assembling an Interskol grinder is no different from assembling grinders of other brands. Serviceable parts and assemblies, free of old grease, are allowed for assembly. Assembly consists of several stages.

How to assemble an angle grinder gearbox Interskol

To assemble the gearbox assembly, it is necessary to assemble the spindle by putting bearings and bevel gears on it.

The gear housing cover pos. 13, bearing pos. 14, bearing caps pos. 15, and bevel gear wheel pos. 16 are put on the spindle pos. 10. The gear is fixed on the spindle with a keyed connection. In the 125 angle grinder, a ball with a diameter of 3 mm is used as a key. To fix it on the spindle, the gear is fixed with a locking ring, pos. 17. The assembled spindle is inserted into the needle bearing pos. 18. And the needle bearing is pressed into the gearbox housing, pos. 21.

The assembly of the gearbox USHM 230 begins with the assembly of the spindle assembly, pos. 8, onto which the bearing, pos. 9, and the retaining ring, pos. 10, are mounted. The gear wheel, pos. 11, is pressed onto the spindle. The spindle is inserted into the roller bearing pos. 12. Bearing size NK1210.

To facilitate the process of pressing the driven gear, pos. 11, onto the spindle, pos. 8, heat the gear and cool the spindle.

How does an angle grinder work?

The design of the grinder consists of the following main parts: electrical and mechanical . In the mechanical component of the angle grinder, the main character is a bevel gearbox , which reduces the speed to an acceptable value. In an electric the commutator motor determines the operation of the angle grinder, where power is transferred to it using a special switch. Of course, its failure interrupts the supply of electrical energy from the network.

Scheme of operation of the grinder. Source here

How to assemble an angle grinder Interskol

The assembly algorithm for the Interskol grinder is as follows:

- The stator is inserted into the housing;

- The stator is covered with plastic protection;

- A rotor with a protected rubber bushing on the commutator bearing is inserted into the stator;

- The second end of the rotor is inserted into the gearbox housing;

- The drive gear is mounted on the rotor and secured with a nut with a right-hand thread;

- The gearbox housing is attached to the stator housing with four screws;

- The smooth rotation of the rotor is checked;

- A cover with a driven gear is placed on the gearbox housing;

- Tighten 4 (four) screws securing the gearbox cover;

- The smooth rotation of the tool spindle is checked;

- Carbon brushes are installed;

- The back cover is put on or the handle is assembled;

- A test run of the tool is carried out to check the smooth operation.

According to the given algorithm, all grinders of the Interskol family are collected without exception.

Several features when disassembling and assembling the Interskol grinder:

- To efficiently remove old grease from the gearbox housing, it is better to heat the latter with a professional hairdryer until the lubricant becomes liquid and then remove it;

- In some models of Interskol angle grinders, the drive gear is fixed on the shaft with two nuts, one of which is a locking nut S=12;

- Carefully unscrew or tighten the fixing nut of the rotor driven gear in the Interskol angle grinder 115;

- Place lubricant in the gearbox housing that is less than half its volume;

- When disassembling, carefully inspect the condition of the collector lamellas; there should be no signs of burning or worn out tracks.

Diagram of a commutator motor with a rotation direction switch

So, we open the device and see a bunch of dust and dirt that has accumulated over a long period of use, we clean it all and wash it with napkins and degreasers.

We check the brushes, and all electrical connections on the terminals, having tightened and cleaned, we take out the rotor of the commutator electric motor and check it by visually inspecting the windings and plates, so that nothing sticks, the bearings should be intact without cracks, and they should rotate freely without jamming, noise and play .

Next, we proceed to the switch, as it turned out, it became the culprit, here the switch button switches two conductors of the circuit at once. We clean the drive lever itself with silicone grease so that it moves more easily in its guide groove all the way to the switch.

The switch can be removed and disassembled; I couldn’t repair the burnt out half, so I shorted one of the wires directly, and the second is now used to turn it on and off.

Over time, the contact came loose in the switch, began to spark and heat up, and part of it melted.

You can, of course, replace the entire switch, which would be correct, but the owner wanted it as cheaply as possible, since the tool is not very expensive, and it’s not new anymore, so I had to do this, a new switch costs about 400-500 rubles in the city, which not very cheap.

After assembling the angle grinder, we make sure to test and check the operating modes at idle before handing it over to the owner.

So, I’ll briefly describe what’s what and why. I really like these grinders, they have been tested over the years. There are my own sores, which I rate as completely insignificant. One of its most important advantages is a very reliable gearbox, gears and housings as a whole, a powerful motor, and convenient dimensions. The previous one, which is still there, burned down after two years of my abuse of it. I didn’t change the rotor on that one, I decided to just buy a new one, because I doubted the quality of the spare parts, I was afraid that they might send a linden for the original, or that the quality in general was not the same. But with that new one, trouble happened; apparently, some kind of metal scale got inside the armature channel and shorted it. I rummaged around, picked up an interesting option that inspired confidence and ordered it paired with two sets of custom-made brushes, which are also quite decent in appearance and inspire confidence. ) In general, I wanted to do all this with the old one while the new one was alive, but who knew. In general, here is a video, there are comparisons, and a description of the repair process with tips on what and how. I hope you will enjoy. )

Later, in an hour or two, I’ll add a short video with the results, so to speak. )

Question, is it only me that Movavi produces such lags? Tell him...

For one thing, here is the link where I got it, no complaints or claims on my part, I checked it myself, I’m happy with everything. rotorua.com.ua/product/ja…lgarki-interskol-125-900/

A few words about lubrication of the Interskol grinder

Before assembling the mechanical components of the Interskol angle grinder, be sure to lubricate the parts with the recommended lubricant. Lubricants from foreign and Russian manufacturers are widely represented on the Russian lubricants market. Today you can purchase high-quality lubricants from domestic manufacturers. They are in no way inferior in quality to their foreign counterparts, but are several times cheaper.

A special lubricant with high adhesion has been developed for grinder gearboxes. Adhesion is the property of a substance to adhere to a lubricated surface.

Conclusions:

- When choosing an angle grinder, opt for a Russian angle grinder from Interskol;

- You will receive a reliable, durable, ergonomic, cheap tool;

- Give preference to Interskol grinders of the USHM 125 class;

- In the household they are more in demand and safer.

I wish you success!

Useful instructions - how to replace the brushes and cord of the sander

Often the Interskol angle grinder stops working due to damage to the cord or wear on the brush, so it is unlikely that they will reach the stator and the device is not working at full capacity.

You already know how to remove the cord from the previous instructions for removing the button of an angle grinder (from point 1 to point 3). All that remains is to figure out how to get to the brushes and replace them with new ones.

Also check the commutator, which may be scratched by worn brushes. Scratches can be cleaned up with zero-grade sandpaper.

VIDEO REVIEW » alt =»»> If your coffee grinder stops turning on when you press the start button, do not rush to throw it in the cart and buy a new one. Most likely, the whole point is in the “Start” button, for the repair of which you do not need special skills and knowledge. Replacing a grinder button from Interskol and other companies is much cheaper than buying a new angle grinder.

Source