How does he work

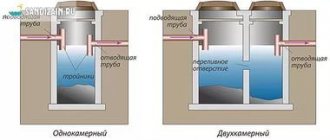

All used water and wastewater flows from the house through pipes into the septic tank. There they settle and undergo primary purification with the help of special microorganisms. At the end of this process, the wastewater can be transported to filtration fields.

According to the technology, the tank goes deep into the ground to a depth of one and a half to two meters, this is enough to avoid the need for additional insulation. Indeed, in most of Russia, the ground simply does not freeze that deeply. In addition, a small amount of heat emanates from the container itself, generated due to the activity of bacteria and chemical reactions during the decomposition of organic substances.

In any case, it is worth taking care of sufficient thermal insulation of the pipes connected to it, since they do not lie so deep and can freeze even in slight frosts.

But if for some reason the container is on the ground or you live in a region where the thermometer drops significantly below zero, then it is necessary to insulate the septic tank in advance.

Installation of insulating blind area

If you need to quickly insulate a septic tank when winter has already begun, a simple method can help out, which we will tell you about now.

Its main task is to prevent freezing of drains in the first two chambers of the septic tank. Such insulation is carried out in temporary and permanent versions. If the soil is not frozen and it can be graded, the platform should be leveled above the septic tanks and foam sheets should be laid on it so that the width of the planned blind area is greater than the vertical freezing point of the soil. For example, if the ground freezes to 180 cm, then 2 widths of blind area need to be laid on both sides of the chamber. The result should be a platform made of foam sheets measuring 4x4 m. The thickness of the insulation in this case does not matter. The area of the covered surface is important. With a temporary blind area, foam sheets can be pressed down with boards and bricks.

If possible, it is better to insulate a septic tank with penoplex in a major design.

Otherwise, we will have to return to this problem every year. The choice of blind area size is carried out in the same way as in the temporary version. Further work should be done as follows:

- Above the septic tank, you need to select soil to a depth of 20-30 cm and make a sandy substrate in the excavation.

- After this, lay the foam plastic on the sand, connecting its sheets to each other using factory grooves located at the ends of the products.

- Then the insulation must be covered with a ten-centimeter layer of sand to avoid damage to the material.

- Geotextiles are laid on top.

- On top of it, you can carry out crushed stone preparation, concreting, laying tiles, or create any other hard covering that will allow you to move freely on it without compromising the thermal insulation.

Is it possible to install a treatment plant in winter?

Surprisingly, many experts advise installing a wastewater treatment plant in winter. Installing a septic tank in winter has the following advantages:

- Since construction and renovation work stops during this period, you won’t have to wait for a specialist. Also, the masters will be able to give you maximum attention.

- It is better to install a septic tank in winter for the reason that the groundwater level during this period decreases to a minimum, so digging a pit and a trench for the supply and drainage of wastewater will not arise.

- In principle, there is no difference when installation work is carried out. The only problem may be unfavorable weather conditions.

- Since no one lives at the dacha in winter, the work will not bring any inconvenience to the household.

- In winter, discounts often appear on many building materials and services provided, so you can save money.

Installation of a septic tank in winter is carried out in the same sequence as at other times of the year:

- First, a pit and trenches are dug for the supply sewer pipeline and the discharge of treated wastewater.

- After this, sand cushions are made at the bottom of the pits, which are then compacted.

- A septic tank is installed, a pipeline is laid and connected.

- The pit and trenches are backfilled.

Insulation of the supply pipe

The supply pipe of the Topas septic tank, according to the installation diagram, is placed at an angle, the water in the main does not stagnate. However, there is a risk of gradual icing of the inner walls of the pipes, making it difficult for the next portions of waste to pass through. To avoid emergency situations, supply and connecting pipes are wrapped with mineral wool when laying. With a standard height for connecting pipes (32-52 cm), residents of private houses and dachas in Russia make do with a 5 cm layer of thermal insulation. The pipe insulation is also covered with a waterproofing compound.

Conservation of septic tank Topas

Activated sludge contains bacteria that consume human waste, convert it into harmless substances, and then can be used as fertilizer. If you completely drain the water from the septic tank for the winter, then a critically low temperature below -15 ᵒC can completely destroy all existing living flora.

In addition, in the spring, an empty tank can be torn from the foundation by the lifting force of groundwater and raised to the surface, which will lead to complete failure of all equipment.

How to clean a Topas septic tank

All purchased Topaz septic tank models are supplied with detailed instructions on how to prepare the septic tank for winter. Popularly it can be stated as follows:

1. First of all, the installation must be completely disconnected from the electrical network at the main electrical distribution panel. If the design allows, it is advisable to lock the switchboard to avoid accidental switching on, which can lead to electrical injury.

2. All chambers of the septic tank and the filter are cleaned of solid, undecomposed residues. The activated sludge remains intact in the chamber so that bacteria do not die.

3. All removable electrical equipment, such as a compressor for water aeration and a sump pump, is turned off and dismantled.

3. The level of water that remains in the septic tank for the winter must be at least 75% of the optimal level. Excess water must be pumped out, and the missing water must be added from the water supply network.

4. Even with careful insulation, water may freeze. To prevent the formed ice from crushing the septic tank, plastic bottles can be placed in the water. They are filled with sand to 1/3 of their volume in order to take a vertical position. Each bottle is tied with a rope to the body of the septic tank so that they can be easily removed in the spring.

5. The septic tank lid is carefully insulated. For this, polystyrene foam, sawdust, hay and straw are used. The insulation layer must be covered with plastic film or other similar material. In this case, it is imperative to ensure active air exchange inside the tank in order to support the vital activity of bacteria. You can make small holes in the foam.

6. How to insulate a septic tank for the winter determines its performance for the entire summer period. The main thing is to preserve the vital activity of bacteria.

Location of elements of the Topas septic tank

Preservation of septic tank Unilos

In this case, the algorithm of actions is approximately the same. First of all, the stabilizer tank is cleaned or from various solid residues that cannot be decomposed. Considering that septic tanks from this manufacturer are intended for use all year round, then such cleaning must be performed periodically.

Preservation of the Unilos septic tank for the winter

The water level is brought to 1/3 of the total. All existing equipment is disconnected from the power supply, dismantled and placed in a warm place.

The maintenance hatch can be insulated in any way, but air circulation inside the septic tank must be ensured so that bacteria do not die. In case of possible freezing of water, it is necessary to perform approximately the same measures as in the previous version.

Preservation of septic tank Astra

These cleaning plants are equipped with a special device called an airlift. With its help, you can clean the tank from silt and other sediments. Therefore, before conservation, this procedure is performed without much difficulty.

Using a drainage pump, the septic tank stabilizer is cleaned and the filter is washed. The power is turned off and electrical equipment is dismantled. The septic tank lid is insulated using all available means.

Astra septic tank diagram

High-quality and timely conservation ensures long-term operation of such devices. Only specialized enterprises can provide full preparation for the winter period, which, for a relatively small fee, will carry out all the work in accordance with the regulations.

Useful tips for preserving a septic tank for the winter

Local treatment facilities in the form of an inventory septic tank are a rather complex device. Therefore, after the installation has been installed and put into operation, it is advisable to carefully study the attached installation and operating instructions.

All manufacturer’s recommendations must be followed strictly so that you can operate the Tver septic tank in winter and summer without unwanted breakdowns.

Heat-insulating box for sewerage insulation

This is the laying of a drainage main on the surface of the earth, provided that it is impossible to lay pipes in the ground. In permafrost conditions this is very problematic and labor-intensive. In addition, communications can be damaged by moving soil, and some negative factors may arise in the frozen layer of earth:

- Sewerage is a source of constant heat, with liquid at a positive temperature.

- Not all thermal insulation can prevent heat exchange between communications and soil.

- This contributes to the thawing of the soil around the ground, and the formation of a swampy area.

Diagram of the thermal insulation box

As a result, the soil begins to subsidence, it becomes wet and heavy. The load on the collector increases significantly, and there is a high probability of pipe damage at the seams. In such situations, sewerage is laid in boxes, wooden and concrete boxes. These structures protect communications from frost, since there is thermal insulation material inside the boxes:

- Styrofoam;

- expanded clay;

- isover;

- glass wool

An example of a thermal insulation device made of foam plastic.

Also, when installing externally, do not forget about the technological slope, but in this situation it is not always possible to arrange such a slope, so a fecal pump is installed on the collector. This type of insulation is often installed in permafrost zones, during which a pit is dug into which a box is installed and a drainage system is laid. The pipes are wrapped with heat-insulating material, the top of the box is closed with a lid and covered with earth.

How to properly preserve a septic tank for the winter

If the cleaning station was purchased ready-made, it should be accompanied by instructions with a detailed description of the winter preservation of the septic tank. Here is the sequence of actions that are recommended to be performed:

- First you need to de-energize the station. To do this, you need to use an automatic switch mounted somewhere in the house and/or press the on/off button directly on the station body.

- After this, you need to remove the air compressor. Since this device is mounted in the working compartment of the station using special clips, it will be quite easy to disconnect it.

- If the treatment station is equipped with a forced discharge system, it is necessary to dismantle the pump with which clean water is removed from the system.

- Then you need to check the liquid level in the septic tank. The optimal loading size for a septic tank before winter storage is ¾ of the total volume.

- If the amount of liquid in the septic tank does not reach this value (which happens quite often), you need to add regular water to the container to make up for the missing volume.

- All that remains is to insulate the septic tank lid by placing a layer of insulation (for example, polystyrene foam or expanded polystyrene) under a layer of stones hiding the septic tank lid.

The last point is not necessary if the winters in the area are not severe. A properly preserved and insulated septic tank will survive the winter cold without much damage to its inhabitants, since the temperature of the liquid inside the system will remain quite high.

The process of insulating the septic tank lid is presented in more detail in the video:

Some more useful tips for owners of industrial septic tank models:

- if the treatment station is equipped with a sludge stabilizer with a built-in air lift, it is recommended to clean this section before preserving the septic tank;

- the receiving chamber of the septic tank should also be cleared of solid accumulations;

- if you don’t have polystyrene foam on hand, insulate the cover of the treatment station with other suitable materials, for example, dry grass, straw, mulch, etc.

Please note that conservation of the septic tank should begin closer to winter, when the soil is cold, perhaps slightly frozen. This will slightly reduce the impact of changes in the soil caused by cold weather on the septic tank.

When preserving industrial septic tanks, you should turn off the power to the device and remove all electrical appliances. They are usually mounted in accessible places; dismantling requires minimal time and effort.

Some owners are concerned that an ice crust will appear inside the plastic container on the surface of the liquid and damage the walls of the septic tank. These concerns are justified only in areas with a sufficiently large depth of soil freezing. To prevent such a nuisance, you should make several floats for the septic tank. Making them is very simple:

- Find several plastic bottles with a volume of 1.5-2 liters.

- Pour a little sand into each bottle so that part of the float remains on the surface when immersed in water. In this case, the bottle must maintain a vertical position.

- Tie a long rope to the neck of each float.

- Lower the floats into the container.

- Secure the rope so that when the septic tank is re-opened, the floats can be easily removed.

These simple steps will protect the septic tank from damage even during very severe frosts.

Insulation for sewer pipes

Since we are talking about insulating the external sewer system in a private house, let’s consider how to insulate pipes with your own hands. The most important thing in the process of insulating external sewerage is the choice of material that will determine the installation features and provide a given level of reduction in heat loss.

It should be noted that sewer insulation, as a separate type, is a non-existent material. That is, there is no single solution, and in each case it is necessary to select insulation based on the individual characteristics of the pipeline.

Thermal insulation of sewer pipes is carried out by any of the thermal insulation materials on the market.

There are only two determining factors when choosing insulation:

- climate zone. The lower the winter temperature, the lower the thermal conductivity index the insulation should have;

- pipe laying method. The choice of pipe insulation depends on the depth to which the pipes are laid (below or above the freezing level). The technology for insulating external sewers using thermal insulation comes down to two methods: the pipe is wrapped with insulation in several layers or a box is built around it.

Which insulation for sewer pipes is better to choose?

A good building thermal insulator must meet a number of requirements:

- low thermal conductivity coefficient;

- ease of installation;

- resistance to various factors: moisture, biological activity, ultraviolet radiation, mechanical or chemical influences;

- tightness of insulation;

- resource of use;

- price.

Technology for spring re-preservation of a septic tank

In the spring, the septic tank must be properly re-opened. To do this, almost all operations that were carried out during conservation should be done in reverse order:

- remove the insulation layer;

- remove the floats;

- install pumps, compressors and other equipment;

- connect power supply.

After this, the septic tank can be used as usual. After a few days of normal use, the system will return to normal. Usually there is no need to introduce new bacteria into the septic tank.

All owners of autonomous treatment facilities know that inside plastic tanks live living bacteria (aerobic and anaerobic), which help purify wastewater so much that it can be used for watering a garden or as process water. However, the septic tank is often left unattended in winter if you leave the dacha, or if you live in the house all year round, it is exposed to low temperatures. What happens to the microscopic workers of this structure? And how to protect them and wastewater from freezing in winter? Some owners are interested in the question of how to install a septic tank that will work in winter, or how to build this structure in winter? You will find answers to these and many other questions in our article.

Some owners, fearing that the septic tank would freeze in winter, made one big mistake - they completely drained the wastewater from the treatment plant and pipeline. Most likely, they did this by analogy with the heating and plumbing system, fearing that if the water froze, the plastic tank would expand and rupture. You shouldn’t do this, because the result will always be sad:

- If you return to your dacha in the spring, you will find your septic tank on top, floating in the pit. The thing is that during a flood, groundwater will easily push an empty container upward, since its volume is quite impressive and its weight is small.

- But worse could happen. Since the soil in which the tank is dug is not static, it can move as a result of temperature changes and changes in groundwater levels. During this process, the septic tank will experience significant loads. As a result, the autonomous sewerage tank will simply burst or become deformed.

As a result of this, the septic tank in winter will become unsuitable for further use. Owners will need to replace the damaged product, buy a new septic tank and install it, which will entail considerable expenses.

Details

How to insulate a system

For thermal insulation of a septic tank at a summer cottage, sawdust, leaves, and straw are used. To strengthen the material, cobblestones are placed on top. If the treatment plant is built from bricks, concrete rings, or plastic tanks, then other methods for insulation are required. The devices last for many years, so the materials must withstand a long service life so that they do not have to be replaced frequently. For example, straw may rot.

There are main methods that are used as insulation:

1. The septic tank is filled with expanded clay, which is based on clay. The material consists of porous granules of different sizes. Expanded clay has good qualities for use, it does not rot, does not allow fungus to form, and at the same time has an affordable price. Expanded clay is also resistant to moisture, has a long service life, and insulates the structure well. The material should be poured into the space between the septic tank and the soil in a layer of more than twenty centimeters. It is important to strengthen the insulation in the place where the sewer pipe enters the container.

2.Use mineral wool. It is easier to install cotton wool than to use expanded clay. The material insulates the septic tank at a high level, is resistant to chemicals and temperature changes. If the material is subject to external influence, then it retains its qualities, but mineral wool quickly absorbs water. A waterproofing film must be placed on top of the material. Mineral wool comes in the form of sheets that are attached to the septic tank with glue or dowels.

3.Use of extruded polystyrene foam. The material is resistant to temperature changes, is not afraid of moisture, and is easy to attach to a septic tank because it is light in weight. Expanded polystyrene is attached to the outer wall of the device with dowels or coy. Polyurethane foam is used to treat joints between strips of material.

4.Use of polyurethane foam. The material is considered one of the most commonly used insulation materials. This insulation has different forms because it is used in different areas of construction. It is produced in the form of blocks, rolls, sheets. The material is durable and strong. Does not form mold due to humidity, withstands external influences without forming cracks. At the same time, the material is very cheap, but heats well.

5. Install the heating cable. If a septic tank is used in regions with a harsh climate, then this measure is justified. With the help of a heating cable, the septic tank will withstand any temperature changes. It is installed in septic tanks powered by aerobic bacteria. The entire system should be insulated using sheet or bulk material, and the cable itself should be protected from moisture.

In addition to the cleaning device, the pipeline should be insulated. The pipes are wrapped in mineral wool material, and waterproofing is placed on top of the mineral wool. The waste pipe is fixed using a foam insulating box. If the soil settles, the pipe will not change its angle of inclination.

When insulating with your own hands, you must adhere to some rules:

1. The thickness of the insulating layer depends on the climatic characteristics of the region, the composition of the insulation, and the depth of the septic tank in the ground.

2. if the septic tank is located in the northern region, then insulate the septic tank from the sides, from above.

3. when insulating a pipe entering a septic tank, you should remember that the pipe can freeze, even if it is correctly laid at an angle. The diameter of the pipe may be reduced to a minimum size.

4. if the septic tank is used at the dacha only in the summer, it should be preserved for the winter.

How to preserve the device

If you use a septic tank only in the warm season, you should preserve the device for the winter. The procedure will reduce the negative impact of frozen earth on the walls of the septic tank.

Attention! Before conservation, there is no need to drain all the drainage from the septic tank, so that in the spring groundwater does not push the structure out of the hole, or the septic tank does not crack when the soil layers are displaced.

The conservation procedure can be carried out by specialists. Then you won't have to worry about doing something wrong. You can also do the preservation yourself, following the instructions in the instructions for the septic tank.

The following sequential steps must be followed:

1. The septic tank is disconnected from electricity, the air supply pumps are disconnected. These actions are not difficult to carry out, because there are special fasteners in the tank for this.

2. Three-quarters of all drains are drained of liquid from the septic tank, or water is added if there is a shortage.

3. insulation of pipes and septic tank lids is carried out.

Attention! Thirty days before storing the device, a product based on aerobic bacteria must be added to the septic tank. They will break down solid particles settled at the bottom of the chamber and eliminate odors. With proper conservation, the septic tank will maintain a warm temperature all winter, and the autonomous sewage system will not be affected.

Rules for preserving a wastewater treatment plant for the winter

If you are using a ready-made factory cleaning product, then it must be accompanied by instructions that describe in detail how to preserve the septic tank for the winter. If for some reason you cannot study the instructions, then you can use our tips on how to preserve the cleaning device for the winter:

- First of all, the volatile station must be de-energized. To do this, you can use a machine installed inside the house, or turn it off using a button on the unit itself.

- Now you can remove the air compressor. This product is fixed in the working compartment of the treatment plant using special clips, so you can disconnect it with your own hands.

- If water is drained from the station forcibly, then it is necessary to dismantle the pumping equipment. You can also remove the pump that drains purified water with your own hands.

- After this, the water level in the septic tank is checked. This can be done using a rope or other improvised product. For proper winterization of the sewer system, the water level in the treatment plant must be at least ¾ of the total volume.

- If there is too much liquid in the tank, then it is worth draining wastewater from the tank. But more often it happens that there is slightly less water than required for wintering, so it will have to be added.

- Finally, it is necessary to carefully insulate the cover of the sewerage system. This can be done with penoplex, polystyrene foam or polystyrene foam. A layer of stones is laid on top of the heat-insulating material, reliably fixing the lid.

If the winters in your region are not very severe, then the lid does not need to be insulated. Proper preservation and insulation of the septic tank will help the microscopic inhabitants of the treatment plant survive the winter cold, since the temperature in the tank will remain quite high (+4°C). This ensures that the septic tank does not freeze in winter.

The following tips will be useful to owners of factory deep cleaning products:

- If the septic tank has an activated sludge stabilizer with a built-in air lift, then this section must be thoroughly cleaned before conservation.

- The chamber into which the waste flows directly from the sewer must also be cleared of solid deposits at the bottom.

- To insulate the lid, you can use available materials - dry grass, mulch, straw, etc.

- Preservation can begin with the onset of cold weather, when the soil is slightly frozen. This will reduce the impact of soil deformation movements on the reservoir.

In regions where the depth of soil freezing is significant, an ice crust may form on the surface of the water in the septic tank, to prevent this from happening, you can do the following:

- You should take several PET bottles with a volume of 1.5 to 2 liters.

- Sand is poured into the bottles half the volume. This will allow it to float like a float in a vertical position when immersed in water.

- We tie a rope to the neck of each float bottle.

- We lower the products into a tank of water.

- We fix the ends of the rope to the surface so that in the spring you can easily remove the container from the tank.

The most expensive methods of insulating the wastewater system

To prevent the drains from freezing, you can use more expensive methods and materials. There are two options:

- Connecting the electrical cable . The technology is similar to installing a “warm floor” in a room. The container and pipes are lined with cable. As electricity passes through it, sufficient temperature will be created to combat freezing. In this case, insulation will also be required. The requirements for tightness are even higher, because the wiring cannot be allowed to get wet. The disadvantage of this technique is that it is energy dependent. There must be a stable supply at the site. The advantage is that in such a situation you can immediately power the entire system of the waste treatment and recycling station.

- Using polyurethane foam . The composition is sprayed onto the container and pipes from a special sprayer. A dense protective layer is created that does not allow water, cold and other external threats to pass through. You can only insulate a septic tank in the summer. If we insulate a septic tank for the winter in this way, we must definitely contact specialists, because without sprayers and the correct mixture of composition, observing the subtleties of technology, it will not be possible to achieve the desired result.

What if you still need a septic tank in winter?

According to experts, winter conservation of a septic tank only makes sense if the house is left unattended for more than one month

And if the dacha is still visited every 2-3 weeks, the treatment facilities will overwinter just fine without special precautions

For example, the same one calmly tolerates the absence of drains for two weeks, the bacteria remain alive, active and multiply quite successfully. The energy consumption of such a system is not at all high, so the bills for the electricity used by the septic tank will not bankrupt the owners, and the level of comfort at the dacha will remain the same.

Mixed methods of insulating external sewerage

The methods listed above can be used individually or combined. The following combinations are often used:

- when installing drainage systems using an open method, thermal insulation material and electrical wire are used;

- when arranging communications in the ground, at the lower level, where the ground does not freeze, use polystyrene foam;

- in permafrost conditions, they use insulation in the duct and electrical wire, this is due to the difficulty of carrying out excavation work.

You can combine other insulation methods; everything will depend on the desires of the owner, financial capabilities and region of residence. Watch the video on how to properly insulate a sewer.

Cheap option for insulating a septic tank

It is not necessary to invest large amounts of money on insulating a septic tank. After all, it is quite easy to cope with such a task using cheap materials.

This section of the septic tank is the most delicate. Organic materials are not suitable for its insulation due to their short service life. Indeed, straw and sawdust retain heat very well. But they quickly deteriorate, thereby losing their beneficial qualities. The summer resident will have to regularly replace rotted material to prevent the septic tank from freezing in the cold.

Expanded clay - a cheap insulation option

Expanded clay allows you to save your family budget. It is famous for its thermal characteristics. And the price for this material is quite low. Another advantage of expanded clay is its naturalness and lightness. With its help, the summer resident will be able to insulate the pit on his own. For expanded clay to be beneficial, it should be laid in a layer of at least 20 centimeters. They are recommended to tightly fill the upper part of the septic tank, as well as the conducting pipe.

Mineral wool and polystyrene foam in the best traditions of insulation

The most common materials for insulation are mineral wool and expanded polystyrene. They also did not ignore septic tanks. And they are often used for similar purposes. When starting insulation with mineral wool, you should not think that it is very expensive - the price of the work will depend on the type of wool chosen. All of them belong to the group of mineral wools. Glass wool is much cheaper than stone wool, but it is more difficult to work with. Here the high cost of insulation will depend on your choice. Important points to consider when choosing this insulation method:

- It will be more convenient to work with rolled materials. They simply wrap all components of the sewer system.

- It is worth securing the mineral wool using wire or twine.

- Don’t forget about waterproofing, because even though it is mineral, it is still cotton wool and has a “good” ability to absorb moisture.

- When laying the waterproofing layer, do not forget to overlap it, it will not allow moisture to pass through to the insulation.

insulation of a septic tank at the stage of its installation and preparatory work.

Most often, polystyrene foam is used as insulation. Here it is worth knowing that the best of them is extruded foam. It is the most durable and can withstand heavy loads. Another important advantage is minimal moisture absorption.

With its help, sewer pipes are insulated with the so-called shell. The septic tank is covered with solid sheets, which should be glued to the surface.

A new word in insulation

One of the modern options for insulating both pipes and septic tanks is the use of cables. The best option is a self-regulating cable, which is able to determine on its own where heating is needed and where it is not. It plugs into an outlet like a regular electrical appliance. This option is economical and easy to install, since you can simply wrap it around the pipes and the septic tank itself.

Another option is polyurethane foam. This foam is poured into the gaps between the septic tank and the pit. It does not need additional fastening, and it perfectly holds any finish. Its thermal insulation qualities are at the highest level.

Considering that any treatment plants, due to their functional purpose, are forced to come into contact with water, an important role is played by the thermal insulation of the septic tank and pipes. Nobody wants an autonomous sewer system to unexpectedly become a source of problems, in particular, to become clogged, and all the “happiness” that goes down into it makes itself known through clogged risers, etc. pieces. It is obvious that the insulation of the septic tank must be carried out already at the stage of its construction, in particular, when installing tanks and laying pipes.

Naturally, for summer residents who use a septic tank only in the warm season, it is enough to insulate only the container (pipes, including the aeration field pipes, do not need to be insulated), and this can be done at the end of the season - just cover the installation site of the septic tank with branches or straw, pressing it all down with boards or stones. In winter, when snow falls, this measure will significantly insulate the septic tank, preventing the water remaining in the tank from freezing.

How to insulate a septic tank

If there is a possibility of drains freezing, then proper insulation of the septic tank will help you in this difficult task. But what kind of insulation is best to use for a septic tank, you will find out further.

Polystyrene foam will not work because it tends to absorb moisture, which is an excellent heat conductor and the situation will only get worse. For the same reason, when deepening, you should not sprinkle the tank with expanded clay to insulate it. Since this mineral is destroyed quite quickly under soil pressure, as well as from exposure to moisture.

When insulating any septic tank with your own hands, experts recommend using special insulation materials. Extruded polystyrene foam Penoplex will cope best with this task. It has very low thermal conductivity and zero moisture absorption, which allows you to reliably protect the septic tank from freezing. It is also perfect for insulating concrete rings and for insulating plastic Eurocubes.

For additional safety, it is also necessary to insulate pipes with special materials, since, as practice shows, they are the weakest link in the drainage chain in winter.

When thermally insulated with Penoplex, the sewage system will properly perform its functions even in the most severe frosts.

Advantages of Penoplex when insulating a septic tank

Penoplex has a number of advantages over other types of thermal insulation materials:

- has low thermal conductivity,

- does not absorb moisture at all,

- ease of use - all manipulations for thermal insulation of a septic tank can be easily done with your own hands,

- durable - service life more than 50 years,

- environmentally friendly - does not contain phenol resins and is produced without the use of freon,

- safe - completely non-flammable material.

Take care in advance about high-quality thermal insulation of the sewer system and you will not have to think about its operation throughout the winter!

Basic materials

First, let's figure out what exactly needs to be insulated. The pipe inlet and its upper part are most exposed to cold. It is recommended to insulate the entire installation to fully protect it from frost. Most importantly, it is prohibited to use organic materials for protection. They won't be of much use and are also susceptible to rotting. We list the main materials that can be used.

Expanded clay

The use of expanded clay is a budget method of insulation. This material has fairly good thermal characteristics. The minimum thickness of the expanded clay layer is 20 cm. It is poured between the walls and edges of the pit.

Mineral wool, glass wool

These materials can protect the septic tank well, but are not resistant to liquids. Therefore, additional waterproofing is necessary. Getting wet causes a lack of thermal insulation properties.

Roll materials are used for installation of thermal insulation. The septic tank and pipes are wrapped, and they can be secured with reliable wire. Waterproofing of materials is done using roofing felt. You can also fasten roofing felt with wire.

Tip: mineral wool and glass wool are materials that can be used on a limited budget. If possible, it is better to choose more expensive materials.

Expanded polystyrene

Among all materials, extruded foam is most often used. It has sufficient strength, which has a positive effect on protection from soil influence. Expanded polystyrene also has good waterproofing characteristics. It is necessary to protect the pipe with a foam plastic shell, and the septic tank itself should be covered with foam plastic using an adhesive solution.

Foamed polyurethane

Polyurethane has:

- excellent thermal insulation;

- protection against exposure to liquids;

- vapor barrier.

Polyurethane foam can be applied to any material. No mounting hardware is required, so simplicity is guaranteed. After applying the foam, the pit is backfilled with soil.

Electric cable

This method is expensive. Thermal insulation is carried out by a cable connected to the electrical network. The heating capacity is enough to warm up the pipes and septic tank. In addition to purchasing the cable itself, you also need to purchase waterproofing materials and insulation. The use of cable is suitable for septic tanks with an aerator: then the problem with supplying electricity is eliminated.

Why is it recommended to insulate a septic tank?

Insulating a septic tank for the winter is a mandatory procedure that will extend the life of this equipment. After all, if it freezes, the sewer system will not be able to continue to function normally.

And this will make it very difficult for a person to live in a country house during not the warmest periods. Proper placement of the treatment facility’s container guarantees its protection from even the most severe frosts. After all, the temperature in the depths of the soil usually remains above zero. Namely, it is at this level that it is customary to install a septic tank made of concrete rings.

Unfortunately, even a perfectly designed septic tank installed by qualified workers can suffer from the cold. It is impossible to insure one hundred percent against this misfortune. Therefore, it is still worthwhile to insulate the system, thereby protecting yourself from possible problems.