Connecting a washing machine to a faucet is required when renovations have already been made in the bathroom or kitchen, and the cold water connection points for the equipment have not been installed.

There can be many reasons. For example, you planned to connect the washing machine somewhere else, but your plans went awry, or you simply forgot to take out the outlet for connecting the washing machine and hid the pipes under the tiles. Now it doesn’t matter, the main thing is that there is only one option for connecting the washing machine - a mixer, and you need to somehow implement it.

SEARCHING FOR A LOCATION FOR INSTALLATION

First of all, you need to choose a suitable place for the machine in the house. It is advisable to find the installation point before going to the hardware store. Otherwise, finding free space will turn into a headache, and installation work will be delayed indefinitely. Most people do not focus on finding a place, but the procedure is of paramount importance.

BATHROOM

Traditionally, the bathroom is used as a permanent home for the washing machine. Connecting a washing machine in the bathroom is quite logical: there are already the necessary communication elements to include the device in the overall system.

This method has two significant drawbacks. Firstly, high humidity levels in the bathroom negatively affect the electronics inside the machine. Accumulation of condensation on microcircuits leads to rapid equipment breakdown. Secondly, the features of the home’s layout. Often the area of the room is not enough to accommodate washing equipment.

KITCHEN

Often, when installing a machine, preference is given to the eating area. If free space allows, why not. A factor in the implementation of a unit in the kitchen is usually the lack of square meters in the bathroom. Place the “washing machine” next to the sink or directly under the sink. The presence of communications facilitates easy installation of equipment, and the close arrangement of elements reduces the work period and saves consumables. Both built-in and standard models of machines are suitable for installation.

But the method also has disadvantages. One is associated with changes in humidity and temperature changes during the cooking process. The other relates to the kitchen area. In a small space, where even cooking is inconvenient, fussing with the laundry will become a burden.

UTILITY OR HALLWAY

A hallway or utility room will serve as a permanent shelter for an automatic machine, if the size of the room allows you to install the device.

The only obstacle on the way is the issue of communication. To power the unit with electricity and connect it to the water supply system, you will have to draw additional networks to the installation site of the machine.

Determining a suitable location depends entirely on the layout of the room and the personal preferences of the owner. Just one parting word: when deciding a question, you should thoroughly weigh all the arguments and make an informed choice.

Where is the best place to install a washing machine - choosing a location

When determining how to properly connect a washing machine, first of all, choose the location wisely, based on the criteria of ease of placement, aesthetics, and proximity to water supply and electrical networks. Usually in a private house there is enough space in all rooms and problems with a lack of space for installing an assistant do not arise; besides, in individual construction, the location of household appliances and communications connections are laid out at the design stage.

Apartments in most multi-storey buildings have a much smaller area and standardly placed communications, while the selection of the optimal and convenient option is complicated, and it is necessary to use unconventional solutions and methods of connecting to the water supply system. In apartment buildings, when choosing a place to install washing machines, preference is often given to bathrooms and combined bathrooms; less often, equipment is placed in large kitchens and very rarely in toilets and corridors.

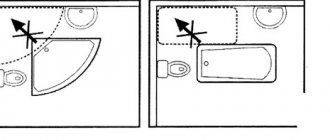

Fig. 2 Examples of placing washing machines in the bathroom

Bathroom or combined bathroom

The bathroom has a large enough area to install a washing machine near the bathtub; it is often located under the heated towel rail; the main problem with such placement is the distance from water supplies.

For this location, in order to save space, a model with a narrow body (about 40 cm) is usually chosen, and special attention should be paid to its stable and even location on the floor surface - the model has less weight, support area and is more susceptible to vibration.

With some layout options, you can place the washing machine next to the sink and cover it with a moisture-resistant countertop, which can be used for domestic purposes.

A very good option that allows you to save maximum space is to place the washing machine under a specially designed sink with a siphon located behind it. In addition to saving space and aesthetic appearance, this location is closest to communications - this makes it easier to connect the washing machine to the water supply and sewerage system. In addition, connecting to the electrical network is simplified - if the mirror above the sink is equipped with lighting, you can use one electrical line and socket.

Rice. 3 Washing machine in the kitchen

Kitchen

When installing a washing machine in a kitchen, two main methods are used - free-standing or built into the kitchen unit. When placed under one tabletop, to give an aesthetic appearance, the installation space is covered with a door facade in order to create a single composition.

In the kitchen, they try to place the machine as close to the sink as possible - in this case, pulling the sewer pipes and drain hose from the machine is simplified. To connect to the electrical network, it usually uses electrical sockets lowered down just above floor level and hidden behind the kitchen facades.

Corridor

The corridor arrangement is very rare and is used in extreme cases; in addition to the need to install sewerage and water pipes to the washing machine, its noise when working in an open room creates additional discomfort. To hide the outgoing pipes and hoses, and the unit is not conspicuous, it is more rational to install the machine in a separate cabinet or built-in cabinet, matching the color of the corridor furniture.

Rice. 4 Washing machine in the toilet

Related article:

How to close pipes in a toilet: various options and technology for carrying out the work. For those who are reading how to connect a washing machine to the water supply, it will be interesting to read how you can hide pipes in the toilet. In a separate article we describe examples of materials and modern technologies for arranging pipe shafts in a toilet. Read it, maybe you will find an interesting solution for yourself!

Toilet

Installing a washing machine in a small toilet is an even more extreme option than in the hallway; often the only place where it can be placed is the space above the toilet. If the location of the pipes allows, you can make a shelf for it from corners or an L-shaped profile mounted on opposite walls. It should be taken into account that the weight of a typical washing machine is 50 - 80 kg, so the shelf must be designed for a significant load.

If you do not provide measures to secure the legs or limit the mobility of the machine, as a result of vibration during spinning, it may fall from the shelf - this will lead to damage to the body and the sanitary toilet.

NECESSARY TOOLS FOR INSTALLATION WORK

How to quickly and efficiently connect an automatic washing machine? Before starting installation work, you should ensure that you have an arsenal of tools. For a quality installation you will need:

- set of wrenches;

- several slotted and Phillips screwdrivers of different diameters;

- pliers;

- hacksaw for metal;

- construction tool – level;

- knife;

- pipe cutter;

- roulette.

In addition to tools, you need to prepare consumables:

- rubber linings or a special carpet with an anti-vibration effect (for wooden floors);

- check valve;

- sealant;

- sealant (fum tape or plumbing thread);

- spare flexible high pressure hose (for supplying clean water);

- additional hose for draining waste fluid;

- tee (for inserting a metal-plastic pipe with a tap);

- three-core cable designed to power household appliances. Here it is important to choose the optimal wire cross-section, since insufficient thickness will lead to an overload of the electrical network and even a fire. Therefore, the recommended wire cross-section is at least 2.5 mm2;

- 16 A circuit breaker. The device successfully suppresses power outages. The device will protect family members from accidental electric shocks and extend the life of the machine.

After collecting all the necessary tools and materials, you can move on to the next stage - preparing the machine for connection.

Tools for work

To independently connect the machine to metal pipes, you will need a set of tools for cutting lines and installing valves. Threaded connections are sealed with flax tow or special sealing tape. If a plastic pipeline is used in the room, then equipment for soldering polypropylene pipes is needed.

Additionally, you will need fittings, valves, adapter and corner bushings, flexible hoses with threaded couplings (the list of components depends on the distance of the washing machine from the switching point).

It is recommended to purchase high-quality components; when installing low-cost products, there is a risk of parts being destroyed during installation or operation.

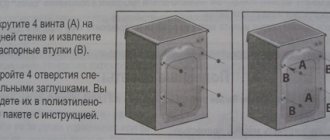

PRE-SETTING THE WASHING MACHINE

A purchase that has just been delivered to your home requires preliminary preparation. Correct connection of the washing machine begins with removing the “non-working” shipping shell. The latches are designed to reduce the risk of deformation of the machine during transportation, but in stationary conditions they should be discarded.

- On the back side, you need to remove the clamps that secure the outlet hose and the network cable.

- There are also bolts for securing the drum on the rear panel. They must be unscrewed, and plastic plugs are placed in place of the holes (included in the basic configuration of the machine).

- At the base of the machine there are clamping bars that separate the tank of the machine and the walls of the body. Wooden pads are needed for transportation, and must be disposed of before use.

You should not throw away the shipping items right away. You may have to return them to their place when contacting the service center. Therefore, it is better to leave the fasteners in storage. You should remove the operating instructions and spare parts from the drum of the machine.

Now that the washing machine is completely ready for connection, you can begin installation work.

Connecting an automatic washing machine to the sewer with your own hands.

This can be done in one of 2 ways. Temporary and permanent.

- The first method involves the absence of a permanent connection to the sewer. The drain hose is simply directed into the bathroom or toilet.

- The second method is divided into two options. For the first option, a siphon is required. Moreover, it must be of a special design. It contains a separate input for washing machines. The second option involves the absence of a siphon. The pipe is connected directly to the sewer pipe. The main thing is that the water drainage hose does not come into contact with the waste water in the pipe. Then the hose must be carefully sealed. The height between the floor and the bend should be no more than 50 cm.

WATER CONNECTION OPTIONS

How to connect an automatic washing machine to water? Various options are suitable for tapping into the water supply system. Let's look at the most common ones.

PREPARED BAND

Connecting a washing machine to water through a ready-made outlet is the most basic and rational solution. At the time of laying communications, a separate line is allocated specifically for connecting the “washing machine”. The isolated pipe at the end is closed with a tap or plug until connected to the device.

In this scenario, the owner will simply connect the unit to the system. One end of the braided hose is screwed onto the threaded connection of the faucet, and the other end is attached to the corresponding branch pipe of the “washer”. Then open the tap valve and check the connection for defects. To avoid leaks, each connection is additionally reinforced with a special sealant or sealing tape.

TEE

An alternative solution when there is no ready-made outlet or there is no desire to tie into the system yourself. The essence of the circuit is to power the “machine” from a functioning highway. A cold water supply hose to a sink, toilet or sink is suitable for connection. A tee is introduced into the system, which has an additional function - filling the washing tank. The “washing machine” hose is connected through the splitter to collect water.

To install you will need:

- wrench of the required size;

- sealing tape;

- tee with tap;

- additional extension hose (if necessary).

Installation involves inserting a tee in place of the old connection of the cold water pipe. You need to unscrew the hose nut with a wrench and screw in the tee. All joint elements should be pre-sealed, the nuts should be securely tightened with a wrench, and then checked for leaks.

This method has a significant drawback - a drop in water pressure when the machine and sink mixer operate simultaneously. At the moment the automatic device is filled, the water pressure in the mixer drops to almost zero.

BATHROOM MIXER

The third solution is applicable if the water supply system is located in a hard-to-reach area. How to connect a washing machine in the bathroom without any hassle?

First of all, you will need a special three-way faucet and an extension cord to connect the washing machine. You will also need a set of matching wrenches and a few extra spacers.

Independent work begins with shutting off the water in the outlets. Then you need to unscrew the mixer using wrenches. A tap with an additional free outlet is screwed onto the cold water outlet. An extension cord is attached to the hot water supply line. A previously removed bathroom faucet is installed on top of the structure. Now a washing machine is connected to the free outlet of the tap.

After the completed manipulations, you will get an independently operating mixer with an additional dedicated line for the machine, which can be shut off at any time. When connecting for the first time, it is important to make sure that the structure is tight and there are no leaks.

INSERT IN AN ARBITRARY PLACE

The most difficult connection method of those listed is tapping at an arbitrary point in the water supply system. A certain level of training will be required from the master. But independent work will not be difficult if you have the appropriate tools and materials. How to connect a washing machine to water in the required place?

The technological process largely depends on the material of the pipe that the master will have to deal with.

Steel pipe

Steel pipes have almost completely become obsolete, but are still found in old buildings. The purpose of the work is to punch a hole in the metal pipe and secure the drain valve for the “washing machine”.

We stock up on the following tools:

- electric drill;

- set of wrenches;

- saddle coupling;

- tap;

- sealant (fum tape).

First you need to turn off the main tap and get rid of the remaining water through the mixer. Then you should find a suitable point to create the hole. The designated area must be cleaned of rust and paint. Next, a preliminary “fitting” of the tap on the pipe is carried out. Place a rag under the pipe to absorb spilled water when using a drill and drill a hole of the required diameter. The joint elements are cleaned of chips, treated with sealant and joined together.

Metal-plastic pipe

A cross section of a metal-plastic pipe clearly demonstrates the features of its design. It resembles a “sandwich”, where the metal base is enclosed in a plastic shell on both sides. Working with a metal-plastic pipe consists of introducing a tee into the system. In the right place, the pipe is cut and the adapter is screwed in. The machine is connected through the free outlet.

For installation work you will need:

- tee with tap;

- metal hacksaw or pipe cutter;

- set of wrenches;

- sealant;

- calibrator

How to connect a washing machine to a metal-plastic pipe? The first step is to turn off the main water tap and drain the remaining water through the nearest faucet. Then, in the designated area near the washing machine, cut the pipe with a pipe cutter. The separated ends need to be bent in different directions for the convenience of further work. Bevels are made on each edge using a calibrator. Remove the nuts with ferrules from the tee and attach them to each edge of the pipe. Elements with notches are additionally treated with fum tape in the direction of the thread. Then a tee is attached to the empty space, and the free outlet is connected to the washing machine.

Polypropylene pipe

Plastic pipes are gaining more and more popularity. Most often, when laying the main line, the connection of the “washing machine” is taken into account and an adapter is initially introduced. If a mistake was made in the work, you will have to install it yourself.

The installation technology largely corresponds to working with metal-plastic. Only here the tee is not pressed with nuts, but is soldered under the influence of high temperature.

Before making repairs yourself, you should prepare:

- pipe cutter;

- tee with tap;

- soldering iron;

- sealant.

The instructions for work are as follows: traditionally, the action begins with shutting off the water supply through the emergency tap. The remaining water must be drained through the mixer. The marked area for insertion should be located in an accessible place near the “washing machine”. Using a pipe cutter, cut out a piece of pipe, with a margin of 1.5 cm on each side. The final length of the removed section should be 3 cm shorter than the length of the adapter.

One end of the pipe must be thoroughly dried and heated with a soldering iron to the required temperature for 5 seconds. Then quickly connect to the tee and press the parts tightly for 10 seconds. A similar procedure must be carried out with the other edge of the pipe.

Fum tape is wound onto the free outlet and the tap is screwed on. The hose from the washing machine is connected to the tap and the water supply is turned on.

Ways to tap into a water supply system yourself

If the installation is carried out in an apartment, into laid internal pipes (metal-plastic or polyethylene), then a regular tee will be needed. And the lack of pressure in the system, that is, a closed valve on the main pipe, after the meter.

It is impossible to insert a pipe into a polypropylene pipeline without soldering. You can connect to metal-plastic pipes using special fittings, in particular these are tees that are fixed using compression or push fittings.

If you have a steel pipeline, you will need an overhead coupling with rubber gaskets and a special threaded outlet for a washing machine; an analogue can be a modern compression fitting.

Installing an overhead coupling involves turning off the water. Holes are drilled in the selected pipe area. The two halves of the coupling are then placed over this area and bolted tightly together. A shut-off valve is installed in the central outlet, which has a threaded pipe for connecting the hose from the washing machine.

If a tee is used to connect the washing machine to the water supply. A small cut is made in the pipeline so that each end of the pipe fits tightly onto the tee without being deformed.

The fitting from the tee cannot be installed in a narrow area, so during the installation process one end is bent, the tee is inserted into it, and then the fitting is inserted into another part of the pipe.

The final fixation of the ends of the pipe is carried out by screwing the union nuts to the tee. Do the same with compression tees when installing a branch on polyethylene or metal-plastic pipes.

Plumbing under pressure

If we are talking about connecting to a common main line, without the ability to shut off the water, then you will have to work under pressure.

For this type of insertion, special clamps are used. The technology provides for efficiency and speed of installation.

Before cutting into a pipe under pressure, you must consider:

- dismantling protection and insulation at the insertion point;

- the diameter of the branch pipe is smaller than the main pipe;

- additional fixation of the elements is necessary, the flange is fixed with a valve on which a device for making holes is installed;

- when working with a steel product, a pipe is used instead of a clamp, which is pre-welded. A valve (branch valve) is mounted to the branch pipe, on which a cutter is provided;

- the seam on the main pipe is boiled;

- the next step is to install a cutter of a certain size; if the hole is made, then the cutter is removed;

- Upon completion of the insertion, the anti-corrosion coating and insulation are restored.

Attention! independent connection to the water main must be registered with the water utility and SES. According to the rules, design and estimate documentation is first prepared, and then the insertion is carried out.

INSTALLATION OF DRAIN SYSTEM

Everything is clear with the supply of clean water to the unit, but how to connect the washing machine to the sewer? An insertion into the sewer system solves the problem of discharging dirty, waste liquid. The drainage organization scheme can be divided into 2 categories:

- permanent - stationary drain in a certain place;

- temporary – a forced measure for a short-term period (until the creation of a permanent flow).

Next, the most common options for organizing wastewater discharge will be discussed in detail.

READY STOCK

Connecting a washing machine through a ready-made system is the most correct and logical solution. To connect to the sewer system, the automatic device has a special drainage hose, which is located on the back of the device. If the hose is short, its length can be increased if necessary. However, the maximum length of the drain hose should not exceed 4 meters. This is necessary for the pump to successfully cope with pumping out the waste.

Connecting to the finished outlet consists of fixing the drainage hose of the machine in the corresponding sewer outlet.

DRAIN THROUGH A BATH, TOILET OR SINK

This drainage arrangement is considered a temporary option, since it entails household inconveniences. Making an indirect drain is not difficult, but after washing, dirt from the sewage will remain in the sink or toilet. And if the drain is clogged, there is a risk of flooding the apartment.

It is very easy to connect the washing machine yourself using the drain hose holder. Simply install the holder on the edge of the drainage pipe and secure it to the edge of the sink, toilet or bathtub.

INTEGRATION INTO THE SEWER THROUGH A SIPHON

The siphon option also allows you to fight back with small forces. Compared to the previous method, this scheme serves on an ongoing basis. The essence of the method is to secure the drainage hose through an additional outlet of the siphon. As a result, the washing machine and sink (or sink) will use a common sewer outlet.

To do this you will need a screwdriver and a clamp. The first step is to remove the plug from the siphon outlet, connect the hose and secure it with a clamp. If the siphon does not have an additional outlet, you should replace the part with a suitable one and follow a similar procedure.

INSERT IN AN ARBITRARY PLACE

Independently inserting into the sewer is the most technically difficult operation. But the reward for your efforts will be a tap that will last for many years. The algorithm of actions largely repeats working with a water line, but with some nuances.

Cast iron pipe

Cast iron lines have long outlived their usefulness. But in old buildings there are still metal pipes. In the case of cast iron sewers, it is better to choose the insertion area near the drain of the sink or sink. There, the pipe diameter is optimal for connection, and the location is ideal for installation manipulations.

To work, you will need a sewer tee, a set of rubber adapters to secure the joints and a sealing agent.

First you need to unscrew the siphon from the sewer drain. Then install a rubber adapter to which the tee is connected. The siphon is attached below using a rubber adapter, and the drain hose of the machine is connected to the free outlet of the tee.

Plastic pipe

Plastic sewerage is a modern solution to the problem. The sequence of actions during installation is completely identical to the previous method. The only difference is the material - cast iron is replaced by plastic.

Discharge into the sewer

The owner can organize a temporary drain of dirty water, in which a flexible hose is directed into the bathtub or toilet during washing. After turning off the machine, the sleeve rolls into a coil or is detached from the body. You can also connect a stationary drain to the sewer, which requires the installation of a special transition element for a siphon with an additional window. The product is mounted between the siphon body and an overflow tube made of elastic plastic.

It is not recommended to use a standard siphon with a modified design, since contaminated liquid will accumulate in the pipeline, which will lead to an unpleasant odor in the room. Another disadvantage of a standard siphon is the risk of waste water from the sink getting into the sleeve and into the internal cavities of the machine (for example, in case of a clogged pipeline).

To prevent backflow of dirty water, it is recommended to place the outlet hose at a height of about 500 mm from the floor surface. Machine manufacturers place the drain hole at a specified distance from the floor surface, which allows water to be drained into sewer channels located at floor level. There is a bracket on the back wall that ensures that the sleeve is held at a given height.

ALIGNMENT

After introducing the “washer” into the water supply system, it is necessary to ensure maximum stability for the unit. A special mat with an anti-vibration effect is placed under the base of the machine, which dampens vibrations from the operation of the device.

Next, the machine needs to be placed in a perfectly level position. The building level will help with this. A level is placed on top of the unit and by changing the length of the threaded legs, the desired condition is achieved. The deflection angle should not exceed 2 degrees.

CONNECTION TO THE ELECTRICAL NETWORK

To connect the washing machine to the electrical network, you need to plug the machine's wire into an outlet. This is the final stage of setting up the washing machine. If the house is old, then the electrical wiring is in a sad state. Therefore, it is first recommended to replace the wires with new ones and connect the grounding contact.

For new buildings, the best solution would be a separate three-wire wire from the meter with automatic 16 A network overload protection. If you have to use an extension cord, you need to make sure there is a grounding contact.

TYPICAL MISTAKES WHEN CONDUCTING INSTALLATION WORK

Often during repairs, beginners make a number of serious mistakes:

- Poor fixation of connections. Under high loads, unreliable fasteners may become detached, and the entire contents will spill out under pressure. All joints should be tightly secured to avoid such problems.

- Small siphon diameter. If the size of the part is incorrectly calculated, the line may burst under high pressure.

- Excessively long drain hose. The standard pump of the machine will not cope with the pumping function if the length of the hose exceeds 4 meters. It is better to limit yourself to a short tube or think about a different location for the “washer”.

- Small sink size when organizing a drain. With large drain volumes, the small sink will fill up in a short time, and then dirty water will rush over the edge. It is advisable to think over this point and choose a different option for connecting to the sewer.

Non-standard options

Installation of built-in equipment

A built-in washing machine is a great space saver in an apartment or house. You can build a cabinet for the washing machine, place it in a closet, on a shelf, mount it in a wall and other places. Only such creative ideas should be carefully thought out to avoid trouble.

In a private house

The classic installation option is the bathroom. All the necessary communications are present here, and it will be convenient to use the machine here. The only risk is increased humidity in the room, which in the future may affect the performance of the equipment.

In a private house there are many unusual ideas for installing a washing machine: in a closet, under the stairs, in a closet, in any buildings located in the courtyard of the house, etc. Only here can a problem arise with communications, water and electricity.

In the kitchen or hallway

If there is not enough space in the most common places, then the equipment can be installed in the kitchen or in the hallway. But it’s unlikely that anyone in the corridor will have the required communications. You will have to bring everything to the installation site, and this will significantly complicate and increase the cost of the process. But it will fit quite comfortably in the kitchen. Most often it is mounted next to the sink or in a built-in kitchen unit. It is worth considering that the temperature and humidity of the kitchen will not always correspond to the operating rules of the device.

Drain installation

At first it may seem that organizing the drainage of such household appliances is as simple and understandable as possible. However, in reality, everything depends on certain connection nuances.

This can be done in two main ways.

- Temporary. With such a connection, the drain hose is lowered into the toilet or bathtub (in case of a combination).

- Stationary. At the same time, a tie-in is made into the sewer. However, here owners quite often face a number of problems.

The machine is connected to the sewerage system in accordance with the following important requirements:

- the length of the drain hose should not be too long, as this may cause a significant load on the drain pump, which may cause it to break;

- as the drain is connected to the siphon, it will be possible to prevent the penetration of characteristic odors into the equipment directly from the sewer, which is a significant advantage.

The drain hose must be connected to the siphon of the washbasin or sewer. The result is a very strong and tight connection.

Now let’s look in detail at how it is possible to ensure the drainage of such household equipment using different methods. You can drain the water from the device into a bathtub or washbasin. This option is quite simple, but not very practical.

Some manufacturers add to the equipment kit such an element as a special hose-hook. It is fixed on the wall of the bathtub or sink. The main advantage of this solution is that to ensure it, there will be no need to connect equipment to the sewerage system.

It should be taken into account that this solution has many more disadvantages. Firstly, the contaminated liquid will stain the bathtub or sink. This problem will be especially acute if the plumbing fixtures are made of acrylic. Secondly, even a very minor blockage in the sink during the draining process can become a provoking factor for flooding of neighbors.

In addition, in many cases, due to strong vibrations during the draining process, the hook falls to the floor, which can also cause leaks. The connection can be made using a siphon. In order for the drainage from the equipment to be stationary, the specified part will be needed.

The siphon is equipped with an outlet for machines. It should be located under the knee part of the siphon. Otherwise, contaminated liquid may be sucked into the equipment itself. Because of this, a bad smell can “settle” in it.

You can also make a connection to a sewer pipe, which should be 4-5 mm thick. Usually a special sealing element and an S-shaped hose are used here. The last part is inserted directly into the pipe so that it does not come into contact with the drains. The top of the hose should be placed at a height of 55 cm from the floor.

CONCLUSION

Connecting a washing machine to the sewer and water supply network on your own will be an insurmountable challenge for an unprepared person. But if you approach the issue with full responsibility, then the work will be within the capabilities of everyone, and not just a professional with extensive experience. Let the prepared material become the main weapon in the golden hands of a home craftsman who wants to set up a washing machine!

Tags:

- Apartment renovation

Rate the material:

Preparing to connect

Before you start connecting the washing machine, you should carry out thorough preparation, which includes:

- Installing equipment on a flat, hard surface to avoid vibration;

- Replacement of pipes at the connection point and installation of filters (if necessary);

- Preparation of sewerage drainage (to ensure proper and timely drainage);

- Protection of electrical wiring from contact with moisture.

You should also pay attention to the hose: its length may not be enough if the washing machine is located far from the connection point. You should make sure that there is no need to purchase a longer hose before starting work.