Home page » steel welding wire

This section discusses steel welding wire.

For blacksmiths, forges, industries and individuals (homemade workers, self-taught people and enthusiasts).

See below for useful information to help you choose.

Choose brands from the list below the article.

Copper-plated welding wire SV08G2S-O ChZSM. Photo Welding Technologies

Steel wire occupies an impressive niche in the list of materials used in industry and in everyday life . Welding, as one of the types, has the properties of effective use in welding technologies.

Scope, purpose

Steel material in the form of wire has found application in automatic and semi-automatic welding . For solid wire, welding is performed in a shielding gas atmosphere (!materials for argon arc welding are in great demand). In cases where the use of a gas cylinder is difficult, the consumable material is made in the form of steel cored wire. Tubular wire is filled inside with a special powder (flux). The flux contains components that protect the weld from the external environment.

Copper-plated steel welding wire (1 kg; diameter 0.8 mm) Elitech. Photo VseInstruments.ru

Steel welding wire serves as a blank for the production of piece electrodes . It is used as an additive for surfacing surfaces in order to give them the necessary mechanical (wear resistance, corrosion resistance and others) properties.

Peculiarities

Semi-automatic welding in a carbon dioxide environment has become very widespread both in large factories and in small enterprises. But what are the features of welding in carbon dioxide? Why is this welding method so popular?

It's simple. During carbon dioxide welding, parts are practically not deformed, which is extremely important in production that does not want to lose profit due to defective products. In addition, for welding in carbon dioxide it is not necessary to thoroughly prepare the metal; the weld will be high-quality and reliable even if you simply remove visible dirt and oil. You can even adjust the parts by eye, and the seam will still turn out acceptable.

The essence of such welding is also simple. An electric arc is excited and with its help the metal melts. Carbon dioxide is supplied to the welding zone, which plays a protective role. The gas stream literally flows around the welding zone and protects it from oxidation and the negative effects of oxygen.

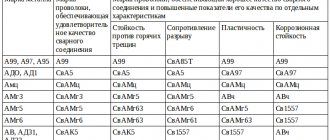

But there is one thing: carbon dioxide is not 100% neutral. So it cannot be used without filler wire. In this case, the wire will prevent oxygen from penetrating the weld pool and oxidizing the metal. In your work, you should use wire with a high content of silicon and manganese. Below you can see a table with recommended wire types.

If the wire you choose contains copper, this means that it has anti-corrosion properties, which is very good. Such wire can be stored for a long time, and it ensures stable arc burning. In addition, the seam is of high quality and without pores. Speaking about diameter, it is difficult to give specific recommendations. Let's say one thing: in our opinion, wire with a diameter of 0.8 millimeters is the most optimal for welding most metals, and besides, it does not place significant loads on the welding machine.

We would like to draw your attention to a common myth. Allegedly, flux-cored wire can fully replace shielding gas when welding with semi-automatic machines. This is a big misconception. Our experience has shown that when welding in a carbon dioxide environment, the seam is guaranteed to be better than when welding without it and using flux-cored wire. But the use of powder filler materials is justified in cases where it is impossible to transport a gas cylinder to the welding site or the likelihood of defects does not play a big role.

Symbols and markings

Solid wire for welding or surfacing is marked in accordance with GOST 2246-70. The designation includes the standard size, method of application, chemical composition, information about manufacturing technology, indicates the possibility of manufacturing electrodes, as well as whether they belong to a wire with a copper-plated surface.

Marking of flux-cored steel wire is based on GOST 26271-84 . The designation of welding and surfacing wire differs.

The designation of welding flux-cored wire does not specify the detailed chemical composition; only the content of carbon, phosphorus and sulfur is specified. The standard size, whether the wire is flux-cored, mechanical characteristics (yield strength, impact strength), and permissible spatial positions during welding operations are indicated. The designation determines the type of seam protection - self-protective or gas-protective.

Copper-coated wire SV-08G2S-O (18 kg; 1.6 mm) CEDAR. Photo VseInstruments.ru

Flux-cored wire for surfacing, in addition to indicating the category of flux-cored wire and the technology of use, the chemical composition of the powder material must be given. Together with the standard size of the wire, the conditions of use are regulated: with gas or other protection, with submerged arc surfacing or in any of the options. In some cases, it is useful to know the accuracy class for deviations of the nominal diameter size. It is also indicated in the designation.

Semi-automatic welding with and without gas. Wire. Recommendations.

Semi-automatic welding has advantages over a non-consumable electrode.

- Everyone knows how important it is to carry out the welding process without breaking the arc, maintaining a constant distance between the electrode and the workpiece (arc clearance). If the parameters are set correctly, the semi-automatic device will independently adjust this clearance if there are slight deviations from the optimal position of the burner. In other words, the device takes on half of the tasks that were previously solved primarily by the skill of the welder.

- No need to hold filler material. The right hand is freed, which allows you to freely manipulate the part manually.

- Speed and efficiency increases.

Standard consumable electrode welding consists of:

- inverter power supply (IPS);

- copper-plated wire feed unit;

- special burner

- mass crocodile

- shielding gas cylinder with flow meter.

There are inverters in which the SMPS and the feed mechanism are assembled under one housing. Such devices, operating on the “all-in-one” principle, are most often purchased to satisfy personal needs:

- welding of sheet material (especially thin sheet),

- welding a canopy or gate at the dacha,

- installation of pipelines, etc.

And also for solving special issues, such as, for example, body repair of passenger cars at service stations.

In factory conditions, more powerful equipment is usually used, so the SMPS and wire feeding are separated in them.

The principle of operation of the semi-automatic device is simple: it rectifies the alternating current entering the input into direct current at the output. At constant current, the current vector is determined by its polarity and how the cable is connected to the terminals.

The wire used is designed for a specific polarity. For common wire type 09G2S, “+” DC current is used on the torch.

During the welding process, when the distance from the consumable electrode to the metal changes, the working current and voltage are automatically adjusted so that the arc does not break. The SMPS “tries” to keep the voltage constant while the current increases or decreases.

The feed mechanism block consists of a spindle on which the reel is fixed, and the wire enters the hole of the feed roller through a guide. The feed wheel is designed for a specific wire diameter and can be replaced.

We have examined frequently repeated questions asked by novice welders who are learning to work on a semi-automatic inverter-type machine.

What protective gas is used when working with a semi-automatic machine?

Semi-automatic welding is carried out in a carbon dioxide environment, which is 100% carbon dioxide. You can work exclusively in argon, or in a mixture of argon and carbon dioxide. The welding wire, which is also an additive, is coated with a copper layer to improve electrical contact and smoothness of its feeding.

What should the shielding gas pressure be?

Choose 0.6 ... 0.8 MPa. This is if everything is fine and a new burner is used. If it wears out, you can add a little gas. The main thing is that there are no pores in the weld. If porosity does occur, then the pressure is insufficient (or very high, which can cause air to enter the welding zone, especially when working with an outer corner). Pores can also arise due to “dirty” gas, if there is be wind or drafts. The purity of the gas is especially noticeable when welding aluminum - the seam will simply become covered with a layer of soot and burning. When working with aluminum, choose only high-purity argon.

| Read the article on the website: Welding aluminum - instructions, apparatus, wire, gas |

What wire do you use? What polarity should be observed?

Copper-plated welding wire OK Autrod 12.51 ESAB

The most universal is 08G2S, all welders without exception are familiar with it. It is used for welding low-carbon and electrical steels. Naturally, this material is now sold under various trademarks. The world-famous company ESAB produces 08G2S under the name OK Autrod 12.51 - its composition is strictly controlled, which ensures stable mechanical properties of the seam. Also subject to control is the condition of the copper-plated surface, which is applied in a layer that is not too thick and not too thin, i.e. has an optimal size. Why is it important? Because low-quality wire quickly leads to failure of the feeding mechanism due to contamination with copper dust and chips.

The quality of the wire and copper coating directly determines the condition of the seam and the feed body.

Solid wire welding is carried out using reverse polarity current, that is, the torch is connected to the output with a plus sign. Also for corrosion-resistant steels, the additive ER-308 LSi is used - it contains 20% chromium and 10% nickel - exactly the ratio that gives the weld the greatest resistance to corrosion.

Is welding possible without shielding gas? If yes, what are its features? What are the pros and cons of this welding method?

Flux Cored Self Shielding Wire E71T-GS

It is possible to do without inert/active gases. In such cases, flux-cored wire is used, which is similar in its action to the piece electrode used in manual arc welding.

Flux-cored wire is a hollow tube filled with flux. During combustion, the latter provides the necessary gas protection from external influences for the correct formation of the weld.

Flux-cored wire is also often called flux-cored wire; it is less rigid than regular wire, therefore, in order to work correctly with it without stopping the feed mechanism, it is necessary to loosen the compression force of the roller. Or you shouldn't tighten it too much.

The wire is soft and will wrinkle. In order to avoid such problems, before feeding it for the first time, you should remove the tip on the burner and only then pull it through. Only install a tip of the appropriate size. There is no need to install a nozzle, since welding will be carried out without shielding gas. On the inverter, you should set the voltage, feed rate and inductance parameters using the smooth adjustment knobs.

Another peculiarity of working with such wire is the need to change the polarity on a semi-automatic inverter. The welder must be adapted for this. For example, on the OVERMAN 180 device, the polarity is changed inside the case next to the feed mechanism (the terminals are unscrewed and the wires are swapped). Do not forget also that the size of the feed roller groove must correspond to the diameter of the wire.

Welding a sheet 1-2 mm thick should be done with short seams at an angle back, in which case the seam is formed much better. For welding thin metal, 0.8 mm wire is commercially available. Maximum diameter 2.4 mm – for serious industrial applications.

Advantages:

- no need to carry heavy cylinders, mobility.

Flaws:

- high cost of wire,

- you need to be careful about its quality,

- A slag crust forms on the surface of the seam, which needs to be cleaned off.

| Read the article on the website: Semi-automatic welding for beginners |

Kinds

Steel welding wire is divided into the following groups :

- low carbon;

- alloyed;

- highly alloyed.

Low-carbon and alloy wires are produced with a copper-plated surface. Copper plating increases corrosion resistance. The stability of the welding arc is increased by reducing friction when feeding through the tip hole and improving the current-carrying characteristics characteristic of copper.

Copper-coated wire SV-08G2S BARS. Photo VseInstruments.ru

The development of wire drawing technology makes it possible to obtain it with a perfectly clean surface. This is where the name of steel welding wire came from - polished . In terms of its characteristics, it is close to copper-plated and creates a more stable arc than steel with a regular surface. Some high-alloy wires (mostly molybdenum-containing wires) are poorly coated with copper. Such products are made with a polished surface.

Useful video

Selecting an electrode for TIG welding

Tungsten was not chosen as an electrode by chance.

The metal is famous for its special refractoriness, for which it simply has no competitors. A tungsten electrode for argon arc welding can be identified by the “W” marking. Other symbols and even color indicate the type of alloying additives. They are necessary to improve the performance and increase the service life of consumables.

Electrodes can be either universal or special - for welding only with direct or only with alternating current.

As in the case of gas, let’s highlight the most popular type of electrode:

- WP (green electrodes) - tungsten electrodes without special additives for welding with alternating current

- Tungsten electrodes alloyed with lanthanum oxide WL-20 (blue color) and WL-15 (gold color) - universal electrodes for welding on direct and alternating currents

There are also tig electrodes with other additives - zirconium, cerium, yttrium oxide - there are quite a lot of them.

Table. Tungsten electrodes - composition and properties

| Electrode | Color/Composition | Properties |

| WP (green) | Tungsten electrodes without special additives. Tungsten is at least 99.5%, the rest is impurities. | Provide arc stability when welding with alternating current. Ideal for welding aluminum parts. |

| WL-20 (blue) WL-15 (gold) | Tungsten electrodes doped with lanthanum oxide 1.8-2.2 La2O3 | Provide easy ignition of the welding arc and its high stability, quick re-ignition. |

| WZ-8 (white) | Tungsten electrodes doped with zirconium oxide 0.7-0.9% ZrO2 | For welding on alternating current. Creates a stable, high-power arc. Withstand significant current loads. |

| WC (gray) | Tungsten electrodes doped with cerium oxide 1.8-2.2% CeO2 | For welding with any type of current, they maintain a stable arc even at low current values. |

| WY-20* (dark blue) | Tungsten electrodes doped with yttrium oxide 1.8-2.2% Y2O3 | Used for welding particularly critical joints. |

In addition to composition and properties, important parameters are diameter and length. The leading position in demand is occupied by electrodes for tig welding with a length of 175 mm. However, in addition to them, there are options of 50, 75 and 150 mm.

With diameter, everything is much more complicated, because it must be selected depending on the thickness of the metal being welded and the type of welding current. The table below will help you with this question. Here are recommendations for the most common WP and WL electrodes:

| TYPE OF CURRENT | Metal thickness, mm | Electrode diameter, mm |

| CONSTANT | 0,8 – 1,5 | 1 — 1,6 |

| 2 — 3 | 2 | |

| 4 — 6 | 3 – 3,2 | |

| 7 — 10 | 4 | |

| VARIABLE | 2 | 1,6 — 2,4 |

| 3 — 5 | 3 — 3,2 | |

| 6 — 10 | 4 |

And the last thing is sharpening the tungsten electrode. Proper sharpening will have a positive effect on arc ignition, combustion stability and the width of the weld. In most cases, the ideal option is a cone-shaped sharpening (for alternating current, a rounded tip is made).

The sharpening length should exceed the electrode diameter by 2-2.5 times. Long and thin grinding of the electrode is especially important when welding thin materials; this gives good focusing of the welding arc.

Characteristics

the same requirements apply to each of them .

Mechanical characteristics should ensure that the wire is pulled through the semi-automatic machine without breaks . The weld filler material must match the strength and other mechanical properties of the base material.

Low-carbon copper-plated welding wire ER70S-6 (1 mm; 15 kg) ELKRAFT. Photo VseInstruments.ru

The chemical composition of filler materials is selected for specific types of metals being welded. It must comply with them, and also take into account the losses of individual elements during different welding methods.

Distinctive features, advantages and disadvantages

The base of any steel welding wire is low carbon steel. The plastic properties of this steel make it possible to provide a drawing process to obtain wire diameters up to 0.3 mm. Carbon content up to 0.12% is its distinctive feature.

The advantage of wire is the variety of properties it can have. Alloying elements in their quantity and percentage allow it to be used for welding metals of various purposes.

Wire ESAB SV-08G2S. Photo 220Volt

Perhaps the main disadvantage is the difficulty in choosing the right filler material for welding not very common alloy steels. Despite the variety in the number of welding wires, it is rarely possible to find complete compliance in chemical composition. This requires a lot of experience and practice.

Recommendations for use

When welding using semi-automatic machines, the diameter of the welding wire must be selected depending on the thickness of the workpieces being welded. The wire feed speed should be determined by the welding parameters that are set on the machine. The normal process is ensured by the correct polarity. Basically, welding occurs in reverse polarity , when the torch is connected to the positive terminal, and the body of the device to the negative terminal. Some types of wire, such as flux-cored steel, are used with straight polarity.

Use of acetylene

For gas welding, acetylene is most often used as a fuel gas. The result of using acetylene is to obtain a high-quality weld. The welding wire for gas welding with acetylene acts as a filler rod.

Manufacturers

Companies related to welding materials must produce a range of steel welding wire. Among them are the best representatives in the production of welding technology products:

- ESAB is a Swedish concern offering a wide range of stainless, copper-plated, aluminum and other types of wire;

- "PRIMA" is a Chinese manufacturer offering a wide range of materials, among which ER70S-6 steel wire stands out;

- "OLIVER" is an enterprise from the Republic of Belarus, whose products are in demand in many countries;

- “LINCOLN” is an American brand that does not have many official dealers in Russia and the CIS countries;

- "HYNDAI" is a world leader in the market for the manufacture of welding materials;

- "DEKA" is a company from China, whose products are in demand due to the optimal price-quality ratio.

Reference. The production of titanium wires is mainly carried out by Russian enterprises, offering the most popular brands, for example, VT1-00Sv.

ESAB welding wire

Consumable material in the form of welding wire is widely used in various welding technologies. The presence of this product in the range of manufacturers with influence in the welding materials market is a prerequisite. ESAB, as a world leader, is distinguished by its production of wide-purpose wires, covering all possible areas of its application. Areas of application ESAB welding wire is in demand in oil and gas, shipbuilding, mechanical engineering, chemical and other industries. IN…

Welding wire: consumption, threading, feeding

To perform one-time welding work at home, you need to decide on the amount of consumables that you will need to purchase in the store. In industrial conditions, the amount of welding wire consumed will affect the final price of the product produced and, ultimately, customer demand. Features of wire Wire consumption is influenced by many factors, including the human factor in the context of whether the welder has the required qualifications. However, the most objective is the meaning...

Welding wire manufacturers

Wire is a consumable material that is in high demand today. Therefore, many companies, in Russia and abroad, specialize in the production of welding wire. The most significant manufacturers, as well as the features of their products, popular brands of consumables and other information useful for craftsmen are presented in this review. List of countries and manufacturing plants The company has modern equipment at its disposal, qualified employees of the enterprises use the latest…

Welding wire: brands, markings, types

Welding work is carried out with any materials - it can be cast iron, steel or non-ferrous metals. Technologies make it possible to perform these works on productive automatic and semi-automatic machines. The functionality of this equipment is ensured by consumables in the form of wire. Application The main purpose is to use consumables on semi-automatic machines in an atmosphere of protective gas. In cases where self-shielding wire is used, welding is performed without gas. The wire is used as surfacing…

A couple of tips on choosing a semi-automatic welding machine

Before choosing a semi-automatic welding machine, read a few important tips:

- The greater the power of the semi-automatic machine, the thicker the metal it can weld;

- Inverter semi-automatic machines are much simpler and more efficient in operation;

- It is preferable to choose a semi-automatic machine whose design will include removable holders;

- It would be good if the instructions for the semi-automatic machine were in Russian, clear and informative to use.

Semi-automatic welding with carbon dioxide differs significantly from manual arc welding. To obtain a high-quality weld, you need to take into account many nuances: gas consumption, wire feed speed, filler material diameter and much more.

Welding wire ER70S

ER70S-6 is a high quality copper-plated welding wire that meets all Russian and international standards. Scope of application, purpose Copper-coated wire (not to be confused with copper consumables) ER70S-6 is used in automatic and semi-automatic welding machines; this material is produced for working with parts, elements and structures made of low-alloy or unalloyed, structural and carbon steel. Widely used in various industries: power generation, electrical engineering,…

Steel welding wire

Welding wire for carbon steels

This section of the SWARBI catalog presents consumables used for welding carbon steels in automatic and semi-automatic machines. In this case, the welding wire fed into the torch acts as a consumable electrode.

Welding parts made of carbon and alloy steels has a number of features that must be taken into account in order to obtain a strong weld without defects. With an increase in the amount of carbon and alloying elements in the chemical composition of steel, weldability decreases and the likelihood of crystallization cracks in the weld zone and around it increases, which leads to a decrease in the strength of the welded joint.

To obtain a high-quality result in semi-automatic or automatic arc welding of alloy and carbon steels, a special welding wire is used (GOST 2246-70, TU U 322-4-392-96). The different chemical composition of different grades of wire makes it suitable for welding certain grades of steel. The content of carbon and alloying components is reflected in the alphanumeric designation of the grade of welding wire. It indicates the percentage of chemical elements on which its applicability depends. For example, welding wire SV08g2s contains 0.08% carbon, 2% manganese, less than 1% silicon and is used for mechanized welding of carbon and low-alloy structural steels.

To improve the properties of the wire, a copper or copper-zinc coating is applied to its surface. This allows you to reduce the contact resistance with the torch tip, reduce metal spattering and ensure stable arc burning. Copper-plated welding wire does not have an abrasive effect on the tip channel, which increases its service life, and is not subject to corrosion.

The most progressive type of welding wire is flux-cored wire, which has a core with flux powders and alloying components (metals, carbides, ferroalloys). Self-shielding flux-cored wire contains deoxidizers and gas- and slag-forming components, the combustion of which releases protective gas and there is no need to supply it from a cylinder. In addition, the use of such wire instead of conventional wire allows you to obtain a number of obvious advantages:

- an open arc allows you to visually control the welding process and correctly distribute the deposited metal;

- the compactness of the equipment increases due to the lack of its components for supplying flux and shielding gas;

- It is possible to weld in different positions and in open areas.

The section presents samples of welding wire of various types from well-known brands BARS, FARINA, HYUNDAI, Novofil, ESAB, Fileur:

- copper-plated solid-section welding wire with a diameter of 0.8 to 1.6 mm for welding carbon and low-carbon steels, similar to SV-08GS and SV-08G2S, as well as with a copper-zinc coating for low-carbon structural steels;

- flux-cored welding wire for submerged surfacing of carbon steel parts, its use can increase labor productivity and improve the quality of surfacing;

- self-shielding flux-cored welding wire for semi-automatic machines, allowing welding without bottled shielding gas, with a diameter of 0.8-1.2 mm, contains a special welding flux enclosed in a tube of thin steel tape.

Despite the fact that the price of flux-cored welding wire is higher than the price of wire with a solid cross-section, its use allows you to reduce the cost of purchasing expensive argon and transporting gas cylinders.

When choosing a wire for welding, you need to take into account that its chemical composition must correspond to the composition of the metal of the parts being welded. Before buying welding wire, you need to carefully familiarize yourself with its chemical composition and use the help of consultants.

Welding wire SV08G2S

Welding wire SV08G2S (spelling Sv-08G2S is also acceptable) is one of the most common brands of filler materials. This brand is often called universal, since it is used for welding and surfacing. In addition, it is used in the manufacture of electrodes. Full information is provided below. Scope of application, purpose SV08G2S wire is used for welding low-alloy and carbon steels, which are widely used in various industries: machine, aircraft and...

Varieties

Acetylene welding wire must be selected for each type of part being welded. The quality of the result obtained greatly depends on this.

- Copper plated . Copper coating reduces contact resistance and protects the wire surface from mechanical damage. Ensures uninterrupted operation of equipment. Guarantees minimal metal spattering.

- Non-copper-plated . Used when working with parts made of low-carbon steel.

- Powder . It is a tube made of low carbon steel. Inside it is filled with special powders, which are deoxidizers and slag-forming substances. Along with the metal, flux may be contained inside the tube. Typically used for automatic welding. The formation of slag is minimal, which makes it easy to separate the slag crust.

- Solid section . Can be used for the manufacture of electrodes. It is independently used for welding in an automatic or semi-automatic way.

- Activated . It has the shape of a tube, but there is a small amount of powder inside. The role of activators is performed by various types of oxidizing agents.

- Gas welding . Used for welding with types of steel such as carbon and low carbon.

- Aluminized . Used for welding aluminum structures in semi-automatic mode. Helps reduce joint porosity.

- Made of stainless steel . Used for welding stainless steels.

- Flux . Used for welding steel of various grades using a semi-automatic method.

- Alloyed . Provides the ability to weld in various gases.

Welding wire for acetylene welding is selected depending on the grade of material of the product being welded in order to obtain a good quality seam.

Welding wire deck

The DEKA trademark is represented on the market with products related to welding technology. In addition to welding equipment and welder protective equipment, a large range of consumables is sold - welding wire, which has found application in many areas of business where there is a need to create strong connections: in the manufacture of various types of industrial, medical and some other types of equipment of complex design. Also in the shipbuilding industry and mechanical engineering. What…