Static current-voltage characteristic.

The static current-voltage characteristic is the dependence of the arc voltage on the supplied welding current at a constant arc length. This characteristic directly depends on the power source. There are three types of static characteristics:

- falling;

- hard;

- increasing.

Welding performed under normal conditions or using argon is characterized by the first type of current-voltage characteristic. In this case, the welding current used has low current values (up to 80 Amperes), allowing for small-sized welds.

With an increase in the current used during welding under normal conditions, the ionization process is activated and at the same time the area of the resulting arc cross-section increases, which greatly facilitates the welding process. During a welding arc in an argon environment, intense ionization of the gas environment itself occurs with a significant increase in the temperature of the shielding gas.

The welding arc, which occurs at a current strength of 80 to 300 Amperes, is characterized by the second type, which is characterized by the addition of low voltage values. In this case, the resulting cross-sectional area will be proportional to the current used during welding, which makes it possible to obtain seams of the required size and connect various structures made of various materials. The conductivity of the welding arc remains constant.

When welding with a current exceeding 300 Amperes, they speak of an increasing current-voltage characteristic. In this case, the resulting voltage increases as a result of the accumulation of a large number of charged particles on the electrode, automatically causing a voltage drop at the cathode.

Thus, we can say that a falling static current-voltage characteristic is characterized by an increase in current strength with a decrease in voltage. Rigid type is characterized by independence of voltage from current. For increasing - the voltage increases with increasing welding electric current.

In the process of manual welding with an electrode with an alloy coating, the characteristic will decrease; as the current increases, it will become hard. When welding using flux or in a carbon dioxide environment, a rigid static characteristic will turn into an increasing one. With a constant current, the voltage can only change depending on the length of the arc.

Welding arc. Characteristics of the welding arc

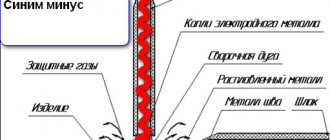

A welding arc is a powerful, long-lasting electrical discharge between energized electrodes in a mixture of gases and vapors.

The arc is characterized by high temperature and high current density. The welding arc as an energy consumer and arc power source (welding transformer, generator or rectifier) forms a mutually interconnected energy system. There are two modes of operation of this system: 1) static, when the voltage and current values in the system do not change for a sufficiently long time; 2) transient (dynamic), when the voltage and current values in the system continuously change. However, in all cases, the burning mode of the welding arc is determined by the current (ID), voltage (UD), the size of the gap between the electrodes (the so-called arc gap) and the connection between them.

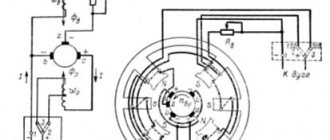

In the arc gap ID (Fig. 1, a) three regions are distinguished: anode 1, cathode 2 and arc column 3. The voltage drop in the anode and cathode regions is constant for given welding conditions. The voltage drop per unit length of the arc column is also a constant value. Therefore, the dependence of the arc voltage on its length is linear (Fig. 1, b).

The stability of the welding arc is determined by the relationship between current and voltage. A graphical representation of this dependence (Fig. 2) at a constant arc length is called the static current-voltage characteristic of the arc. The graph clearly shows three main sections: an increase in current in section I is accompanied by a decrease in arc voltage; in section II, the arc voltage changes little; in section III the tension increases. The combustion modes of the welding arc corresponding to the first section are unstable at the voltages of existing power sources. In practice, the welding arc will be stable in the second and third sections of the current-voltage characteristic. With an increase or decrease in arc length, the characteristics will shift to positions 2 and 3, respectively (see Fig. 2). For electrodes with a smaller diameter, the characteristics shift to the left, for larger diameters - to the right.

Rice. 1. Welding arc burning between non-consumable electrodes: a - arc diagram, b - dependence of arc voltage (Usp) on the arc gap (/d): 1 - anode region, 2 - cathode region, 3 - arc column

Fig. 2 Current-voltage characteristic of the arc (volt-ampere characteristic)

Shown in Fig. 2 volt-ampere characteristic of the arc was taken at a constant length of the welding arc. When welding with a consumable electrode, the length of the arc gap continuously changes. In these cases, you should use the characteristics that determine the relationship between voltage and arc current at a constant feed speed of the electrode wire (Fig. 3, curves 1 and 2). Each feed speed corresponds to a certain current range at which the welding arc burns stably and the electrode melts. In this case, with small changes in current, the voltage changes within large limits. This dependence is usually called the characteristic of stable operation. It, like the current-voltage characteristic, depends on the length of the electrode extension and the feed speed.

These patterns are valid for direct and alternating current, since the type of current does not affect the shape of the current-voltage characteristics of the electric arc. The shape of the characteristic is influenced by the geometry and material of the electrodes, the cooling conditions of the arc column and the nature of the environment in which the discharge occurs.

The stability of the welding arc and welding mode depend on the conditions of existence of the arc discharge and the properties, parameters of the power sources and electrical circuit. The external characteristic of the power source (curve 3 in Fig. 3) is the dependence of the voltage at its terminals on the load current. The following external characteristics of power sources differ (Fig. 4): falling 1, gently falling 6, rigid 5, rising 3 and vertical 2. A power source with one or another external characteristic is selected depending on the welding method. The control device of each source gives a number of external characteristics (“family of characteristics”). The steady-state operating mode of the system: “welding arc - power source” is determined by the intersection point A of the external characteristic of the power source (1, 2, 3, 5 or 6) and the current-voltage characteristic 7 of the welding arc.

Fig. 3 Volt-ampere characteristic of the welding arc (volt-ampere characteristic) 1.2 at a constant wire feed speed (characteristic of stable operation) and external characteristics of power sources 3, 4 and 5

Fig.4 External characteristics of power sources 1, 2, 3, 5, 6 and current-voltage characteristics of the welding arc 4, 7

The welding process will be stable if the arc discharge exists continuously for a long time at given voltage and current values. As can be seen from Fig. 4, at points A and B of the intersection of the external characteristics of the arc 7 and the power source, there will be an equilibrium in current and voltage. If for any reason the current in the welding arc corresponding to point A decreases, its voltage will be less than the steady value of the power source voltage; this will lead to an increase in current, i.e., to a return to point A. On the contrary, with a random increase in current, the steady-state voltages of the power source turn out to be less than the arc voltage; this will lead to a decrease in current and, consequently, to the restoration of the welding arc combustion mode. From similar reasoning it is clear that at point B the welding arc burns unstable. Any random changes in the current develop until it reaches a value corresponding to the stable equilibrium point A or until the arc breaks. With a flattened external characteristic (curve 6), stable arcing will also occur at point A.

When working on a falling section of the current-voltage characteristic of the arc, the external characteristic of the source at the operating point should be steeper than the static characteristic of the welding arc. With increasing arc characteristics, the external characteristics of the source can be hard 5 or even increasing 3.

When manual welding, when changes in arc length are possible, it must have a sufficient margin of stability.

All other things being equal, the stability margin increases with increasing slope of the external characteristic of the power source. Therefore, for manual welding, sources with steeply falling characteristics are used: the welder can lengthen the arc without fear that it will break, or shorten it without fear of an excessive increase in current.

Self-regulation of the welding arc. In automatic or semi-automatic welding with a consumable electrode, its feed speed (va) is equal to the melting speed. If the arc gap is accidentally reduced (curve 4 in Fig. 4), the current increases and the wire will begin to melt faster. As a result, the arc gap will gradually increase and the welding arc will reach its original length. The same thing will happen if the arc is accidentally lengthened. This phenomenon is called self-regulation of the welding arc, since the restoration of the original mode occurs without the influence of any regulator. Self-regulation occurs the more actively, the better the external characteristic of the power source and the higher the electrode feed speed. Therefore, for mechanized consumable electrode welding, power sources with flat-sloping external characteristics should be selected. When welding with direct current in shielding gases, when the static characteristic of the welding arc takes on an increasing shape, it is rational to use sources with a rigid characteristic for self-regulation systems. However, their open-circuit voltage is low and may even be less than the operating voltage of the arc, which makes its initial initiation difficult. In these cases, it is desirable to use power sources in which the external characteristic in the working part is a rigid or gently increasing current-voltage characteristic, and the open-circuit voltage is slightly increased, as shown by the dotted line in Fig. 4.

The AC welding arc requires power sources to reliably restart the welding arc. This is achieved by the correct choice of relationships between the open circuit, ignition and arc voltages and the parameters of the welding circuit. The simplest way to obtain a stable welding arc is to include reactance in the welding circuit. Due to this, at the moment of re-excitation of the arc, the voltage on the arc can increase sharply (Fig. 5) to the value of the ignition voltage (U3). The dotted t/xx curve represents the power supply voltage at no-load. Under load, due to the presence of reactance, the welding current lags behind the voltage in time.

When the arc breaks, the voltage across the arc gap must rise to a value corresponding to the instantaneous value of the no-load voltage of the power source. Due to the current lagging behind the voltage, this voltage is sufficient to re-excite the welding arc (Un).

Metal transfer in a welding arc and requirements for the dynamic properties of power sources. The following types of transfer of electrode metal into the weld pool are distinguished: large-droplet, characteristic of low current densities; small-droplet, jet, when the metal flows from the electrode in very small drops. Drops of molten metal periodically close the arc gap, or if short circuits do not occur, they periodically change the length of the arc. At a high current density in the electrode, fine-droplet transfer of metal is observed, without noticeable fluctuations in the length and voltage of the welding arc.

Voltage, current and arc length undergo periodic changes from no-load to short circuit; in operating mode, an arc burns, a drop forms and grows. Subsequently, if there is a short circuit between the drop and the bath, the current increases sharply. This leads to compression of the drop and destruction of the bridge between the drop and the electrode. The voltage increases almost instantly and the welding arc is excited again, i.e. the process is repeated periodically. Mode changes occur within a fraction of a second. Therefore, the power source must have high dynamic properties, i.e., a high rate of increase in voltage when the circuit is broken and the required rate of increase in current.

Rice. 5 Oscillogram of current and arc voltage when welding with alternating current.

At a low rate of current rise, unmelted wire enters the bath. It heats up relatively slowly over a large area, which is then destroyed. If the current increases too quickly, the bridge between the bath and the drop of electrode metal quickly overheats and collapses with an explosion. Some of the molten metal splashes out and does not enter the seam.

To avoid spatter, it is necessary to increase the electromagnetic inertia of the power source by increasing the inductance of the welding circuit.

Elasticity of the welded arc.

When welding, it is necessary to take into account the length of the arc used in welding, since such an important characteristic as elasticity directly depends on it.

To obtain a high-quality weld, uninterrupted combustion of the welding arc is necessary, which is characterized by the elasticity of the welding arc. An arc is said to be sufficiently elastic if the welding process remains stable as the length of the welded arc increases.

The resulting elasticity is directly proportional to the current value. With high changing parameters of the power source, the transition period is shortened during various changes in the electrical system, which allows you to obtain a high-quality connection in a short period of time.

Volt-ampere characteristic of the arc (volt-ampere characteristic)

Static current-voltage characteristic of the arc - shows the relationship between the steady-state values of the current and voltage of the arc at a constant arc length. An electric arc, as an element of a current circuit, has a pronounced nonlinearity, that is, there is no proportional relationship I and voltage U. The dependences U = f (I), with other constant conditions, for such elements are most often depicted in the form of curves called current-voltage characteristics (see figure). If the U are measured in states of stable discharge equilibrium at different currents, then the characteristics are called static. The static characteristics of the arc depend on the distance between the electrodes (arc length), the material of the electrodes and the parameters of the environment in which the arc burns. The construction of current-voltage characteristics is associated with great difficulties, not only due to the difficulty of measuring the arc length between consumable electrodes, but also maintaining constant other conditions.

Efficiency.

Welding is always accompanied by the release of a large amount of heat, which is used to melt the parts being welded. Almost all consumed electrical energy is transformed into thermal energy, with the help of which the metal melts and the surrounding air is heated.

The efficiency in any welding operation has different values and largely depends on the brand of electrodes, the chemical composition of the flux, the type of welded joint and the speed of welding.

To obtain high-quality welds, when organizing the welding process, it is imperative to take into account all the characteristics of the welding arc and control them during operation. This will optimize the entire process and minimize side energy costs. Compliance with all parameters of the welding arc for the selected type of welding is a necessary condition for ensuring high quality work. In addition, this will ensure a long service life of the connected structures.

Features of the electric arc

Thanks to its wide range of values, the electric arc is compatible with both refractory and conventional consumable electrodes. Under its influence, the metal quickly heats up, after which a melt pool is formed. The conversion of electricity into heat occurs with minimal losses.

By its nature, an electric arc is comparable to other types of charges. Its distinctive features:

- high temperature created by dense current;

- a slight decrease in cathode and anode voltage, which to a small extent depends on the initially specified voltage;

- the electric field between the poles is distributed unevenly;

- stability of the electric arc in space;

- power and current-voltage characteristics are self-regulating;

- the boundaries of the electric arc are clearly defined.

You can light the arc in one of two ways: by striking or by briefly touching it.