How to repair a fistula in a pressurized water pipe

Any leak in a pipe is an emergency that must be quickly neutralized, regardless of the type of purpose of the pipeline (plumbing, heating, etc.). To fix leaking pressurized water pipes at home, it is important to be extremely careful. Especially when it comes to hot water supply. Burns and major flooding cannot be ruled out here. It is worth remembering that patching is not a panacea. If there is a hole in the pipe, the same fate awaits the highway in its other sections. It is better to replace the metal pipeline with a plastic one (polypropylene, PVC) as soon as possible. In addition, it is only possible to repair fistulas on a hot or cold water pipe when the hole is small. If the liquid gushes like a fountain, no clamps or patches will help.

Fistula in a pipe - what it is and how to repair it

Hello, dear readers!

You can easily detect a fistula in a heating or water supply pipe by looking at the fountain of water gushing from the riser. Know that after this the problem must be eliminated as quickly as possible. Otherwise, because of a small hole, your home will soon float. And the apartments located below will set sail with it.

I will tell you how to fix the problem yourself and quickly, until reinforcements arrive in the form of housing office repairmen.

What is a fistula?

A fistula is damage to the pipeline wall in the form of a crack or through hole. Leaks of this nature indicate that it is time to replace a section of pipe. However, it is not always possible to do this immediately after detecting a leak on your own. By the time the called technician arrives, a significant part of the apartment will be flooded with water, not only yours, but also your neighbor’s. But installing a temporary patch is not that difficult.

Reasons for appearance

A fistula appears suddenly, usually at the most inopportune time. For example, when no one is home or it’s late at night. It makes itself felt due to pitting corrosion if the pipes are metal, usually on heating and hot water supply risers. Can also occur in systems with plastic pipes due to excessively high pressure. In the latter case, the type of pipes most likely does not correspond to the design of the heating and hot water supply systems.

Ways to repair a fistula with your own hands

What to do if a fistula takes you by surprise? Do not panic. Take a look around - you will probably find improvised means for sealing a fistula in your home:

- bolt;

- temporary or adhesive bandage;

- cold welding.

If you found any of the above, then consider that the problem is solved. Do not forget that the coolant and hot water are under pressure in the system. Therefore, if possible, turn off the water or coolant supply at the shut-off valves before proceeding with the repair using a method suitable for you.

Sealing with adhesive bandage

One of the most difficult methods of sealing a fistula on a water pipe, but at the same time very reliable. The procedure is as follows:

- Clean the leak area from dirt, then degrease it with gasoline or acetone.

- Prepare a piece of fiberglass fabric 3 times wider than the fistula and of such length that you can wrap it around the pipe at least 6 times.

- Apply epoxy glue to the edges of the fiberglass tape and wrap the tape tightly around the pipe.

- Secure the resulting bandage with metal tape.

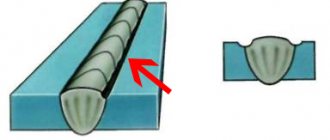

Sealing with an adhesive bandage: 1 – pipe with a fistula, 2 and 3 – tape

Cold welding repair

Cold welding is a special two-component composition, completely ready for use. Usually sold in transparent plastic tubes. The product is intended for sealing holes and other defects in containers for various liquids. Cold welding has also proven itself to be effective in the temporary repair of fistulas.

Before use, the composition must be kneaded in your hands, then covered with it over the hole in the damaged pipeline and thoroughly smoothed with moistened fingers or a spatula. Cold welding dries and hardens in 10–20 minutes. After this time, hot water can be used again.

Methods for sealing a fistula

Sign of a fistula

A fistula that appears in a pipe can be repaired in several ways, each of which requires first draining the water from the system by closing the stop valve and opening all taps. Let's look at the main methods of sealing fistulas in more detail.

Sealing with a bolt

Includes the following steps:

- The fistula is expanded using a drill.

- Using a tap, cut threads on the pipe.

- A bolt is screwed into the resulting hole.

Important: this method is not suitable for old pipes, since it is almost impossible to cut pipe threads on them; attempts to cut them usually lead to an increase in the diameter of the leak.

Sealing with a temporary bandage

This method is usually used when the pipe fistula has an oblong, elongated shape.

A bandage with sealing rubber gaskets is applied to the fistula, and the following materials can be used as a gasket:

- Thick rubber glove;

- Old bicycle tire;

- Medical tourniquet;

- Rubber boot top, etc.

Important: the rubber gasket must have a size significantly larger than the size of the fistula.

The gasket is fixed to the pipe using special clamps or bolts.

Sealing with an adhesive bandage

Sealing with an adhesive bandage: 1 – pipe with a fistula, 2 and 3 – tape

Using an adhesive bandage, the fistula on the pipe is sealed as follows:

- Clean the pipe from dirt with a wire brush, treat its surface with gasoline or acetone and allow to dry for at least 15 minutes.

- The fiberglass fabric is cut into strips, the dimensions of which depend on the diameter of the pipe so that the length of the strip allows for at least 6 layers of winding, and its width exceeds the diameter of the pipe by at least a third.

- The edges of the tape are treated with BF-2 glue, after which one side of the tape is coated with epoxy glue using a spatula.

- Press the spatula firmly so that the tape is saturated with glue.

- Next, tightly wrap the tape onto the treated and cleaned surface of the water pipe so that the center of the tape covers the damaged area.

- The bandage is tightened with a metal tape.

- After a day, you can use the repaired pipe.

Important: in the case of a pipe located in a cold room with an air temperature not exceeding 17°, you should start using the pipe only after 4 days.

Repair using the cold welding method

To temporarily seal the resulting fistula, you can also use a special composition called “cold welding”:

- The fistula is expanded using a drill.

- The surface of the pipe is cleaned and degreased with acetone.

- After drying the pipe, apply the composition to it and wait for it to completely harden for 10 minutes.

Important: work with epoxy glue and “cold welding” should be done with rubber gloves.

If glue or composition gets on your skin, wipe it with cotton wool soaked in acetone, then wash your hands thoroughly with soap and warm water.

Fistula on a pipe - how to repair it correctly

The term “pipe fistula” refers to deformation changes in the form of a through hole in the pipeline. The main reason for the formation of this phenomenon on rolled pipes is considered to be pitting corrosion.

It is a clear signal that the pipe line needs urgent replacement. It is not always possible to perform a full range of pipe repairs with replacement, so it is only partially performed.

At the same time, we must not forget that such measures are temporary, and replacement of areas that have fallen into disrepair cannot be avoided anyway. You can use the help of professional craftsmen, or you can fix everything yourself.

How to eliminate an “accident”

To complete the installation you need to prepare the following tools:

- Drill.

- Bolts (set).

- Brush for cleaning rolled metal.

- BV-2 adhesive and epoxy adhesive type.

- Acetone and gasoline.

- Ketn.

- Putty knife.

Before sealing the fistula in the pipe, water is drained from the network. To do this, you need to close the stop valve and open each tap. The system should be free of residual water.

Next, the size of the corrosion formation is determined. To do this, carefully remove the paint layer and rusty formation with sandpaper. A smooth surface should form in the area of the breakage.

After this, the cleaned area must be degreased with acetone. You can use gasoline for the same purpose. When sealing, this stage of action is very important.

When applying a bandage to a workpiece with an uneven surface, it is impossible to obtain the most airtight joint, and all sealing measures will have to be repeated again.

On a well-cleaned surface of the product, the amount of deformation can be accurately determined. And, guided by the information received, they determine how to further eliminate the deficiency. According to the form of formation, fistulas are divided into: point and elongated. Each of them is eliminated differently.

How is the work carried out?

Repair of fistulas on pipes is carried out using the following methods:

- Using a bolt. This method is used when it is necessary to seal a small hole. The hole is widened with a drill, and a thread is cut in the prepared hole. A prepared screw or self-tapping screw is screwed into it. In old highways it is not recommended to do this. The old age of used metal can lead to the appearance of a larger hole in the “problem” area.

- Bandage with rubber gasket. This method is universal because it is suitable for all pipes and any type of water leak. The bandage is selected depending on the size of the leak. It is recommended to use a rubber gasket, and a strip 0.5 cm larger than the bandage and a centimeter smaller than the circumference of the pipe is cut out of it. It is installed under it and the structure is placed on the fistula area. If it is not very large, then during repairs it is allowed not to interrupt the water supply.

- Repair with adhesive bandage. First you need to prepare a strip of fiberglass, or an ordinary bandage. The size of the tape should be such that it is enough to wrap the product six times. This ribbon is soaked with epoxy glue and wrapped so that the leak is located in the center. At the end, the bandage must be secured with a clamp. This pipe network will be able to function only a day after repair.

- Sealing by cold welding. This option is temporary. It is intended for small holes. Afterwards, it is better to repair the problem area using one of the more reliable methods. The described method is not durable due to the fact that the influence of water and high temperature on liquid welding leads to its weakening. To repair using cold welding, you simply need to apply it to the water leakage area that appears on the product.

Video

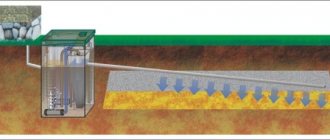

In this article you will learn how to eliminate a fistula in a pressure pipeline.

Troubleshooting plastic products

A fistula on a plastic pipe is repaired in two ways: threaded and soldered.

The threaded method can only be used for products where thread cutting is possible. A piece of pipe line with a fistula that has become unusable is cut off with special scissors.

An insert is prepared from blanks of the required volume. On plastic materials, threads are cut with a tool. Then another structure is secured to the pipe network using fittings and couplings.

Welding on plastic pipe materials begins with cutting off the leaking area. After this, a fitting and a workpiece of the appropriate size are prepared.

A heated soldering iron for welding plastic pipes is used to heat the outer edges of the plastic and the inner edges of the fittings. At the final stage of repair, the prepared pipe is attached with fittings.

This should be done without delay, as plastic tends to harden instantly, and an incorrectly fastened structure cannot be remade again.

Repair of copper products

Copper pipe fistula is not a rare occurrence. Copper pipes have been used in construction for a very long time. They are not only suitable for all types of highways, but are also characterized by high ductility and resistance to corrosion.

Video

Their service life is not limited, and they will easily last the entire period allotted to the house without breakdowns. But, sooner or later, situations arise when these products need to be repaired for fistula.

Copper systems are repaired by welding, which requires the participation of a specialist. To avoid the possibility of a large fistula, the network should be checked regularly. If any damage is noticed, it should be repaired immediately.

Problems in the heating line

Communications do not last forever, and even when using high-quality materials, a fistula can form on the heating pipe.

The underlying reasons for heating leaks are:

- Wear. It is tied to a long period of use of the heating system. Most often, steel products suffer from leaks.

- Violation of operating conditions of the heating system. This includes temperature and pressure surges and water hammer.

- Use of goods of questionable quality.

- Poor sealing of joints.

If a leak appears in the heating pipes, proceed as follows.

Video

You need to prepare several clamps with rubber seals (the most important thing is not to forget to turn off the water, stop operating the heating boiler, disconnect the pumps from the power supply and turn off the necessary valves and taps). Repair of rolled pipes in the heating network depends on their type.

For example, steel pipes with a problem with a threaded joint will require disassembling the joint and applying a new winding layer.

If the destruction has occurred on the heating pipe itself, then the problem area will have to be welded using gas or electric welding.

If a copper pipe is leaking, then it must also be welded. But welding work with copper is quite complex, therefore, it is better to entrust it to specialists.

If metal-plastic pipelines of the heating system are leaking, then the entire section where the leak occurred will need to be replaced. In this type of pipe, it most often forms in compressor-type joints.

On heating pipes made of plastic, the problem is solved in this way. This is the replacement of an entire section. Soldering of polypropylene is recommended to be carried out in accordance with all standards for this work. Any errors can cause the joint to fall apart after a very short period of time.

Video

IMPORTANT! When working with plastic products, it is prohibited to make changes to the wiring diagram.

Features of metal pipelines

If we are talking about how to weld a fistula in a pipe, which is large in size, then there is only one recommended solution - a complete replacement.

And, if the fistula is small, then here are several options for action. But, these recommendations can only be applied when pipes made of metal are leaking.

Video

Option 1. In this case, the defect is eliminated using a medical bandage and cement for sealing. First, a solution of cement and water is diluted. 15-20 strips, 20 cm long, are cut from the bandage. The strips are moistened in the solution and wrapped around the line. The result is something similar to a cocoon. A cement mortar is applied on top of it. All this must dry for 24 hours, and then the pipe network can be started.

Option 2. Pieces of rubber to make repairs. A strip is cut out of rubber, slightly longer than the circumference of the pipe. The problem area is tightly covered with this strip, which is then fixed. For reliability, it must be covered with a bandage with cement, as described in the previous method.

Option 3. Bandage and table salt. This is how the small “gaps” between the joints are covered. To do this, wrap the leak site with a bandage mixed with salt. Salt, when dissolved, fixes the microleak. But this method cannot be used for large formations; you should act differently.

Defects in water supply networks

People often ask how to repair a fistula in a water pipe. Unfortunately, plumbing leaks are a very common occurrence.

In this case, the water leak can be sealed using devices such as a clamp, cold welding, or any other traditional methods.

The condition of the plumbing system must be constantly checked. If the workpieces have served for a long time, and it is not possible to quickly replace them, then it is necessary to prepare several clamps in reserve to make repairs, because a water leak in such products can occur at any time.

Video

If stains of rust appear on the water supply and paint builds up on the pipes in some places, this serves as a signal that pitting corrosion will soon appear.

Before removing such paint, it is recommended to prepare all the tools for repair, because no one knows what size the hole may be under this layer.

IMPORTANT! A fistula in a cold water pipe under a layer of paint is not as dangerous as in its counterpart with hot water. If water from under the removed paint flows out of the pipe during repairs like a fountain, it can cause serious burns to a person.

Leaks in sewer lines

When considering the question of how to eliminate a fistula in a sewer pipe, it should be noted that coping with this task is a little more difficult than repairing water leaks in the joints.

At the beginning of the sealing, an assessment of the defect and strength of the workpiece will be required. Small leaks can be eliminated using plugs for this type of tube rolling. You can also try the repair method - wrapping it with gauze impregnated with epoxy resin.

An option with a rubber gasket secured with a clamp will help to temporarily seal a water leak. It and the repair clamp can be purchased at any building materials store. Also, its gasket can be fixed using wire.

Longitudinal cracks and chips on the pipe can be easily eliminated with sealant. To do this, the fistula is slightly enlarged, degreased and dried.

After this, a sealant is applied to the area. Metal materials in sewers from water leaks are sealed by cold welding.

Repairing leaks with your own hands

Water leaks occur at any time, so sealing fistulas in pipes with your own hands is a very important skill.

For very urgent repair of a fistula, it is recommended to use a clamp. It is a metal tie. And you need to apply the clamp like this:

- The water supply system is shut down.

- The bolts on the clamp are unscrewed and it is wrapped around the water leakage area.

- The nuts on the clamp are tightened with an adjustable wrench, while the pipe itself is held in place with a pipe wrench. Without support when sealing with a clamp, the pipe can be damaged, which will result in additional water leaks and repair costs.

Video

Sealing methods using a locknut and a rubber band are also effective. In general, it is not difficult to repair and eliminate a fistula on a pipe.

If you don’t have confidence in your abilities, then you should invite professional craftsmen. And if the fistula is repaired using one of the temporary methods, then you should worry about how to carry out a full repair of the pipes in the near future.

(2 ratings, average: 5.00 out of 5)

trubanet.ru

How to fix a defect using a bolt

First you need to expand the fistula. This is done using a drill. Threaded elements are cut with a tap. The bolt is screwed into the widened hole. It is worth noting that these repairs are recommended to be performed only if the pipes are not very worn out. If the structure is old, it is unlikely that you will be able to make high-quality carvings on it. This will only increase the defect.

How to fix a pipe fistula yourself

Fistula. What is this? This term refers to a deformation in the pipe in the form of a hole. The main reason for its appearance is considered to be chiseled corrosion. This is a clear sign that the water supply structure is worn out and needs to be replaced. However, it is not always possible for a person to immediately carry out a full range of work to replace the system with a new one. In this case, it is necessary to perform a partial repair to eliminate the fistula. It is worth remembering that such repair work is temporary and does not eliminate the need to replace worn pipes. You can call a professional to carry out the work, but you can also do it yourself.

What is a fistula?

In order to eliminate a fistula, you need to stock up on the following tools and materials:

- Drill;

- Set of bolts;

- Special adhesive composition BV-2;

- Metal brush;

- Epoxy adhesive;

- Petrol;

- Tap;

- Acetone;

- Kern;

- Putty knife.

Caused by rust

Before eliminating the fistula, it is necessary to drain the water from the system. For this purpose, it is necessary to close the stop valve. Then all the taps open.

How to fix a defect using a bolt

First you need to expand the fistula. This is done using a drill. Threaded elements are cut with a tap. The bolt is screwed into the widened hole. It is worth noting that these repairs are recommended to be performed only if the pipes are not very worn out. If the structure is old, it is unlikely that you will be able to make high-quality carvings on it. This will only increase the defect.

Fistula removal.

This type of repair work is optimally performed if an elongated fistula has formed on the structure. In order to seal it, a bandage with a rubber seal is applied. The seal can be made from rubber gloves, an unnecessary bicycle tire, a doctor's tourniquet, or a piece of rubber boots. The size of the seal must be larger than the volume of the defect in the pipe. This gasket is attached to the structure using clamps or a bolt.

How to seal a hole with an adhesive bandage

To begin with, the pipe is cleaned with a metal brush. It is then treated with acetone or gasoline. Wait about 15 minutes. At this time, you can start cutting the fiberglass into equal parts. The optimal sizes of such tapes are directly dependent on the size of the pipes. The tape is cut correctly if it can be wrapped around the structure at least six times. The width of the segment should be three times the diameter of the structure. BV-2 adhesive is applied to the edges of fiberglass sections. Then an epoxy adhesive is applied to one side of the piece using a spatula. It should saturate the segment well. To do this, while applying the glue, the spatula must be pressed well against the surface of the tape. It is then wrapped around the structure. The middle of the segment should be in the area where the fistula formed. The bandage is tightened using a metal tape. The structure is left for a day. If it is located in a cold room, you will have to wait at least 4 days for the system to come into working condition.

We eliminate the defect by “cold welding”

The defect should be expanded using a drill. Then the structure is cleaned of dirt and treated with acetone. You should wait until the structure dries and then apply the “cold welding” compound to it. It dries within ten minutes.

Attention: If you use cold welding or epoxy adhesive during repair work, you should wear rubber gloves. The glue should not come into contact with the skin. If it does get on the skin, it should be immediately removed using cotton wool soaked in acetone, and then the area on which the glue is found should be thoroughly washed with warm water and soap.

In conclusion, we can say that the listed methods for sealing a hole in pipes give only temporary results. We recommend that you replace the water supply with a new one. People who do not allow the structure to wear out do not even know that it is a fistula.

trubygid.ru

How to detect a leak in a heating pipe

One of the “symptoms” of a malfunction of the system is extraneous noise. Vibration, whistling or clicking usually indicate that either the seal is broken or the pressure in the system has changed. In any case, you should pay attention to the noise that arises and, after examining the entire system, determine the place where the noise is most audible. Most likely, it was in this area that the problem arose. Having established the causes of noise in heating pipes, you need to immediately begin eliminating them.

Obvious signs of a leak are smudges at the joints or on the pipe itself. They appear as dark or rusty spots and drips.

However, these signs are clearly visible only on metal pipes. On plastic or metal-plastic that is not subject to corrosion, water droplets quickly evaporate, leaving virtually no traces. What to do if the heating pipe drips? How to eliminate a fistula in a heating pipe? Of course, the first thing you need to do is try to stop the leak. Repair work on different pipes is carried out using different technologies. But there are also some general points. Let us dwell in more detail on the methods of repairing heating pipes made of different materials. Indeed, in some cases, the problem can be solved independently, or, in any case, the leak can be stopped until a repair team is called.

How to repair a fistula - traditional methods

Please note that we are not talking about the most common option - a bolt-on clamp. This remedy is familiar even to housewives, but with the advent of plastic pipes it is not always applicable. The idea is simple: a strip of thin metal is cut along the circumference of the riser, and holes are drilled at the ends. The fistula is sealed with a rubber gasket, tightened with bandage bolts.

If the battery is connected correctly, it can be easily disconnected from the riser and repaired

Also, you should not reinvent the wheel when a leaking heating battery is connected according to the correct circuit - with a bypass, ball valve and balancing valve. Shut off the fittings, calmly remove the heating device and eliminate the leak. If the radiator is connected directly, without shut-off valves, choose the appropriate repair method locally.

Magnet and self-tapping screw

Metal particles travel along the communications with the coolant, especially in systems made of steel pipes. If a small crack appears or a connection leaks, these particles can be used as a sealant. Without draining the water, a small magnet is applied to the pipeline, attracting the metal to the defect point. Practice shows that after 1-2 days the leak is delayed.

Recommendation. The method works well on aluminum and bimetallic radiators; you just need to attach a magnet. This method is not suitable for large damage and plastic pipes.

When the connection is dug, a piece of magnet from an old speaker is applied to it

The option with a screw is simple to implement: select a self-tapping screw of the required diameter and screw it into the hole. The method helps in such cases:

- for point defects measuring 1.5-5 mm;

- on pipes made of copper, polypropylene (PPR) and cross-linked polyethylene;

- on bimetallic and aluminum radiators.

Note. Damaged metal-plastic pipelines are prone to delamination, so a self-tapping screw plug will not help.

To be sure, the screw being screwed in can be coated with automotive silicone sealant or epoxy resin. If the hole in the pipe is quite large, instead of a self-tapping screw, drive a wooden peg into it, sharpened to a cone. Cut the top of the plug flush with the surface and apply a regular clamp.

Causes of fistula formation

Defects form on plastic pipes due to poor quality connections and pressure surges. On metal pipelines, fistulas appear due to the erosion of the walls by pitting corrosion. The process is especially active in heating and hot water supply (DHW) systems, from which water is drained after the end of the heating season. The most vulnerable areas include:

- threaded and welded connections;

- branch locations;

- joints between sections of heating batteries;

- sections of pipelines to which mechanical stress is applied.

To prevent trouble from taking you by surprise, you need to regularly wipe problem areas with toilet paper. If it gets wet, get ready to fix the leak. You can also determine where a fistula will soon appear in the pipe by visual inspection by looking at the swollen paint, which peels off at the site of corrosion. However, you should not remove the rust right away, since it is not known what size the defect is hidden underneath.

Cold welding

If you contact the housing office with a request to repair a fistula in a pipe , a welder will come to you, turn on the machine and weld the hole.

Sealing a fistula in a pipe by welding is a quick way to fix a leak, but not everything is so smooth. When a metal is heated to its melting point, its structure is disrupted, its physical properties and chemical stability change.

After two to three years of operation, a new fistula forms next to the weld, and perhaps more than one. Repairing large-scale damage in the immediate vicinity of the weld is more difficult. You may have to install several clamps with sealing gaskets, and also use a multi-layer “pie” of raw rubber, porous rubber, reinforced rubber and similar materials to seal the pipe.

Cold welding

Cold welding is a trade name for binary adhesive mixtures prepared using epoxy resins, plasticizers and hardeners. Different grades of so-called “cold welding” are intended for use in different conditions. Exact fulfillment of the instructions is the key to successful sealing of fistulas in pipes , radiators, storage tanks and heating devices.

Some brands of adhesives are designed for application to wet metal surfaces. The practice of using cold welding for fistulas in pipes shows that removing rust, high-quality degreasing, and, if possible, drying the metal surface dramatically increases the efficiency of the adhesive mass.

The functionality of an adhesive patch applied to a water supply or heating pipe can only be guaranteed by compliance with the recommended parameters. High-quality cold welding can withstand pressure of tens of atmospheres, that is, it does not allow the resumption of leakage even after a water hammer.

To sum it up...

Having considered several ways to repair fistulas in cold and hot water supply pipes on our own, we are ready to recommend:

- installation of bandages;

- installation of clamps equipped with soft rubber gaskets;

- driving wooden plugs into the holes;

- the use of plastic adhesives based on epoxy.

Repairing large-area damage, as well as sealing fistulas in large-volume containers, is carried out using other methods - applying double-sided patches, welding patches, inserting new pipes, placing waterproof liners in the container. Attempts to use industrial methods for eliminating leaks are impossible to do at home!

How to eliminate leaks in hidden heating pipes?

Sometimes leaks occur in hidden areas of heating pipelines. Sealing the latter from the inside will help to avoid or at least delay the dismantling of building structures to completely replace damaged pipes. How to seal holes in a hidden heating pipe? To do this, use one of the following methods:

- You can add mustard powder to the expansion tank, after which the circulation of the coolant should be resumed. After a few hours, the mustard suspension will seal cracks and small holes from the inside of the pipe. After eliminating the leak in this way, the system must be flushed.

- Factory sealant is poured into the heating circuit for a certain period of time, which settles on the inner walls of the pipelines in places where leaks occur. After sealing, the coolant also needs to be replaced.

It should be understood that internal sealant will not be able to block a large hole or fistula. If they were detected in hidden areas, the system will have to be turned off, after which the riser must be reset, and then proceed to dismantling the structure to replace the leaking spans. If you live in an apartment building, you must notify your neighbors, as well as the relevant utility services, about the plumbing work being carried out.

It is important! 95% of problems in household heating systems are associated with errors made at the design stages, selection of materials, installation and connection of heating circuit elements.

Therefore, special attention should be paid to compliance with the rules and regulations in force in this area. As a result, it will be much easier for you to find the best option for how to seal leaks in heating pipes on your own if they appear during operation of the circuit.