Home / Welding technique

Back

Reading time: 2 min

1

2593

Currently, semi-automatic welding using carbon dioxide is used by both specialists and novice welders.

In this article you will learn a lot of useful information about working with carbon dioxide, its advantages, such as protecting the weld from the negative effects of particles in the air, improving the quality of the work performed, and more.

- What is welding with a semi-automatic welding machine in a CO2 environment?

- Advantages of carbon dioxide welding

- Components for carbon dioxide welding

- conclusions

What is welding with a semi-automatic welding machine in a CO2 environment?

So, let's find out how the semi-automatic welding method with carbon dioxide works. Exposure to high temperatures during the welding process promotes the partial breakdown of carbon dioxide into oxygen and carbon.

This chemical process has a beneficial effect on the final result, protecting the welding site (the so-called weld pool) from various harmful impurities in the air in your work area.

It is also worth noting the excellent interaction of these three gases with iron, which further increases the quality of the weld.

The main disadvantage of carbon dioxide is its ability to oxidize the metal being welded, thereby worsening the quality of the work done.

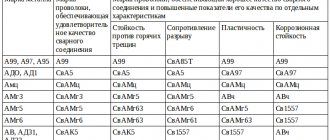

It is quite simple and effective to combat this drawback by adding a large amount of silicon and manganese to the composition of the wire for semi-automatic welding.

This is where the positive chemical properties of the oxides of these elements, released during the welding process, begin to operate. Their interaction with the metal surface contributes to the formation of a reliable welding joint that is resistant to oxidation.

For carbon dioxide welding, use a semi-automatic welding machine, and you can choose its operating mode yourself, based on your experience, or using the recommended parameters from Table 1.

It shows that the main criterion for choosing an operating mode is the thickness of the metal being welded.

Table 1 – Setting parameters for a semi-automatic welding machine with carbon dioxide:

How to cook with carbon dioxide for beginners

As mentioned above, the quality of the weld seam when welding with carbon dioxide largely depends on the degree of preparation of the materials. Also, it is equally important to pay attention to the correct settings of the inverter semi-automatic device and gas consumption.

You should know that for welding each metal, depending on its thickness, its own welding current parameters and a certain wire diameter are selected. It is also important to consider the speed of wire feed into the welding zone.

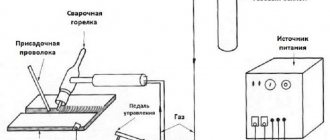

You can adjust the welding wire feed speed on a semi-automatic machine using gears and a mechanism. Semi-automatic welding in a carbon dioxide environment is carried out as follows:

- The semi-automatic torch is located in the welding zone, so that the tip is located at the place where the seam is formed. By pressing the “Start” button, you must simultaneously move the torch, touching the wire to the metal being welded.

- At the same time, the welding arc will be initialized and the semi-automatic welding process will begin.

- During this process, it is necessary to move the welding torch tip evenly along the seam, constantly monitoring its inclination and position.

It is impossible to make sudden movements with a gas torch during semi-automatic welding, as this will lead to a deterioration in the quality of the weld. In addition, do not forget about the main disadvantage of using semi-automatic devices with gas: the protective gas can be blown away by the wind.

In order not to spoil the workpiece, it is important to practice semi-automatic welding with carbon dioxide on an unnecessary piece of metal in advance. This is the only way to select the correct gas flow rate and select the desired welding wire feed speed.

Advantages of carbon dioxide welding

So, we have already learned the principle of semi-automatic welding with carbon dioxide, as well as how to deal with its main disadvantage.

Now let's look at the main advantages of this method compared to its competitor - flux-cored welding:

- the quality of the welded joint is higher, even for beginners in this activity;

- the work speed is 2-3 times faster due to uniform heat dissipation from the welding arc, and therefore labor productivity is much higher;

- the ability to weld even thin metal without fear of deteriorating the quality of the seam;

- There are no flux or slag residues left at the semi-automatic welding site; in case of multilayer metal welding, this advantage will come in handy;

- absence of flux, which means nothing interferes with visual control of the welding arc;

- the quality of surfacing using carbon dioxide is higher than with flux;

- you can carry out soldering work in any spatial position, of any complexity (including work suspended and at an angle) without the use of strips, stands, pads, etc.;

- cost-effectiveness of the method and huge benefits in terms of investment;

- no need to purchase equipment for removing and supplying flux during the welding process;

- the cost of the metal used for surfacing is two times cheaper compared to other methods;

- carbon dioxide itself has a relatively low price, which also reduces the overall cost of work.

Advantages and disadvantages of welding in CO2 environment

Carbon dioxide tig welding is widely used both at home and in various industrial sectors. This is not surprising, because this type of connection has a number of advantages:

- it is possible to connect thin sheet metal;

- you can weld different types of metals, with different characteristics and melting temperatures;

- the electric arc is highly stable;

- the weld pool is reliably protected from oxidation and exposure to negative environmental factors;

- The resulting seam is of very high quality;

- semi-automatic welding technology in a carbon dioxide environment is considered the safest in comparison with other tig methods;

- cost-effectiveness and accessibility. This indicator is due to the fact that 2 is much easier to purchase than mixtures of other gases used for protection during tig welding.

In addition to the advantages, several disadvantages can be noted:

- The quality of carbon dioxide is slightly inferior to other mixtures;

- the device is a little more difficult and longer to clean than after helium, argon or nitrogen;

- Material costs are constantly increasing.

Components for carbon dioxide welding

Carbon dioxide storage cylinder

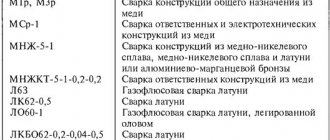

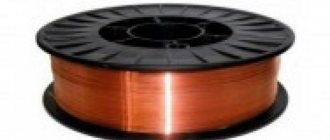

Wire for semi-automatic welding. Used as an electrode. For each case, depending on what metal we will solder, the wire must be selected individually.

Based on the thickness of the metal being welded, the power of the semi-automatic machine and its other features, the diameter of the wire can vary in the range from 0.5 to 3 mm. In practice, copper wire shows the best results, and we recommend using it.

It is necessary to use only clean material, without traces of rust, corrosion, or contamination, which has been stored in proper conditions.

Otherwise, this wire cannot be used unless you want to end up with a poor quality connection. It is recommended to soak the wire in sulfuric acid and then hold it at high temperature for several hours.

Carbon dioxide CO2. Actually, our main highlight of the program and the most important component. Carbon dioxide for semi-automatic welding is harmless to humans and colorless.

CO2 is transported and stored, as a rule, under pressure in special black containers and marked with the same name. Here are some practical and simply useful operating tips:

- for particularly important and complex work, use a container with a 99% carbon dioxide content; in other cases, containers with a 98% content will be sufficient;

- Please note that excess moisture will negatively affect the overall quality of welding. To get rid of it, place the container in a vertical position for one hour, during which time the moisture will settle to the bottom;

- Before starting semi-automatic welding, release a little gas from the container to get rid of nitrogen impurities contained in it that are harmful to welding.

The concept of semi-automatic welding in a CO2 environment

The operating principle for semi-automatic welding in carbon dioxide mode is very similar to the gas welding method with and without gas. That is, you can cook in two ways - using protective gas or not. You can read more about this method here.

The essence of the method under consideration lies in elementary chemistry. Carbon dioxide (CO2) is supplied under pressure to the welding zone. The welding arc provides a high temperature, due to which a decomposition reaction occurs and the gas breaks down into oxygen (O2) and carbon monoxide (2CO). The decay process occurs according to the formula:

2СО2=2О2+2СО

As a result of this reaction, the weld pool is protected by three gases - the initial carbon dioxide and the final reaction products - oxygen and carbon monoxide

Carbon dioxide tends to oxidize with iron and carbon found in the metal. To protect the metal of the product from this process, it is recommended to use wire with a high level of manganese and silicon for the welding machine. These components are more chemically active than iron, so they oxidize first, thereby taking the “blow” and protecting the product. As long as these two elements are present in the welding zone, iron and carbon will not oxidize. Waste, that is, oxides of manganese and silicon, which are formed when exposed to high temperature and oxidation reaction, is a low-melting compound that floats to the surface of the weld pool and crystallizes in the form of slag. This component does not affect the quality of the seam in any way.

For welding in a carbon dioxide environment, one standard 25 kg carbon dioxide cylinder is enough for 15 welding hours. Taking into account the reaction, one kilogram produces almost 500 liters of finished gas. During full operation, the average cost is 10 to 50 liters per minute. But consumption depends on many factors - pressure, type of welding, type of seam, apparatus used, weather conditions, and so on.

This method is called tig welding, that is, this work involves joining metals using electrodes in a protective gas environment. The electrode can be tungsten or graphite.

conclusions

In total, welding with a semi-automatic welding machine in a CO2 environment is a set of continuous advantages, for example, increasing labor productivity, expanding your professional skills, and you will always be satisfied with the result of the work.

Beginners in the first stages of mastering, of course, may experience problems with excessive gas consumption, but this disadvantage is evened out by its fairly low price, and with gained experience, when you master the principles of operation of this method, this problem will disappear altogether.

A little patience, experience in welding, the presence of a semi-automatic machine, carbon dioxide, all the necessary materials and you are completely ready to conquer this method.

Professional experience is gained through practice, so experiment and train yourself with different operating modes, getting better at it, rather than relying on tabular data; this experience is very important if you want to become a professional welder.

Ask professional welders for advice and don’t forget to follow safety precautions. We wish you success!