Content:

Rationing oxygen consumption for metal cutting is fundamental, both when calculating the total costs during the labor process, and when calculating the cost of manufacturing a part and performing certain types of work. Since oxygen is the fuel for cutting parts, the rate of oxygen consumption for cutting metal becomes of key importance, along with energy consumption. There are several methods for the thermal separation of metals, which are divided depending on the method and type of fuel used. Therefore, along with oxygen cutting of metals, in this article we will pay attention to other methods of cutting metal structures. So let's get started.

Calculation standards for flammable gases and oxidizer

The consumption rates of propane and oxygen or acetylene and oxygen or only the oxidizer are calculated as follows:

- The standard fuel or oxidizer consumption per linear meter of cut ( H ) is multiplied by the length of the cutting seam ( L ).

- After this, the product of the same consumption standard ( H ) by the loss coefficient ( k ) associated with purging and setting the cutter is added to the resulting amount.

As a result, the oxygen consumption during welding (or the consumption of flammable gas) is calculated according to the formula:

Moreover, the coefficient k is taken equal to 1.1 (for small-scale production or piece cutting, when it is necessary to frequently turn the cutter on and off) or 1.05 (for large-scale production, when the cutter works almost without interruption).

Determination of gas consumption standards

To accurately determine the volume of gases consumed, it is necessary to determine the basis of the formula - the norm that determines the gas consumption per linear meter of the metal being cut, denoted in the formula by the letter “ H ”.

According to general recommendations, the normalized flow rate is equal to the quotient of the permissible flow rate of the separating apparatus ( p ) (oxygen, plasma or laser cutter) and the metal cutting speed ( V ).

That is, the formula by which the normalized oxygen consumption for cutting metal is calculated ( H ), as well as any other gas participating in the process of thermal separation, is as follows:

The desired result is substituted into the first formula and the specific value of the consumed volume is obtained.

Determination of permissible flow rate and cutting speed

Operands p

(allowable flow rate) and

V

(cutting speed) depend on many factors.

In particular, the value of the permissible flow rate is determined by the passport data of the welding machine. Essentially p

equals the maximum throughput of the cutter nozzle in operating mode.

But the cutting speed is V

– determined based on the depth of the seam, the width of the cutting jet of oxidizer or plasma, the type of material being separated and a whole series of indirect parameters.

As a result, the value of the permissible flow rate is extracted from the “cutter” passport, and the cutting speed is found in reference books that contain special tables or diagrams that connect all the input data.

And according to reference data, the permissible oxygen consumption is 0.6-25 cubic meters per hour. And the maximum cutting speed is 5-420 m/hour. Moreover, laser cutting is characterized by a minimum flow rate (0.6 m3/hour) and a maximum speed (420 m/hour): after all, such a cutter will only cut a 20-mm workpiece.

But a plasma cutter “burns” up to 25 m3/hour of oxygen and 1.2 m3/hour of acetylene. At the same time, it separates even 30-centimeter workpieces, making a cut at a speed of 5 meters per hour.

In a word, in such calculations everything is relative: the greater the speed, the shallower the depth and the greater the flow rate, the lower the speed.

- CONTENT:

- • Basic methods of cutting metal with gas

- • How to calculate the cost of service per meter

- • Gas consumption when cutting metal

- • Features of cutting to size

- • Advantages of the gas cutting method

- • Possibility of deformation

- • Metal cutting process

- • Device of a manual cutting torch

- • Injection cutter device

- • What does gas consumption depend on?

Read also: Bit numbers for self-tapping screws

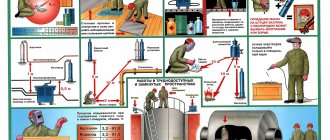

Gas cutting of metal (oxygen/autogenous) is the process of cutting steel and metal products/blanks with an oxygen flow supplied from a special apparatus. The essence of the cutting procedure is the combustion of the metal, using a gas mixture and oxygen supplied to the element being processed. The product is first heated to 1300 degrees with an open flame, then an oxygen stream is supplied, cutting the metal in accordance with the diagram. Modern gas cutting technology allows cutting sheets of any configuration with a thickness of up to 300 mm, in some cases up to 1000 mm.

Types of thermal cutting of metal.

Let's look at three main methods of thermal cutting. The first most common type is oxygen separation cutting. Area of application: cutting sheet and long carbon, low-alloy rolled metal, trimming excess protrusions and edges that formed during casting, preparing parts for welding, etc. This method is not used for separating stainless high-alloy steels, non-ferrous metals and cast iron.

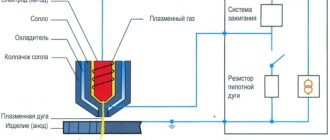

The next type is plasma arc cutting. The scope of application is also cutting, but in this case low- and high-alloy steels, as well as aluminum, copper and their alloys.

And the last type that we will consider in this article is laser cutting, which is one of the innovative methods of cutting metals. This method significantly expands the scope of gas cutting and, thanks to this, it is possible to effectively separate thin-sheet rolled products, special profile rolled products, thin-walled pipes, both from metal and non-metal parts.

The consumption of gas fuel in various methods (oxygen, acetylene, gas substitutes) for separation is determined using specialized tables depending on the cutting mode, as well as on the thickness of the metal being cut.

With the above-mentioned types of cutting, the consumption of gases, which are used to heat the structure being cut, for cutting, and also for the formation of plasma, is determined by type of fuel. Let us repeat that these include: oxygen, substitute gases (propane-butane, natural gas, etc.), acetylene, and nitrogen. In addition to these gases, hydrogen and argon are used, but their scope and popularity of application is not significant, so we will not include them in the content of the article.

When working with a plasma-arc device, it is important to plan in advance the number of replaceable special electrodes (cathodes), with zirconium or hafnium inserts. The consumption rates of these electrodes vary depending on the intensity of the work process and, in general, do not exceed 4 rods per shift. More precise rationing of rod consumption will be indicated in the operating instructions for this unit.

Oxygen cutting of medium thickness steel

Installations for automatic welding of longitudinal seams of shells - in stock!

High performance, convenience, ease of operation and reliability in operation.

Welding screens and protective curtains are in stock!

Radiation protection when welding and cutting. Big choice. Delivery throughout Russia!

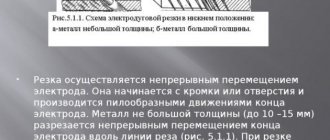

When oxygen separation cutting of steel, in accordance with technological features, cutting of metal of small thicknesses (up to 5 mm), medium thicknesses (5-300 mm) and large thicknesses (over 300 mm) is distinguished. This division is quite arbitrary, however, for each range of cut thicknesses there are general patterns.

The most important technological parameters of oxygen cutting are the consumption of cutting oxygen, the power of the heating flame, and the cutting speed.

Read also: What kind of welding is used to cook cast iron?

To calculate cutting oxygen consumption, the following formula can be recommended, obtained based on the results of data processing from VNIIavtogenmash and foreign companies:

where Vcr is the consumption of “cutting” oxygen, m 3 /s; k2 - coefficient taking into account the state of the metal before cutting (k2 = 0.3 - for rolled products; k2 = 0.6 - for castings and forgings with a thickness of 0.3 to 0.6 m), kр, kп, km - see table . 26.1.

The preheating flame heats the surface layers of the metal to the ignition temperature at the beginning of cutting, and during the cutting process - the front surface of the metal. The power of the heating flame will increase with increasing thickness of the metal being cut and the distance between the end of the cutter and the metal. When cutting contaminated metal, the flame power must be increased. The power of the flame is determined by the consumption of combustible gas, its type and the ratio of the consumption of combustible gas and preheating oxygen. Oxygen cutting uses gaseous and liquid hydrocarbons as fuel. When these fuels burn in a mixture with oxygen, a high-temperature flame is formed.

In table 26.2 provides information about the basic properties of flammable gases.

The consumption of flammable gas and preheating oxygen during cutting can be determined from the following dependencies:

where Vr.r is the consumption of combustible gas, m 3 /s; Vk.p - consumption of heating oxygen, m 3 /s; δ is the thickness of the metal being cut, m. The values of the coefficients included in the given equations for different cutting conditions are given in Table. 26.1 and 26.2. The consumption of iron powder (qf, kg/s) when cutting high-alloy steels is determined by the formula:

qf = 0.025δ 1.5 + 0.0017. (26.10)

At given gas flow rates, the cutting speed decreases exponentially with increasing thickness of the metal being cut, since the dynamic effect of the jet on the melt decreases sharply with distance from the nozzle exit. The cutting speed increases with increasing metal heating temperature due to an increase in the thickness of the liquid layer of metal in the cut, the purity of oxygen and the oxygen pressure in front of the nozzle. Increasing the pressure of “cutting” oxygen in front of the nozzle helps to increase the speed of its flow and its dynamic effect on the oxidized metal. The greatest increase in oxygen flow rate (up to 90%) is observed in the pressure range at the nozzle inlet from 98 to 2940 kPa; a further increase in oxygen pressure in front of the nozzle from 2940 to 9800 kPa makes it possible to increase the oxygen flow rate by only 8%.

Based on a generalization of experimental data, the following dependence was obtained for determining the cutting speed:

where v is cutting speed, m/s; δ—thickness of the metal being cut, m; kd is the cutting speed coefficient, depending on the pressure of the “cutting” oxygen,

where pk is the pressure of “cutting” oxygen, kPa; kch - cutting speed coefficient, depending on the purity of oxygen,

where ε is the purity of oxygen, %; kt, km, kр are selected in accordance with Table 26.1.

Lower cutting speeds are selected for precise cutting of shaped parts, the highest for straight separation oxygen cutting of metal into scrap (Table 26.3).

Volchenko V.N. “Welding and weldable materials.”

Gas consumption for metal cutting: norms.

The oxygen consumption for cutting metal, like the consumption of other gases, is calculated using a special formula:

And in this equation, N is the consumption standards during the working process, cubic meter of gas per meter of cut. L – size of the cut or cut part, meter. Kh is a coefficient that takes into account many features of the work process: gas consumption at the initial stage of cutting, purging and adjustment, ignition of the plasma arc, heating of the metal, and, as a rule, it is equal to 1.1 for single production, or 1.05 for industrial production.

The rate of oxygen consumption for cutting metal and other gases (N, cubic meter per meter of cut) during separation, depending on the power of the equipment and the cutting mode, is calculated using the following formula:

Where P is the permissible gas flow rate, which is indicated in the technical characteristics of the equipment used, cubic meter per hour, and V is the separation rate meter per hour.

The main values of gas consumption for various cutting speed ranges for some types of equipment, which can be used for large-scale calculations in industrial production, are given in the following table.

The use of various gases as fuel for metal separation machines is determined by the requirements for the equipment used and depending on the technological process. The dependence of thickness and cutting speed on the permissible gas flow rate is directly proportional and this value can be easily and simply determined by interpolation. And therefore, it is possible to make an enlarged, estimated calculation of the consumption of various gases, regardless of the type of thermal cutting of metals, based on the size of the cut, the thickness of the metal, as well as the power of the equipment.

In the end, it is important to note that the regulation of gas flow is one of the important features on which the efficiency and speed of the work process depends, so you should not forget about the flow standards, especially during the separation of metal on a huge scale.

The main processes in laser cutting that affect its quality have long been well known to everyone: heating, melting, partial evaporation of the metal and further evacuation of the molten material from the cutting zone using auxiliary gas. Gas is perhaps the key participant in the process that affects the quality of the edge.

Auxiliary gas

If you think about it, the phrase “assist gas” in relation to laser cutting does not best reflect its actual function. Gas is not just an assistant in the cutting process, but rather a partner, working closely with the laser beam [1]. In the case of oxygen, this is the mechanical evacuation of the melt and its participation in the cutting process due to additional heating by the heat generated during the exothermic reaction. In the case of inert nitrogen, this is only mechanical removal of the melt. This has been known to everyone for so long and well that many production operators, especially those just starting to work with lasers, do not even think about controlling the gas parameters in case of obtaining a low-quality edge. Often, operators simply slow down the cutting speed to improve edge quality. Yes, this trick works. This often improves the quality of the edge. But at the same time, the productivity of the machine decreases and the main task of laser cutting is leveled, for which, in fact, the laser machine was purchased - to make many parts at high speed with decent quality and accuracy. What else could be causing the edge quality problem besides speed? Perhaps in the gas pressure, which is easy to check by changing it in the table of machine operating parameters. Perhaps it’s a matter of gas flow, which, yes, depends on pressure, but is actually determined by the diameter of the nozzle. Checking the effect of nozzle diameter will take a little longer, as it will require replacing the nozzle tip. And not all companies have a full set of nozzle tips with diameters from 0.8 mm for oxygen to 3 (+) mm, more typical for nitrogen. The problem may also be associated with a non-optimal gap between the end of the nozzle and the metal surface, with radiation focusing, that is, with a non-optimal position of the focal plane relative to the sheet. Also, unstable edge quality can be caused by unstable gas quality. Let's start with the choice of gas.

Choice of gas: expensive gas reduces costs!

The choice of auxiliary (cutting) gas should be based on a thorough analysis of the production cycle and all costs, including gas, be it nitrogen, oxygen or compressed air. Due to the exothermic oxidation reaction, oxygen allows thicker materials to be effectively cut at relatively low laser power, but if the edges are welded or painted, the oxides will need to be cleaned off. Cutting with nitrogen, of course, occurs without the formation of oxides, but a clean edge (without burr) when cutting with nitrogen requires high pressure and gas flow.

Generally, oxygen is used to cut mild steel of any thickness. It happens that they cut aluminum and its alloys, sometimes stainless steel up to 5 mm thick and copper. Stainless steel thicker than 5mm is usually cut with nitrogen (if the laser power is sufficient) as pure nitrogen produces a cleaner, shinier edge. The increased nitrogen consumption is compensated by the absence of additional cleaning operations: the lower the oxygen content as an impurity, the more shiny the cut edge.

Cutting with air or nitrogen from a nitrogen generator has become quite popular over the years. But taking into account how clean (without oil and water vapor) the air or nitrogen is and whether its pressure is sufficient. Air is used primarily for thin materials and when there are no edge requirements at all. Since air consists mainly of nitrogen, its pressure must be high. The compressor cannot always provide enough pressure for a clean cut. In addition, if the compressed air contains residual oil or water, then as a result, films of oil (or water) will be deposited on the lens, increasing absorption and scattering of laser radiation on the lens, leading to its destruction, reducing cutting power and even stopping cutting.

What do we check if the cutting quality is unsatisfactory (ALGORITHM)

Focusing. Check the optimal focus position for a given material and gas using the optimal cutting width. The nozzle must be clean and undamaged.

Laser power. Must correspond to the passport characteristics of the machine and the optimum for a given material thickness. If there is a problem, check the shape of the spot, verticality and the level of power reaching the metal surface.

Cutting speed. If there is no compliance with the manufacturers' recommendations, you need to look for the optimal speed yourself. If the focus position is already optimal, then one possible reason for the discrepancy may be a difference in the chemical composition of the metal from what the machine manufacturers worked with.

Cutting gas. a. Check the type of gas - oxygen or nitrogen. The correct choice of gas for a given material can be assessed based on the type and thickness of the metal, as well as taking into account subsequent operations and the need for post-processing of the edge. If the part is made of ferrous metal, up to 5 mm thick, then if the edge is subject to welding or powder coating, it is better to use nitrogen. In all other cases - oxygen. Stainless steel is typically cut with nitrogen. b. It is necessary to take into account the purity indicators and composition of gas impurities, operating pressure and nozzle diameter.

Distance from the edge of the nozzle to the surface of the sheet. It should not be too large, up to 1 mm. If the distance is too large, the gas does not optimally enter the cutting zone and the efficiency of melt removal from there is reduced.

Nitrogen from the generator is also typically used for cutting thin materials with low edge quality requirements. In the case of a generator, you need to understand that all generators operate according to the principle: either the volume or purity of the gas. That is, the purer the gas required, the less it will be. Therefore, you will have to use additional nitrogen expansion tanks and compressors to create a sufficient supply of nitrogen of the required purity at the required pressure. In this case, problems with purity and impurities in nitrogen may be the same as when cutting with compressed air or low-purity technical nitrogen. This is residual oil (rare, but possible), water vapor and, as a result, condensation on the lens, its further destruction, reduction in the quality and speed of cutting, and so on. And now it’s time to take out the calculator and take into account all the direct, hidden and indirect costs associated with cutting compressed air or nitrogen from a generator, in addition to the standard ones: electricity consumed by the compressor, space occupied, maintenance, and so on.

If gas is supplied to your enterprise by a gas company - a manufacturer or supplier of technical gases, and is not produced at your enterprise, then you have guarantees from the supplier or manufacturer regarding the purity of the gas and the composition of impurities. And if with nitrogen for cutting the problems are not so much in purity, but in the stability of the composition, then this is not the case with oxygen. The purity of oxygen must be 99.8–99.95%. If the oxygen purity is 99.7% or lower, then there is a high chance that there will be a lot of burr on the edge, and the cutting process will be of unstable quality, especially when cutting steel with a thickness of more than 5 mm. In the worst case scenario, cutting can practically stop. So it turns out that high-quality gas with a stable composition will reduce the cost of cutting due to increased speed, reduced scrap, elimination of additional post-processing operations, and so on.

Understanding the reasons for defects, it makes sense to systematically deal with each of the parameters, eliminating them in turn, and when it comes to cutting gas, you should also trace its entire path from the place of production and pumping through cylinders to the point of its use on your machine in the cutting head .

The path of gas from the place of its production to the cutting head of the laser machine

If you suspect that the reason for the defect lies precisely in the gas, you will actually have to check each stage, starting from the place of gas production, and make sure that the conditions of production, storage and delivery are not violated, the quality control service of the manufacturer is working , and the gas quality remains unchanged from the manufacturer's air separation unit to the gate of your enterprise.

Auxiliary/cutting gas can be supplied in a gaseous (compressed) state in cylinders or monoblocks under high pressure, as well as in a liquefied state. Standard cylinder parameters are 40 liters at a pressure of 150 bar. However, modern manufacturers of technical gases have brought to the market cylinders with a volume of 50 liters, into which gas (for example, nitrogen) can be pumped up to a pressure of 300 bar. From such cylinders monoblocks are assembled, consisting of 16 cylinders connected into a single vessel. It is clear that the capacity of such a monoblock is higher than standard ones, consisting of 40-liter cylinders. And as a result, logistics turns out to be more profitable. Monoblocks are usually rented. At the same time, the manufacturer takes full responsibility for their maintenance and checks them in a timely manner. The format and volume of gas supply depends on the monthly gas demand. Starting from a certain volume, working with cryogenic gases becomes more profitable. In liquefied form, gas supplies can be carried out in cryogenic vessels of various sizes: from a Dewar vessel to a cryogenic tank with an atmospheric evaporator. The parameters of such a container are selected depending on your need for this gas per month and the operating pressure required at the entrance to the machine.

How can you make sure that the production, storage and delivery conditions do not lead to a deterioration in the quality of gas and that you receive gas of the declared quality? Just by visiting the production facility - an air separation plant or a cylinder filling station - and becoming familiar with the production and logistics procedures, as well as quality control, to the extent that the gas manufacturing company will allow you.

If you have decided to work with cryogenic gases and have determined the required gas pressure and the need for its quantity, you need to think about what volume of cryogenic tank and what capacity evaporator to choose. It should be understood that the main task of the evaporator is to provide the gas flow necessary for the process, that is, the volume of gas per unit time, but not its pressure. It is determined by the operating pressure of the container. Therefore, for laser cutting with nitrogen, it is necessary either to use a high-pressure tank, or to use additional solutions external to the tank to increase the nitrogen pressure to that required for the operation of the machine. The most popular are high-pressure cryogenic tanks, even though in Russia their installation requires passing certain procedures at Rostechnadzor. In the end, everything pays off due to the uninterrupted supply of gas of the same quality without the need to stop production even while refilling the tank. Gas supply to the machine. Pipeline.

Ideally, the piping should be made of stainless steel or copper and should not contain too many right angle pipe joints. It is advisable to make rounding corners as smooth as possible, with rounding angles of more than 90 degrees, since a pressure drop occurs at the corners. When designing a pipeline for nitrogen cutting, its diameter must be such as to ensure the flow of nitrogen at the required rate to all laser machines that it is intended to serve. Before using the pipeline, it would also be a good idea to thoroughly flush it with pure nitrogen to avoid contamination of the lens. This is especially important if the pipeline is copper and assembled by soldering.

Nitrogen cutting involves high gas consumption and, as a result, high monthly consumption. Let me first remind you of the difference between gas consumption and consumption. People often confuse these concepts, since the units of measurement in both cases are cubic meters of gas per unit of time. The difference is that gas consumption is a function of the geometry of the gas pipeline and depends only on the diameter of the pipeline and the operating pressure in it, while gas consumption is an integral characteristic that depends on the duration of the period of time during which the gas was consumed. It could be a second, an hour, a day, a month, a year. For example, cutting with nitrogen requires a high flow rate, but if the machine is not running, then the nitrogen consumption will be zero.

If you have any suspicions about the pipeline, do not forget to pay attention to all its components, from pipe diameters to fittings, valves, reducers, flexible hoses, ramps, if any. Find the element with the minimum diameter. It is this that must provide the nitrogen flow required for cutting.

NOZZLE AND GAS CONSUMPTION

Let me remind you once again what gas consumption is. Essentially, it is a characteristic of a pipeline, depending on its diameter and operating pressure, as well as the thermodynamic characteristics of the gas flowing through the pipe. Flow is the volume of gas that flows through a pipe or opening per unit time. How is consumption different from consumption? Consumption is an integral characteristic that depends on how long the installation operates, that is, how long gas flows through the hole. Thus, if the machine is not operating, then there will be no gas consumption, but the pipeline (including the nozzle) must provide a certain gas flow rate in m3/hour.

Ensuring that there is enough gas flow for cutting is a very important factor, especially for nitrogen fiber laser cutting. The width of the cut when cutting with a fiber laser is smaller than when cutting with a CO2 laser, so the nozzle must have a larger diameter. Naturally, in this regard, production owners begin to have doubts about the increasing need for nitrogen and, as a consequence, increasing costs. But to correctly assess production costs, it should be taken into account that the productivity of a fiber laser when cutting with nitrogen is generally higher, especially for thin materials. To make a correct cost calculation, you need to sum up all costs and expenses, including investments in equipment, maintenance, spare parts, taxes and salaries, electricity and water costs, and so on, and calculate the costs per 1 linear meter of cut. Then it turns out that an increase in cutting speed (and, as a consequence, an increase in the number of meters cut) leads to less gas being spent per meter of gas.

Nevertheless, an increase in the nozzle diameter even by 0.5 mm leads to a much more noticeable increase in gas consumption (according to the quadratic law) than with an increase in pressure (according to the linear law), and this is worth remembering, especially when cutting with oxygen. If you overdo it, the roughness of the edge will immediately increase and, possibly, burr will appear. This happens due to the fact that with an increase in the volume of oxygen involved in cutting, the number of acts of chemical oxidation reactions increases. Since they occur with the release of heat (an exothermic reaction), which also goes towards heating and melting the metal, there is more melt and it is more difficult to blow it out.

What is kerf?

The short English word kerf refers to the width of the cut. Does it match the diameter of the beam on the surface of the sheet? Not always. Especially when the focus level is set incorrectly.

A focused laser beam has maximum intensity with a minimum diameter at the focus. Outside the focus, the beam, as is known, expands, and, consequently, the width of the cut also changes. Typically, in cutting programs from machine libraries created and preset by machine tool manufacturers, all process parameters are selected for a specific cutting width so that the cutting gas removes the melt from the cut zone cleanly and efficiently. However, there is a nuance here. These parameter sets are selected for a specific material. There are situations when the material that currently needs to be cut is different from what was used to create the library. In this case, you will have to select new parameters, including the focus level. When the focus position changes, the width of the cut also changes. If the cut becomes wider, you may have to reduce the cutting speed to obtain a quality edge. As a result, we can say that the optimal cutting width is the key to maximum cutting speed with a high-quality edge. Optimizing all other parameters - nozzle diameter, gas pressure, and so on will only add speed. And then your technology will take off.

Literature

1. BY: TIM HESTON “Gas gives the big assist in laser cutting” 2. THE FABRICATOR SEPTEMBER 2021, JULY 13, 2015. https://www.thefabricator.com/article/lasercutting/gas-gives-the-big- assi...

Source: RITM Mechanical Engineering magazine No. 2-2018

Gas (oxygen) metal cutting

So, [gas cutting of metal] is the most popular now. Why?

Because it is extremely simple to perform, you do not need to use any phase inverters (as in an electric cutter), and you do not have to comply with mandatory room regulations (the presence of a central grounding cable).

And almost all gas cutters are mobile, that is, they can be transported by ordinary transport.

When cutting, a gas cutter uses two gases - oxygen itself, with the help of which the process of metal separation is carried out, as well as a heater, which is most often propane or acetylene.

The heater heats the surface that is planned to be cut to a temperature of 1000-1200 degrees, after which a stream of oxygen is supplied. Upon contact with a heated surface, the jet ignites.

Basic methods of cutting metal with gas

Spear cutting - this operation is used to process stainless steel, cast iron and low-carbon steel of large diameters. The essence of cutting is that the spear is heated to the melting temperature and pressed against the workpiece being cut. The method is common in the field of mechanical engineering and metallurgy.

Oxygen-flux cutting is used to work with high-alloy chromium and chromium-nickel alloys. This method is characterized by the fact that powdered flux is introduced into the gas (oxygen) stream; it serves as an additional source of heat.

Air arc cutting is based on melting metal using an electric arc. When using this method, gas is supplied along the entire electrode.

Propane cutting is performed when it is necessary to cut titanium, low-alloy and low-carbon steel alloys. Equipment of this type cannot cut metal thicker than 300 mm.

| Material thickness, cm | Penetration, sec. | Cutting width, cm | Propane consumption, m3 | Oxygen consumption, m3 |

| 0,4 | From 5 to 8 | 0,25 | 0,035 | 0,289 |

| 1,0 | From 8 to 13 | 0,3 | 0,041 | 0,415 |

| 2,0 | From 13 to 18 | 0,4 | 0,051 | 0,623 |

| 4,0 | From 22 to 28 | 0,45 | 0,071 | 1,037 |

| 6,0 | From 25 to 30 | 0,5 | 0,071 | 1,461 |

Gas cutting technology

Modern technology for gas cutting of metal is somewhat different from that described above. For example, when working with “light metals,” temperatures of 1000 degrees Celsius and higher can simply destroy the metal you are working with (melt and evaporate).

In these cases, the cutting itself is performed with simultaneous heating. The cutting torch tip has a pyramid shape with 3 nozzles.

A heating mixture is supplied through two side ones, and a thin nozzle is mounted in the center to supply oxygen under high pressure.

Oxygen cutting technology

In modern cutters, oxygen is supplied under pressure of 12 atmospheres! Simply put, even skin can be damaged under a stream of air (meaning an unlit stream).

The flux that is formed during such cutting is either thrown out to the sides by a heating flame, or is burned directly through the entire metal (if through cutting is performed).

Do not forget that cutting metal with gas has a great advantage over electric cutting. Which?

No “ragged” seam is created. And if you additionally use overlays (stencils, as professional welders call them), then the cutting seam turns out to be very neat!

But keep in mind that cutting metal with oxygen does not mean using metals that melt at temperatures below 600 degrees Celsius. In this case, simple removal of the top layer of metal will be performed, rather than cutting it.

In such cases, it is recommended to use so-called mobile heaters - ordinary cans with compressed gas and a nozzle at the end of the tube.

Standard oxyfuel metal cutting technology involves the use of a guide cutter that is controlled by the operator. The gas supply is regulated using two valves (in some models - one common).

The cutter handle itself has two tubes, which are built into the handle. The first handle supplies fuel for the heater, the second (usually the central one) supplies oxygen. That is, as many as 3 tubes are connected to the main nozzle!

Propane is supplied through two, oxygen is supplied through the third. Older cutter models used two tips that worked in a similar way.

What is the gas consumption when cutting metal? This depends on the temperature to which the metal itself is heated during operation.

In a standard P1-01 cutter, in one hour of operation, on average, about 10 cubic meters of oxygen and 0.7 cubic meters of acetylene are consumed (when using propane - 1 cubic meter of fuel).

But in the R2-01 cutter the consumption is much higher - 21 m3 of oxygen and 1.2 m3 of acetylene! The heater consumption depends on the heating temperature and the plane that is cut.

“Older” cutters also use the so-called direction of the nozzles, which also partially affects the flow rate (the closer to the oxygen stream, the larger the jet has to be supplied).

Oxygen consumption per 1 ton of metal

Table of cutting thicknesses and gas consumption for NX type mouthpiecesThis results in a cut. Oxygen is supplied under high pressure, often reaching 12 atmospheres; such a jet, even without fire, can cut the skin.

The structure of the cutting apparatus is designed as follows:

- gas-burner;

- two cylinders;

- mixer;

- pressure regulator;

- hoses.

A gas burner consists of a head with several nozzles, usually three are enough. A flammable substance is supplied through two side ones, and oxygen is supplied through the third, which is located in the middle. The cylinders are designed directly for gas and oxygen; depending on the volume of intended work, cylinders of appropriate capacity are selected.

Gas-burner

To ensure one hour of continuous operation, an average of 0.7 m3 of acetylene (1 m3 of propane) and 10 m3 of oxygen will be consumed.

In general, the required amount of feedstock will depend on the density of the metal and the required temperature to heat it.

Propane consumption can be reduced by using special nozzle attachments that fix the gas supply in a certain direction; the closer the supply is to the oxygen stream, the higher the fuel consumption.

Hoses are necessary for supplying oxygen and flammable substances from cylinders to the mixer; they are also called hoses. The material from which the hoses are made is two-layer rubber, between the layers there is a frame made of cotton thread. Diameter – up to 12 mm, possibility of operation at air temperatures not lower than -35 °C.

A pressure regulator is necessary to provide different cutting modes and speeds. By supplying less fuel, it is possible to ensure the low temperature required for thin steel or low-strength metal, and also reduce the consumption of raw materials.

Another important function of the reducer is to maintain a uniform pressure level. If the gas supply is interrupted during the cutting process, the metal will quickly cool and further processing will become impossible.

Metal cutting with propane and oxygen

Necessary equipment

Cutter P101

The very first cutter was the P1-01 device, it was designed back in the USSR, then more modernized models appeared - P2 and P3. The devices differ in the size of the nozzles and the power of the gearbox. More modern manual settings:

- Change;

- Quicky;

- Orbit;

- Secator.

They differ in their range of additional functions and performance.

Quicky-E can carry out shape cutting according to specified drawings, the operating speed reaches 1000 mm per minute, the maximum permissible metal thickness is up to 100 mm. The device has a set of removable nozzles to ensure processing of metal sheets or pipes of various thicknesses.

Autogenous cutting machine Messer

This device can operate using various types of flammable gas, unlike the prototype P1-01, which runs only on acetylene.

The Secator manual cutter has improved characteristics compared to its analogues.

Cutter R2-01

With its help, you can process metal up to 300 mm thick, this is provided by additional attachments included in the kit, they are removable and can be purchased additionally as they wear out. Secator can produce the following types of cutting:

- curly;

- straight;

- ring;

- under the bevel.

The speed can be adjusted in the range from 100 to 1200 mm per minute, and the built-in freewheel ensures smooth movement of the machine along the sheet metal. The air-cooled gearbox ensures cleaner operation and reduces fuel consumption.

The above models are manual, that is, they are compact and controlled by the hands of a master. But for large volumes of processed metal, working with such

Stationary cutting unit

installations are inconvenient and ineffective. For industrial production, stationary cutting installations are used - this is essentially the same technology.

They are a machine with a table top into which a cutting mechanism is built. Its operation is ensured by electric

a compressor that requires an electrical network with at least 380 V and three-phase sockets. The technology of operation of models of stationary cutting units is in no way different from manual ones. The only difference is in productivity, maximum heating temperature, and the ability to process metal with a thickness of more than 300 mm.

Conditions for cutting metal with gas

Gas cutting of metal will be effective only when the ignition temperature of the metal is lower than the melting point. Such proportions are observed in low-carbon alloys; they melt at 1500 °C, and the ignition process occurs at 1300 °C.

For high-quality operation of the installation, it is necessary to ensure a constant supply of gas, since oxygen requires a constant amount of heat, which is maintained mainly (70%) by the combustion of metal and only 30% is provided by the gas flame. If it is stopped, the metal will stop producing heat and oxygen will not be able to perform its functions.

Cutter operation, metal cutting training

The maximum temperature of hand-held gas cutters reaches 1300 °C, this is a sufficient value for processing most types of metal, however, there are those that begin to melt at particularly high temperatures, for example, aluminum oxide - 2050 °C (this is almost three times more than the melting point of pure aluminum), steel containing chromium – 2000 °C, nickel – 1985 °C.

If the metal is not sufficiently heated and the melting process has not begun, oxygen will not be able to displace refractory oxides. The opposite of this situation is when the metal has a low melting point and, under the influence of burning gas, it can simply melt, so this cutting method cannot be used for cast iron.

Gas cutting equipment

So, in Russia, since the times of the USSR, the P1-01 cutter was considered the most common. It is manual with an injection nozzle, which produces a high-pressure jet that cuts metal “like a hot knife through butter.”

More powerful models are R2-01 and R3-01P. Their main difference is the size of the nozzle, the operating pressure of oxygen in the system, and the operating pressure of the heating mixture supply.

There are also autonomous tables - this is gas equipment for cutting metal in automatic mode, which is carried out without the participation of an operator.

The control of such a table is numerical-software. That is, a person simply sets cutting parameters.

Such equipment for oxygen cutting of metal is used exclusively on sheet metals, where either straight cutting or arc cutting is performed.

It is worth noting that there are a huge number of models of these tables, but almost all of them are analogues of the AN-01, which was developed by Shepelev back in the USSR!

Oxygen cutter diagram

These, for example, are “Smena”, “Orbit”, “Secator”, “Quicky-E”. All of them have operating temperatures in the range of 1000-3200 degrees Celsius. Works with both acetylene and propane heaters.

Quicky models also use mixed acetylene-propane heating. In this case, only a bifurcated nozzle is used. That is, acetylene is supplied to one of them, propane is supplied to the second.

By the way, it is worth noting that in such cutting the heating mixture is supplied from the center (that is, from the oxygen jet).

There are also so-called stationary cutters for gas cutting of metal.

They differ from mobile ones, it’s not hard to guess, in that they are built into a special niche-machine, which can be moved by the operator of the device.

Such cutters are more convenient for work, but are very expensive. But their cutting power is more than enough to cut a thick layer of high-strength metal!

This became possible due to the fact that such cutters use an additional supercharger, with the help of which both the heater and the oxygen stream are supplied under even greater pressure.

The additional compressor runs on electricity, also three-phase (380 Volts). Because of this, he cannot be mobile! This cutter is used exclusively in professional enterprises.

Portable cutter – Gugark

Gugark is the most popular representative of such cutters.

§ 12. Manual gas cutting of pipes

Standards for 1 m of cut Table 036

| Wall thickness, mm | Material consumption by type of cutting, l, using | Line code | |||||

| Acetylene | propane-butane mixture | natural gas | |||||

| Acetylene | Oxygen | Propane-butane | Oxygen | Natural gas | Oxygen | ||

| 3 | 11,98 | 53,92 | 8,72 | 69,08 | 19,49 | 69,08 | 01 |

| 4 | 15,93 | 71,85 | 11,57 | 92,04 | 25,94 | 92,04 | 02 |

| 5 | 19,96 | 89,84 | 14,49 | 115,05 | 32,43 | 115,05 | 03 |

| 6 | 23,95 | 107,81 | 17,39 | 138,03 | 38,93 | 138,03 | 04 |

| 8 | 27,92 | 143,69 | 22,26 | 184 | 49,68 | 184 | 05 |

| 10 | 28,07 | 180,77 | 23 | 230,08 | 50,62 | 230,08 | 06 |

| 12 | 33,62 | 215,55 | 25,66 | 275,98 | 55,95 | 275,98 | 07 |

| 15 | 45,94 | 294,66 | 35,08 | 377,29 | 79,23 | 377,29 | 08 |

| 18 | 46,37 | 335,33 | 36 | 413,99 | 79,69 | 413,99 | 09 |

| 20 | 51,52 | 372,6 | 36,1 | 460 | 81,88 | 460 | 10 |

| 25 | 64,39 | 465,75 | 44,85 | 575 | 102,35 | 575 | 11 |

| Column code | 01 | 02 | 03 | 04 | 05 | 06 | |

Standards for 1 cut Table 037

| Wall thickness, mm | Material consumption by type of cutting, l, using | Line code | |||||

| acetylene | propane-butane mixture | natural gas | |||||

| Acetylene | Oxygen | Propane-butane | Oxygen | Natural gas | Oxygen | ||

| 45 ´ 3 | 1,58 | 7,11 | 1,15 | 9,11 | 2,57 | 9,11 | 01 |

| 45 ´ 4 | 2,05 | 9,25 | 1,49 | 11,85 | 3,34 | 11,85 | 02 |

| 57 ´ 3 | 2,03 | 9,14 | 1,48 | 11,71 | 3,3 | 11,71 | 03 |

| 57 ´ 4 | 2,66 | 11,96 | 1,93 | 15,32 | 4,32 | 15,32 | 04 |

| 76 ´ 5 | 4,45 | 20,03 | 3,23 | 25,65 | 7,23 | 25,65 | 05 |

| 89 ´ 5 | 5,26 | 23,69 | 3,82 | 30,34 | 8,55 | 30,34 | 06 |

| 108 ´ 6 | 7,67 | 34,53 | 5,57 | 44,21 | 12,47 | 44,21 | 07 |

| 133 ´ 6 | 9,55 | 42,97 | 6,93 | 55,04 | 15,52 | 55,04 | 08 |

| 133 ´ 8 | 12,53 | 56,4 | 9,09 | 72,22 | 20,37 | 72,22 | 09 |

| 159 ´ 8 | 15,14 | 68,13 | 10,99 | 87,24 | 24,6 | 87,24 | 10 |

| 219 ´ 6 | 16,01 | 72,1 | 11,63 | 92,33 | 26,03 | 92,33 | 11 |

| 219 ´ 8 | 18 | 91,46 | 14,75 | 121,95 | 32,92 | 121,95 | 12 |

| 219 ´ 10 | 18,42 | 118,63 | 15,1 | 150,99 | 33,22 | 150,99 | 13 |

| 219 ´ 12 | 21,86 | 140,99 | 16,69 | 179,53 | 37,69 | 179,53 | 14 |

| 273 ´ 8 | 23 | 119,58 | 18,52 | 153,11 | 41,34 | 153,11 | 15 |

| 273 ´ 10 | 23,17 | 148,33 | 18,99 | 189,93 | 41,79 | 189,93 | 16 |

| 273 ´ 12 | 27,55 | 176,65 | 21,03 | 226,18 | 47,5 | 226,18 | 17 |

| 273 ´ 15 | 37,22 | 238,71 | 28,42 | 305,65 | 64,19 | 305,65 | 18 |

| 325 ´ 8 | 27 | 143,04 | 22,16 | 183,15 | 49,45 | 183,15 | 19 |

| 325 ´ 10 | 27,75 | 177,67 | 22,75 | 227,49 | 50,05 | 227,49 | 20 |

| 325 ´ 12 | 33,04 | 211,85 | 25,23 | 271,26 | 56,96 | 271,26 | 21 |

| 325 ´ 15 | 40,9 | 262,27 | 31,23 | 335,82 | 70,52 | 335,82 | 22 |

| 377 ´ 8 | 31,99 | 166,5 | 25,79 | 213,18 | 57,55 | 213,18 | 23 |

| 377 ´ 10 | 32,34 | 207 | 26,5 | 265,05 | 58,31 | 265,05 | 24 |

| 377 ´ 12 | 38,53 | 247,04 | 29,42 | 316,32 | 66,43 | 316,32 | 25 |

| 377 ´ 15 | 47,76 | 306,27 | 36,47 | 392,15 | 82,35 | 392,15 | 26 |

| 426 ´ 10 | 36,59 | 234,63 | 27,94 | 300,43 | 63,09 | 300,43 | 27 |

| 426 ´ 12 | 43,69 | 280,21 | 33,36 | 358,78 | 75,34 | 358,78 | 28 |

| 426 ´ 15 | 54,23 | 347,72 | 41,41 | 445,23 | 93,5 | 445,23 | 29 |

| 465 ´ 8 | 39,81 | 206,21 | 31,94 | 264,04 | 71,29 | 264,04 | 30 |

| 465 ´ 10 | 40,11 | 256,64 | 32,86 | 328,6 | 72,29 | 328,6 | 31 |

| 465 ´ 12 | 47,82 | 306,61 | 36,51 | 392,59 | 82,44 | 392,59 | 32 |

| 465 ´ 15 | 59,38 | 380,73 | 45,34 | 487,49 | 102,37 | 487,49 | 33 |

| 465 ´ 18 | 65,08 | 470,67 | 46,32 | 581,07 | 103,43 | 581,07 | 34 |

| 465 ´ 20 | 71,99 | 520,63 | 50,18 | 642,76 | 114,41 | 642,76 | 35 |

| 465 ´ 25 | 88,97 | 643,48 | 61,96 | 794,42 | 141,41 | 794,42 | 36 |

| 530 ´ 6 | 39,39 | 177,33 | 28,61 | 227,06 | 64,03 | 227,06 | 37 |

| 530 ´ 8 | 45,33 | 235,55 | 36,49 | 301,6 | 81,43 | 301,6 | 38 |

| 530 ´ 10 | 45,82 | 293,29 | 37,55 | 375,54 | 82,62 | 375,54 | 39 |

| 530 ´ 12 | 54,68 | 350,6 | 41,75 | 448,91 | 94,27 | 448,91 | 40 |

| 530 ´ 15 | 67,95 | 435,73 | 51,88 | 557,91 | 117,16 | 557,91 | 41 |

| 630 ´ 6 | 46,91 | 211,17 | 34,07 | 270,39 | 76,25 | 270,39 | 42 |

| 630 ´ 8 | 54,35 | 280,67 | 43,49 | 359,38 | 97,03 | 359,38 | 43 |

| 630 ´ 10 | 54,63 | 349,7 | 44,77 | 447,76 | 98,51 | 447,76 | 44 |

| 630 ´ 12 | 65,23 | 418,29 | 49,81 | 535,58 | 112,47 | 535,58 | 45 |

| 630 ´ 15 | 81,15 | 520,33 | 61,96 | 666,24 | 139,91 | 666,24 | 46 |

| Column code | 01 | 02 | 03 | 04 | 05 | 06 | |

| Note. When cutting with beveled edges at an angle of 50° and 30°, the standards must be increased by 1.55 and 1.16 times, respectively. | |||||||

Popular services on the market

If you need to cut metal, the easiest way is to hire a craftsman or specialist who will provide you with the necessary services. After all, not every home has a cutter with two cylinders of oxygen and a heater in the garage.

Moreover, working with such equipment is very dangerous without experience! If you don’t know how, then it’s better not to take on this matter - entrust the work to professionals!

Well, on average, the price of gas cutting of metal consists of the following indicators: the metal that will need to be worked with, the cutter used, the thickness of the metal, the quality and type of cut.

For example, conventional sheet cutting is the cheapest. Pipe cutting costs much more, since this type of work uses additional pads!

But depth cutting is an expensive pleasure, since it uses expensive equipment.

Moreover, if such work is carried out “on site”, it will be very expensive. Vehicles that can transport cutting stations must be additionally re-equipped.

Oxygen cutting of metal - video:

Well, gas cutting of sheet metal can be done even with an ordinary gas soldering iron. If you are using aluminum or copper, it should be sufficient for the job.

In some cases, gas welding can be used. But instead of carbon dioxide, propane, acetylene or butylene is supplied (not every gas welding supports the use of such gas, be careful)!

The most expensive sheet metal cutting is the one that is performed along a prepared cutting contour. In this case, a CNC machine is used, the services of which are not cheap!

By the way, if you need to perform cutting rather than cutting, then in some cases it will be much easier and cheaper to use a knife for cutting metal rather than a gas cutter. You can find out more about this directly from the master you want to entrust with the work.

Nowadays, many enterprises offer on-site gas cutting of metal.

Here it is, assessed according to the following parameters:

- metal with which it will be necessary to work;

- difficulty of performing the work;

- cutter used.

By the way, it is recommended to buy gas cylinders yourself! Many companies sell it at too high a price (about 1,000 rubles for an acetylene cylinder, although its market value is about 400 rubles).

It also takes into account how long the work will take. On average, an hour of work by a master is paid approximately 300 rubles. Now you can calculate in advance how much metal cutting services will cost you!

And finally, we should talk about those cases when poor quality work is performed. Very often, many people use propane or propylene instead of acetylene - its cheap analogue. Or they use cheaper cutters than they advertised.

For example, instead of P2-01, P1-01 or the like is used. This, by the way, is the most common problem! You can tell these two cutters apart by visual inspection.

The P1-01 model has a double nozzle with a gold mount (golden color), while the P2-01 has a steel mount (black or copper tint).

By the way, the P1-01 cutter is not that expensive, so you can even buy it! The average cost is between 900-1000 rubles per piece. Well, of course, you will need to purchase two cylinders - with oxygen and a heater, and a transport cart.

On average, the whole set will cost you 3,000 rubles, no more. It will be enough for 3 hours of metal cutting. For household needs this is more than enough.

And when working with a gas cutter, be sure to follow safety rules! And this is the use of a protective mask, overalls and gloves. Gloves are a must!

Kickback when cutting with gas

The reverse impact phenomenon involves changing the direction of combustion of the gas mixture jet. In this case, the combustion front is drawn into the nozzle and then begins to spread inside the burner and along the hoses. In the worst case, it can cause gearboxes or even gas cylinders to explode. This is a serious threat to the health and life of employees and the safety of material assets. To avoid dire consequences, the cutter is equipped with a check valve that cuts off the gas supply when the pressure changes.

Kickback when cutting metal

Oxygen and propane consumption for metal cutting

Oxygen and propane consumption for metal cutting

The cost of the metal cutting process is determined by the consumption of oxygen and propane, added to the cutter’s wages. Moreover, the consumption of oxidizer and fuel depends on the technology of thermal separation of metals.

Therefore, we will begin our article with a description of cutting methods.

Metal cutting technologies

Today, three standard technologies for thermal separation of metal workpieces are used in industry:

- Oxygen cutting.

- Plasma cutting.

- Laser cutting.

The first technology, oxygen cutting, is used to separate carbon and low-alloy steel workpieces. In addition, an oxygen cutter can be used to trim the edges of already cut workpieces, prepare the joint interface area before welding, and “clean up” the surface of the cast part. The consumption of working gases, in this case, is determined by the consumption of both fuel (combustible gas) and oxidizer (oxygen).

The second technology – plasma cutting – is used for separating steels of all types (from structural to high-alloy), non-ferrous metals and their alloys. There are no materials out of reach for a plasma cutter – it cuts even the most refractory metals.

Moreover, the quality of the cutting seam, in this case, is significantly higher than that of competing technology. When determining the volumes of working gases, in this case, oxygen consumption is important - when cutting metal with plasma, it is the oxidizer that is responsible for the combustion of the material. And the plasma itself is used as a catalyst for the process of thermal oxidation of the metal.

The third technology, laser cutting, is used to separate thin-sheet workpieces. Accordingly, the volumes of consumed gases, in this case, will be significantly less than in oxygen and plasma cutting, which are designed to work with large, thick-walled workpieces.

Oxygen or nitrogen for cutting metal?

Oxygen cutting is the cheapest. Nitrogen cutting is much more expensive, but when processing almost all metals except ferrous metals, we use nitrogen if we want to preserve the properties of the metal.

You CANNOT cut stainless steel with oxygen. If we cut it with oxygen, the material will essentially burn, because combustion is nothing more than oxidation at high temperature, and oxygen is a combustion catalyst. Thus, we make rust from stainless steel, oxidize it, that is, we simply remove all its stainless properties.

And nitrogen is a non-flammable gas, it is inert, nothing burns in it, it performs another function - it protects the metal from oxidation, cools it and removes combustion products from the cut zone.

Ferrous metals are usually cut with oxygen. Chernukha can also be cut with nitrogen, but this will be too expensive and unprofitable, and since it does not have stainless properties, there is no point in preserving them.

One more nuance - we use nitrogen to cut everything except titanium , which during laser cutting reacts with nitrogen, crumbles, and loses its structure and properties. To cut titanium you need argon .

Pros and cons

Gas cutting and welding of metals has many advantages, but we are only interested in cutting that has the following advantages:

- It is in demand when thick metal is being cut or cutting according to a stencil is needed, and the grinder cannot cope with curved sections.

- The gas analogue is much more convenient to work with, is lightweight, and operates twice as fast as equipment with a gasoline engine.

- Propane is less expensive than acetylene and gasoline, so its use is more profitable.

- The cut edge is much narrower, and the structure is cleaner than from an angle grinder or gasoline equipment.

Disadvantages - a narrow range of metals subject to similar processing.

Surface cutting

Users, of course, are interested in the following question: how to use the cutter during shape cutting. This technique is performed using a tool nozzle, while the molten slag heats the metal, but without exceeding the melting point . The cutter is positioned at an angle of up to 80 degrees, and after oxygen is supplied, the angle changes within 18-45 0.

Grooves are formed when adjusting the cutting speed; if a larger size is needed, then change the angle of the mouthpiece and slow down the cutting speed slightly, adjusting the oxygen supply. The width of the grooves is changed by adjusting the supply of a jet of burning gas through the nozzle; this parameter is equal to 1 to 6, while care must be taken to ensure that there are no backflows.

Metal cutting instructions

It is important to connect and prepare the torch correctly. Tubes with valves at the ends are connected to the cylinders. Next, the gas supply is checked (if it is oxygen-propane metal cutting) - the valve closes, the valve on the cylinder opens. Then, watching the pressure gauge, the valve is slowly opened. The pressure should be 0.35–0.55 atmospheres. Then you need to blow out the hose - open the valve. Gas begins to escape with a characteristic sound. If the pressure gauge shows stable pressure, the valve closes.

The next step is to check the oxygen supply and adjust the pressure. First, the valve on the cylinder opens, then the regulator (flow pressure 1.7-2.7 atmospheres). To purge the hose, open the oxygen valves on the cutter. There are two of them: for feeding into the nozzle and forming a mixture. First you need to open the first one, then the second one (for 3-5 seconds).

Attention! Before igniting the valve, make sure that there are no leaks in the connections, that children are not playing nearby and that animals are not walking around.

The gas supply valve is opened first to allow oxygen to escape, which remains in the mixer after checking. The valve must be turned until gas can be heard escaping. The lighter placed in front of the cutter should touch the mouthpiece. After pressing the lever, sparks ignite the gas.

You need to open the oxygen valve immediately. Its sufficient volume is indicated by a change in the color of the flame to blue. In order for the torch to increase in size, more oxygen must be supplied. The pressure of gas and oxygen when cutting metal depends entirely on the thickness of the workpiece.

Important! If the flame is unstable and “spitting,” there is too much oxygen. The volume must be reduced so that the flame is in the shape of a cone.

According to the technology of gas cutting of metal, the flame was brought to the material with the tip, heating the surface. After the molten metal appears, the supply of oxygen begins, igniting it. The jet increases until the material is completely cut through. At the same time, the mouthpiece moves along the cutting line. Sparks and slag are removed with a jet.

Read also: What color is the phase wire indicated?

The optimal cutting speed is determined by the sparks - they should fly away at an angle of 85-90 o. If the angle is smaller, the speed must be reduced. If the workpiece is thick, it must be placed at an angle to allow the slag to drain. It is not recommended to stop without finishing the process. At the end of the work, first the oxygen is shut off, then the gas.

Preparatory work

How to set up a cutter for cutting metal - first of all, you need to make sure that the product is in good condition and ready for work, then perform the following procedure:

- The hoses from the cylinders are connected to the cutter, having previously purged the product to remove foreign inclusions from the inside.

- Oxygen is connected to a right-hand thread fitting, and propane is connected to a left-hand thread fitting.

- Set the propane supply level to 0.5, and oxygen to 5.0 atmospheres.

- We check connections for leaks, as well as the operation of gearboxes and pressure gauges.

If gas leaks are detected, tighten the nuts or change the gaskets.

The diagram shows the correct connection of the cylinders to the cutter.

Beginning of work

How to cut metal with a gas cutter - having completed the preparation, the performer slightly opens the propane valve, ignites a gas stream, and the nozzle of the product rests on the surface of the metal. Now you need to adjust the flame strength by alternately adding propane and oxygen. After setting the optimal force of the jet of the burning mixture, the product is located at a right angle to the surface of the part, the nozzle is located no closer than 5 mm.

If the cut begins in the middle of the sheet, then the starting point is set at the beginning of the cut. The surface is heated to a temperature of at least 1000 0 C, in appearance it becomes wet, then the oxygen supply is increased to form a powerful, narrowly directed jet.

Features of manual cutting

One of the most common mistakes made by a cutter, which leads to a large number of defects, is a delay in the oxygen jet. The reasons for this phenomenon are unequal combustion conditions along the depth of the cut. In the middle and lower layers of the workpiece, part of the torch energy is wasted on unproductive heating of neighboring areas. In addition, part of the energy is spent on the formation of oxides. As a result, the torch lags behind the burner, and the cutting front, instead of vertical, becomes inclined backwards. If a sheet is being cut and high precision cutting is required, such a defect is unacceptable. To combat this undesirable phenomenon, the burner nozzles are tilted slightly back. Part of the torch is reflected from the cutting front, heating becomes uniform and the required accuracy is ensured, although the speed is reduced.

In addition to the speed of movement of the cutter, the smoothness of this movement is extremely important. Jerks lead to the formation of thermal stresses and, ultimately, structural defects. It is equally important to maintain the specified angle of inclination of the nozzles to the surface being cut.

Oxygen gas cutting is not suitable for cutting metals with a low melting point and high thermal conductivity. Aluminum parts, for example, will simply melt.

The accuracy of manual cutting is increased by using templates and patterns made from materials with a high melting point.

They are placed on the sheet to be cut and the contours are smoothly traced with a torch. At the same time, cutting accuracy and the quality of the cut surface are increased, and the waste rate is reduced.