The product manufacturing process is organized in accordance with various criteria and approaches. To optimize their production cycles and increase financial results, enterprises are very thoughtful about the way they manufacture their products. There are several generally accepted ways of producing products.

Serial production is a special form of organization of the production cycle, based on certain technological, economic features, specialization, as well as the range of products of the enterprise.

Factors of production

The type of production is influenced by a number of its characteristics and features. These are technical, organizational and economic indicators of the enterprise’s activities. They are determined by the composition and breadth of the product range, the volume of finished products, as well as their stability and regularity of release.

Depending on the level of specialization and concentration, single, serial and mass production are distinguished. They are determined by a number of factors. First of all, the type of production is influenced by the volume of output and its nomenclature. When organizing the production cycle, the degree of constancy of the list of products being created, as well as the workload of work places, is taken into account.

This or that type of organization of the production process is applicable to the entire enterprise, its sections, or even individual workplaces. Attributing a company to a certain category is quite arbitrary.

Choice of serial production

⇐ PreviousPage 2 of 8Next ⇒| Serial production | Number of products in a series (batch) | ||

| large | average | small | |

| Small-scale | 3 ― 10 | 5 ― 25 | 10 ― 50 |

| Medium production | 11 ― 50 | 26 ― 200 | 51 ― 500 |

| Large-scale | St.50 | St.200 | St.500 |

When classified by mass M

(kg) we will conventionally consider parts: small (light) at , medium at and large (heavy) at .

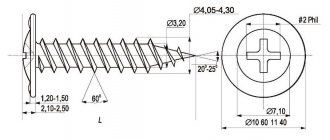

Example 2. Determine the type of production at the parts manufacturing site (see Fig. 1) for the conditions of example 1.

Using the classification conditions (see above), we classify the parts as average in mass ( M

= 4.96 kg).

Further, taking into account the annual program N

= 4800 pcs., according to Table 1, we will accept the type of production as serial. Let’s use relationship (4) and calculate the batch size of simultaneously processed workpieces for mass production conditions, having previously assumed that for the uninterrupted operation of the assembly shop there must be a stock of finished parts for 10 days, then

Table 3

Selecting the type of tool or instrument production based on the weight of the part

| Weight of the part (product), kg | Size of the annual production program, pcs. | |||

| single | small-scale | serial | large-scale | massive |

| 1,0 | 10 ― 2000 | 1500 ― 100000 | 75000 ― 200000 | |

| 1,0 ― 2,5 | 10 ― 1000 | 1000 ― 50000 | 50000 ― 100000 | |

| 2,5 ― 5,0 | 10 ― 500 | 500 ― 35000 | 35000 ― 75000 | |

| 10,0 | 10 ― 300 | 300 ― 25000 | 25000 ― 50000 | |

| 10 ― 200 | 20 ― 10000 | 1000 ― 25000 |

We will accept for further calculations n

= 200 pcs.

This quantity will allow two batches to be put into production every month (200·12·2 = 4800). Having compared the value of n

with the data in Table 2, we will consider the production to be medium-scale and it is for the conditions of such production that we will further design the technological process.

Note that with a further increase in the batch volume according to Table 2, we would have to focus on production with large-scale production of parts.

SELECTION OF WORKPIECE

A workpiece is a production item from which a part or an integral assembly unit is made by changing the shape, dimensions, surface roughness and material properties.

Selecting a workpiece means: establishing a rational shape, method of production, dimensions and manufacturing tolerances, allowances only for the surfaces being processed, and finally, a range of additional technical requirements and conditions that allow the development of a technological process for its production.

The shapes and dimensions of the workpiece must ensure minimal metal consumption and sufficient rigidity of the part, as well as the possibility of using the most advanced, productive and economical processing methods on machine tools. In mass flow and serial production, they strive to bring the configuration of the workpiece closer to the finished part, increase accuracy and improve the quality of surfaces. At the same time, the volume of mechanical processing is sharply reduced, and the utilization factor hm reaches 0.7–0.8 or more. In conditions of small-scale and single-piece production, the requirements for the configuration of the workpiece are less stringent, and the desired value is hm > 0.6.

Based on the type of basic manufacturing method, the following types of workpieces are distinguished:

- obtained by casting (castings);

― obtained by pressure treatment (forged and stamping forgings);

― rolled products;

― welded and combined workpieces;

- obtained by powder metallurgy;

- obtained from structural ceramics.

The method of manufacturing a workpiece is largely determined by the material, shape and dimensions of the part, the program and timing of production, the technical capabilities of procurement shops, economic considerations and other factors. It is believed that the chosen method should ensure the production of a workpiece that would allow the production of a part (including a full cycle of mechanical, thermal and other processing) at the lowest cost.

Each type of workpiece can be manufactured in one or more ways, similar to the basic one. For example, small blanks of the simplest form from AL9 alloy can be produced by casting: into the ground, into a mold, into a shell mold, according to custom models, under pressure; by vacuum suction method, stamping from liquid metal, etc. Each method has certain technical capabilities to ensure the accuracy of the shape and location of surfaces, the accuracy of dimensions, the roughness and depth of the defective layer of surfaces, requirements for permissible wall thickness, and the size of casting (stamping) radii and slopes, to the size and location of the resulting holes, etc. Technical capabilities are widely presented in [5, 7, 9, 10, 30] and other reference books and manuals.

The initial data for selecting a workpiece is a drawing of the part with technical requirements for manufacturing, indicating the weight and grade of material; annual production volume and accepted type of production, data on the technological capabilities and resources of the enterprise, etc. Taking them into account, a method for obtaining a workpiece is adopted and a drawing is developed. A drawing of the workpiece is drawn with the required number of projections of sections and sections. An allowance is placed on each of the surfaces to be processed. The amount of allowance is taken according to tables from the specified literature. For the most critical functional surfaces of parts, the amount of allowance is determined by calculation and analytical method (see section 8). The nominal dimensions of the workpieces are obtained by summing (for holes by subtracting) the nominal dimensions of the parts with the amount of the accepted allowance. Maximum deviations (or tolerances) of dimensions are established based on the achieved accuracy (initial index and accuracy class Ti) of obtaining the workpiece using the accepted method [5, 7, 10, 15], etc. At the same time, the necessary technical requirements for the workpiece must be indicated on the drawing: hardness of the material, usually in Brinell units (HB); accuracy; ESKD symbols indicate permissible errors in the shape and location of surfaces; nominal values and maximum deviations of technological slopes, radii, transitions; degree and methods of cleaning surfaces (etching, tumbling, shot blasting, etc.); methods for eliminating surface defects (dents, clamps, sink marks, displacement of planes, etc.); methods and quality of pre-processing (for example, peeling, trimming, straightening, centering, etc.); methods for controlling dimensions and hardness (visual, using templates, ultrasonic, etc.); surfaces taken as rough technological bases, etc.

In accordance with GOST 26645-85, the technical requirements of the casting drawing must indicate casting accuracy standards [30, p. 219-241]. They are given in the following order: class of dimensional accuracy of the casting (required), degree of warping, degree of surface accuracy, class of mass accuracy (required) and casting displacement tolerance. For example, for a casting of the 8th class of dimensional accuracy, 5th degree of warping, 4th degree of surface accuracy, 7th class of mass accuracy with a displacement tolerance of 0.8 mm:

casting accuracy 8-5-4-7 cm 0.8 (GOST 26645-85.) It is allowed to replace non-standardized indicators of casting accuracy with zeros, and omit the offset designation, then:

casting accuracy 8-0-0-7 (GOST 26645-85.)

The technical requirements for drawings of steel forgings produced by hot forging methods (GOST 7505-89) provide for reflecting their design characteristics [30, table. 24-37 on p. 254―266]:

1. Accuracy class (T1, T2, T3, T4 and T5) - set depending on the technological process and equipment for manufacturing the forging, as well as based on the requirements for the accuracy of its dimensions.

2. Steel group (M1, M2 and M3) - indicate the percentage of carbon and alloying elements in the forging material.

3. Degree of complexity (C1, C2, C3 and C4), which is one of the design characteristics of the forging shape (qualitatively assessing it), and also used in assigning allowances and tolerances.

4. Configuration of the die connector surface: P - flat; IS - symmetrically curved; In - asymmetrically curved.

The initial index [30, table 27], tolerances on dimensions and deviations in the shape and location of surfaces depend on these characteristics.

Drawings of blanks are drawn on the same scale and in the same formats as the parts shown. The contours of the part are inscribed in blue or thin black lines into the contours of the workpiece. The mass of the workpiece is calculated based on its nominal dimensions. Ultimately, the drawing and technical requirements must contain enough information to develop working documentation for the production of workpieces in the procurement shops of real production facilities. In the explanatory note, the drawing of the workpiece is placed directly behind the text.

When choosing a workpiece, students compare 2–3 possible ways of making it. Of the alternatives, the most cost-effective one is accepted, and the profitability of the method should be thoroughly and correctly justified. The text of the explanatory note together with the workpiece drawing, economic calculations and conclusions should not exceed 2.5–3 seconds.

Example 3. Select a rational method for obtaining and draw up a drawing of a blank part (Fig. 1) for production under mass production conditions with N = 4800 pcs. in year.

Gear blanks of similar shapes, when mass produced, are usually produced by stamping in open dies on hammers or crank hot stamping presses (CGSP). The literature [10, 14, 17] indicates that stamping on a CGSP ensures the production of relatively accurate forgings without shift in the parting plane, whose allowances are 30% smaller than those of workpieces produced on hammers. The productivity of stamping on presses is 1.5–2 times higher than on hammers; work happens without any shocks. Holes are stamped and stitched on presses. Forgings produced at the CGSP make it possible to slightly reduce the amount of machining and provide a material utilization factor within the range m = 0.7–0.75.

In the case of obtaining billets from rolled products, the volume of mechanical processing increases sharply, and the value of m drops to 0.4 and below.

Consequently, stamping on a CGSH machine can be considered the most rational way to obtain a workpiece. Let's design a drawing of the workpiece (see Fig. 2). Further according to the table. 22 [30, p.247] we will determine the allowances for the processed surfaces corresponding to GOST 7505-89, taking into account which the calculated mass of the workpiece will be G

= 6.42 kg.

According to the specified standard, the forging material—steel 40X—belongs to the M2 steel group, Table 24 [30, p. 255]; the configuration of the workpiece corresponds to a forging of degree of complexity C2 [30, p. 256]; accuracy class - T4 (forgings produced in open dies on GKShP, table 25 [30, p. 255]). For the combination of G

= 6.42 with M2, C2 and T4, the original index is 14, table. 27 [30, p. 257]. Using the obtained index value from the table. 28 [30, p. 260], we will establish and transfer to the drawing the tolerances and maximum deviations for the rim diameter of 225 mm, the rim thickness of 29 mm, the hub length of 45 mm and other dimensions of the wheel blank. Let’s complete the drawing by recording the required minimum technical requirements (see workpiece drawing).

Estimated cost of the workpiece according to the method [5, p. 31-39] will be, rub:

,

where is the base cost of 1 ton of stampings, rub.; * C

b = 373 [5, p.37]; — mass of the workpiece, kg; — mass of the finished part, kg; ; , , , and are coefficients depending on the accuracy class, degree of complexity, weight, grade of material and production volume for stampings of accuracy class T4 according to GOST 7505-89, [5, p.37]; — for low-alloy steel M2, [5, p. 37]; and , table. 2.12 [5, p.38]; table 2.13 [5, p.38]; — price of 1 ton of waste, rub. , table 2.7 [5, p. 32].

Taking into account the parameter values

rub.

The cost of the workpiece obtained by hammer, due to the increase in allowances and total weight, will be slightly higher.

| The cost of a billet from rolled steel 40X worth RUR/kg* [5, p. 30] and table. 2.6 [5, p.31] - , where - costs for workpiece material, rub; ― technological cost of cutting rolled products into piece blanks, rub. (A) Part length mm (see Fig. 1). Let us leave minimum allowances for trimming the ends of 0.5 mm per side and, taking rolled stock with a diameter of 255 mm for the workpieces, we will determine the weight of the workpiece kg, where is the steel density, . According to formula (a) RUR. ― exceeds the cost of the workpiece obtained at the CGSP, even without. Moreover, it is unacceptably small. Thus, the option of obtaining blanks at the CGSP should be considered the most acceptable. ⇐ Previous2Next ⇒ What Causes Trends in Stock and Commodity Markets Freight Train Theory Explained My first 17 years of market research consisted of trying to figure out when... What does the IS operation and maintenance department do? Responsible for the safety of data (copying schedules, copying, etc.)… WHAT IS CONFIDENT BEHAVIOR IN INTERPERSONAL RELATIONSHIPS? Historically, there are three main patterns of differences that exist between... What to do if there is no reciprocity? And now let's come down from heaven to earth. Have you landed? Let's continue the conversation... Didn't find what you were looking for? Use Google search on the site: |

Types of production

The main types of production existing today (single, serial, mass) have a number of characteristic features.

Single production is characterized by a small volume of production of identical products. There is no provision for their repair or re-issue.

In mass production, finished products are produced in batches. Moreover, they are produced at a certain frequency. There are small-scale, large-scale and medium-scale types of production.

Mass production is characterized by the largest scale. Products in this case are manufactured continuously and in large quantities. This requires quite a lot of time.

Mass and serial production

In industry, there are three types of production organization: single, serial, mass. In single production, each workshop produces a variety of products. Each type of it is produced in small batches, which are no longer repeated, or is made even in a single copy (for example, unique machines, large turbines, ships). The workshops are equipped with universal equipment on which a wide variety of operations are performed. Single production also includes pilot production—the production of 1-2 units of products for testing. Its cost is very high (see Cost of production). In single production, the process of mechanization and automation is difficult (compared to serial and mass production), and a relatively large number of operations are performed manually (since, for example, for several parts it does not make sense to manufacture special equipment).

In mass production, products are produced in relatively large batches, or series. The production of a series of products of the same type is usually repeated at regular intervals. When series are relaunched, changes are often made to the design and technology of products and the organization of workplaces.

Depending on the size of the series, large-scale, medium-scale and small-scale production are distinguished. The larger the series, the lower the cost per unit of production (part or product). In mass production, each workshop produces a homogeneous and long-lasting assortment of products. The workshops are dominated by special equipment designed for the production of one product, production and automatic lines. Products are produced in mass quantities. Its cost is lower. Such production is typical for the automotive, textile, shoe industries, etc.

The transition from single to serial and from serial to mass production significantly reduces the labor intensity and cost of work.

Mass production makes it possible to widely introduce flow methods of organizing production (see Automation and mechanization of production). With flow, one or more homogeneous operations are assigned to each workplace. In this case, workplaces are located along the technological process and are equipped with high-performance tools and equipment. In the flow method, workpieces are fed from one workplace to another continuously, in a stream, using special conveyors.

The flow method reduces the processing time of parts and helps to establish rhythmic work. It is easier to make the production line automatic. The move to in-line production also reduces labor intensity.

The use of a reconfigurable automatic line and equipment made from standard assemblies has a great effect.

If necessary, such a line can be quickly reconfigured to produce new products. An important condition for mass production is specialization. It becomes possible to use high-performance specialized machines and automatic lines designed for the production and processing of certain parts. Specialized or special machines are designed to perform a small number of operations, but have high processing accuracy and high productivity.

At the current level of scientific and technological progress, special directions have been created and developed for the mechanization of not only mass, but also serial and even individual production. If automation and mechanization of mass production is carried out through the introduction of production lines and rotary technologies, then for mechanization and automation of small-scale and individual production, the main direction is flexible production systems (FPS) or flexible automated production (FAP). Flexible automated production can be quickly switched from producing one type of product to another. This creates the possibility of automating even small-scale and individual production.

Flexible automated production includes several automated systems: processing, assembly, transport and storage, tool support, supply of raw materials, workpieces and materials, waste disposal, etc.; as well as automation systems for scientific research and the work of engineers of all specialties working directly in production.

A characteristic feature of automation is the rapid development of robotics, rotary and rotary-conveyor lines, flexible automated production, ensuring high labor productivity.

Basic properties of serial production

The serial type of production is the most common type of organization of production in many industries. Products in this case are characterized by structural uniformity. They are produced in series of small, medium or large sizes. Intervals are repeated at certain intervals. During the production cycle, some time is required to produce products, as well as breaks when the equipment is at rest.

The concept of “series” should be understood as a certain number of similar products that are created by a single enterprise.

The range of goods in this type of production is quite large. This indicator looks more diverse only with a single approach to organizing the release of goods. A certain part of the products are similar in technological and design characteristics.

Production circulation: from several units to large batches of finished products

accepts orders for the production of metal products from enterprises occupying their niche in the instrument-making and mechanical engineering industries, as well as private small-scale orders from various legal entities (construction companies, design bureaus and others). For individuals, there is a demand for the production of piece orders of window grilles, balcony railings, sections of rolled metal and corrugated sheets for fences of private cottages, institutions and industrial areas. There is a high demand for services for the production of housings for devices and automation equipment. Designers turn to our specialists with individual orders for the production of decorative metal products.

New metalworking equipment with program control allows you to economically and quickly fulfill orders for the production of parts, assemblies, and product bodies in various runs. Small-scale orders are accepted from 10 copies of metal products. Large volumes of orders are fulfilled within the terms specified in the contract.

Automated control of the technological process on CNC equipment ensures exact compliance of the technical parameters of the manufactured finished products with the original drawings.

Features and Benefits

The organization of mass production has a number of characteristic features. One of them is the repeatability and frequency of the manufacturing process of finished products. This makes the production cycle rhythmic.

Products are produced in large or relatively large volumes. This makes it possible to unify the products being created, as well as the technological processes themselves. Products can be manufactured according to standards and regulations. This makes it possible to use them in construction series in large quantities. This approach reduces their cost.

In addition to improving the quality of finished products, as well as reducing their cost, organizations have the opportunity to purchase special equipment designed for the production of standard parts and assemblies. Productivity in this case also increases.

Main features

The characteristics of serial production allow us to highlight the main features of this method of organizing the production of goods. These include production in series with a wide range of similar parts and assemblies. In this case, production activities are decentralized into workshops, departments, etc. Their specialization increases.

Products are manufactured both on the basis of orders and from previously unknown customers. The workers have an average level of qualifications. Manual labor is characterized by small volumes.

Production cycles are short. The technological process is typified. In this case, high-tech equipment is used. Quality control is automated. Statistical methods are used to manage compliance with product standards.

Flaws

Batch production is a system that has a number of advantages. But this approach to organizing production also has some disadvantages. First of all, it should be noted that the cycle time is longer when the equipment operates irregularly.

Frequent changeovers and maintenance of equipment and machines require a significant investment of time. In this case, non-production costs increase. There are long interruptions in production. They arise as a result of preparatory work for the manufacture of goods and parts.

If the wrong approach to organizing the production process is used, the cost of products may increase and turnover may decrease. This may also reduce labor productivity. Therefore, the process of organizing serial production of goods must be approached seriously, a number of calculations and planning must be performed.

Introduction into serial production of the finished product

Our company can organize mass production of products according to an existing sample. If the client has a ready-made example or sample of a product, then we are ready to launch mass production of products using an accelerated method, including the following steps:

- In-plant planning - determining the start date and duration of work;

- Accounting for production factors - formation of reserves of consumables;

- Organization of serial production - deployment of the technological chain in the workshops.

You can discuss the details of cooperation in more detail in a personal conversation with experts from the PIK Industrial Development Center.

Subtypes

Serial production is conventionally divided into small, medium and large production. This division is conditional. This is due to the presence of some characteristic features of the single and mass production principle in some subtypes.

Some features that mass and batch production have are successfully combined in the large-scale subcategory. At the same time, the series are on a large scale. A lot of time is spent on their production. The breaks between games are small and rare.

If the batches are small, these types of cycles define some features of a single method of manufacturing goods. This approach is often used to create a small batch of special order parts. Moreover, recently this approach has been significantly improved. The use of computer technology makes it possible to reduce the cost of working time and to produce several different types of parts on one production line.

Standard algorithm for preparing a product for mass production:

- Preparation of project documentation in accordance with GOSTs and the rules of the ESKD of the Russian Federation - all documents are consistently prepared and approved by the customer from the technical proposal to the detailed design;

- Production of a prototype - production of a trial version of the product according to working drawings;

- Testing and modernization of the resulting sample - improvement of the product (if necessary) based on the results of experiments and tests;

- Launching mass production - preparing the plant for the production of a batch of goods, purchasing raw materials and supplies, establishing a regular technological process.

Points 2 and 3 may be repeated if the sample product failed practical tests, or there is no confidence that a one-time adjustment of the sample will completely eliminate all flaws.

In reality, this happens extremely rarely, and only with absolutely innovative products, where sometimes a lot of unstudied and unknown factors are hidden. We recommend that you carefully design and refine test products before releasing the product into mass production. As a result of pilot tests, depending on the technological complexity, changes can be made either to the design drawings or to the prototype itself, i.e. it may need to be reissued taking into account the structural adjustments made.

For our customers, we offer to establish serial production of products in various volumes:

- Small-scale production is a process close to single-piece production, when single copies or small batches are needed (most often one-time or with rare restarts);

- Serial production of equipment - medium and large batches, but limited in time, that is, periodic production of products in large quantities.

Having determined all the required time and material resources, technological preparation for the implementation of all work processes takes place.

Calendar distribution

The rhythmicity and efficiency of releasing finished products in batches makes it possible to organize calendar development. Batch production requires distribution over several stages.

If parts, assemblies or blanks are planned to be produced for a whole year, they are distributed by month. After this, the planning period determines the time fund during which the equipment will work to produce the required items.

The remainder of the time is also assessed. It is used to create other goods that are provided for in the production program. Such products are distributed in accordance with calendar plans according to the terms of contracts with suppliers and customers.

Creating Sets

Mass production enterprises can produce entire sets of products, the production time of which is in close time intervals. These types of parts and assemblies are combined. Such sets allow you to load the equipment relatively evenly. This reduces the number of item combinations that are assigned to individual months.

A set of certain parts is assigned to a selected segment of the calendar period. The company is interested in periodically repeating such combinations throughout the year. This allows for rhythmic production of products.

The annual program for the nomenclature and volume of creation of finished goods must be fully completed within the calendar period. Moreover, when creating sets of products, various combinations of parts are calculated. This makes it possible to check production capacity utilization.

Operational production planning system

Serial production is a rather complex type of organization in which several part operations are assigned to one workplace. Therefore, several systems are used for operational planning. These include the development of future production by cycle sets, by backlogs, and also by complete numbers. Plans are created based on the continuous production process.

To determine future cycle sets based on inter-shop indicators, the initial documents are the plan for the production of goods for the year, as well as information about the composition of the set. They list all the parts and blanks that are included in the composition. The planning department takes into account calendar standards for each unit of production and the entire set.

This approach allows the enterprise to properly organize mass production, increase the productivity of equipment and labor resources. Correcting planning cycles when creating sets provides the opportunity to choose the most profitable option for creating finished goods.

Main purpose of production

Production is a purposeful human activity, which is the process of creating any material goods or services in demand for society. Material goods include all useful things that people use to satisfy their material needs: furniture, cosmetics, vehicles, electronics, jewelry, etc. In addition to material goods, people also need services: shoe repair, tailoring, house cleaning, legal advice.

Thus, the main goal of production is to satisfy all the diverse human needs that exist in society. Production forms the basis of the economic life of society, because every person is involved in the processes of creation, distribution, exchange and consumption of products. The result of production is the manufacturer making a profit. Profit is the income received from the sale of manufactured products, from which the costs of their production have been subtracted.

Example of profit calculation. A manufacturer spends 15 rubles to produce one loaf of bread. This amount includes the cost of flour and other ingredients necessary for the production of bread, labor of workers, and payment for rent of production premises. The manufacturer sells one loaf of bread for 40 rubles, but his net profit is only 25 rubles, since the amount of production costs (15 rubles) must be subtracted from the total revenue to correctly calculate the profit.

The higher the profit, the more efficient and successful the production activity is considered.

To organize production, various resources are needed, without which the creation of a production process would be impossible. Economists also call production resources factors of production.

Factors of production include:

- Labor force . The physical and mental labor of people is the main production resource, because the volume of production and the quality of the products created depend on the skills, qualifications, and knowledge of workers.

- Natural resources . Water, gas, solar energy, precious metals, minerals, soil, fertilizers - all this is necessary for a person to create one type of product or another.

- Intellectual abilities . Thanks to the presence of intelligence, a person is able to organize the production process in such a way as to make the most efficient use of natural resources and extract the greatest benefit from them. Thanks to the development of human intelligence, science is developing, new production technologies are being invented that make it possible to produce new types of goods in large volumes.

- Capital - represents cash and all material objects used for the production of products (warehouses, transport, machines and other production equipment, buildings).

In modern society, there are various types of production, depending on the type of product or service being created. All production organizations (factories, factories, firms) belong to various sectors of the economy - a set of production enterprises that create the same type of product. This includes agricultural, industrial, food, housing and transport production. Man did not immediately come to the division of production into economic sectors; it was formed as a result of the long historical development of human society, the emergence of the division of labor, the emergence and development of trade.

Benefits of Cycle Set Scheduling

Serial production of products cannot be carried out effectively without planning across workshops and backlogs of the enterprise. Analysts calculate the planned launch dates for the cycle set. This work is carried out in each workshop of the company. Planning is carried out on the basis of previously established deadlines and the order of submission of kits for their assembly. In this case, the standard indicator of the duration of each cycle is taken into account. The entire system must function smoothly, fulfilling the tasks of the enterprise.

Planning provides a number of benefits to a company. The production of goods occurs rhythmically, reducing the downtime of equipment and the storage of blanks, components and parts.

Backlog work planning

The most flexible system in the planning process is the system for developing backlog programs. First, the fundamental level is determined for calculating the backlog of parts and components in each workshop. When organizing the production process, the task is to maintain the level of production of goods by structural units in accordance with the calculated level. The volume of planned tasks for each product is determined in days or five days relative to the final production output.

It is economically beneficial to reduce the operations of adjusting structures, since the stability of the dimensions of parts makes it possible to reduce the specific weight of each manual operation of workers. They perform several specialized operations.

Development of group processes

The serial type of production is distinguished by its diversity and complexity of organization. It includes machine tool and machine-building enterprises. For medium and small-scale production, it is advisable to use the group planning method.

The essence of this approach involves the development of group processes and the creation of an appropriate tooling base. All parts are divided by type. At the same time, their technological and design similarities, as well as the same type of equipment used, are taken into account.

From each group, when planning, the most complex part is selected, for which structural elements similar to other products are determined. If this is not the case, a complex unit of production is developed. Equipment and machines are designed using it. This allows you to produce any part of the group. This approach makes mass production cost-effective.

Serial production is the most common form of organizing the process of producing finished products. Knowing its features, as well as applying planning methods, the analytical service is able to increase the profitability of finished products and improve technological cycles.

The main tasks of intra-shop planning in mass and large-scale production are [p.198]

Consistent decision-making involves solving a problem and thus obtaining additional information that allows one to move towards a deeper solution. For example, as an experiment, a new product is sold in a small town, and if successful, large-scale production is launched. It may also mean making a flexible decision at first, awaiting more accurate information, and then

For example, General Electric Corporation's approach to business portfolio analysis involves assessing a number of indicators in two areas. To assess the attractiveness of a particular industry, the corporation takes into account the size of the market, its growth rate, the amount of profit generated from it, the intensity of competition, the cyclical and seasonal nature of business activity, as well as the possibility of reducing the cost of a commodity unit in large-scale production or through the experience accumulated by managers. GE measures the strength of its commercial operations by measuring its market share, its price competitiveness, the quality of its products, its knowledge of its market, its sales efficiency, and its geographic advantages. The best are considered to be those with good indicators in all these positions, the worst are those with weak indicators. Based on this analysis, General Electric then allocates resources among individual production facilities. [p.581]

Mass or large-scale production is used to make a large number of products that are identical or very similar to each other. [p.96]

In addition to direct technology transfer, there is indirect technology transfer abroad on a long-term basis. Currently, Japanese industry has superiority in mass and large-scale production technologies, which can be transferred abroad not so much in the usual form of written technical documentation, but in the form of live communication between engineering and technical personnel. But in Japan there are not enough engineers and technicians, and it is even more impossible to send them abroad. Therefore, the best way to transfer technology is to set up factories in countries where local engineers and workers can be hired and trained on site. In Japan, direct industrial training is always given the highest priority. If local personnel move to other companies, technical expertise will spread. In the Japanese attitude to technology, the most important thing is the accumulated experience, which can be simply difficult to express on paper. Direct teaching is the best, most effective way to transfer technical knowledge. [p.235]

Large-scale production includes factories for the production of rubber and plastic products, aniline paint products. [p.21]

According to the experience of mechanical engineering, it is generally accepted that if equipment is readjusted during a work shift once or more often, production is classified as small-scale. Small-scale production is found in the production of some dyes, paints, chemical-pharmaceuticals, some types of plastic products and technical rubber products. The larger the series, the less frequent the process changeover. Therefore, large-scale production is economically more efficient. [p.21]

In conditions of mass and large-scale production with a predominance of flow forms of organization, the production capacity of a site is determined in natural meters [p.102]

For products of mass and large-scale production, the determination of production volumes is carried out in this order for the first calendar year - the volume of products produced for the period from the date of introduction of the product into production until the end of the year for the second calendar year - the increase in production volume in [p.291]

In mass production, products are produced in periodically repeating batches. Each series includes homogeneous products. Depending on the size of the series, small-, medium- and large-scale production is distinguished. The batch size also determines the frequency of changes in production processes. Workplaces in mass production enterprises are to a certain extent specialized. In most cases, subject specialization of workplaces is used, i.e., each of them is constantly assigned several operations for the production of parts, the processing of which is carried out in batches. This type of production has higher technical and economic indicators compared to single production. [p.19]

The latest resolutions of the party and government set the task of further improving material and technical supplies based on scientific management methods and the widespread introduction of electronic computer technology. The party's decisions focus on the need to strengthen direct communication between suppliers and consumers and reduce intermediate links in the material supply system, primarily for the supply of products consumed consistently and in large quantities (primarily for enterprises of mass and large-scale production). [p.108]

The AO coefficient takes into account inevitable downtime that occurs for technological and organizational reasons (emergency repairs, workers being busy doing other work, etc.). It depends on the type of production, operating mode in the workshop, as well as on the nature of the equipment. In approximate calculations of the economic efficiency of options, 0 can be taken equal to 0.85 - for individual and small-scale production 0.80 - large-scale production 0.70 - mass production. In refined calculations of the efficiency of options, k0 should be set based on the specific conditions of use of the equipment. [p.45]

In large mechanical engineering associations for mass and large-scale production, preparation for the production of new products is usually carried out centrally. In mass production factories, a mixed preparation system predominates, while in small-scale and individual-type enterprises, a decentralized one predominates. [p.29]

Thus, with the exception of single and small-scale production, for each new product it is necessary, as a rule, to develop technological processes for the procurement, processing and assembly phases, to produce sets of technological equipment, and sometimes special equipment. It should be taken into account that when preparing the production of a modern complex product, for every 10 thousand original parts in large-scale production, it is necessary to develop up to 50 thousand technological maps and more than 30 thousand types of technological equipment. As a result, TPP often turns out to be the most labor-intensive phase of technical preparation of production. [p.160]

For the system of collapsible fixtures (CPF), standards have been developed for the elements of fixture bodies, and the minimum number of standard sizes of elements that are necessary and sufficient to create any machine fixture used in processing parts has been determined. It uses the usual standardized installation, fixing, clamping and fastening parts. The system involves disassembling fixtures and reusing standardized elements only after the product has been discontinued and is most suitable for large-scale production. [p.169]

The transition to mass and large-scale production required the creation of a system of continuous monitoring and regulation of production. This problem was solved on the basis of the introduction of dispatching, as well as the development of standards defining the order of the calendar movement of objects of labor in production. The First All-Union Conference on product quality and organization of technical control in the metal and electrical industries, held in 1930, developed [p.15]

In mass production, the most important calendar and planning standards are the size of the batch and the frequency of its repetition, or the frequency of launching the batch. It should be noted that the concepts of series and batch of products (parts, assembly units) often coincide. But in large-scale production with a large annual (quarterly) production program for the production of products of individual items, the series is divided into parts (batches) that are put into production periodically. In this case, a series is understood as the total number of products of a specific name in the production program (in the section Production plan and sales of industrial products of the enterprise’s technical industrial and financial plan). [p.260]

Automation of TPS in mass and large-scale production is currently based mainly on the use of open-loop automatic control systems that implement the simplest algorithms for controlling processing modes such as parametric or time programs generated on the basis of a priori information (2). Most of the grinding equipment of domestic and imported production, pilot production automobile factories and car service centers in the cities of Almaty, Astana and Atyrau are equipped with such devices. [p.140]

In mass and large-scale production, to determine the output of each worker per shift or billing period, an operational census of the balances of unprocessed parts or unassembled products at the end of the shift or billing period is carried out. Workers' output is defined as the balance of parts or blanks at the beginning of the shift, increased by the number of parts transferred to the workplace during the shift, minus the balance of unprocessed or unassembled parts (blanks) at the end of the shift. The output of each worker calculated in this way is documented in reports or output accounting sheets. [p.141]

If an enterprise has mass or large-scale production, specifications for materials for all parts, uses piecework wages and standardization of all production processes, then under the standard-cost system, accounting work comes down to accounting and identifying minor deviations from standards. [p.205]

In conditions of large-scale production with a long cycle of assembly work with small differences in the processing time of parts included in a certain unit, a type of group kit is used - a unit kit. This planning and accounting unit combines parts of one or different products based on the unity or similarity of the technological route and the size of the advance in a given workshop. [p.206]

Differentiated time norms imply a more complex structure. In this case, individual categories of time spent are determined as a percentage of the main and operational time. For mass and large-scale production, the rate of piece time is calculated differentially using the formula [p.23]

I. Accepted number of measurements 5 measurements, accuracy 6%, large-scale production Kf = J,lrl,2 (see tables 1 and 2). 2. Calculation of time norms [p.43]

For comparison, we will standardize the same operation according to the standards for large-scale production. The operation is performed on the same equipment with the same cutting tool under the same cutting conditions. Consequently, the main time remains unchanged, i.e., T0 - 6.84 minutes. [p.106]

Broaching is one of the most productive methods of cutting a wide variety of surfaces, providing high precision and cleanliness of processing. But broaching requires an expensive and complex tool, so this processing method is economically justified only with a large volume of products, i.e. in mass and large-scale production. [p.106]

In mass and large-scale production, multi-machine maintenance has already become quite widespread, but the capabilities of this method in mass production are still completely underutilized. [p.123]

Machine production of rods is most widely used in mass and large-scale production. Depending on the machine model, according to standards [13], the duration of each set of techniques is determined. [p.143]

In the electrical industry, under conditions of mass and large-scale production, the average amounts of recycled waste sold for individual groups of materials range from 15-25% for ferrous metals, 10-20% for non-ferrous metals, 10-15% for plastics, 3-3 for wires and cables. 5%. For serial and single production, a coefficient of 1.2-1.5 can be applied to the indicated values. The amount of returnable waste depends on the degree of progressiveness of the technological process used [p.66]

Mechanical engineering is a complex industry; it unites a large number of industries that produce both products of mass and large-scale production, as well as products of individual and small-scale production. Mechanical engineering is characterized by all forms of production specialization (subject, technological, subject-technological). Mechanical engineering of mass and large-scale production (automotive, tractor and agricultural engineering, etc.) has a similar structure of organizations, consisting mainly of main (procurement, mechanical, assembly) and auxiliary workshops. Such organizations, as a rule, have mass production of products, repeat the production process and do not have production redistributions. Therefore, these organizations use standard cost accounting. [p.297]

Lateral semi-finished product In mass and large-scale production, where the cost of production of each processing stage in the work in progress is calculated, it is estimated according to direct costs [p.114]

Depending on the number of simultaneously produced identical products included in a series, small-scale, medium-scale and large-scale production are distinguished. [p.330]

Small-scale production is equipped primarily with universal equipment; it produces products in small quantities. Large-scale production takes on the features of mass production. The development of serial production and the increase in produced batches depends on the level of specialization of this production, the deepening of which creates favorable conditions for the replacement of single production, a significant increase in batches, and the transition to mass production. [p.330]

A group set is a collection of parts of the same name, which are processed using the same technological process, have the same processing batches, production time, and lead times for assembly. A group kit is used in accounting and planning of large-scale production, while the kit is considered as one conditional part. With a subject-closed type of production, the group set includes parts processed simultaneously at all workplaces of the site, assigned to a single technological route. [p.96]

The production of some spare parts is possible in repair shops. However, this way is also not effective enough. In automation equipment, a significant share is made up of components obtained using advanced technological processes (stamping, pressing, printed wiring, vacuum deposition, etc.). The same technology requires application in mass and large-scale production. Repair shops have to use universal equipment, which increases the cost of repairs. For example, plates, device brackets and other elements at an electrical plant are made by stamping followed by deburring. In operation, the costs of their production increase by 10-12 times. [p.214]

At large machine-building enterprises with mass and large-scale production, preparation for the production of new products is carried out centrally under the leadership of the chief engineer. The chief designer, chief technologist, head of the laboratory, head of the planning department, economists, sociologists, and programmers report to the chief engineer. Processing of the created structures takes place in an experimental workshop or pilot production. Technological preparation is carried out in workshops. [p.156]

Enterprises with mass, large-scale production achieve competitive advantages mainly due to [p.215]

The principle of division of labor is quite widely implemented at power engineering enterprises. The high labor intensity and long duration of many operations for machining leading parts of turbines and some boiler units creates the main prerequisite for organizing a number of technological processes according to the rules of large-scale production. This allows you to assign individual operations to one workplace and automate production. [p.35]

With constant continuous-flow production, flow sections (production lines) are loaded with the same products, i.e., the same standard size for a long period, which usually corresponds to the conditions of mass, less often large-scale production. The entire process is carried out 2 J i 1 without any interruptions, machine readjustments [p.72]

In mass and partially large-scale production, the statistical method of technical control has become widespread. The starting point of this method was the idea that in order to produce economically, one should fight not against random, but only against certain causes. The statistical method is based on the application of probability theory and mathematical statistics. Its essence boils down to the following [p.153]

Enterprises draw up a production plan according to the range of products established by industrial associations, taking into account orders through direct connections. The transfer of enterprises with mass and large-scale production (which is typical for the chemical and petrochemical industries) to direct long-term connections on the basis of long-term business contracts significantly increases the role of the economic agreement in production planning. . This is related to the increased dependence of economic incentive funds on the fulfillment of the supply plan under contracts and orders [p.176]

General machine-building standards for auxiliary time, for servicing the workplace and preparatory and final time for technical regulation of machine tools. Large-scale production. Ed. 2nd clarified, and add. M. NIITruda, 1975. 344 p. [p.182]

General machine-building time standards for full-time metalworking work on machine assembly. Mass and large-scale production. M. NIITruda, 1973. 147 p. [p.183]

The cross-cutting method is used in industries with mass and large-scale production, where raw materials and materials undergo successive several phases of processing (reprocessing). At the same time, a distinction is made between semi-finished and semi-finished methods of calculation, depending on the characteristics of production [p.156]

Another aspect not taken into account in the example is the processes of filling a cup with instant coffee and water. In the example under consideration, the costs associated with this are classified as structural. If we were talking about large-scale production here, then it would be necessary to include all positions of the technological process (the so-called technological time) in the structure of product costs. The issue of classifying costs as product or structural is decided taking into account the effect of the time factor. The movement of the hand that results in the creation of the physical substance of the product being sold is an element of food costs. The subsequent conversation with the buyer to advise him on the purchase choice is an element of structural costs. [p.53]