Why is this equipment needed?

The need for such a durable and reliable material as metal is constantly growing, which leads to the need to open new metallurgical enterprises and modernize existing ones. The list of industries in which metal simply cannot be used can be continued indefinitely. These are mechanical engineering, automobile and shipbuilding, construction and many others.

In order for metal ore to be turned into rolled metal of a certain grade, it is necessary to perform a lot of basic and auxiliary operations, for each of which special equipment is used. One of the main types of metallurgical equipment, which produces a sheet of metal as a result of plastic deformation from a hot billet, is a rolling mill. It is here that the bulk of the work carried out by metallurgical enterprises is carried out.

Types of rolling mills

As we have already found out, a rolling mill is equipment on which, through sequential operations, a metal billet is transformed into long products with the required geometric parameters. Depending on the parameters of the final product, these machines can be of several types. Billet and crimping (slabing and blooming) are designed to produce a billet from a large metal ingot, which is supplied for further processing to a special rolling device. The latter type of equipment, which already produces rolled metal of the required configuration, includes section, pipe and wire mills.

The category of section mills includes equipment for the production of various types of rolled products. Thus, these can be mills for the production of sheet steel, angles, channels, rails, etc. Depending on their functionality, such mills can be large- and medium-grade, rail-rolling and MPS category, on which profiles of various sections are produced. Sheet rolling mills, capable of processing workpieces by cold or hot forming, are used to produce metal plates (50–350 mm thick), sheet metal (3–50 mm) and strips (1.2–20 mm). After production, finished products are wound into rolls weighing up to 50 tons.

The classification of rolling mills that produce various types of seamless pipes divides them into the following categories:

- continuous extensions, which produce pipes with a cross-section of up to 110 mm;

- short straightening mills necessary for the production of pipes with a diameter of 60–450 mm;

- three-roll type equipment - for the production of thick-walled pipes with a diameter of 35–200 mm (pipes produced on such equipment are characterized by a reduced degree of wall thickness);

- pilgrim mills used for the production of seamless pipes of significant diameter (400–700 mm).

Rolling stand of a sheet rolling mill

Modern enterprises also use parts-rolling or special-type mills. They are used for the production of profile and pipe blanks, the length of which does not exceed 3 meters. In addition, the capabilities of such equipment make it possible to use it to produce workpieces in the form of balls, bent profiles, gears, screws, pipes with a ribbed section, etc. The workpieces are processed already at enterprises that use them to produce their products.

Rail and beam mill units

The 950/800 linear type rail and beam mill produces railway rails weighing up to 75 kg/m, large-section I-beams with a height of up to 600 mm, channels with a height of up to 400 mm, angle steel with a flange width of up to 250 mm and round billets with a diameter of up to 350 mm and a length of up to 8m. Blooms with a cross section of up to 350 x 350 mm and a length of up to 6 m are used as the initial workpiece.

From the blooming 1150, the blooms are fed by a schlepper to the heating furnaces and, after inspection and cleaning, they enter the first line of the mill, which consists of a reversible two-roll stand 950 x 2350. Here, as a rule, a roughly profiled strip up to 12 m long is obtained in five passes. Then the strip is transferred by roller tables to the first working three-roll stand 800 x 1900 of the roughing line. On this line, the strip is given a more precise profile and it is rolled out to a length of up to 30 m in four passes. The strip is inserted into the second three-roll stand of the same line using roller conveyors and a chain schlepper. Here, with the help of calibrations, the strip is given the proper profile in 3-4 passes and it is rolled out to 100 m.

The semi-finished product is transferred to the finishing two-roll stand 850 x 1200 by roller tables and chain slappers, where the semi-finished product is given its final profile in one pass.

Then, depending on the purpose, the strip is modified on the following units.

When rolling rails, a strip from a finishing stand 850 x 1200 is transferred by roller tables to hot cutting saws for cutting into measured pieces 25 m long. Then the semi-finished product is inspected, marked and sent for straightening to a straightening machine. After straightening, the rails are moved by roller tables and slappers to the refrigerator for cooling.

The cooled rails are sent to isothermal holding and normalization furnaces.

Then they are straightened in roller straightening machines along the lower base; final straightening in another plane is carried out on vertical straightening presses. After this, the rails are sent to automatic lines, where their ends are milled, mounting holes are drilled, and the surface of the heads is hardened. After the automatic lines, the rails arrive at the control table, where a comprehensive check of their quality is carried out and defects are corrected. Finished products arrive at the warehouse.

When rolling I-beams and T-beams, channels and angle steel, the rolled semi-finished product from a finishing stand 850 x 1300 is placed on a cutting section with a roller conveyor, where it is cut into measured lengths of 25 m. Then the semi-finished product is marked and sent to the refrigerator, which has a tilter for turning the semi-finished product with so that cooling is carried out more evenly. The cooled semi-finished product is transferred by roller conveyors to the correct section, where it is straightened in one plane by roller straightening machines and, after turning in another plane, by a correct press. The straightened rolled products are sent to the sorting area with subsequent transfer to the finished product warehouse.

Defective areas must be trimmed using a cold saw. To increase rolling accuracy, instead of a finishing stand, a universal stand with vertical and horizontal rolls is used.

Units for rolling round profiles include heating equipment, roller conveyors, slappers and two groups of stands: roughing, consisting of one two-roll stand 950 x 2350 and two three-roll stands 800 x 1900, and finishing - two-roll stand 850 x 1200. After marking and control, round rolled products roller conveyors are fed to saws for cutting into measured lengths, then to the refrigerator and to the finished product warehouse.

Components of a rolling mill

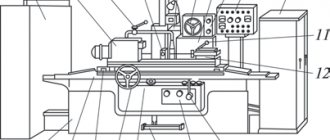

The design of any rolling mill includes three main elements: the so-called working stands, transmission devices and drive motors. The rollers along which sheet or profile metal moves are part of the working stands. They also include installation mechanisms, frames, plates and wiring. The movement of all working parts of the rolling mill is provided by powerful electric motors, which are connected to them through elements of the transmission device: couplings, spindles and gears.

You should know that the main characteristic of billet and crimping rolling mills is the diameter of the work roll. If, in the process of processing a workpiece, several working stands are used at once, then the diameter of the roll on which the finishing operation is performed is used as such a characteristic.

A section rolling mill, where products of complex shapes and with fairly accurate geometric parameters are produced, includes several stands at once through which the rolled stock passes sequentially during its processing.

Modern enterprises today use universal rolling mills equipped with 3 or 5 working stands. Some of the rolls of such mills (2–3) have a diameter of 1350 mm, the rest - 800 mm. Equipment for producing sheet metal of considerable thickness is, as a rule, equipped with one or two working stands. The working width of such mills, determined by the length of the rolls, is in the range of 3.5–5.5 meters. A sheet metal mill is most often equipped with additional working stands with vertical rolls, which ensure compression of the side edges of the formed sheet of metal. Sheet metal in the form of strips is produced in a device equipped with 10–15 working stands equipped with horizontal rolls with a length of 1.5–2.5 meters and vertical rolls for crimping the ends.

A rolling mill, as can be seen from its design, can be of considerable length. The most notable thing in this regard is pipe rolling equipment, which includes three mills simultaneously. At the first of them, a hole is pierced in a metal workpiece, at the second, the workpiece is drawn into a pipe, and at the third, calibration is performed, which is carried out to give the finished product the required diameter. On part rolling mills, the workpiece is subjected to both helical and transverse processing.

Rolling mill design

Auxiliary and transport equipment for rolling mills

The metal rolled in the mill is subjected to finishing: the ends are cut off, cut into pieces of the required length, straightened, the wire rod is rolled into coils, broadband steel is wound into rolls, etc. Roll finishing operations are mechanized: they are produced by auxiliary machines and mechanisms. These include stationary and flying, circular saws, leveling presses, winders, refrigerators, etc.

Rolled strips must be moved from one device to another. For this purpose, special transport equipment is provided: plate, roller and scraper conveyors, roller conveyors, conveyors, manipulators, pushers, ejectors and pushers.

The rolls of rolling mills with their necks rest on liners made of plastic or wood plastics or rolling bearings, usually four-row, installed in the pads of the rolling stands.

Closed-type or fluid friction bearings provide precise mill adjustment and relatively low energy consumption and are practically not subject to wear. Fluid friction in such bearings, even at high specific pressures in the journal (up to 25 MN/m2 and above), is ensured by careful processing of the rubbing parts and good sealing Oil the bearing is injected at a pressure of 0.1. . . 0.15 MPa, providing a friction coefficient of 0.001. . .0.008, the same as for rolling bearings.

To change and fix the position of the rolls in the vertical and axial directions and hold them in the desired position, various mechanisms are used:

- pressing devices for upper, middle, lower and vertical rolls;

- balancing devices for upper and middle rolls;

- devices for axial installation.

In horizontal stands, the gap between the rolls is established by moving the upper roll, and in stands with vertical rolls - by moving them simultaneously.

Different types of pressing and balancing devices are used in different mills. Pressing devices consist of a pressure nut and a pressure screw. In general, the design of the pressing device is determined by such parameters as speed, magnitude and number of movements per hour. Thus, the speed of roll movement in different mills varies from 0.05 to 250 mm/s, and the number of movements per hour is up to 700.

Pressing devices are manufactured in the following types:

- with manual drive of the pressure screw or wedge;

- driven by an electric motor with a helical gearbox.

The balancing device ensures that the upper cushion is constantly pressed against the pressure screw during idle, eliminates the screw gap in the nut and thereby eliminates a possible impact (from bottom to top) when the metal is captured by the rolls.

In stands with a manual pressing device, for small movements, the upper roll is balanced by rods with springs resting on the upper cross member. For significant movements of the roll, a load or hydraulic device is used.

Devices for axial installation of rolls on mills make it possible to move and fix rolls not only in the vertical plane, but also in the direction of the roll axis. Axial adjustment is carried out by moving using the bolts of the cassette with the liner (Fig. 12). In this case, the cushions themselves are fixed in the opening of the frame with support strips bolted to the frame.

Rice. 12. Device for axial installation of rolls : 1 - cushion; 2 - bolt; 3 - cassette; 4 - roll; 5 - liner

On section mills, rolls are adjusted in the axial direction by moving the chocks by pressing side bolts that pass through the frame and flanges of the chocks or through strips resting with one end on the chock and the other on the bed. There are other ways to move and fix the rolls in the axial direction.

Roll reinforcement is all types of devices and devices that are necessary to guide and hold the rolled strip in the desired position both when feeding to the rolls and when exiting the rolls:

- input fittings ensuring correct supply (rulers, funnels, boxes, passes, etc.);

- outlet fittings ensuring correct exit of the strip from the rolls (rulers, wiring);

- transfer devices that ensure the transfer of the strip from one stand to another, with or without turning (various tubes, helical wires, turning rollers), bypass fittings that ensure automatic transfer of the strip from caliber to caliber both in one stand and from one stand to another

The roller fittings installed on the front side of the stand include, in particular, guide input rulers, which are a stationary continuation of the caliber collars. The input rulers ensure directed feeding of the strip into the rolls.

When rolling, for example, an oval in a round gauge, the strip must be continuously kept from stalling and twisting. The rulers have an appropriate profile, and they are very carefully installed according to the caliber in the receiving box. Such profiled rulers are called passes. In this case, particularly difficult service conditions for the guide fittings are observed, since the gaps come into contact with hot metal during operation and experience high sliding speeds. All this leads to intensive wear of the working surfaces of the passes.

Rulers are replaced with roller passes, which causes rolling friction rather than sliding friction. In Fig. 13 shows the design of a box with roller passes used when rolling a circle.

Due to the dissimilarity of the diameters of the work rolls and their peripheral speeds (their number of revolutions is equal), the rolled strip, upon exiting the rolls, bends towards the roll of smaller diameter. To prevent this, outlet fittings are used.

Rice. 13. Roller input box for feeding oval strip into round gauge 450 mill

To ensure that the strip, when the metal leaves the rolls, does not bend in a vertical or horizontal plane and does not twist around its axis, rulers are installed on the wiring bars, as on the front side, as well as lower and, where necessary, upper wiring.

Turning of strips after exiting one stand before feeding into the next is carried out automatically using turning wires. To reduce the load, the wires are replaced with turning rolls.

Making a rolling mill with your own hands

If you need a low-power rolling mill for use in a home workshop, then it is quite possible to make it yourself. Despite the simplicity of its design, such equipment can be used to perform various types of work. So, with its help you will be able to independently produce wire of various diameters, straighten or cut sheet metal, the thickness of which does not exceed 0.5 mm.

Read also: Bolts with a smooth head

In order to manufacture such rolling equipment, you will need the following structural elements: two powerful racks, a steel rod with a diameter of 5 cm, a top plate, bolts and nuts (M10), two gears and a gear, bronze bushings and bearings, springs and stops.

The design of such a home-made rolling mill is assembled in the following sequence:

- from racks and a steel plate, by connecting them with bolts and nuts, a kind of cage is created;

- two working shafts are mounted on the racks, which are previously machined from a steel bar and hardened to give them increased hardness;

- the lower shaft is installed between the racks using bushings with bearings, and the upper shaft, which is movable, is mounted on special sliders, the upward movement of which is limited by stops;

- constant compression of the two working shafts will be provided by springs, which should be secured simultaneously to the base plate and the upper shaft.

Manual rolling mill option

In order for such a rolling mill to work, it is necessary to ensure synchronous rotation of the working shafts. This problem is solved by means of a gear transmission, which transmits torque from a gear mounted on the lower shaft to a gear mounted on the same axis with the upper shaft. To set the entire mechanism in motion, it is necessary to rotate the handle, rigidly connected to the lower gear. Conveniently, the gap between the working shafts of such a mill can be adjusted.

The versatility of such equipment is ensured by installing shafts of different designs on it. Thus, the use of shafts in the form of circular knives makes it possible to cut sheet metal, and working elements with grooves of the required size make it possible to produce wire. You can use such simple equipment to form stiffeners on the workpiece. To do this, it is necessary to install working shafts on it, which will touch their surfaces according to the “groove-ridge” principle.

We offer a rolling machine for the production of Euro pickets! Profitable!

Peculiarities:

Profiling machine is used for

Chinese provides you with a machine for making presses 40t 63t 100t 160t 600t 3600t etc. etc. Besides the press making machine

Rolling of round parts

Cold rolling of precious metals, non-ferrous metals,

We offer a rolling machine for the production of Euro pickets!

The profiling machine is used to produce fence profiles. IN

The automatic line for the production of KNAUF type profiles is designed for the production of high-quality cold-formed steel construction

This equipment operates using electrical synchronous control technology. The welding process and welding time are controlled by digital integral

- Steel thickness: 0.3—1.2mm

- Tape width: 450mm

- Production speed: 0-20 m/min

Part of the equipment:

Main characteristics

- Steel thickness: 0.3-1.2mm

- Tape width: 305mm

- Production speed: 0-20 m/min

Line composition:

- Uncoiler, rolling mill, hydraulic shears, control system, receiving table.

- Line material:

The Chinese well-known reliable company Jin Bin LLC has been supplying machines for corrugated sheets and metal tiles for many years. Our roll forming

Sandwich panel production line in China

The main technological process of this line:

The main technological process of this line:

- Loadable raw material - unwinding

- recess

- heating

- bend

The production facility develops and manufactures universal roll forming mills. Roll forming mill

The production facility develops and manufactures bending and rolling mills. The bending and rolling mill is

Line for the production of corrugated sheet profiles, detailed information on

KOCKS carbide rolling ring is suitable for three-roll rolling mills, mainly for the production of special steel such as bearing steel, spring steel

The working layer contains fine intercrystalline graphite. The size, shape and placement of graphite and carbide can be controlled by coquelation and alloy content.

We offer equipment for organizing the production of round, square and rectangular pipes. We also recommend offers from partners – Fiber Optic

Machine for making strip 6*12 mm from a round rod with a diameter of 10

The SVP08 three-roll helical rolling mill is on sale in Lipetsk. The mill allows the production of calibrated rods by the method of hot plastic deformation.

A machine for the production of clamps is on sale in Chelyabinsk The machine is designed for mass production of special curved profile products from rolled

EFESCO company supplies high-tech equipment from China such as: Equipment for diamond drilling and drilling, Equipment for

The reinforced machine for assembling bends SBWT 1250x1.5 is designed for the manufacture and assembly of segment bends, transitions, plugs and other shaped products by

They are part of a continuous steel casting installation and are designed to form the dimensions of the ingot. Price

Included in the chain conveyor of a pipe rolling mill. Price

The cushions are special castings (possibly from forgings), housing parts of rolling bearings with incoming parts: covers, seal units and

produces and sells spare parts for conveyor equipment: Conveyor rollers from D-57 to D-250, Roller conveyors; Roller guides and

produces and sells: Conveyor rollers from D-57 to D-250, Roller conveyors; Guide and support roller supports; Conveyor drums, Gearboxes,

Rolling mills are used to roll metal to produce structural profiles, sheet materials, tubular products, etc. We have mills available

Line for the production of finned spiral wound

This summer we are offering a straightening machine for angle bars at a very good price! You save up to 1,000,000 rubles. The equipment is certified. Provided

Material thickness (0.8-2.0)mm Material length (0-6000)mm Production speed #65288;8-12)m/min Main machine power 22kw/30kw Main purpose

Press shears, Guillotines, rolling and sheet bending machines Nedbox Company Sells all types of machines for working with metal such as: Press shears of all types

Line composition: 1) Uncoiler 2) Rolling mill (pairs of forming shafts). 3) Hydraulic punch and cutting device 4) Automatic system

Read also: Determination of wire cross-section by diameter table

Production

Do you want to post an ad?

According to the catalog of the Internet portal Equipnet.ru, it is proposed to purchase equipment for rolling production at enterprises of various levels. Rolling equipment and tools are used to plastically deform metal by moving it through rotating rolls; rolling is complemented by cutting, coiling and other technological operations. If you need equipment for the production of rolled metal, on our website you will find the latest offers from manufacturers, importers and other business representatives.

Units for large-, medium- and small-section mills

The large-section mill 600 is designed for the production of I-beams with a height of up to 200 mm, angle steel with a flange width of up to 160 mm, round steel with a diameter of up to 120 mm, square profiles with a section of up to 100 x 100 mm, strips with a width of up to 200 and a height of up to 50 mm and rails weighing up to 24 kg/m. The blank is a bloom with a cross section of 300 x 300 mm and a length of 6 m.

The mill consists of 17 working stands installed along three parallel lines. The lines are connected by five schleppers, which allows you to bypass some cages. For tilting, tilters with a rotation angle of 45 and 90° are used. The last cage can be made in a universal design. Of these stands, five (2-6) and three (8-10) are combined into two groups, the rest are arranged sequentially and in a checkerboard pattern:

Billets from heating furnaces, according to the technological cycle, after removing the scale, enter the corresponding mill stands. As with previous units, scissors, saws, pushers, manipulators, straightening machines and straightening presses are widely used. To process the end elements of profiles, mechanical equipment, stampers and hardening devices are used.

The continuous medium-grade mill 450, consisting of 16 stands, is designed for the production of the following profiles: a circle with a diameter of up to 60 mm, a square with a side of up to 55 mm, a strip with a width of up to 200 mm and a thickness of up to 22 mm, as well as an angle with a flange width of up to 125 mm, I-beam and channel up to 300 mm high. The billet used is a rolled product with a cross-section of up to 200 x 250 mm and a length of up to 12 m. After the billet mill 850/700/500, the billets enter two heating furnaces with walking beams. After heating, the workpieces are conveyed along a roller conveyor to shears for trimming the front and rear ends and to hydroscale descaling. Next, the metal is transferred to a continuous roughing group of working mill stands, consisting of nine two-roll stands 630 x 1300, of which No. 1, No. 3, No. 4, No. 6, No. 7 and No. 9 are horizontal and No. 2, No. 5 and No. 8 - combined design can have both vertical and horizontal rolls. The cages are divided into three groups of three cages each with two horizontal and one combined cage between them. Along the intermediate roller table, the roll is sent to the finishing group containing seven stands: three (No. 10, No. 13 and No. 15) of the combined type 530 x 630 and four (No. 11, No. 12, No. 14 and No. 16) of the universal type with with horizontal rolls 530 x 630 and with vertical idle rolls 900 x 600.

Practice shows that a good option for rolling beams, channels and strips is the use of combined stands with horizontal rolls and the end of rolling in a universal stand. The angle is rolled by the combined action of combined and universal stands on the roll.

In front of the finishing group, flying shears are installed for cutting the ends of the rolled material and hydraulic shears for cutting it into measured lengths. After finishing rolling, the finished profile is sent to the refrigerator, stamping, cutting and finished product warehouse.

The small-section mill 250 is designed for the production of long profiles in coils weighing up to 2.1 tons. The initial blank is a square with a cross-section of 150 x 150 mm and a length of up to 12 m. Manufactured products include: round steel with a diameter of up to 42 mm, square with a cross-section up to 36 x 36 mm and hexagonal. The mill consists of 20 stands with alternating horizontal and vertical rolls; the cages are combined into three continuous groups. The workpieces are heated in a walking hearth furnace. The rolled and cooled metal is wound on three coilers. The finishing department has leveling machines, flaw detectors and abrasive cleaning machines.

Types of rental equipment

The Equipnet.ru catalog presents rolling machines and devices for metalworking that can be used in enterprises of various industries. It is used for the manufacture of metal siding, metal tiles, steel pipes and hundreds of other types of products; properly selected production equipment is guaranteed to recoup all purchase costs.

Using the Equipnet.ru portal, you can buy at a low cost the following types of equipment for metalworking and the production of finished products:

- Ready lines for the production of metal profiles. They will allow the enterprise to equip the enterprise with everything necessary in a short time and begin producing products in large quantities. Automated lines provide high precision metalworking.

- Lines for the production of profiled sheets. This material is actively used in the construction of fences and fences, laying roofs, wall cladding; profiled sheeting is in constant demand, and its popularity continues to grow. A ready-made line for the production of profiled sheets will become a guaranteed source of profit.

- Manual profile benders designed for bending profiles of various sizes and thicknesses. The equipment can become part of an automated line; this technique allows you to work with three workpieces simultaneously.

- Separate components for rolling mills. Any equipment breakdown leads to work stoppages and losses, so it is important to take care of high-quality spare parts. Suppliers offer a variety of parts, and the catalog provides a detailed description of each item.

On our website you can easily find everything you need to equip a modern production complex; the purchased equipment will last for years and bring considerable profit. To clarify the price and terms of sale, you can communicate directly with suppliers and find regular partners.

Rolling machines are critical equipment in obtaining metal in the form in which it is needed. They will be discussed in the article.

Hot rolling mills

- Rail and beam and beam mills With rolls with a diameter of 750.900 mm for rolling railway rails, beams, channels and other large profiles;

- Large-, medium- and small-section mills Large-section with rolls with a diameter of 500.750 mm, medium-section with rolls with a diameter of 350.450 mm, small-section with rolls with a diameter of 250.325 mm

- Wire mills Designed for rolling wire with a diameter of 5–10 mm. Wire of a smaller diameter is obtained by drawing. Wire mills can be stepped, semi-continuous and continuous.

Section hot rolling mills.

In modern metallurgical production, about half of all rolling is carried out on hot rolling mills, so the highest demands are placed on the process and equipment in terms of dimensional accuracy and final properties of the metal.

A hot rolling mill is an installation that includes various mechanisms: preparing, straightening at high temperatures and providing the metal with final processing. The key mechanism in a rolling mill is the roll system, which is in direct contact with the metal, giving it the necessary geometric dimensions, shape, quality and surface properties.

As a rule, two work rolls are in direct contact with the material.

The most common are two, three and four roll mills:

— twin-roll mills are used for large profiles and thick sheets

— three-roll for sectional profiles and medium-sized sheets. In three-roll mills, reversible movement of the sheet is achieved without changing the direction of rotation of the drive.

— four-roll mills are widely used for rolling various types and grades of rolled products.

Universal stands, in addition to horizontal ones, have vertical rolls that compress metal on the right and left. They are used for rolling rails and wide I-beams.

Recently, all stages of the production of long products, from casting blanks to final processing of products, have been trying to be combined into one production line. This allows you to eliminate some labor-intensive operations (ingot processing, heating, transportation, etc.) from the process, the metal consumption of the product is reduced, the area occupied by the line is reduced, and automation is simplified. Increased efficiency is achieved due to lower energy consumption (for unnecessary operations), eliminating the cost of equipment and labor for transporting products.

The main disadvantage of this method is that the productivity of the entire system is limited by the speed of the slowest operation - casting blanks. To correct this situation, either use several crystallizers in continuous casting machines (CCMs), or feed the ingots to the rolling mill without separating - continuously.

Hot rolling mills can produce products with different profiles for different needs and applications. The profiles depend on the shape and size of the rolls.

- fittings

Mainly used in construction when creating reinforced concrete structures as a reinforcing layer. Such reinforcement has a diameter of 8 mm, it is made of carbon steel and supplied in measured pieces of 6 or 12 m. Reinforcement of smaller diameters (6-9 mm) can be supplied in coils and modified directly at the site of use (unwinding, cutting). Reinforcement for reinforced concrete, as a rule, has ribs (corrugations) for better adhesion to concrete, however, there is also smooth reinforcement that is not used in construction.

— wire rod

As a rule, it is a thick wire with a diameter of 5 to 10 mm, wound into coils (from 1 mm for the production of electrical cables). Produced by stepwise compression on all sides on mills. Electrical cables, wire, nails and much more are subsequently made from wire rod.

- tee, I-beam, channel

Hot-rolled beams are produced on mills using a stand and specially shaped rolls. Beams are widely used in construction as load-bearing structures of interfloor ceilings, bridge and overpass structures, structures of various projections (balconies, canopies), to create window and door openings. In addition, beams are widely used for the construction of integral frames of metal structures as both horizontal and vertical elements. The dimensions of the beams are standardized - the profile height ranges from 50 to 600 mm, the length is a multiple of 4 to 12 meters or unmeasured. As a rule, carbon or low-alloy steel is used as materials.

- corner

The production and use of steel angles is generally similar to T-beams and channels, however, the angle is lighter, smaller in size and able to withstand smaller loads. It is difficult to imagine a metal structure that does not use a steel angle as a main or additional element. In combination with channels and brands, the corner is used for interfloor ceilings, window and door openings, and various metal structures. As a cheaper profile, the corner has proven itself in dacha farming for creating new metal structures or repairing and strengthening existing ones. Simple or lightly loaded metal structures can consist only of corners.

The dimensions of the corner shelves are from 20 to 250 mm, the length is a multiple of 4 to 12 meters. Material – structural or low-alloy steel.

- band

Strip steel has the most universal and widely used application among other profiles. In addition to the actual use of steel strip for finishing building facades, when creating gratings, fences, it is used as a blank for creating cutting tools, washers, nuts, large springs and much more. In addition, welded channels and brands are made from steel strip, which have some advantages over hot-rolled ones and are very widely used.

The range of strips ranges from: width from 20 to 200 mm, thickness from 4 to 18 mm. The length of the strip made of low-alloy or carbon steel is from 3 to 12 meters, of alloy steel up to 6 meters. The strip can also be supplied in a roll.

- circle, square, hexagon

Rolled products of such sections are produced by pressing from all sides. The products are widely used in construction, mechanical engineering, and also as blanks for the production of hardware (bolts, screws) and various parts and tools. They can be made of regular or high precision from carbon or alloy steel. The diameter of a circle is from 5 to 250 mm, the diameter of the inscribed circle of a hexagon is from 4 to 100 mm, the side of a square is from 4 to 200 mm. The length is a multiple of 2 to 12 m or “infinite” in a roll with a small diameter/side size. The steel square can be twisted, but not more than 24 degrees.

General information

Today, metal is the most common material from which a huge variety of things are made, from small household parts to large industrial objects. However, there is a very important point that not everyone knows about. Simply smelting metal and then turning it into an ingot is not enough. After the formation of the ingot, any metal is transferred to the rolling shop. The only equipment available in such workshops is rolling machines. It is these devices that give the desired shape, which is suitable for subsequent use of the metal. It is worth noting that this equipment is one of the oldest today. However, over the years of its use, the machine has proven itself so well, has such good characteristics and productivity indicators that it is still used to this day.

Machine device

In essence, the rolling machine structure is not complex or difficult to maintain, assemble or repair. The sole purpose of this device is to give shape to ingots of metal. In other words, the rolling mill receives large ingots, and as they pass through the rolling mill, it shapes them into more conventional sheet metal. In order to achieve this effect, the design of the rolling machine has two rollers that constantly rotate towards each other. From a technological point of view, this work is considered quite simple. In addition, the constant improvement of technology has allowed many improvements and modifications to be made in the operation of this device. Thanks to these changes, all equipment of this type is now capable of fully automatic operation.

Rolling

A metal rolling machine performs another very important function. It doesn't just give a leaf shape. As the ingot passes through this machine, the metal becomes more uniform and denser in structure. This is due to the fact that the rollers completely rub out or close any cracks or empty spaces that may well have formed on the ingot.

Another important point is that the process of turning or rolling metal into sheet form takes place in several stages and with the participation of several types of machines. Primary rolling is carried out by blooming and slab devices. It is worth noting that before sending the ingot for rolling on these machines, it needs to be slightly heated. Increasing the temperature of the metal will increase the ductility of the material during rolling. If we talk about the productivity of such machines, it is enormous. One machine is capable of producing about 6 million tons of metal per year. This takes into account the fact that the weight of ingots supplied for rolling can range from 1 to 18 tons.

Fundamentals of rolling technology on reversing mills

RANGE OF BLOMS, SLABS AND BILLETS

Rolled products produced on special crimping mills - bloomings, blooming-slabs and slabs are called bloom or slab, respectively, and are a semi-product, i.e. is an intermediate product of the technological process intended for further processing. The semi-products also include various types of billets rolled on billet mills, and sutunka (flat billets with a thickness of 4 to 35 mm for piece or batch rolling of thin sheets with a thickness of 0.18...3.00 mm).

Bloom is a semi-product of metallurgical production in the form of a square billet, rolled from an ingot on a blooming machine (with a square side of 140...450 mm) or obtained on a continuous caster (with a side of more than 100 mm). Blooms serve as the starting material for billet and section rolling mills. Square (or close to it) blooms with rounded corners and shaped blooms are rolled according to the cross-sectional shape. The range of square blooms is defined by GOST 4693-77 and includes 18 standard sizes from 140×140 mm to 450×450 mm with radii of curvature from 20 to 60 mm; permissible deviations of dimensions along the side of the square are within 5... 10 mm. The length of the supplied blooms made of structural steel grades with cross-sectional sizes up to 200 mm is 2...6 m, from 210 to 250 mm - 1.5...4 m, from 260 to 450 mm - 1...4 m. Blooms of high-quality steel of all sizes are supplied length 1...4 m. For large-section mills, the assortment of which includes shaped profiles (beams, channels, etc.), shaped blooms are rolled on a blooming machine according to special technical conditions.

Slab is a semi-product of metallurgical production in the form of a rectangular billet with a large width-to-height ratio (up to 15), used to produce sheet or strip products. Slabs are made by rolling ingots on crimping mills (slabs, blooming-slabs and slabs) or produced on a continuous caster. GOST 9137-77 provides for the rolling of 21 standard sizes of slabs with a thickness from 100 to 250 mm with gradations of 5 mm to a thickness of 145 mm and 10 mm for a thickness of 150 mm. In terms of width, slabs are supplied in sizes 300...2000mm with gradations of 20mm up to a width of 700mm and 50mm for a width over 700mm. Permissible deviations in slab dimensions in thickness are ±4...5 mm, in width ±10 mm. The length of the slabs is supplied in the range from 1300 to 5000 mm. Slabs intended for rolling on broadband mills can have a length of up to 10... 12 m.

In the production conditions of individual plants, rolling of blooms and slabs can be carried out according to special specifications and their dimensions may differ from the dimensions established by the relevant standards.

Depending on their purpose, billets are divided into square conversion, axial, forging and pipe. Convertible square billets are produced mainly by rolling blooms on continuous billet mills or by rolling blooms and small ingots on linear billet mills. In accordance with GOST 4693-77, rolling of blanks of 30 standard sizes with a square side from 40 to 250 mm and curvature radii from 7 to 35 mm, respectively, is provided. The length of the supplied workpieces with cross-sectional dimensions up to 100mm is 3...9m, from 105 to 150mm - 2...8 m, over 150 mm - 2...6 m. Workpieces of all cross-sectional sizes from alloy steel grades are supplied in lengths of 1...6 m .

Axial blanks can be supplied with square and round cross-section. Square billets are rolled on blooming or rail and beam mills, and they are intended for the manufacture of axles for broad gauge railway rolling stock (cars, diesel locomotives, motor cars). GOST 4728-72 provides for 11 standard sizes of workpieces with cross-sectional dimensions from 190×190 mm to 350×350 mm.

Axial round billets with a diameter of 150 mm are rolled from blooms on large-section and rail and beam mills. These blanks are used for the manufacture of tram car axles.

Forging blanks of square and rectangular cross-section are used for rolling section profiles and sutunka, as well as forgings in machine-building plants.

Pipe blanks are rolled with a diameter of 80...270 mm on billet, special pipe, rail and beam and section mills. They serve as the starting material for the production of seamless pipes by pressing and on pipe rolling mills.

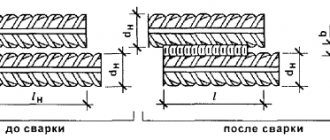

The shape of ingots for bloom rolling (high-quality ingots) is determined by two main parameters:

— the ratio of the height of the ingot (without the profitable part) to the diameter of the circle inscribed in the cross section in the middle height of the part of the ingot;

- taper of the ingot on each side.

The shape of the molds for casting steel is shown in Fig. 1. Calm steel is poured into molds, expanded upward with a profitable extension (Fig. 1, a). The ratio of height to diameter of the inscribed circle of ingots is usually 3...3.5. The taper for ingots of carbon and alloy steels lies within 2...4%, and for high-alloy steels - 5...7%. Taking into account that taper allows you to create a direction of solidification (crystallization) of the metal in the mold, reduce the axial porosity of the ingot and facilitate its removal from the mold, in some cases, for casting high-alloy steels in order to increase the density of the metal, double taper is used: 2...4% at the bottom parts and 7...8% in the upper part of the mold. It should be borne in mind that reducing the height of the ingot at a constant diameter of the inscribed circle also helps to improve the density of the metal.

The cross-sectional aspect ratio for average dimensions for high-quality ingots, as a rule, is 1.10...1.15, and the average weight is 7...10 tons. This size ratio is explained by the fact that on blooming the number of passes is odd and, therefore, one at a time side has one more passage than the other. Therefore, the difference in the sides of the average section of the ingot is taken equal to the average reduction per pass (70... 100 mm).

Ingots for rolling slabs have a cross section with an average aspect ratio of 1.5...3.0 and a mass of 10...25 tons.

The shape of sheet ingots is determined by three parameters:

— the ratio of the average width to the average thickness of the ingot;

— the ratio of the height of the ingot to the average width;

- taper of wide and narrow side edges.

The ratio of height to average width for quiet steel ingots is usually 1.0... 1.5, the ratio of width to thickness is 2.0...3.0, the taper along the wide edge is 2.5...3.5% and on the narrow edge 2.0 …3.0%.

Sheet ingots of boiling and semi-quiet steel have an average width to thickness ratio of 1.5...2.0, a height to average width ratio of 1.2...2.0, a taper along the wide edge of 2.5...3.5% and a taper along the narrow edge 0.9…2.0%.

The optimal weight and dimensions of the ingot depend on a number of factors and, first of all, on the chemical composition of the steel, the purpose of the ingots, the diameter of the rolls and the drive power. Ingots of alloy and high-alloy steels, as a rule, have less weight and size than ingots of carbon steels. An increase in the weight of the ingot due to an increase in the cross-sectional dimensions due to the insufficient relative depth of penetration of deformation in the first passes can lead to the appearance of significant internal stresses and disruption of the continuity of the metal. Increasing the weight of ingots by increasing their height increases productivity, but it is relatively small, since it leads to an increase in machine time. A significantly greater increase in productivity is achieved by increasing the final dimensions of the blooms and while maintaining the weight of the ingots. Therefore, it is advisable to roll blooms with the largest possible cross-section.

2. COMPRESSION MODES WHEN ROLLING BLOOMS

The main stages of designing the calibration of blooming rolls consist of calculating the compression mode along the passes, the number of passes, the number and order of edges, determining the amount of metal broadening and the cross-sectional dimensions of the roll along the passes. Based on the calculation results, the dimensions of the calibers and their location (installation) on the rolls are determined.

Issues related to the choice of the size of reductions and their distribution among passes are of paramount importance for the productivity of the mill and the quality of the rolled blooms. The amount of compression is determined by the gripping conditions, the plasticity of the metal, the strength of the rolls and mill parts, and the drive power.

The compression mode must satisfy the following requirements:

— obtaining blooms of a given shape, size and quality;

— no overload of the main drive electric motors and no excess of permissible rolling forces

— ensuring normal conditions for capturing rolled products by rollers;

- minimum duration of the rolling cycle, for which it is necessary to strive to reduce the number of passes, turnings and transfers

Blooming or slabing

Before being rolled out, the ingots are heated in special wells. The temperature maintained in such devices can reach 1800 degrees Celsius. After passing through the well, an electric car is used, which, in fact, delivers the heated ingot to the blooming or slab rolling stock. The difference between these machines is that blooming has only two rollers, but slab has four. It is important to understand that the passage of this stage and the processing process itself are only primary, since at the exit from blooming or slabging the ingot still does not have the full form of sheet material. These units are designed to form bars. Depending on its shape and size, the resulting material is divided into blooms or slabs. An important note: the use of blooming or slab rolling machines is carried out only at those industrial facilities where the metal will subsequently be poured into molds.

Read also: Double switch wiring diagram

Billet mill units

Billet mills supply billets to section, wire and tube rolling mills.

Continuous billet mills with one group of stands (for example, mill 700) roll blooms with a cross-section from 140 x 140 to 200 x 200 mm or large billets with dimensions from 125 x 125 to 140 x 140 mm. Continuous billet mills with two groups of stands (for example, mill 700/500) produce from the first group blooms with a cross-section from 140 x 140 to 200 x 200 mm and blanks with dimensions from 120 x 120 to 140 x 140 mm. From the second group of stands a finished workpiece with dimensions ranging from 60 x 60 to 100 x 100 mm is obtained. Sequential pipe blanking mills produce round billets with a diameter of 75-300 mm for piercing mills.

Let's consider the layout of the units of a continuous billet mill 900/700/500, consisting of 14 two-roll stands installed in three groups. The first group consists of two stands with a roll diameter of 900 mm, the second roughing group includes six stands - 900/1300 in the first and second stands and 730/1300 in the rest. The finishing third continuous group consists of six stands with a roll diameter of 530/900 mm. There is an alternation of horizontal and vertical rolls, starting from the 5th stand.

After cutting into cut lengths, the hot blooms are transported along a roller conveyor to the first group, installed separately from the second group. The distance between the first and second groups allows you to install a tilter on a roller table for free tilting of blooms.

The second group makes it possible to obtain workpieces with the corresponding dimensions of 200 x 200, 170 x 170 and 150 x 150 mm from the 4th, 6th and 8th stands.

Finished workpieces are transported by transverse conveyors to a side roller conveyor, where they are cut into measured lengths using scissors with a force of 10 MN and sent to the refrigerator. Workpieces 150 x 150 mm are moved along a roller conveyor to the finishing group.

Here it is also possible to obtain blanks with a cross-section of 120 x 120, 100 x 100 and 80 x 80 mm at the exit from the 10th, 12th and 14th stands. To establish a constant temperature at the roll, before the ninth stand, the workpieces are held for some time using stops. The feed system is equipped with tilters. Scissors are used to trim uneven ends, after which the workpieces are sent to the refrigerator.

General characteristics of the machine

Rolling mills are devices that have smooth rollers through which metal is passed to form sheets. Currently, there is a huge range of these devices. The biggest difference between the machines is the shape of the rollers. For example, there is a unit that was originally made for the production of rails. The shape of its rollers was prepared specifically for this task even during the production of the machine. It is also important to understand that the machine has several pairs of rollers through which the metal passes. Constant progress has led to the fact that all types of devices are capable of operating in constant automatic mode. The speed at which the stands pull the ingot through the machine can reach a record 290 km/h. The productivity of such a rolling mill per year reaches several million tons. Today, units such as casting and rolling units are gaining great popularity. The advantage is that they can act as a separate full-fledged production line, unlike conventional rolling mills.

Currently, there are such types of machines as blank, sheet, strip, sectional, and some types are capable of producing wire or beams.

Pipe rental

Another large category of rolling machines is intended for the production not of sheet metal, but of metal pipes. There are only three main types of pipe rolling machines that are in use today. These include stitching, sheeting and finishing machines.

If we talk about piercing mills, then they can have three different types of rollers used to perform rolling. There are barrel, mushroom and disc rollers. A device of the first type, that is, barrel-shaped, is characterized by the fact that these machine elements have a double-taper shape with a diameter of 450 to 1000 mm. Both parts are located in the horizontal plane, but along the vertical axis you can adjust the feed angle from 5 to 18 degrees or more.

Screw rolling

The profile pipe rolling machine can also perform metal screw processing. In this type of operation, double cone rolls create tensile and shear stress in the metal. It is important to note that the radial stress of the workpiece can reach quite large values, which creates a cavity of small diameter, which has uneven walls. In order to obtain a hole with the required diameter and at the same time avoid the presence of irregularities and make smooth walls, it is necessary to carry out rolling on a mandrel. By mandrel we mean a cone-shaped tool, which is located at the end of the rod between the rollers along the path of movement of the metal workpiece. There is a special stop for attaching the rod with such a mandrel. As the metal moves forward, it is stitched by this frame, which passes through the hole, widening and aligning it.

It is quite problematic to collect reviews of a rolling machine for profile pipes, since such units are mainly used only by large enterprises. However, here the very use of these particular units already indicates that they work stably and well. In other words, conclusions can be drawn based on the fact that for a huge period of time all metalworking factories use such machines. This means that the presence of automatic mode and enormous performance do their job. The disadvantages include the fact that the dimensions of such devices are quite large, and stopping them and starting them again is very problematic.

Rolling and notching machine

The most famous manufacturer of this unit is Kadzama. This device is also called a roller press. The design of this thing is very simple, and it is intended for cutting out cardboard, paper or plastic boxes for confectionery products.

The advantages of this device include the fact that it pays for itself quite quickly. The first 10,000 boxes are the approximate cost of one such machine. The cost of finished products, that is, boxes, is also very low. You only have to pay for the raw material itself – cardboard. Working with this type of machine is very simple. All that is needed is just two things. First, a sheet of cardboard is placed on the cutting knives, and then the feed handle is turned. The dimensions of such a device are also quite small. You can even install it on a regular table.

How to make a rolling machine?

In order to make a rolling machine for the production of profiles, you will need 3 mandatory things - metal, bearings and a lathe. The design of the machine itself is also quite simple. The components of a one-piece rolling machine are a table to which a worm gear motor is attached. In addition, it is necessary to attach 7 additional receiving stands to the table. It is important to know here that each cage consists of several components, and they all have interlocking with each other. That is, each cage is connected to the next. Another nuance concerns the rollers. In this model of the machine they are removable, and they are mounted on shafts. This type of arrangement and the type of rollers itself opens up wide possibilities for the production of various profiles according to their dimensions, as well as the type of product. If there is such a desire, then you can install a new type of rollers that will allow you to produce LSTK profiles. In order not to make mistakes during manufacturing, it is best to make a drawing of the rolling machine before you begin assembling it.

Wire mill units

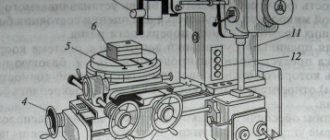

Continuous mill 250 is designed for hot rolling of aluminum wire rod with a diameter of 7-11 mm. The initial workpiece is a cast billet with a cross-section of 300 x 300 mm and a length of up to 3 m. The mill consists of 20 working stands, divided into three groups: the roughing group has six stands 400 x 700 and two stands 350 x 700 (Figure 3), two intermediate groups - two working stands 300 x 700 and two finishing groups - four successively located vertical stands 250 x 400 (Figure 4).

Figure 3 – Main working line of 350×700 mill stands 250

Rolling in the rough and two intermediate groups is carried out in two threads, in the finishing group - in one thread.

In three continuous furnaces, the billets are heated to a given temperature and then alternately placed into the right and left gauges of the roughing group of stands, where they are rolled to a square with a cross-section of 22 x 22 mm. Structurally, roughing stands are designed like all hot rolling mills. From the electric motor 6, rotation is transmitted through the gearbox 5, gear coupling 4, gear cage 3, universal spindles 2 to the rolls 1 of cage 9. To support the spindles, special supporting devices 7 are installed. The cage, spindles and gear cage are mounted on a rigid platen 8. Approximately this design in all horizontal stands of the roughing group. Behind the last roughing group, flying shears are installed for cutting the front end of the rolled product on the fly before putting it into finishing groups. Between the intermediate groups of stands and between the last intermediate and finishing group, special loopers are provided, which serve to maintain continuous operation of the unit when the speeds of neighboring stands are not coordinated.

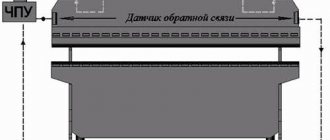

Figure 4 – Finishing stand with vertical rolls of mill 250

Figure 4 shows a finishing stand with vertical rolls of mill 250. It consists of 2 vertical rolls installed in chocks 1. Wire rod is formed in 3 roll grooves. At the exit from the last finishing stand, the wire rod is wound into coils on one of two coilers. Then the formed bundle is pushed onto the conveyor by a pusher and moved for bundling to the baler, and then to the finished product warehouse.