In this article, we review models of inverter-type welding machines for the most common type of welding - manual arc welding (or MMA - “Metal Manual Arc”) with piece coated electrodes.

So, you have made a decision: buy a welding inverter. How to choose a device so that it serves you for a long time? How to find an inverter without paying extra money? Which brand is more reliable?

In this part of the article you can find answers to the following questions:

- Inverter classes are household, professional and industrial.

- How to choose a household inverter? General principles.

- Will the inverter work on your power grid?

- Popular brands and brands - which are better and why, examples.

- Why is it profitable to buy an inverter in?

- Video review of popular inverter models.

In other parts of the article we will answer the questions:

How to use an inverter correctly? Popular inverters in 2019

Choosing a professional inverter.

Selection and features of the power supply network. Functional features of inverters.

• Examples of choosing a professional inverter.

A large selection of inverter welding machines (inverter rectifiers), more commonly referred to as “welding inverters,” makes the task of choosing an inverter welding machine very difficult for both novice amateur welders and experienced suppliers and experienced specialists. On our website, in the Welding Inverters section, there are no less than 80 different models, and this is far from the limit.

Before you start choosing a welding inverter, determine the class of the device.

Choosing a welding inverter for home and garden

Depending on the class, welding inverters are household, semi-professional and professional. The former are affordable and suitable for simple work and occasional use. Professional (universal) inverters are designed for many hours of daily use. The golden mean can be called semi-professional units. Today I will tell you what technical parameters deserve attention when choosing.

How to choose an inverter current welding machine for home

First of all, I advise you to select the maximum welding current (unit of measurement - Amperes, designation - Imax). The fact is that the thickness of the metal with which you can work depends on the current. Let's say, for welding a channel, angle and other ferrous metal up to 1 cm, an inverter of 160-180 A is enough.

If you have to work with a greater thickness, you need all 200 A. In everyday life, sheets thicker than 2 cm are practically not used, so a current of 250 A is clearly overkill for a summer house and at home. You shouldn’t overpay for extra power; it’s better to give this money for higher-class equipment.

The minimum current is needed when working with stainless steel and steel up to 2 mm. Usually the lower limit is 10 A, but there are examples whose minimum is rated at 30-40 A. Such units are good when there is a separate semi-automatic welding machine for thin metals.

Check the current setting. Optimal mode settings for a specific metal and electrode are provided by smooth adjustment.

How to choose a welding inverter for your home or cottage if there are dozens of brands?

Main advantages and disadvantages of the device

You should pay attention to the following advantages of the device:

- small dimensions, which makes it easy to move it over long distances without unnecessary effort;

- no difficulties in setting up and assembling;

- well suited for novice welders, as it does not require special skills to create a high-quality seam;

- can work with various types of metals;

- high performance with relatively low electrical energy consumption;

- even with voltage fluctuations, optimal stabilization of the work process is ensured;

- ensuring high-level security;

- the presence of additional functionality allows you to optimize the welding process.

Among the main disadvantages of such equipment are:

- inverter devices are afraid of metal dust, which, when ingested, causes a short circuit and failure of the board;

- operation at subzero temperatures can lead to condensation and failure

- some models cannot withstand voltage surges;

- Repairing such a product is sometimes very difficult and expensive.

If the device is of high quality, then it will last for many years without breakdowns. When deciding which inverter to choose, it is recommended to start from what it will be used for.

About categories and prices

All inverter manual arc welding machines working with consumable electrodes, designated MMA, can be divided into two large groups:

- Household - for occasional use and simple work. If you are not planning a large-scale construction project, you will need the device once every two to three months to repair something, weld something, etc., then the working life of the units of this group is sufficient. These are the cheapest of the inverter welders. They cost 3-5 thousand rubles or so, produced in China.

- Professional - for long hours of daily work. This is an option for those who will use an inverter in production or are planning large-scale construction: build a dacha or house, weld a metal fence and stairs. The cost of these units is about $300-400.

There is also an intermediate class - semi-professional. In terms of characteristics and price, they are approximately in the middle. This is a good choice for those who love to make things and also love a good tool. All gradations are very arbitrary, but if you tell the seller what class you want the device to be, he will understand you and offer several options.

There are also universal or combined welding inverters. They can weld in several modes, one of which is usually manual arc welding. These units belong to the professional class and are convenient for their versatility - some can also work as a cutter, as well as cook in an environment of inert gases, which allows you to weld thin metal and stainless steel without any problems. This equipment will be useful if you also have a car - you can do repairs yourself, as well as cook all sorts of small things around the house.

Welding generators

This is quite complex equipment that combines a generator (gasoline or diesel) and a welding power source. Moreover, welding can be done from both direct and alternating current. The equipment is already quite expensive, but it is the best option for those villages or construction sites where there is no electricity yet, or it is very unstable. If your holiday village is not yet electrified, you need a similar unit.

A welding generator is a combination of a diesel or gasoline electric generator and a welding machine

Can conventional electric welding machines be powered by a generator? They can, but if it also powers household appliances or other electrical equipment in the network, then they will have to be turned off during operation: the voltage will “jump”, which can cause them to break. There is one more point: welding machines require a generator of a simpler design (they are not so demanding on the characteristics of the power source). Because his scheme is much simpler. As a result, a welding generator costs less than an electric welding + generator pair.

If you do not have electricity, or there are significant interruptions in it, it is more profitable to buy not a welding machine for your home and/or cottage, but a welding generator.

The choice here begins with the type of generator: gasoline or diesel. Then select the type of welding power source: transformer, rectifier or inverter. Then there are the usual electric welding parameters described above.

Determining the characteristics

Choosing a price category is good, but you also need to select technical specifications. First, let's decide on the power supply. If you are choosing a unit for private use at home or in the country, most likely you will be more satisfied with power from a 220 V network. There are also welding inverters from 380 V, but it is unlikely that anyone has such sources at home. And if there is one, choose three-phase inverters. There are much fewer of them, but they also exist.

Welding current

How to choose a welding inverter based on technical characteristics? In this matter, they proceed from the products and their thickness that you plan to work with. First of all, select the maximum welding current that the unit can produce. It is designated Imax, the unit of measurement is Amperes.

There is a fairly clear relationship between the thickness of the metal you want to work with and the current that will be needed for welding. This dependence is presented in the table.

| Diameter of electrodes, mm | Metal thickness, mm | Welding current, Amps |

| 1.5 mm | 1.2 - 2.0 mm | 30 - 75 A |

| 2.0 mm | 1.5 - 3.0 mm | 40 - 100 A |

| 2.5 mm | 1.5 - 5.0 mm | 50 - 120 A |

| 3.0 mm | 2.0 - 12.0 mm | 100 - 150 A |

| 4.0 mm | 4.0 - 20, mm | 120 - 200 A |

| 5.0 mm | 10 - 40 mm | 170 - 270 A |

If you are going to weld ferrous metal (angles, channels, etc.) with a thickness of no more than 1 cm, it is enough for you that the inverter can produce 160-180 Amperes. If, at least from time to time, you have to work with greater thickness, you need a current of up to 200 Amps. Sheets of iron thicker than 2 cm are not used anywhere in everyday life, so 220-250 Amps for a home or cottage is clearly too much. It’s hardly worth overpaying for unnecessary power; then it’s better to spend the money on purchasing a unit of a higher class (or on a good chameleon mask, without which it will be difficult for a novice welder).

In addition to the welding inverter, you will also need protective gloves and a welder’s mask

The minimum current Imin is needed when welding thin metals with an inverter. If you need to weld steel or stainless steel up to 2 mm thick, you will need to heat the parts being welded as little as possible. This is where the minimum current is needed. As a rule, the lower limit of adjustment is 10 A, but there are units on which you cannot set it to less than 30-40 A. They are good for those cases if you have special equipment for “delicate” operations (for example, a semi-automatic welding machine).

The organization of current regulation is also important. It can be stepped or smooth. Continuous adjustment is better - it allows you to more accurately select the operating mode for each metal and electrode.

Open circuit voltage

This characteristic is measured with the equipment turned on and no load. Denoted as Uxx, the unit of measurement is Volts (V). It determines how easily the welding arc will be ignited and how stable the arc will be. The range of values is 40-90 V. The higher the declared open circuit voltage, the easier the welding will be.

Technical characteristics of the welding inverter Fubag in 160

Supply voltage

As already mentioned, most inverters operate from a 220 V network. But on Russian networks, a more or less stable voltage is maintained only in large cities. In rural areas, a voltage of 190 V is already good. But the good thing about inverter welding machines is that they are undemanding in terms of supply voltage. They cook quietly at 180-190 V, and some models can “pull” an electrode with a 3 mm diameter even at 150 V.

If the voltage in your village is low, pay attention to this indicator. It is usually written simply as “voltage” and the minimum and maximum values are indicated through a dash: for example, 150-245 V. Sometimes you can see the following entry: 220 V +10%, -30%. This means that the device will cook normally if the supply voltage is in the range from 154 V to 244 V (220 V - 30% = 154 V, and 220 V + 10% = 244 V).

Maximum current operating mode

If you have to work at the maximum possible current, then the unit will have to be given time to cool down. That is, cook for a while, rest for a while. These intervals are counted for 10 minutes, designated in the technical data as “DC at maximum current”, measured as a percentage - %.

For example, if the characteristic specifies the PV at a maximum current of 40%, this means that out of 10 minutes you can cook 4, and 6 you will wait until the device cools down. At least 50-60% are considered normal characteristics, 70% and above are considered good.

Technical characteristics of inverter welding TORUS-165 MASTER (Torus 165 Master)

Please note that this requirement only applies to the maximum current, or close to it. At medium or low currents there is no need for forced stops. You will still have to change the electrodes or position or move the part from time to time. So there will be pauses.

That's all the technical parameters that are needed. Now you know how to choose a welding inverter based on its characteristics. But that's not all. There are also additional functions. For beginners they can be very useful. And some operational issues may also influence the choice.

TIG inverters for garage

TIG welding in the garage is used for welding cracks in the oil pan (mostly aluminum), repairing alloy wheels (an alloy of aluminum with other metals), welding cracks in cylinder heads (aluminum). If you have a cutting and drilling machine, as well as a small pipe bender, then you can produce stainless steel heated towel rails in the garage.

Criterias of choice

If you are planning such work in the garage, then choose a welding inverter with TIG welding according to the following parameters:

- Current strength. To weld a car tray or heated towel rails, an inverter with a maximum current of 160 A is enough. There, in general, all work is carried out at 50-60 A. But deep boiling of a cylinder head or wheel rim will only be possible with a machine at 200-300 A.

- Supply voltage. Incoming voltage affects power. 220 V models are suitable for welding metal with a thickness of 1.5-5 mm. Next, I advise you to look towards 380 V TIG inverters.

- Maximum diameter of tungsten electrode. A 1.6 mm needle will “take” thin metal, and the seam will be narrow and neat, and for welding car rims, look for models with a tungsten electrode diameter of 3.2-4 mm.

- Length of the burner cable channel. When working at a workbench, a hose length of 4 m is sufficient. If you have to cook a large stainless steel structure with argon, it is better to buy an 8 m burner.

- Type of transistors. The inverter can be one of two types - MOSFET and IGBT. The second one produces increased power and I recommend buying equipment with such transistors for welding wheel rims.

- Possibility of welding on alternating current. If you are going to weld stainless steel, then this function is not needed, but for alloy wheels, cylinder head and oil pans you can’t do without it.

TOP 5 TIG inverters for the garage

As usual, TOP from me, making it easier for you to choose the best welding machine for the garage:

- PTK Master TIG 200 D90 is a simple and inexpensive model with non-contact arc excitation.

- Svarog PRO TIG 200 P DSP (W212) - this already has a pulse mode and more subtle settings.

- PTK Master TIG 200 P AC/DC D92 is the most affordable device with an alternating current welding mode. I recommend it for working with aluminum in the garage.

- Fubag INTIG 200 AC/DC Pulse is a cool model with alternating and direct current, pulse welding. Very convenient control.

- Svarog TECH TIG 315 P DSP AC/DC (E106) - inverter with power supply from 380 V, alternating current, memory for 30 types of settings. An excellent choice for welding alloy wheels and other aluminum repair work.

Additional functions of inverter welding machines

The presence or absence of service functions is not critical, but it makes life a lot easier, especially for a beginner. Their set is usually standard:

- “Hot start” HOT START - affects the ignition of the arc. When igniting, an additional impulse is given, which makes it easy to start welding.

- “Arc Force” - ARC FORCE - when the electrode suddenly approaches the metal, the welding current automatically increases. This prevents the electrode from sticking.

- “Anti-stick” - ANTI STICK - turns off the power when the electrode gets stuck, turns it on after it comes off. A convenient function, especially relevant for novice welders.

There are some other useful features. For example, indication and automatic shutdown when overheating. This is a useful addition - it is not always possible to keep track of the time or the overheating indicator. Automatic shutdown saves you from burnout and expensive repairs.

A welding machine for manual electric arc welding allows you to weld almost all metals, except non-ferrous ones

Pay attention to the package: in addition to the welding machine, there is usually a power cable (sometimes it is removable, sometimes it is stationary), two welding cables - one with a clamp for attaching to the part, the second with an electrode holder. It is better if the cables are light, flexible and long. But such luxury is not always available. More often, working cables are about 2 meters long, which is not always convenient. When looking at the cables, pay attention to how they are terminated, soldered (preferably) or clamped/rolled.

Pay attention to the warranty period, as well as how close the nearest service center is to your home/dacha. The lack of a service network is an alarming sign. This means that even if there is a warranty breakdown, you will have to repair it yourself, for money. You won’t send your device for repairs across half of our rather large country...

How does the device work?

Welding transformers are already fading into the background. With the advent of inverters, welding metal structures has become much easier. Their design is simple and lightweight. The equipment itself can be easily placed in a small bag or car for transportation, for example, to the country. At the same time, learning the welding process using an inverter is much easier than using a transformer. This device does not require such effort and special training.

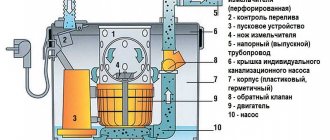

Before starting work, it is recommended to understand the basic principles of operation of this equipment. The operating principle consists of several stages of converting electric current using an inverter type. The basic process is as follows:

- Electrical alternating current from the main network is converted into direct current while passing through the spiral, which allows the arc to be stabilized.

- Direct current is again converted to alternating current. At the same time, its frequency increases several times.

- After this, the voltage level of the electric current is reduced to the most optimal value. As a result, it is possible to achieve the maximum current value.

- After this, the voltage level in the network is rectified.

This principle of operation allows the conversion units to be significantly smaller than those of transformers, which is convenient for a novice welder. Due to this design, the dimensions of all equipment are quite small, which makes it easy to buy such a device for a summer residence and use it at home.

In order to start welding work, it is necessary to connect the electrode holder to the electrode, and the ground clamp to the structure to be welded. Then touch the electrode to the part, which will lead to an electrical short circuit and the formation of an arc for welding. When the electrode melts, the coating on its surface burns and protects the weld pool from oxygen. This discharge will generate enough heat to melt any metals, and the thickness will depend on the strength of the welding current.

The electrode must be held at a distance of several millimeters from the surface to be treated. As a result of high temperatures, the welded part and the rod begin to melt at the point where the electric arc passes and are combined into a monolithic structure. The joint can be easily identified by the weld seam, from which the slag will need to be removed after work. If you want to get an aesthetically beautiful part, the seam itself should be processed with a grinder.

If you follow all the rules of welding, the weld should not differ significantly from the original structure of the metal. In some cases, it is possible to achieve a more effective result. Let's consider which welding machine is better to choose. To do this, it is recommended to study the pros and cons of the device.

How to choose a welding inverter manufacturer

Now you know how to choose a welding inverter based on technical characteristics. The most difficult task remains: choosing the brand of the device, or rather, the manufacturer.

Chinese welding machines or?

In the category of household welding inverters, almost all units come from China. There are brands that are completely unknown to anyone, and there are brands that have been working for years and have earned a certain authority. Well-known Chinese brands are, as a rule, equipment produced by reputable factories equipped with modern equipment.

The “owners” of the brand are Europeans, Americans and even Russians, and production facilities are located in China. This scheme has long been worked out and is well known. That’s why recently even two lines have appeared in the descriptions of devices: “homeland of the brand” and “country of manufacture.” To call these inverters “Chinese” is not entirely correct, but they were manufactured there. In general, it's up to you.

Chinese inverter welding machines known on the market do not have the lowest prices. But they have been tested, and most of them have a network of service workshops or a repair contract with one of the similar services. Here are a few brands that have mostly good reviews:

- Welding inverters Resanta. The homeland of the brand is Latvia, the manufacturer is China. There are three lines: SAI - models with a maximum welding current from 140 A to 250 A, supply voltage from 170 V to 250 V. Price from 6.5 thousand rubles for SAI 140, up to 14 thousand rubles. for the 250 amp model.

- SAI PN - models operating at reduced voltage - from 150 V. Price from 11 thousand rubles. for a 160-amp unit, up to 18-19 thousand rubles for a power of 250 amperes.

- SAI K are compact models that have less weight and dimensions, and have the same characteristics as SAI. Priced from 7.3 thousand rubles for a 160-amp device, up to 12 thousand rubles for 250 A. Resanta welding inverters of the SAI, PN (reduced voltage) and K (compact) lines (To increase the size of the picture, right-click on it )

- Household models ARS 165, ARS 205;

- Welding inverters Fubag (Fubag), the homeland of the brand is Germany, the manufacturer is China or France. The IN series is assembled in France, and the IR series in China. Permissible deviation in supply voltage 220 V +/- 15% (190 - 250 V). The Fubag IN series of welders can operate in MMA and TIG modes (welding in an argon environment; the TIG mode requires a special set of equipment - purchased additionally). Price from 11.8 thousand rubles for a device with a capacity of 16 Amperes, up to 18 thousand rubles. for a power of 220 amperes.

- The IR series of inverter welding machines is MMA welding only and has anti-stick and hot start functions. Price from 7 thousand rubles. for 160 ampere and up to 9.5 thousand rubles for 220 ampere.

- Another representative of Russian inverters produced in China is the Kedr inverter welding machines. “Cedar MMA” series - work only with consumable electrodes. There is a “hot start” and “anti-stick” function. Prices from 7.5 thousand rubles. for the lowest power (170 Amperes) and up to 9.5 thousand rubles. for a 220 Ampere unit.

- The “Cedar ARC” series is a professional series of units, they also have an arc stabilization function, the price starts from 10.5 thousand rubles for a unit with a capacity of 160 amperes, and up to 28 thousand rubles for a 400 ampere unit.

- Interskol inverter welding machines. This is another brand originally from Russia that produces equipment in China. Feature of the package: the power plug is not included in the package. It is stated that the device operates with a power supply from 140 to 240 V. There are two lines: “Interskol ISA, for MMA (manual electric arc welding with a consumable electrode). Prices from 6.5 thousand rubles. for a device delivering 160 amperes, up to 10 thousand rubles. for a power of 250 amperes.

- Intersokl ISP series - in addition to MMA welding, it can work in MIG/MAG mode (in an environment of inert or shielding gases). The price for ISP 160 amperes is 19 thousand rubles, for ISP 200 amperes - 21 thousand rubles.

- FoxWeld welding inverters are made in China. Good characteristics, wide choice. There are several lines of budget welders for dachas that operate at reduced voltage. FoxWeld Summer resident - price from 7.2 thousand rubles for a 160 A unit. A digital display with large numbers makes it easier to perceive information. Supply voltage is 180-240 V, although not the best performance at maximum current: PV 40%. Open circuit voltage 56 V.

- FoxWeld Corundum - With generally similar characteristics, it has the best current-voltage characteristic: open circuit voltage 78 V.

- FoxWeld Master can work with a argon arc welding kit. PV at maximum current is even lower: 35%. There are functions of “hot start” and “anti-sticking”, arc forced.

The best welding machines for manual arc welding

An inverter device is the optimal choice for a subsidiary farm. They are inexpensive, compact and easy to use. Even a layman, after burning a couple of dozen electrodes, will be able to weld simple structures from a profile pipe and corners. They differ from each other only in peak current, maximum electrode diameter (4 or 5 mm) and additional options such as anti-sticking.

1

Fubag IR 200 (MMA)

Rating:5.0

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 200 A (MMA)

- power: 6.50 kVA / 8.10 kW

- electrode diameter: 1.60-5mm

Average price: RUB 8,530

Compact, internationally awarded design for work in hard-to-reach places. The shape of the case with ribs and the weight allow you to hold the device with one hand. It gets ready for use quickly – thanks to the bayonet connectors, the wires are connected in 10 seconds. The handle smoothly regulates the current with an accuracy of several A. It is capable of working properly in low voltage networks - from 150 V and welding parts up to 8 mm thick.

Peculiarities:

- anti-sticking, hot start and arc forcing functions;

- work with electrodes 1.6-5 mm;

- one-handed design;

- work in low voltage conditions;

- indication of overheating and switching on.

2

Wester MINI 200T (MMA)

Rating:4.9

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 200 A (MMA)

- electrode diameter: 1.60-5mm

- anti-stick

Average price: RUB 7,299

It is used for connecting non-ferrous and ferrous metals at voltages starting from 150 V. It is not afraid of voltage surges up to 255 V. A stepless current regulator allows you to adapt the arc to work with different metals of different thicknesses. Compatible with electrodes with a thickness of 1.6 to 5 mm - you can weld sheet steel and cut thick-walled profiles. Operating temperature starts from -100 C – can be used outdoors and in unheated rooms in winter. The 60% duty cycle becomes 100% when the current is reduced to 140 A.

Peculiarities:

- anti-stick electrode option;

- hot start function;

- degree of protection IP 21;

- overheat protection;

- wide operating voltage range.

3

KRÜGER WIK-300A

Rating:4.8

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 300 A (MMA)

- power: 5 kW

- electrode diameter: 1.60-6mm

- anti-stick

- arc forcing

- hot start

Average price: 6,990 rub.

The Kruger WIK-300A inverter welding machine is designed for manual arc welding in domestic and professional conditions. In field conditions it runs on a generator. A powerful fan is provided to prevent engine overheating. There is an electronic display for controlling the operating parameters of the device, a current regulator within the range of 20-300 A. The Kruger device is also equipped with a temperature sensor that automatically turns off the motor when overloaded.

Peculiarities:

- hot start option;

- simple arc ignition;

- ease of transportation due to low weight of 3.6 kg;

- operation from a generator;

- acceptable price;

- protection against overloads and overheating.

4

RESANTA SAI-190 (MMA)

Rating:4.8

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 190 A (MMA)

- power: 5.50 kW

- electrode diameter: 5 mm

Average price: RUB 7,290

Budget inverter with a turn-on time at peak load of 7 minutes. For a beginner, it supports anti-sticking - when the electrode sticks to the workpiece, no power is supplied, making it easy to tear it off, and auto-increasing current to ignite the arc. There is a power and overheat indicator on the front panel. Heating is controlled by a temperature sensor, which extends the life of the device.

Peculiarities:

- duty cycle – 70%;

- ease of ignition of the electrode;

- preventing electronics from overheating;

- wide operating voltage range;

- adjustable arc force.

5

BISON MASTER MMA SA-190K (MMA)

Rating:4.7

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 190 A (MMA)

- power: 5.40 kVA

- electrode diameter: 1.60-4mm

Average price: RUB 5,610

An inverter for the garden and home, welding with refractory electrodes with a variety of coatings. A microprocessor with electronics allows you to adapt to any conditions, adjusting the current in the range of 20-190 A. Assembled with fewer components than competitors, which reduces the likelihood of breakdown. The temperature sensor monitors the temperature of the power elements, preventing them from overheating and failure. The boards are protected from dust by high-temperature varnish. A large fan and perforations in the case increase the efficiency of heat transfer.

Peculiarities:

- quick start function;

- simplified arc ignition;

- anti-stick electrode;

- possibility of power supply from a generator in field conditions;

- protection against overloads and overheating.

6

Sibrtech IDS-190 (MMA)

Rating:4.6

- welding inverter

- manual arc welding MMA

- Max. welding current: 190 A (MMA)

- electrode diameter: 1.60-4mm

- anti-stick

Average price: RUB 4,950

Domestic welding inverter for home, workshop and garage. It is characterized by high performance - on time - 80% and arc stability during voltage sags or surges. It is equipped with a knob for smoothly adjusting the current within the range of 40-190 A, which is enough to operate electrodes with a diameter of up to 4 mm. The indicator panel is represented by three LEDs that indicate power supply, overheating and overload. Electronics will prevent excessive heat and heavy loads.

Peculiarities:

- IP 21 protection;

- working cycle – 8 minutes;

- operation at unstable voltage;

- options Arc Force, Hot Start, Anti Stick.

7

CALIBER MICRO SVI-205 (MMA)

Rating:4.5

- NAKS certificate: no

- welding inverter

- manual arc welding MMA

- Max. welding current: 205 A (MMA)

- power: 3.60 kW

- electrode diameter: 1.60-5mm

Average price: 4,500 rub.

A small-sized inverter for working with metals up to 6-7 mm thick, which will not take up much space in the trunk or on a workshop shelf. It features an updated design and electronic components that have reduced weight and improved performance. The carrying strap and low weight allow you to work with the device on your shoulder while standing on a ladder. Stably ignites and maintains an arc, regardless of the magnitude of the incoming voltage. It has all the advantages of massive devices: voltage stabilization, easier arc ignition, prevention of electrode sticking.

Peculiarities:

- compact dimensions;

- welding with 4 mm electrodes;

- overload prevention;

- Duration of activation is 5 minutes.

Voltage level

The device can connect to the following networks:

- 220 V – usually used purely for domestic purposes;

- 380 V - suitable for those who have a three-phase current supply system - this is extremely rare in apartments or houses;

- mixed type - works on a 220 or 380 V network, which depends on the conditions of use.

It is also important to consider the stability of the voltage level. If there are frequent fluctuations in electrical current, even the most powerful equipment will constantly turn off. If you know that your network is unstable, it is recommended to buy less powerful devices.

Maximum and minimum current for welding

The higher the welding current, the easier it will be to process even thick sheets of metal. For home use, you should not buy overly powerful units. You simply cannot connect them to the network. If you select an insufficient current level, you risk not processing the metal sheets that you need.

Most modern single-phase devices are designed for a current of 200-250 A. The question arises, which welding machine is easier to work with. It all depends on what you are going to process. For a summer residence, a current exceeding 180A is rarely needed

It is important to look not only at the maximum value, but also at the minimum, since the device will also be used for welding thin metal layers. For various types of activities, you will need a device with a wide range of operating current.

The current strength can be adjusted in the following ways:

- smoothly - allows you to adjust the parameters to the slightest value, which will provide the opportunity to make a high-quality seam;

- stepwise - usually set in a certain step, so the quality of welding is significantly lower than in the previous version.

Service

Knowing how to operate a welding machine is key. But it is also important to understand how to take care of it. Inverter chips are hypersensitive to dust, so they need to be constantly cleaned.

There is no need to do this yourself, as you may damage the contacts inside the device. Yes, qualified craftsmen do the cleaning themselves, but a beginner cannot handle it.

About once a month, take the inverter to a service center to a technician - this will give you peace of mind. In workshops, dust is removed from devices using compressed air and microtubes; not everyone has such tools.

Check cables for integrity and kinks. Damage to the network cable is especially dangerous - the one through which the inverter is connected to the power source (generator or network).

Change the cables at least once a month, as new ones will always work properly, and if they break, you will know that the problem is not with them.