Standards

| Name | Code | Standards |

| Long and shaped rolled products | B22 | GOST 1133-71, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006 |

| Sheets and strips | B23 | GOST 19903-74, GOST 19904-90, GOST 103-2006, GOST 19903-90 |

| Metal forming. Forgings | B03 | GOST 25054-81, OST 108.109.01-92, OST 5R.9125-84, TU 108.11.894-87, TU 108.11.930-87, TU 0893-022-00212179-2004, TU 05764417-023-94, TU 108.11.917-87, ST TsKBA 010-2004 |

| Sheets and strips | B33 | GOST 4405-75, GOST 5582-75, GOST 7350-77, GOST 10885-85, GOST R 51393-99, TU 108-1151-82, TU 108.11.906-87, TU 108-930-80, TU 14- 105-451-86, TU 14-1-2542-78, TU 14-1-3199-81, TU 14-1-3874-84, TU 14-1-394-72, TU 14-1-4114-86 , TU 14-1-4364-87, TU 14-1-4780-90, TU 14-1-5040-91, TU 14-1-5041-91, TU 14-1-3485-82, TU 05764417-038 -95, TU 05764417-048-96, TU 0900-005-05764417-99, TU 5.961-11823-2003 |

| Ribbons | B34 | GOST 4986-79, TU 14-1-1370-75, TU 14-1-4606-89 |

| Classification, nomenclature and general norms | B30 | GOST 5632-72 |

| Long and shaped rolled products | B32 | GOST 5949-75, GOST 7417-75, GOST 8559-75, GOST 8560-78, GOST 14955-77, GOST 18907-73, TU 14-1-686-88, TU 14-1-2787-79, TU 14 -1-3564-83, TU 14-1-3581-83, TU 14-1-5039-91, TU 14-1-748-73, TU 14-11-245-88, TU 14-1-2787- 2004, TU 14-131-1110-2013, TU 14-1-1271-75 |

| Steel pipes and connecting parts for them | B62 | GOST 9940-81, GOST 9941-81, GOST 10498-82, GOST 11068-81, GOST 14162-79, GOST 19277-73, GOST 24030-80, TU 14-159-165-87, TU 14-3-1070 -81, TU 14-3-1109-82, TU 14-3-1306-85, TU 14-3-1391-85, TU 14-3-197-89, TU 14-3-308-74, TU 14 -3-451-75, TU 14-3-561-77, TU 14-3-760-78, TU 14-3-761-78, TU 14-3-769-78, TU 14-3-935- 80, TU 1380-001-08620133-93, TU 14-159-249-94, TU 14-3R-197-2001, TU 14-159-259-95, TU 108-713-77, TU 1380-001- 08620133-05, TU 14-158-135-2003, TU 14-3Р-110-2009, TU 14-3Р-115-2010, TU 14-131-880-97, TU 14-225-25-97, TU 14-158-137-2003, TU 95.349-2000, TU 14-3-1654-89 |

| Blanks. Blanks. Slabs | B31 | OST 3-1686-90, OST 95-29-72, TU 3-1083-83, TU 108.668-86, TU 14-105-495-87, TU 14-132-138-86, TU 14-132-163 -86, TU 14-1-3844-84, TU 14-1-3845-84, TU 14-1-565-84, TU 14-1-632-73, TU 14-1-685-88, TU 14 -1-790-73, TU 14-133-139-82, TU 14-133-177-94, TU 08.001.05015348-92, TU 14-3-770-78, TU 14-1-2583-78, TU 108-11-223-77, TU 14-1-3129-81 |

| Welding and cutting of metals. Soldering, riveting | B05 | OST 95 10441-2002, OST 24.125.02-89 |

| Thermal and thermochemical processing of metals | B04 | STP 26.260.484-2004, ST TsKBA 016-2005 |

| Sheets and strips | B53 | TU 1-9-637-74 |

Mechanical properties of the alloy

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Cold-deformed pipes, GOST 9941-81 | 549 | 37 | ||||||

| Pipes, GOST 10498-82 | 529 | 40 | ||||||

| Pipes, GOST 11068-81 | 530 | 216 | 37 | |||||

| Hot-deformed pipes, GOST 9940-81 | 510 | 40 | ||||||

| Rod, GOST 5949-75 | Ø 60 | 490 | 196 | 40 | 55 | Quenching 1020 - 1100oC, Air cooling, | ||

| The rod is cold-worked, GOST 18907-73 | 880-930 | |||||||

| The wire is annealed. | Ø 8 | 1400-1600 | 20 | |||||

| Forgings, GOST 25054-81 | 490 | 196 | 35-38 | 40-52 | ||||

| Thick sheet, GOST 7350-77 | 510 | 205 | 43 | Quenching 1030 - 1080oC, Air cooling, | ||||

| Thin sheet, GOST 5582-75 | 530 | 205 | 40 | Quenching 1050 - 1080oC, Cooling water, |

What is unique about stainless steels?

Stainless steel was patented in England in 1913. The author of this invention, which, without exaggeration, became the most important stage in the development of not only steel, but also other industries, is metallurgist Harry Brearley.

The addition of an element such as chromium to their chemical composition made it possible to endow ordinary steel alloys with unique characteristics and obtain corrosion-resistant steels from them.

It is chromium, which must be at least 10.5% in stainless steel alloys, that provides these materials with such characteristics as:

- exceptionally high corrosion resistance;

- very high strength;

- good weldability;

- ease of processing using cold deformation methods;

- long service life without loss of original characteristics;

- aesthetically attractive appearance of products made from alloys of this category.

Influence of alloying elements on the properties of steels

Stainless steels necessarily contain chromium and iron in their chemical composition. These elements complement each other, which is what gives these materials such unique characteristics. In particular, chromium, combining with oxygen, creates an oxide film on the surface of the stainless alloy, which becomes a reliable obstacle to corrosion processes.

In order to provide stainless steel with additional characteristics and significantly improve existing properties, alloying additives are introduced into its chemical composition - nickel, titanium, molybdenum, niobium, cobalt, etc. This alloying makes it possible to create various types of stainless steel alloys that differ from each other their characteristics and, accordingly, purpose.

We are already so accustomed to corrosion-resistant steel that we don’t even notice how much more comfortable our lives have become due to the presence of stainless steel in it.

Stainless steel contains carbon in its chemical composition, which gives it high hardness and strength. It should be noted that this chemical element is an essential component of any steel alloy and has a serious impact on its properties.

The unique characteristics of stainless steel make it possible to successfully use this metal in a variety of areas related to the operation of products and equipment in conditions of high humidity and constant exposure to aggressive environments. Stainless steels are actively used for the production of products for both industrial and household purposes. In particular, it is from this metal that cutlery and knives are most often made, elements of communications and enclosing structures, equipment parts, etc.

Chemical composition

Steel is an alloy of carbon and iron, in which the iron atoms are located in a crystal lattice, and the remaining elements, depending on their size and behavior, change it. In terms of carbon concentration, steel 08Х18Н10Т is a highly alloyed carbon alloy. Where the main alloying elements are chromium, nickel and titanium.

The basic rule of metallurgy on which changes in strength are based is: “Distortion of the structural lattice increases strength.” Thus, a carbon atom, which has a size much smaller than an iron atom, penetrates into the crystal lattice and distorts it, giving it strength. Other elements that can replace iron atoms and exhibit properties characteristic of each of them also merge in the same way.

Chrome is the hardest metal in existence. At a concentration of more than 13% it imparts corrosion resistance. How does this happen. By reacting with an oxygen atom, chromium creates an oxide film only a few atoms in size. The oxides are not much larger in size than the chromium atom itself (unlike iron oxides, which have a 3-volume), so it creates a dense shell on the surface itself, preventing the penetration of oxygen and other gases. This protection works even when heated. If such a film is scratched, new oxides immediately form in its place. This process is called patenting.

In difficult temperature operating conditions, where steel experiences constant temperature loads, chromium carbides are formed along the grain boundaries, which leads to the destruction of the metal, i.e. intergranular corrosion. To eliminate this process, nickel is added to the alloy, which is an austenite stabilizer, preserving this structure at room temperature (for comparison: in conventional carbon steels, the temperature of transformation of austenite into more stable structures is 650-750 ºC).

Titanium is added to the alloy in an amount of 0.6% and contributes to the stability of 08Х18Н10Т in aggressive environments.

Types of stainless steel and its classification

The entire variety of anti-corrosion steel types is divided into 5 large groups. The basis for this division is the microstructure of the material. Of these, representatives of the following 3 groups are most often found:

- Martensitic steel is distinguished by the letter “C” in the marking. It acquires its properties not only due to its composition, but also as a result of hardening and tempering. Applicable in the production of cutlery and cutting tools. Slightly magnetized, has increased hardness.

- Ferritic alloy is softer than martensitic alloy. Also endowed with magnetic properties. Its designation contains the letter “F”.

- Austenitic steel, containing 15-20% Cr and 5-15% Ni, is not magnetized and has the highest resistance to corrosion. Denoted by the letter "A". Steel grades from this group are most common in industrial production, as well as in the manufacture of hardware and fastening devices.

In turn, austenitic alloys are divided into 5 classes, additionally indicated by a digital value:

- A1 is the least resistant to corrosion due to the sulfur contained in the chemical composition. Used for the manufacture of parts for mechanical and moving units.

- A2 is steel that is resistant to moisture, but is not suitable for work in environments containing acids, alkalis, chlorine and salts. Ecologically harmless, not magnetized, not subject to hardening. Excellent for the manufacture of all types of fasteners intended for use in non-aggressive conditions.

- A3 - similar in properties to class A2 steel. However, this metal better resists corrosion in high-temperature environments, due to the stabilization of the alloy with niobium, titanium or tantalum.

- A4 - differs from A2 steel in the presence of molybdenum in an amount of 2-3%. This small additive gives the metal high resistance to acids, alkalis, and salts. Can operate in low temperatures, down to -60°C. A4 fasteners are intended for the construction of bridges and coastal structures. It is used in shipbuilding, chemical and oil and gas enterprises.

- A5 is steel stabilized with titanium, which makes it highly resistant to corrosion at high temperatures. Other technical characteristics are similar to class A4.

In different countries, fasteners are produced according to different standards. In Russia these are GOST standards, in Germany – DIN, in the USA – AISI, in Europe – EN and international ISO. Many fasteners manufactured according to the standards of different countries are considered analogues. However, this is not entirely correct, since small differences still exist, if only due to the inconsistency of measurement systems. Therefore, it is better to entrust the replacement of fasteners when assembling structures that differ from those indicated in the drawings to specialists.

Characteristics of steel grade 08Х18Н10Т

| Standard | GOST 5949-75 - Graded and calibrated steel, corrosion-resistant, heat-resistant and heat-resistant. Specifications | |

| Application | Welded equipment operating in highly aggressive environments, heat exchangers, muffles, pipes, furnace fittings, electrodes of spark plugs; austenitic steel | |

Steel 08Х18Н10Т

belongs to the class of alloyed, corrosion-resistant, heat-resistant steels of the austenitic group.

Supplied in the form of long products and sheets, calibrated rods and forged blanks.

History of discovery

Today it is difficult to imagine a world without numerous inventions. Many of them were made by accident. This is how stainless steel appeared. The first historical mention of this metal can be found in the records of Harry Brierley. This metallurgist researcher in 1912 took an order from one of the weapons companies to find an effective way to extend the service life of gun barrels. The practitioner began to work in his usual style - he began mixing different components. The man tested the finished alloys for heat resistance and durability. If the indicators were low, the blanks were sent to a landfill. One of the details stood out among all with its brilliance. After a detailed study of the analysis, scientists found that the alloy consists of several elements:

- iron - 85.3%;

- chromium - 12.8%;

- manganese - 0.44%;

- carbon - 0.24%;

- silicon - 0.2%.

Not all researchers give the lead in the discovery of the stainless flock to Harry Brierley. Some believe that stainless steel was discovered by Pierre Berthier, a French mining engineer. He discovered that certain compounds of iron and chromium, which can be found in nature, stand out for their high acid resistance. He was the first to suggest making dishes and cutlery from them.

General information

Purpose

Welded equipment operating in highly aggressive environments (solutions of nitric, acetic acids, solutions of alkalis and salts), heat exchangers, muffles, pipes, furnace fittings, electrodes of spark plugs. Corrosion-resistant and heat-resistant austenitic steel.

Structure

The microstructure of this grade of steel in the hardened state is austenite. After this steel is heated to 450-850°C, chromium carbide begins to precipitate at the boundaries of austenite grains. When heated, this steel tends to create intergranular corrosion, and the ductile properties of the material also decrease slightly. After hardening, this grade of steel becomes more resistant to intergranular corrosion. This steel is non-magnetic. Scale is formed in air at temperatures exceeding 850 °C. It is recommended to operate this steel at a temperature of 800°C.

Chemical composition in % of steel 08Х18Н10Т

| C | Si | Mn | P | S | Cr | Mo | Ni | V | Ti | Cu | W | Fe |

| <0,08 | <0,8 | <2,0 | <0,035 | <0,02 | 17,0-19,0 | <0,3 | 9,0-11,0 | <0,2 | <0,7 | <0,4 | <0,2 | Rest |

The chemical composition is the main thing on which the characteristics of steel 08Х18Н10Т depend.

The main element in the alloy is carbon, its content in this steel is 0.08%. To improve performance properties, chromium is added to the alloy - from 17 to 19%. The percentage of nickel is 9–11%. The alloy of this steel contains silicon, manganese and molybdenum in small concentrations - up to 0.9%. Titanium in an amount of 0.7% significantly changes the properties of steel 08Х18Н10Т.

The influence of chemical composition on the properties of steel

All properties of steel 08Х18Н10Т depend on the introduction of a sufficiently large percentage of chromium and nickel into the alloy. It should be taken into account that a high concentration of chromium significantly increases corrosion resistance. A large percentage of nickel has a negative impact on performance characteristics. Carbon, which is the main element, at low content can worsen hardness and strength, but increase weldability.

Mechanical properties

Impact strength of steel as delivered

| Assortment | Heat treatment | Index | Т= +20 °С | Т= -25 °С |

| Bar | Quenching at 1050 °C, water | KCV, J/cm2 | 216 | 181 |

| Bar | Quenching at 1050 °C, water | KCV, J/cm2 | 167 | 147 |

Mechanical properties in long-term strength tests

| Test temperature, °C | Creep limit, MPa | Creep rate %/hour | Long-term strength limit, MPa | Test duration, hours |

| 600 | 74 | 1/100000 | 147 | 10000 |

| — | — | — | 108 | 100000 |

| 650 | 29 — 39 | 1/100000 | 78 — 98 | 10000 |

Mechanical properties of steel at elevated temperatures

| Test temperature, °C | Yield strength, σ0.2, MPa | Tensile strength, σв, MPa | Elongation at break, δ5, % | Relative narrowing, ψ, % | Impact strength KCU at 20°C, J/cm2 |

| 20 | 275 | 610 | 41 | 63 | 245 |

| 300 | 200 | 450 | 31 | 65 | — |

| 400 | 175 | 440 | 31 | 65 | 313 |

| 500 | 175 | 440 | 29 | 65 | 363 |

| 600 | 175 | 390 | 25 | 61 | 353 |

| 700 | 160 | 270 | 26 | 59 | 333 |

Corrosion resistance of steel 08Х18Н10Т

According to GOST 7350-77, GOST 5582-72, GOST 4986-79, steel 08Х18Н10Т should not be prone to intergranular corrosion when tested using the AM and AMU methods GOST 6032-89 with a holding time in control solutions of 24 and 8 hours, respectively. Tests carried out on samples after provoking heating at 650 °C for 1 hour.

Technological properties

| Forging temperature |

| Start 1220, end 900. Sections up to 300 mm are cooled in air. |

| Weldability |

| welding methods: RDS, ADS under submerged arc and gas shield, ArDS, KTS and EShS. |

Heat treatment

But it is not enough to obtain an alloy with a given chemical. composition, it is much more important to obtain the desired mechanical properties of the 08Х18Н10Т alloy. To obtain a stable structure and stabilize austenite in the finished product, the steel is subjected to hardening at a temperature of 1020-1100ºC followed by low-temperature tempering.

Impact strength

Impact strength, KCU, J/cm 2

| Delivery condition, heat treatment | +20 | +20 (KCV) | -25 | -25 (KCV) |

| Rod with a cross section of 12 mm. Quenching 1050 C, water. | 167 | 216 | 147 | 181 |

| Rod with a cross section of 12 mm. Quenching 1050 C, water. | 167 | 147 |

Receiving technology

When processing parts, it is important to obtain the desired mechanical properties. Their combination is obtained thanks to two components:

- chemical composition;

- thermal and/or mechanical treatment - steel 08Х18Н10Т is no exception.

Stainless steel has features that combine plasticity, which makes it possible to roll out metal with a thickness of less than 1 mm, and strength, which is sufficient for the manufacture of critical utilities and parts operating under high pressure in highly aggressive environments.

Steel marking 08Х18Н10Т

Explanation:

“08” indicates a carbon content of up to 0.08%, “X18” indicates the introduction of chromium into the alloy in an amount of 18%, “H10” indicates a nickel content of up to 10%, the letter “T” at the end of the marking indicates the titanium content in the amount of up to 1.0%. Decoding 08Х18Н10Т fully reveals the main indicators of steel.

At the beginning of the alloy steel grade there may also be additional designations:

R - high-speed;

Ш - ball bearing;

A - automatic (do not confuse with the letter A at the end of the name, which indicates the purity of the steel!);

E - electrical.

It is also worth noting some features of these subtypes of alloy steels:

- in ball bearing steels, the chromium content is indicated in tenths of a percent (for example, ShKh4 steel contains 0.4% chromium);

- in grades of high-speed steel, after the letter P there is immediately a number indicating the tungsten content as a percentage. Also, all high-speed steels contain 4% chromium (X).

To show the method of steel deoxidation, there are special letter designations:

- sp - mild steel;

- ps - semi-quiet steel;

- kp - boiling steel.

Now let’s take a closer look at how to decipher the grade of non-alloy steel, which is divided into ordinary and high-quality.

Ordinary unalloyed steel (St3, St3kp) has the letters St at the very beginning. This is followed by numbers indicating the carbon content in steel in tenths of a percent. At the end there may be special indices: for example, St3kp steel belongs to the boiling category, as indicated by the letters kp at the very end. The absence of an index means that this steel is calm. When it is necessary to reflect the guarantee of weldability in the marking, the lowercase letters St. are added at the end. For example: St3st.

High-quality unalloyed steel (St10, St30, St20, St45) contains a two-digit number in the marking, indicating the average carbon content in the steel in hundredths of a percent. Thus, steel grade St10 contains 0.1% carbon; St30 has 0.3% carbon; St20 - 0.2%; St45 contains 0.45% carbon.

Structural low-alloy steel 09G2S contains the following chemical elements: 0.09% carbon, 2% manganese and a small amount of silicon (approximately 1%).

Steels 10KhSND and 15KhSND differ only in different carbon content: 0.1% and 0.15%, respectively. There is very little chromium (X), silicon (C), nickel (H) and copper (D) here (up to 1-1.5%), so numbers are not placed after the letter.

High-quality steels are used for the production of steam boilers and high-pressure vessels. Their markings have the letter K at the end: 20K, 30K, 22K.

If the steel is structural casting, then the letter L is placed at the end of the marking. For example: 40ХЛ, 35ХЛ.

Non-alloy tool steels are designated by the letter U. This is followed by a number expressing the average carbon content in the steel: U10, U7, U8. If the steel is also high-quality, this is also noted in the marking: U8A, U10A, U12A. If it is necessary to emphasize the increased manganese content, an additional letter G is used. For example, there are U8GA and U10GA steels.

Tool alloy steels have the same designation as structural alloy steels. For example, the HVG brand indicates the presence of three main alloying elements: chromium (X), tungsten (B) and manganese (G). The carbon content here is approximately 1%, and therefore the number is not written at the beginning of the stamp. Another type of steel, 9KhVG, has a lower carbon content compared to KhVG: here there is 0.9% carbon.

High-speed steels are marked with the letter P, followed by the tungsten content in %. Let's take steel R6M5F3 as an example. It is high-speed (P), contains 6% tungsten, 5% molybdenum (M) and 3% vanadium (F).

Unalloyed electrical steel (ARMCO) has a very low electrical resistivity. This is achieved due to the minimal amount of carbon in the composition (less than 0.04%). Such steel is also commonly called technically pure iron. The marking of electrical non-alloy steels consists only of numbers. For example: 10880, 21880, etc. Each number contains important information. The very first digit shows the type of processing: 1 - forged or hot-rolled; 2 - calibrated. The second digit indicates the presence/absence of a normalized aging coefficient: 0 - without a coefficient; 1 - with a coefficient. The third digit is the group according to the main standardized characteristic. The last two are associated with the values of the main standardized characteristic.

Structural steel is marked with the letter C, followed by the minimum yield strength of the steel. Additional designations are also used: K - increased corrosion resistance (S390K, S375K); T - heat-strengthened rolled products (S345T, S390T); D - increased copper content (S345D, S375D).

Aluminum casting alloys are designated by the letters AL at the beginning of the marking. Here are some examples: AL4, AL19, AL27.

Aluminum alloys for forging and stamping contain the letters AK, and then the conditional number of this alloy: AK6, AK5.

There are also wrought alloys containing aluminum. Avial alloy: AB, aluminum-magnesium alloy: AMg; aluminum-manganese alloy: AMts.

Now you have learned how to decipher the grade of steel containing various chemical elements. This steel marking was developed back in the USSR and is still in effect not only in the Russian Federation, but also in the CIS countries.

European steel markings are subject to the EN 100 27 standard. Japan and the United States have their own standards. There is currently no single world classification of steels.

Understanding the general rules for designating grades of unalloyed and alloyed steels, as well as by correctly deciphering steel grades, you can easily determine what kind of steel a specific part is made of. Competent employees will help you determine the required grade of steel that can withstand the required pressure and specified temperature conditions. We always have in stock (or on order) steel fittings for pipelines, bent elbows and other pipeline fittings made of various grades of steel.

An example of decoding steel grade 12Х18Н10Т

12Х18Н10Т is a popular austenitic steel, which is used in welding machines operating in dilute acid solutions, in solutions of alkalis and salts, as well as in parts operating under high pressure and in a wide temperature range. So, what do these mysterious symbols in the name mean, and how to combine them correctly?

The two numbers at the very beginning of the alloy steel grade are the average carbon content in hundredths of a percent. In our case, the carbon content is 0.12%. Sometimes, instead of two numbers, there is only one: it shows how much carbon (C) is contained in tenths of a percent. If there are no numbers at the beginning of the steel grade, this means that there is a fairly decent amount of carbon in it - from 1% and above.

The letter X and the number 18 following it indicate that this brand contains 18% chromium. Please note: the ratio of an element in fractions of a percent expresses only the first number at the beginning of the mark, and this only applies to carbon! All other numbers present in the name express the number of specific elements as a percentage.

Combination H10 follows. As you may have guessed, this is 10% nickel.

At the very end there is the letter T without any numbers. This means that the content of the element is too small to pay attention to. As a rule, about 1% (sometimes up to 1.5%). It turns out that in this grade of alloy steel the amount of titanium does not exceed 1.5%. If suddenly at the very end of the brand you find a modestly standing letter A, remember that it plays a very important role: this means high-quality steel, the content of phosphorus and sulfur in which is kept to a minimum. Two letters A at the very end (AA) indicate that this grade of steel is especially pure, i.e. there is practically no sulfur and phosphorus here.

In the course of a simple analysis of combinations of letters and numbers, we found out that the steel grade 12Х18Н10Т (structural cryogenic, austenitic class) reports the following information about itself: 0.12% carbon, 18% chromium (X), 10% nickel (N) and a small content titanium (T), not exceeding 1.5%.

The main advantages of the alloy

Stainless steel grade 08Х18Н10Т is manufactured in accordance with the requirements of GOST 5632-72. It has high ductility, allowing it to easily produce thin-walled parts. When welding, it does not require preheating and subsequent cooling of the weld. The metal can be perfectly processed using any milling equipment.

Pots, pans and other utensils can be made from it. And due to the affordable price, the cost of such dishes turns out to be very affordable.

Heat treatment

But it is not enough to obtain an alloy with a given chemical. composition, it is much more important to obtain the desired mechanical properties of the 08Х18Н10Т alloy. To obtain a stable structure and stabilize austenite in the finished product, the steel is subjected to hardening at a temperature of 1020-1100ºC followed by low-temperature tempering.

Additional advantages 08Х18Н10Т

- High ductility, which is used for the manufacture of thin-walled parts;

- Excellent weldability, which does not require heating and subsequent tempering of the weld;

- High machinability with milling tools;

- Absolute inertness to food products;

- And of course, the price, or rather the ratio of price and capabilities - all this makes 08Х18Н10Т steel accessible and widespread in everyday life.

This is interesting: At what angle to sharpen drills for metal. Sharpening options that can be done by hand

About areas of application

Stainless heat-resistant steel is the main material for a wide variety of industries. Among the main ones are enterprises producing seamless pipes, rolled sheets and all kinds of parts for mechanical engineering. Steel 08x18n10t is actively used by manufacturers of apparatus and devices in the chemical and food industries, factories for the production of consumer goods. The basis of the product range is cold-rolled strip and sheet steel, which is subsequently involved in welding work. These can be either thick sheets, thin-walled pipes and muffles, as well as electrodes or spark plugs.

Another feature of stainless steel 08x18n10t is excellent polishability. This allows the material to be widely used in the automotive industry (exhaust manifolds), mechanical engineering, electric power industry, fuel industry and even architecture. In general, the 08x18n10t grade is distinguished by its reliability and durability, so it often acts as an inexpensive alternative to a number of other stainless alloys.

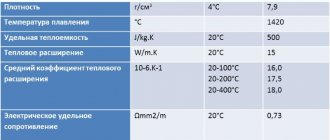

Physical properties of steel 08x18n10t

Stainless steel 08x18n10t has good weldability. Recommended welding methods are manual arc welding, argon-arc welding in a protective gas environment with a tungsten electrode, spot welding, ESW.

In an unhardened state, this grade of steel is prone to intergranular corrosion. The recommended maximum temperature at which it is possible to operate steel 08x18n10t without changing the mechanical properties is 800°C.

Steel 08x18n10t is well polished, including to a mirror finish.

Which is better: carbon steel or stainless steel?

Stainless steel is used:

- in the energy and chemical industries when working with aggressive environments;

- in medicine, aircraft manufacturing, where durability and increased strength of instruments are required;

- in construction and other areas where the type of parts plays an important role.

Carbon steel is needed there:

- where a lot of durable material is required - for example, in the construction of pipelines;

- where there is no need for improved metal properties - in particular, in the production of small parts of mechanisms and tools.

The considered types of steel cannot be placed in the same row. Materials are selected based on the project budget and area of application.

List of similar brands

The characteristics of steel 08Х18Н10Т are identical to those of some foreign brands of stainless steel. These include:

- AISI 321, S32100 – America;

- 1.4541, 1.4878, X10CrNiTi18-9, X6CrNiTi18-10 – Germany;

- SUS321 – Japan;

- 321F00, Z6CN18-10, Z6CNT18-10 – France;

- 321S12, 321S18, 321S20, 321S22, 321S31 – England;

- 1.4541, X10CrNiTi18-10, X6CrNiTi18-10 – Europe;

- X6CrNiTi18-11, X8CrNiTi1811 – Italy;

- F3523, X6CrNiTi18-10 – Spain;

- 0Cr18Ni11Ti, 1Cr18Ni9Ti, OCr18Ni10Ti – China;

- 2337 – Sweden;

- 0H18N10T, 1H18N10T, 1H18N9T – Poland;

- 17246, 17247, 17248 – Czech Republic;

- X6CrNiTi18-10S, X6CrNiTi1810K-KW – Austria

Among the alloys produced in Russia, one can note 10Х17Н13М2Т and 10Х17Н13М2 (do not contain titanium), as well as 10Х17Н13МЗТ, which contains a high content of molybdenum.

A cheaper analogue, 12X17, is also produced in Russia. It has anti-corrosion properties. But its use is impossible at extremely high temperatures. In addition, its chemical and physical characteristics remain unchanged only when in slightly aggressive environments.

Foreign analogues of Steel 08Х18Н10Т

| USA | Germany | Japan | France | England | European Union |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN |

| 321 | 1,4541 | SUS321 | 321F00 | 321S12 | 1,4541 |

| S32100 | 1,4878 | Z6CN18-10 | 321S18 | X10CrNiTi18-10 | |

| X10CrNiTi18-9 | Z6CNT18-10 | 321S20 | X6CrNiTi18-10 | ||

| X12CrNiTi18-9 | 321S22 | ||||

| X6CrNiTi18-10 | 321S31 | ||||

| Italy | Spain | China | Poland | Czech | Austria |

| UNI | UNE | G.B. | PN | CSN | ONORM |

| X6CrNiTi18-11 | F.3523 | 0Cr18Ni11Ti | 0H18N10T | 17246 | X6CrNiTi18-10S |

| X8CrNiTi1811 | X6CrNiTi18-10 | 1Cr18Ni9Ti | 1H18N10T | 17247 | X6CrNiTi1810K-KW |

| OCr18Ni10Ti | 1H18N9T | 17248 |

Legend

| Mechanical properties | |

| σB | temporary tensile strength (tensile strength), MPa |

| σ0.2 | conditional yield strength, MPa |

| σcom | compressive strength, MPa |

| σco0.2 | compressive yield strength, MPa |

| σ0.05 | elastic limit, MPa |

| σben | bending strength, MPa |

| σ-1 | endurance limit during bending test with a symmetrical loading cycle, MPa |

| δ5, δ4, δ10 | relative elongation after rupture, % |

| ψ | relative narrowing, % |

| ν | relative shift, % |

| ε | relative settlement at the appearance of the first crack, % |

| τK | ultimate torsional strength, maximum shear stress, MPa |

| τ-1 | endurance limit during torsion testing with a symmetrical loading cycle, MPa |

| KCU and KCV | impact strength, determined on a sample with concentrators of the U and V types, J/cm2 |

| HRСе and HRB | Rockwell hardness (scale C and B respectively) |

| HB | Brinell hardness |

| H.V. | Vickers hardness |

| HSD | Shore hardness |

| Physical properties | |

| E | normal modulus of elasticity, GPa |

| G | modulus of elasticity in torsional shear, GPa |

| ρn | density, kg/m3 |

| λ | thermal conductivity coefficient, W/(m∙°C) |

| ρ | electrical resistivity, Ohm∙m |

| α | linear thermal expansion coefficient, 10-61/°С |

| With | specific heat capacity, J/(kg∙°С) |

Sources

- https://InstrumentBaza.ru/materialy/08h18n10t-harakteristiki.html

- https://paes250.ru/vidy-stali/plotnost-08h18n10t.html

- https://pressadv.ru/stali/08h18n10t-harakteristiki.html

- https://iopent.ru/pro-materialy/plotnost-08h18n10t.html

- https://intehstroy-spb.ru/spravochnik/nerzhaveyuschaya-stal-marki-08h18n10t.html

- https://ipmet.ru/nerzhaveyushhaya-stal-08x-18n-10t-xarakteristiki-priminenie-analogi/

- https://uraltm08.ru/stati/kak-rasshifrovat-marku-stali.html

- https://svarkaipayka.ru/material/stal/tehnicheskie-harakteristiki-stali-08h18n10t.html

- https://vse-stali.ru/stali-i-splavy-korrozionnostojkie-zharoprochnye-zharostojkie-iznosostojkie/stal-08h18n10t/