Pliers are the name of a tool belonging to the pliers type. It is used to perform various manipulations with objects, and their scope of application extends from construction to medicine. For example, dentists use pliers to remove teeth. In everyday life and during repair work, types of pliers such as pliers and pliers are used.

The difference between them is not obvious to many. However, they differ not only in appearance, but also in their functional purpose. Each type of work requires certain devices.

Features of the handles

Both types of tools used in everyday life or at work have handles, which come in two types:

- one-component - completely made of plastic or rubberized for use in aggressive environments,

- two-component - with a base made of shockproof or simple plastic and a rubber coating.

One-piece handles can fly off or turn if the rubber is poorly glued and the plastic slips off. The rubberized handles are held perfectly by hand, but they are cut and scratched. The advantage of two-component handles is the strength of the plastic and non-slip properties due to the rubber coating.

Types of pliers, features and scope of application

Such tools are used to work with a wide variety of materials. The flat working surface allows you to hold almost any workpiece. There are combined versions on sale that are used in a wide variety of cases. The classification is as follows:

- Sponges can be made narrow or long, and can be used to work with various materials in conditions of limited access.

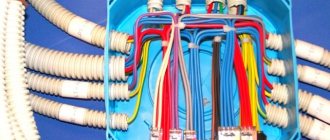

- The working surface can bend at a certain angle. They are also intended for use in cases where access to the main elements is difficult. This tool is found in an electrician's kit.

- Platypuses are represented by a kind of tweezers, which are designed to have a high impact.

- You can use a mechanism with special attachments. By increasing the elasticity of the working surface, it is possible to fix parts with high fragility.

Do not forget that working with electronics requires special mechanisms, the handle of which is subject to additional insulation. When producing such a product, the manufacturer must indicate what the maximum operating voltage is. Most pliers are capable of operating at voltages up to 1000 V. If the information is not indicated, then using this option is not recommended.

Application

The scope of application of such tools is limitless. Despite the differences, using pliers and pliers you can remove nails and screws, tighten nuts, change a tap, and perform the following operations:

- when installing structures,

- during installation and repair of plumbing equipment,

- electrical installation, electrical repair.

However, electrical operations can only be performed with dielectric pliers that can withstand a certain voltage level in order to eliminate the risk of harm to health.

Pliers or pliers

Despite the external similarity of pliers and pliers, they have functional and structural differences. At first, craftsmen began to use pliers.

This product has oblong-shaped metal clamps with small recesses inside. They ideally hold small parts, wires, fasteners, and facilitate bending of wires and metal plates. The smooth surface of the jaws allows you to capture and hold the entire area of the workpiece without causing harm to the material of the part.

The transformation of ancient pliers led to the appearance of pliers, where the following appeared:

- recesses of various diameters with applied corrugations between metal jaws, allowing you to firmly hold spherical objects,

- cutting grooves inside the jaws for cutting cables, thin wires,

- cutting notches on the outside cutting through thick wires and even chain-link mesh.

These types of tools are a hybrid of wire cutters and pliers. Due to the ability to perform the functions of different tools, pliers are purchased more often. However, pliers are indispensable for precision work and use in confined spaces.

Pliers and pliers, the difference between which is not only in the structure of the jaws, differ in functionality.

General view and purpose of the tool

To determine the differences between the tools, it is important to determine their purpose and scope of use.

Pliers

This term refers to a hand tool that is used for various plumbing jobs. It can also be used in electrical installations. The sponges have a pyramidal shape. In this case, the internal flat surfaces are covered with notches. The working part of the device, which turns into handles, is driven by hinges.

Expert opinion

Karnaukh Ekaterina Vladimirovna

Graduated from the National University of Shipbuilding, majoring in Enterprise Economics

Pliers can be used for gripping, bending and twisting metal elements. There are several types of pliers that are used to perform different jobs. They differ in the length and width of the jaws. The tool is often equipped with insulating handles, which allows it to be used for work under voltage.

For convenient use of pliers, several modifications are produced:

- With long, narrow jaws that allow you to work in restricted areas.

- With curved jaws that help to access the required part in electronics or other complex mechanisms.

- With elongated jaws, which are used for a strong grip on parts and materials.

- With a set of attachments that are suitable for working with fragile elements.

Pliers

This is a hand tool that is used in plumbing. It is also used for electrical installation work. With the help of such devices, it is convenient to grab and hold various parts, regardless of their shape, including cylindrical ones. To achieve the desired effect, the jaws of the pliers are supplemented with recesses of different diameters with a notch applied to the working area.

Pliers that can be used for electrical work have special insulated handles. They are designed to operate at voltages up to 1000 volts.

There are also universal devices. They combine the functions of pliers, side cutters and cutters, helping to cut through wire of different diameters. To make the tool, high-quality steel is used, which has undergone a series of treatments. The finished tool is coated with a special anti-corrosion material using chrome plating or oxidation.

Depending on the design, the following types of pliers are distinguished:

- Combined - often used in domestic conditions to perform plumbing and installation work.

- Combined adjustable - equipped with pipes and round objects of different diameters.

- Dielectric – equipped with special insulation on the handles.

- For eyelets - such devices help install rings, rivets and all kinds of holders.

Types of pliers

Despite the versatility of pliers, it is better to choose a tool for stripping wires, insulation, cutting cables, and other operations that is appropriate for the task for which it is intended. They are:

- metalworking (combined),

- elongated,

- electrical installation (dielectric),

- grommet,

- adjustable (pipe).

The sizes of pliers and pliers are different. There are “miniature” models for performing delicate work, for example, products 10 cm long are intended for modeling or beading operations.

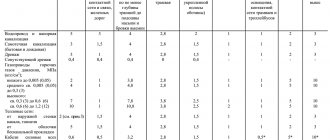

GOST 17 438-72 determines the dimensions of pliers for installation, auto repair and other work. For example, pliers with a length of 160, 180, 200 mm are suitable for installers, and pliers with a length of 200, 250, 300 mm are suitable for production workers.

Pliers

This is the most common tool of standard sizes that is found in every home. The design of metalwork pliers is distinguished by finely grooved jaws, after which there are necessarily a toothed notch, side cutters, and next to the hinge there are cutting elements for cutting wires and wires.

Combined

Combined models of pliers are equipped with a lot of functions and capabilities, as they are made on the principle of a penknife, equipped with various additional options.

Eyelet

Highly specialized models of eyelet pliers are easily recognizable. Outwardly they look like a hole punch. The devices make holes in the material, where fastening rings made of metal or plastic are immediately mounted. The scope of application of the products is the shoe, leather goods industry, ateliers, shoemakers.

Pipe

Such models are also called adjustable. These are the largest products among their counterparts. Only plumbers use them. They do an excellent job of gripping and holding gas or water pipes. The design of such products is equipped with an adjustable hinge mechanism, which allows you to change the diameter of the toothed hole to the size of round objects. In this case, the difference between pliers and pliers is obvious, which make it possible to adjust the compression force and the distance between the jaws.

Extended models

The length of the sponges of such models can reach 20 cm. Their appearance resembles tweezers with handles. Such products are intended for use in narrow holes, cavities, and crevices.

Electrical installation

Structurally, such products do not differ from others, but their handles are protected by special material. Thanks to the insulation on the handles, they can be used when connecting devices to the mains. According to state standards, models of wire stripping tools can withstand electrical voltages of up to 1000 watts. Manufacturers indicate this parameter on handles that are brightly colored. A tool for stripping wires and insulation is called a stripper.

Pliers and pliers: what is the difference between the variations of pliers tools

The history of the appearance of devices of this group goes back at least to the era of the Greek gods. Since time immemorial, mankind has been familiar with blacksmith's pliers. Over time, changes occurred not only in human society, but also in tools. When exactly and by whom exactly the design of pliers, which are the prototype of modern products, was created is unknown. However, the undeniable fact is that the thing turned out to be incredibly practical and necessary.

Many people do not see the difference between pliers and pliers, since they look very similar

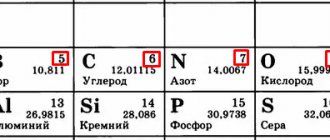

Modern pliers tools are characterized by great diversity. The main variations that are presented to consumers are:

- mites;

- round nose pliers;

- wire cutters;

- pliers;

- pliers.

Each of the above categories has subtypes that differ in such parameters as the size of the working surface, shape, and purpose. For example, round nose pliers are best suited for cutting cable cores.

This is interesting! The cone-shaped shape of the tool provides comfort when bending cable cores.

Pliers are considered a more functional tool than pliers

Different shapes of the cutting part and its different dimensions dictate the operating characteristics of the cutters. For example, products designed for repairing electronic devices are characterized by smaller sizes. You should know that they are completely unsuitable for cutting cables for various purposes, as this is inconvenient and impractical.

To perform work related to delicate materials, special attachments are used - plastic or made from other raw materials. The presence of notches on the pliers allows for maximum reliability in fixing the part during the soldering process of boards. At the same time, the special shape and angle of the jaws make it possible to get into the most inaccessible areas.

What is the difference between pliers and pliers: the main parameters of the tools

According to the interpretation of GOST, pliers are a tool designed to grip and clamp pipes and parts of various shapes. Externally, the products are very similar to pliers. They are equipped with flat jaws, which are an extension of the working area for gripping bolts or tubes. In addition, the tools presented are most often equipped with side cutters to remove insulation.

Let's take a closer look at the difference between pliers and pliers. The following features of these tools should be noted:

Pliers and pliers have different working surface shapes

- the ability to adjust the gap of the working surface of the jaws and the degree of force of the product by rearranging the hinge is provided only for pliers;

- pliers are tools designed to perform only one action, while pliers are multifunctional products;

- pliers are equipped with wire cutters for cutting thin wire; high-strength steel is used in their manufacture;

- often pliers are characterized by a flat working surface with a notch along the entire length.

This is interesting! On the modern market you can also find 200 mm combination pliers, but this is the exception rather than the rule.

In addition, it is worth noting that the design of the pliers is designed for greater compression force. This means that manufacturers select the appropriate grade of material for these products—one that is characterized by a greater degree of strength.

Perhaps the most significant difference between pliers and pliers is that the former provide the ability to solve a larger number of different everyday tasks. In many ways, they can be an excellent replacement for end cutters, small house vices or side cutters, gripping almost any small-sized object.

With pliers, the width of the jaws along the entire length is always the same, unlike pliers

How to use pliers

Electricians, builders and plumbers must use the appropriate tool models. They need to be lubricated so that they move smoothly and the jaws fit tightly. During operation, it is necessary to ensure that when gripping flat or cylindrical parts, the tool does not pinch your fingers. In the process of forceful squeezing, you should not push, but pull the handles.

Characteristics of pliers

You can read what pliers are in the encyclopedia. According to its description, this is an instrument with pyramidal jaws, on the inside of which there are notches. Pliers are needed when it is necessary to grab and bend small flat-shaped metal elements, twist cables, wires, wires. Product lengths range from 125 to 200 mm.

For comfortable work, the weight of pliers and pliers with different possibilities of use cannot be too light to withstand force. Lightness is a sign of low quality.

What are pliers, features of the tool

Without exaggeration, this tool can be called practical and, moreover, multifunctional. They are a close relative of pliers, not only in appearance, but also in purpose, so you need to find out the difference between pliers and pliers.

The tool in question is widely used in the electrical installation industry and plumbing. On the working surface of the pliers there is a notch with notches, the main purpose of which is the ability to capture and hold various types of surfaces.

The surface of the jaws of the pliers in question is combined and that is why the range of its use is so wide. Apart from the notch, part of the working area of the pliers is a flat surface. Some types of tools also have a couple of small and shallow recesses so that you can work with different sizes of parts at the same time.

Among other things, the important features of the pliers include the ability to regulate the pressure of the lips (for such purposes, the hinges are located in special grooves). Switching from one diameter to another is very simple, and everyone, even a beginner, can handle this action - the handles are moved apart and the hinges are moved into the selected recess).

Most types of this tool have side cutters in their design, which make it possible to quickly and safely remove insulation from the cores and cut cable cores, and wire can also be cut. On one side of the tool there are edges for the ability to cut wire from a hard type of metal.

There are several types of pliers - for plumbing and for the electrical industry. The latter must be provided with an inscription indicating what voltage they are designed for.

Types of pliers

Each type of pliers has its own characteristics. Conventional models differ from universal pliers in that they do not have serrations on the jaws or cutting edges. Different types of pliers can be made of metal, plastic, or combinations thereof, but are classified according to functionality.

Thin-nose

These pliers are characterized by elongated gripping parts with serrated serrations. Narrow elements allow you to hook screws and small parts. The cutting edges are designed to work with wires, wires, and cables. CS55 steel is used for manufacturing.

Platypuses

This version of the tool, made from CS55 steel, has curved jaws, which is very convenient on angled planes. Models are equipped with clamping surfaces with serrated notches and cutting edges. This type of plier is great for cutting wires, but not nails.

Round nose pliers

It is convenient to bend wire with round nose pliers because the design of the jaws is round in shape. Round nose pliers are needed to complete the process:

- curly bending of wire,

- installation and dismantling of small parts,

- removal of insulation.

The pliers are made primarily from chrome vanadium steel with a mandatory oxidation procedure, which guarantees long service life.

Side cutters

The purpose of side cutters is to cut through wiring. Their design has only cutting edges. There are no clamping surfaces. They are a great help for electricians, installers, and repairmen. Many people are interested in the difference between side cutters and what can replace such pliers. In short, special pliers can be called side cutters.