Types of units

All products produced by manufacturers are divided into certain types, based on the welding method and the current source. The usual network voltage of 220 V and 6 - 32 A is not suitable for such work. It needs to be transformed. For this purpose, the following types of equipment are produced:

| Kinds | Description |

| Inverters | Equipment that consumes alternating current of 50 Hz from the network and converts it to 100 Hz. In this case, the voltage is rectified twice. Welding is carried out at a direct current of 30 to 300 A with a voltage of 50 - 80 V. The seams are smooth and the penetration is deep. There is virtually no metal spattering. The design diagram of inverter type includes: • step-down transformer; • diode bridges; • board with keys; • second transformer; • transistors. The product is compact, quiet in operation and lightweight. Inverters are divided into the following subgroups based on the type of transistor: • Mosfet (budget option, weigh a lot, are reliable, have a free layout, large parts and maintainability); • IGBT (modern models installed in premium welding machines). |

| Transformers | Inexpensive units. They include two windings: primary and secondary. The operating principle is magnetic induction. Welding occurs under alternating voltage. Able to join ferrous metals. They are distinguished by reliability and ease of operation. They weigh a lot, they buzz loudly, the dimensions are impressive, and the metal splashes a lot. |

| Rectifiers | Affordable welding machines. Create a high-quality seam. It operates from a 220 V network, lowering it to a value of 40 - 80 V, while increasing the current to 200 - 400 A. The products differ in power. The structures are equipped with starting and protection elements. The devices are reliable and wear-resistant. They serve faithfully for a long time. Scope of application - in everyday life and at work. Welds ferrous and non-ferrous metals, as well as cast iron. Disadvantages include large size and significant weight. |

Based on the type of welding, structures are divided into the following categories:

- Semi-automatic MIG/MAG welding. A torch is used to make the seam. The metal connection occurs through an electric arc. Continuous supply of additive allows you to make neat seams. Works with metal thickness from 0.6 to 20 mm. Connects stainless steel, ferrous metal and aluminum. You do not need to carry a cylinder with you. Inconvenient to use outdoors. Gusts of wind can blow out the gas.

- Gas welding. We are talking about an acetylene generator that produces gas from carbide and water. It is necessary to have an additional oxygen cylinder, which helps to reach temperatures of up to 3000 degrees. The method is often used for welding containers and pipes up to 4 mm thick. No electricity is needed to operate. You can use the unit far from civilization. Welding speed is low. Significant heating may cause the structure to become deformed.

- Manual arc welding MMA. Such products are manufactured on the basis of rectifiers, transformers and inverters. In the hands of the welder there is a holder with a melting electrode. The arc is closed by a metal rod and is a filler material. Allows you to connect ferrous metal. When installing electrodes equipped with a stainless steel rod, alloy steel can be connected. For a quality connection you will need experience in this matter. Manipulations occur slowly, and you have to constantly monitor the arc as the electrode becomes smaller.

- Argon arc welding TIG. Inverters are used for welding. The connection occurs using an electric arc. Able to weld elements made of stainless steel or ferrous metals.

- Spot welding. Available for single-sided and double-sided welding. In the first version there is a pistol with a reverse hammer, in the second - pliers. The scope of application of the products is the assembly of gates, gates, boxes, body repair. Manual models weigh up to 16 kg and can be moved from place to place. On the market you can find stationary machines for resistance welding. In this case, the thickness of the metal sheets being connected can vary in the range from 3 to 9 mm.

- Universal. According to buyers, the best. They include several modes: MIG+TIG, MIG+MMA, TIG+MMA, three in one.

- Plasma welding. The main component is an electric arc that burns in the nozzle between the anode and cathode. It passes air from the compressor, forming plasma. When using filler wire, the method can be used for welding products.

Welding small parts at home - Metalworker's Guide

Everyone has long known about welding techniques. However, few people know about the existence of various categories of connecting processes using all kinds of energy carriers, the need for which is due to huge demand. The dominant, most common type of welding in domestic conditions is spot welding.

How to cook with electric welding with your own hands

R

Scientific electric welding has been and will be popular among home craftsmen, since you can figure out how to weld with your own hands at a level sufficient for everyday life in literally a matter of hours. This is attractive, considering how much welding work is in demand in repairs and work on the manufacture of various structures in a garage, house, or estate.

Connecting parts by welding has become even more popular in our time, which is due to the advent of affordable and convenient equipment, and now manual welding with an inverter has become commonplace.

.

1.

The essence and principle of electric welding.

2.

What happens during welding?

3.

Types of electric welding.

4.

Types of welding machines for manual arc welding. 5.

Types of welded joints.

Weld seam and its preparation. 6.

Preparation of the seam site.

7.

Equipment and auxiliary devices for electric welding.

8.

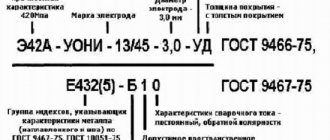

Electrodes for welding.

9.

How to weld metal parts using manual consumable electrode welding.

10.

Conclusion.

Old welding machine and inverter

The essence and principle of electric welding

In order to learn how to use electric welding, to understand its inherent capabilities and limitations, it is necessary to at least in general understand what processes occur in its blinding flame.

Important!

Welding metal parts is far from a harmless task, if you remember that temperatures here are sometimes over 8000°C (for comparison, the temperature on the surface of the Sun is 5730°C!). This temperature generates powerful radiation and even a casual glance at the arc flame is sometimes enough to severely burn the eye tissue (electrophotophthalmia).

The main “tool” of electric welding is an electric arc - a continuous discharge in a gas environment, which represents the “fourth” state of matter - plasma.

The colossal temperature of the plasma makes it possible to weld parts by electric welding: the metal melts and, crystallizing at the junction of the workpieces, creates a single product from several parts.

What happens during welding?

In the most general form, the following happens during welding. If we apply voltage to a metal part and to a welding electrode, then when they touch, a short circuit will occur, at the point of contact the temperature will instantly increase, and the accompanying thermionic emission. That is, the metal begins to emit electrons.

Now, even if the electrode is moved a little, electricity will still pass through the gap. current, that is, an electric arc will occur.

Its further combustion is supported by the formation of free ions - molecules of a substance that have an electrical charge. They are formed due to the high temperature of the arc, and the process itself is called thermal ionization.

Some of the ions are scattered through the process of diffusion, which increases exponentially with increasing distance between the electrode and the part. The current resistance increases sharply, the arc weakens and goes out.

Electric welding

Types of electric welding

Many types and subtypes of electric welding are based on this principle:

- electric welding using a consumable electrode;

- submerged arc welding;

- gas-shielded arc welding;

- electroslag welding;

- welding with forced formation of a seam;

- plasma welding;

- contact point, suture contact, etc.

Mini welding machines

It stands o - not the official name. Products are divided only into household and professional. We can talk about intermediate units. Manufacturers from China have launched the production of popular models with compact dimensions and light weight, which are easy to use and portable. Based on practice, mini-devices are those whose body has parameters of 20*20*10 cm. They are made on the basis of transistors and operate on a constant type of current. You can find small models of transformers that produce alternating voltage. Area of use: house, summer cottage.

The positive points include:

- Lightweight (2 – 3 kg). Can be worn on a shoulder strap.

- Compactness. Placed for storage in a closet or workshop. Can be placed for transportation in the trunk of a passenger car without taking up much free space. If necessary, the device can be delivered to its destination by hand on foot or by public transport.

- Fine adjustment. The presence of microcircuits makes it possible to configure the instrument and set the required current strength.

- Small load on the power grid. The connection is provided to a regular outlet. In this case, the wiring will not overheat. Power consumption does not exceed that of an iron or electric kettle.

- The quality of the work performed. If you have the knowledge and proper experience, you will get high-quality seams.

- Ampere reserve Despite its small size, the device is able to cope with sheets with a thickness of 3 to 8 mm.

- With additional features. A review of reviews shows that this aspect is worth paying special attention to. This will make it easier to start the arc and minimize the possibility of electrode sticking.

- Mobility. There is no need to have a source of electricity on hand in the form of a network. It is enough to connect the device to a gas generator and you can cook in the field.

- A budget option. Any home craftsman with average income can afford to purchase such an accessory.

The designs have few disadvantages, but they are worth mentioning:

- the diameter of the electrodes is small (from 2 to 3 mm);

- lack of effective cooling (a small case does not accommodate a full-fledged cooling system, which leads to overheating and automatic shutdown of the unit);

- budget equipment (the cables are short and reach a length of up to 1.5 meters, there is no rigid handle or suitcase, the service life is limited);

- the stated current range does not correspond to reality;

- fear of voltage surges.

Scope of use of compact models

Compact units are purchased for home use and are in the arsenal of any master. Thanks to this device, you can independently perform the following manipulations:

- weld the fence;

- bring a water pipe to the garden;

- cook a barbecue or gazebo;

- repair the crack between the post and the hinge on the gate;

- install a greenhouse;

- build an outdoor shower;

- install a long fence;

- work at heights;

- fix the antenna on the roof.

What to look for when choosing products? The impossibility of using it for commercial purposes. She cannot do regular work. Short term and occasional use only. Significant loads can quickly damage the product. The maximum permissible metal thickness is 8 mm. Experts do not recommend welding critical structures with such a device.

Design features and operating principle

In the manufacture of mini inverter welding machines, the following parts are used:

- soft start relay;

- bridge type rectifier with powerful diodes;

- high frequency generator;

- current sensor;

- integral stabilizer;

- transformer;

- low pass filter;

- cooling system;

- transistors and diode radiators.

The work flow is as follows:

- The alternating current supplied to the diode-type rectifier becomes constant.

- By means of a generator, current is generated at a high frequency.

- The alternating current is directed to the primary winding of the transformer.

- The transformer steps down the current, which results in a reduction in voltage. It is enough to ignite the arc. The high-frequency current is converted into direct current through a rectifier.

- The parts are welded.

Making a device with your own hands at home

Real craftsmen do not throw away devices that have become unusable, but store them in a secluded place “just in case.” There are plenty of things like old televisions, microwave ovens, irons, and all kinds of electrical equipment in every barn. If desired, many useful devices can be made from parts, including mini-welding machines. If it is difficult to imagine how to make a homemade unit, clear step-by-step instructions posted on the Internet will come to the rescue.

Here is one of the video options:

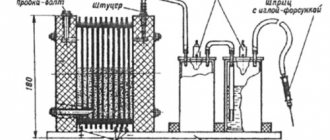

For home use, it is best to have a portable point-type tool. It is suitable for connecting small parts. Allows you to weld a nickel plate to a lithium laptop battery during repair work. To create conditions for spot welding, you need to acquire the following components:

- diode bridge;

- low-power transformer;

- automatic 20 A;

- battery of capacitors;

- powerful current relay;

- two copper rods.

The secondary winding is removed from the transformer. It is replaced by three turns of welding wire. The secondary winding must be connected to a diode rectifier. The output is connected to a bank of capacitors connected in parallel. The outputs of the capacitors are connected to the copper electrodes via a relay.

DIY miniature device

Despite the abundance and variety of models on the market, making welding equipment yourself is still popular.

In particular, the assembly of mini contact welding devices, suitable devices for which are not always possible to find.

To use the contact method of welding sheet metal of a car body, a device called a spotter is made.

If spot welding pliers clamp parts between two electrodes, then this device allows you to perform it only on one side, holding the spotter “gun” in your hand.

Important! Regardless of the welding method when repairing a car, be sure to remove its battery before starting work.

The lead of a round battery is often used as electrodes for this version of homemade mini-welding.

Assembling an inverter with your own hands is of purely amateur interest . There are plenty of detailed diagrams on the Internet, but purchasing parts and assembly will cost more than purchasing a finished device. However, the fact that you assembled the product yourself is worth a lot.

How to choose the right model for home use

Which product is best to buy depends on many factors, including the purpose and frequency of use. Small devices are suitable for jewelers. To install a fence or gazebo, you will need more powerful devices. Everyone's selection criteria are different. Some choose which company has the best product, others pay attention to functionality, others are interested in what it costs, and others believe that the best option is new products from the best manufacturers.

Experts advise when purchasing to pay attention to the following product parameters:

- power;

- type of welding;

- dimensions;

- area of use.

If you plan to use the device at the household level, then it is better to give preference to portable or small-sized welding machines. Mini-equipment has low power and is convenient to store and transport. The scheme of work is elementary.

Single-phase and two-phase models are available on sale. Which one to choose depends on many factors. Before making a final decision, it is worth consulting with an experienced sales manager. The focus is on power and individual needs.

The opinion that everything Chinese is bad is not correct. It was like that before. Today, a large number of high-quality products are produced on the territory of the Middle Kingdom, which in terms of characteristics and functionality are not inferior to their European counterparts. Only the price is more reasonable.

You can't lose sight of the material used. It must be reliable, wear-resistant, high quality, durable and have a long service life. In order not to overpay for a product, you need to decide on the scope of its application. Additional options may not be needed in everyday life.

Where to buy welding equipment? You can visit a specialized retail outlet, get acquainted with the offered assortment, and choose the right products from the abundance. If in doubt, you can talk to a professional salesperson.

There is another purchasing option - order the product online in an online store. This is a risky move. Much depends on the supplier and his integrity. Instead of expensive products from a well-known world brand, you can get a cheap Chinese counterfeit.

Design and principle of operation

Despite the variety of models and types of welding machines, they are all based on the use of a voltaic arc. Its temperature exceeds 6 thousand degrees Celsius, which makes it possible to melt even refractory metals: nickel, molybdenum, special steels.

The process itself is akin to a short circuit. However, in arc welding, it is controlled by an electrical device called a transformer.

The smallest size welding inverter is distinguished from conventional devices by an additional circuit. It increases the frequency of electricity, which increases efficiency to 87 - 90%. In many ways, this makes it possible to make the device miniature.

Rating of high-quality mini welding machines up to 15,000 rubles

BestWeld, BESTMINI 180 MMA

This design is capable of functioning at temperatures of -20°C. The inverter type device is used for working with small workpieces. For operation, electrodes with a diameter of 1.6x4 mm are required. The possibility of adjusting the arc force deserves special attention. The housing is classified as frost-resistant and moisture-resistant, which allows you to work outdoors at any time of the year. Weight – 2.7 kg.

The average price of a new product is 10,850 rubles.

BestWeld, BESTMINI 180 MMA

Advantages:

- small dimensions;

- mobility;

- ease of operation;

- protected housing;

- Possibility of adjusting arc force.

Flaws:

- The original wire is a bit short.

Fubag IR 200 (MMA) VRD 38900

The power factor of this model is 6.5/8.1 kW. The design has small dimensions. It is in well-deserved demand among domestic consumers, largely due to the ability to work in hard-to-reach places. You can hold the device with one hand. The risk of slipping is eliminated due to the ribbed surface. It will take a few seconds to connect the wire due to the presence of a bayonet connector. There is a smooth adjustment through an ergonomic handle with an increased sensitivity coefficient. The device operates from a network in the range of 150-240 V. The thickness of the welding seam is 0.8 cm. The use of wire with a diameter of 1.6-5 mm is allowed.

You can purchase the device at a price of 9810 rubles.

Fubag IR 200 (MMA) VRD 38900

Advantages:

- there is an indicator for turning on and overheating;

- can be held with one hand;

- protection against sticking;

- can operate in low voltage conditions;

- an option that allows you to force the arc;

- small dimensions;

- hot start option;

- service life.

Flaws:

- not identified.

SPEC Mini-250PN MMA

This model is characterized by increased service life and ease of use. Due to its compact dimensions, the product can be carried with one hand. In addition, the model has excellent performance characteristics. To work with the device, you can use electrodes with a diameter of 1.6-5 mm. This will allow you to weld elements up to 1 cm thick. The body is classified as moisture-resistant, however, welding in the rain is not recommended. Due to the unique design features, the risk of fingers coming into contact with internal elements is eliminated.

Cost – 8000 rub.

SPEC Mini-250PN MMA

Advantages:

- hidden functionality;

- protected housing;

- small dimensions;

- Excellent value for money and quality;

- safety;

- increased service life.

Flaws:

- The original cable is a bit short.

Wester, MINI 200T MMA

This popular model is in deserved demand among domestic consumers. It attracts not only with its compact size, but also with ease of use and build quality. A characteristic feature is the presence of a wide range of operating temperatures. This will allow you to work in any conditions, regardless of weather conditions. The welding current coefficient is 30-200 A. The output voltage is 155-255 V. The diameter of the electrodes used is standard.

Average price – 7999 rub.

Wester, MINI 200T MMA

Advantages:

- excellent performance characteristics;

- compact dimensions;

- Can be carried with one hand;

- protected housing;

- wide range of operating temperatures.

Flaws:

- not identified.

Wester, MINI 160T MMA

A characteristic feature of this model is considered to be the presence of anti-stick and hot start options. An excellent device for solving everyday problems in a private home. Can be used both indoors and outdoors. It does not take much time to weld thin metal workpieces. The quality of the seams is high. To work, you will need a household outlet and an extension cord, since its own wire is short. For further work it is necessary to purchase electrodes with a diameter of 1.6-4 mm. The output voltage coefficient is 155-255 V.

Cost – 7150 rub.

Wester, MINI 160T MMA

Advantages:

- useful options;

- compact dimensions;

- quality of seams;

- ease of operation;

- protected housing;

- hidden functionality.

Flaws:

- The original cable is a bit short.

Advantages and disadvantages

A small welding machine is primarily convenient for transportation and storage. Small dimensions and weight, the presence of a belt allows you to carry out welding work in hard-to-reach places. You can work with it almost anywhere, the only requirement is the presence of a 220 V network.

The devices provide adjustment of the welding current. Special stabilizers ensure stable burning of the electric arc, which allows you to obtain a high-quality weld.

These are very convenient devices for novice welders. Compared to professional welding equipment, mini machines have a low cost.

Disadvantages are closely related to advantages. Small dimensions and weight do not allow the creation of high-power devices. As a consequence, it is impossible to work with electrodes of large diameters.

It is impossible to weld thick-walled workpieces, since there is not enough welding current for this. At extreme operating conditions, problems arise due to equipment overheating. Small dimensions greatly limit the functionality of a mini welding machine.

Rating of high-quality mini welding machines up to 7,000 rubles

BISON MASTER MMA SA-190K (MMA)

An excellent device for home use. For further work, you will need refractory electrodes with a diameter of 1.6-4 mm. Coverage may vary. It is based on the use of a microprocessor that is capable of functioning in any conditions. Adjustment is allowed in the range of 20-190 A. The manufacturer artificially reduced the risk of a significant breakdown due to the use of fewer components. An installed temperature sensor is responsible for monitoring the power elements. The risk of their failure or overheating is minimal. The boards are protected with a special (high temperature) varnish. Perforations on the case and a large fan are responsible for improved heat transfer.

Cost – 6520 rub.

BISON MASTER MMA SA-190K (MMA)

Advantages:

- built-in protection against overheating and overloads;

- electrode anti-stick option;

- compact dimensions;

- quick start option;

- possibility of connecting the system to a generator (mobile battery).

Flaws:

- not identified.

Sibrtech IDS-190 (MMA)

An excellent welding machine designed for home use. It will become an indispensable attribute for a garage, workshop, private home or cottage. Will allow you to solve any everyday problems. An increased productivity coefficient is noted. Also noteworthy is the stability of operation during voltage surges and sags. An ergonomic handle ensures smooth current adjustment. The operating range is 40-190 A. The indicator is sufficient to work with electrodes with a diameter of 1.6-4 mm. There are three LEDs on the indicator panel, indicating overload, overheating and the start of power supply. Manufacturer-installed electronics eliminate the risk of significant load and heat.

Average price – 5400 rub.

Sibrtech IDS-190 (MMA)

Advantages:

- anti-stick option;

- protected housing;

- hidden functionality;

- mobility;

- compact dimensions;

- duration of the working cycle.

Flaws:

- not identified.

FoxWeld Varteg 190 mini

This compact and productive device will become an indispensable assistant for the master. Suitable for home use. For normal operation, you will need a regular 220 V outlet. This indicator is sufficient for welding metal workpieces 1 cm thick. For further work, you will need electrodes with a diameter of 1.5-4 mm. A durable, protected housing ensures an increased service life. The material used is resistant not only to temperature changes, but also to moisture. Weight – 2500 g allows you to carry the device with one hand at any distance.

Cost – 5045 rub.

FoxWeld Varteg 190 mini

Advantages:

- a hot start and anti-stick option is provided;

- compact dimensions;

- Arc forced option;

- hidden functionality;

- protected housing.

Flaws:

- It gets very hot during operation.

Small details

In order not to damage the camera matrix while filming welding work, I used a four-fold neutral density filter. Since the diameter of the filter turned out to be much smaller than the norm, I made an adapter from the lid of a jar of mustard. No matter how funny it may be, it was necessary to spend more time solving this problem than preparing and carrying out welding work.

Rating of high-quality mini welding machines up to 5000 rubles

FoxWeld Kvazarrus 190 mini

This device guarantees high quality seams. In this case, you should pay attention to the price of the device, which is more than affordable. At the output, the coefficient reaches 140-240 V. An excellent model for everyday use and solving small household problems. Allows you to work with metal workpieces 1 cm thick. For normal operation, you will need access to your home network. The welding current indicator is 20-190 A. The diameter of the electrodes used is 1.6-4 mm.

Cost – 4970 rub.

FoxWeld Kvazarrus 190 mini

Advantages:

- hidden functionality;

- compact dimensions;

- build quality;

- ease of use;

- Excellent value for money and quality;

- quality of seams.

Flaws:

- The original cable is a bit short.

CALIBER, MINI SVI-180AP MMA

This model is popular because its efficiency reaches 85%. An inverter-type welding machine will become an indispensable assistant for any master. To operate, a connection to a 220 V outlet is required. The built-in electrics can withstand small voltage surges. The power declared by the manufacturer is 3.8 kW. The indicator is enough to solve simple everyday problems. For further work, you will need electrodes with a diameter of 1.6-3.2 mm. Suitable for welding small metal products.

Average price – 4890 rub.

CALIBER, MINI SVI-180AP MMA

Advantages:

- safety;

- anti-stick and hot start options are provided;

- hidden functionality;

- resistance to voltage surges;

- compact dimensions.

Flaws:

- gets very hot during operation.

CHAMPION IW-140/6.1A mini MMA

A product from a time-tested manufacturer, which is in deserved demand among European consumers. The device belongs to the universal category and is suitable for performing everyday tasks. Can be used in extreme conditions. Multifunctional design. There is an option for hot start, anti-stick and arc force. The package includes a user manual and a warranty card.

Cost – 4700 rub.

CHAMPION IW-140/6.1A mini MMA

Advantages:

- compact dimensions;

- hidden functionality;

- mobility;

- universal purpose;

- Excellent value for money and quality.

Flaws:

- The case does not belong to the category of durable.

CHAMPION, IW-160/7.2A mini MMA

This budget device can be ordered on Ali Express. Also, a popular model can be found on the shelves of domestic stores. A multifunctional device, the cost of which is more than affordable. The design belongs to the universal category, as it can be used both indoors and outdoors. Bad weather will also not interfere with the planned work. The lightweight and compact device is characterized by an increased service life. The efficiency indicator barely exceeds 80%, which is a significant drawback.

Average price – 4550 rub.

CHAMPION, IW-160/7.2A mini MMA

Advantages:

- increased level of security;

- wide range of operating temperatures;

- service life;

- possibility of use in any conditions;

- Excellent value for money and quality.

Flaws:

- low efficiency.

CALIBER MICRO SVI-205 (MMA)

This compact and easy-to-use device will be an excellent addition to your existing workshop tools. It copes well with metal workpieces up to 0.7 cm thick. The installed electronics work properly. The design of the case is stylish and modern. Performance characteristics are good. For greater convenience during transportation, you can use a branded strap. It can also be operated while standing on a stepladder when performing welding operations. Regardless of the input voltage, the device stably maintains and ignites the arc.

Cost – 4229 rubles.

CALIBER MICRO SVI-205 (MMA)

Advantages:

- session duration – 300 seconds;

- build quality;

- compact dimensions;

- overload protection;

- service life.

Flaws:

- not identified.

Characteristics of some models

The concept of mini is transforming over time. More recently, all inverter machines could be classified as mini in comparison with transformer-based traditional welding machines.

Now inverter welding machines have become a kind of standard, and only more miniature devices are called mini machines.

The inverter device “Special mini 210” belongs to the mini category. It weighs only 2.5 kg and has compact dimensions of 190x200x290 mm. The maximum welding current is 210 A, power consumption 6 kW, voltage 220 V.

The older model “Spets mini 250” has a welding current of 250 A, a power consumption of 8 kW, is powered by a 220 V household network, and weighs 4.2 kg.

The Rainbow 180 mini device has a welding current of 180 A, a power of 5 kW and a weight of 6 kg. All welding machines can weld with electrodes from 1.6 to 4 mm. Some of the best in this class are Finnish welding machines, for example, the Kemppi Minarc 150VRD model.

This device is capable of operating in manual and argon arc welding modes. It automatically adjusts the arc parameters, and can use any electrodes; there are no special requirements.

The device can operate in conditions of high humidity and dust, at negative and positive temperatures. It has small dimensions and weighs about 4 kg.

It is difficult to say which model of welding machine is the smallest in the world, since many companies already produce such devices. Moreover, the price range is quite wide. Chinese models are considered the most affordable.

If you follow the operating instructions, the mini equipment will last a long time. The main thing is not to exceed the maximum welding time, use only the recommended brands and diameters of electrodes, and constantly monitor the cooling system .

Capacitor welding

Capacitor spot welding is carried out by using previously stored energy. This energy accumulated in the capacitors while they were being charged from the rectifier. When discharge occurs at the right moment, the energy is converted into heat.

Varieties:

Without transformer . In the process, the capacitor is connected directly to the parts. Its discharge begins when the upper part is struck.

The ends begin to melt, as a result of which they are connected. This type is used in the butt method.

Transformer . Here the capacitors are discharged into the primary winding of the transformer, and the parts are clamped between the electrodes of the secondary circuit. The transformer variety is used for the point and seam method of welding parts.

Among other methods, we can recommend plasma welding, which can work with metal that is thicker. As well as more functional and versatile semi-automatic welding.

Spot welding is a high-tech method of welding parts, it is available mainly to professionals. But with strict adherence to the technology, the result should be very worthy and, importantly, the places of such connections will be absolutely invisible.