In the process of machining parts, they almost always require their fixed fixation in a certain position.

For these purposes, a vice is used, which, moreover, allows you to free both hands and eliminate the need to exert physical force to hold the workpieces.

Various types of this tool are used in production areas, in home workshops, for processing materials manually or using machine equipment of varying complexity.

Purpose and operating principle of a vice

Vices are used for sawing, planing, drilling and performing many other workpiece processing operations.

Their main purpose is the stationary fixation of the processed material relative to any plane.

Also, in some cases, the tool can replace clamps, for example, when gluing two workpieces, when they need to be pressed tightly against each other, while processing several parts at the same time.

Craftsmen use a vice where holding the workpiece with your hands is inconvenient, impossible or simply dangerous.

Device and characteristics

A standard vice consists of the following main elements:

- The base is actually the body of a vice with a base plate designed to fix the tool on a table, machine or workbench, sometimes equipped with an anvil. The fastening is most often bolted, vacuum (suction cup type) or magnetic.

- Sponges. As a rule, there are two of them: fixed and movable. The first is part of the base, and the part is clamped by moving the second jaw towards the first along the guides.

Each sponge has flat, removable pads called cheeks. The inner surface can be completely smooth, which prevents damage to the soft part when clamping it, grooved with deep milling, which provides better adhesion and, therefore, fixation of workpieces, or with fine notches for the same purposes.

In the second case, each individual cell of the corrugated pattern has the shape of a sharp or cut pyramid, or vertical or horizontal grooves are cut along the entire length on the cheek. - The clamping screw with a rotary handle is the actual mechanism responsible for the movement of the jaw. The lead screw passes through the entire structure of the tool, and the handle is necessary to rotate it without the use of a wrench or other tool.

The design of different types of vices may differ significantly from that described above.

For example, instead of mechanical pressure with a screw, hydraulics can be used.

Also, some tools have double jaws, that is, two pairs located one above the other.

In this case, the upper jaws are the main ones and, as a rule, have a classic design.

The lower ones are additional, for solving specific problems.

A good example is V-shaped cast or prefabricated designs designed to hold workpieces with a round cross-section.

Another interesting addition, which is most often found on small benchtop vices, is the jaw locking button, with which the process of unclamping or fixing workpieces is greatly accelerated.

Material

Depending on the material used to make the vice, there are:

- Metal - most often these are cast iron tools; steel, aluminum, and duralumin options are also often found.

- Wooden ones are part of a carpentry workbench, sometimes an independent structure. Designed for fixing wooden workpieces. All elements, except for the clamping mechanism (rarely that too) are made of soft, but at the same time durable wood species, such as pine.

Cheeks are often made of soft materials such as non-ferrous metals, wood and even hard rubber.

Considering that they can be purchased separately, the mechanical characteristics are selected individually for the material of the clamped part.

Hard hardened (up to approximately 45 HRC) steel jaws are also produced.

Dimensions and weight

Considering the huge number of types of vices, we can safely talk about a truly wide range of their sizes.

Classic locksmith tools, which are rightfully considered the most popular, as they are suitable for solving most problems, have the following sizes:

- • Small: length – 290 mm, height – 140 mm, jaw height – 50 mm, jaw stroke – 80 mm, weight – 8 kg.

- • Medium: length – 372 mm, height – 180 mm, jaw height – 70 mm, jaw stroke – 125 mm, weight – 14 kg.

- • Large: length – 458 mm, height – 220 mm, jaw height – 90 mm, weight – 27 kg, and the jaws extend by 160 mm.

There are models whose dimensions are much larger than those indicated above.

For example, the length of the classic T-250 vice is 668 mm, and the weight is 60 kg.

Their high jaws protrude 125 mm and are 250 mm wide.

Approximate dimensions of chair vise:

- Length, width and height: 370 – 400 mm, 180 – 200 mm, 180 – 200 mm.

- Working stroke of the movable jaw: 120 – 160 mm.

- Height of jaws: 65 – 75 mm.

- Weight: 13 – 19 kg.

On average, hand vices have a length of 22 – 90 mm, a width of 6 – 45 mm, and a height of 100 – 150 mm.

What are the different sizes and weights of vices?

The weight of a vice depends on its dimensions - as the size increases, the weight also increases. It is also related to the material of the base, bed and jaws. Here are the three main categories of vises:

- Small - length and width no more than 29x14 cm with a stroke of the working part of 80 mm. The weight of the vice does not exceed 8 kg.

- Medium - the jaws expand up to 125 mm, and the dimensions are 37x18 cm. The weight reaches 14 kg.

- Large jaws are capable of fixing parts with a width of up to 160 mm, and the dimensions of the vice are 45.8x22 cm. The weight of the device is up to 30 kg. Due to their large size and heavy weight, they are used only in specialized industries and workshops.

Vise clamping force

The higher the compression force of the vice, the more force must be applied to the fixed workpiece in order to overcome the frictional force of the jaws and move it.

In fact, this is one of the most important parameters, since it is known that the tool is created for the stationary fixation of the workpieces.

If the clamping force is insufficient, then, for example, while drilling a clamped workpiece, not only a significant decrease in the accuracy of the operation is possible, but also a fracture of the drill itself.

On average, the clamping force of a bench vice, depending on the size, is 15–55 kN, and a chair vice – from 20 to 30 kN.

What is a bench vise?

Any craftsman knows that a bench vice is a device that ensures the immobility of a metal workpiece during its processing manually or mechanically. Depending on the type and structure, they are capable of tightly fixing everything: from the smallest golden curl of a future piece of jewelry to a large auto part. The main parameters, design and requirements for bench vices are set out in state standard 4045-75.

The device of a bench vice

Modern manufacturers have provided us with the widest range of options for the appearance of vices. However, any model basically has the same elements of the internal structure:

- Robust support base with a fastening mechanism that tightly secures the tool to the surface.

- Two jaws - static and moving, directly clamping the product.

- The plates on the jaw planes are usually replaceable, with a cut surface for better adhesion to the part.

- A running screw that regulates the movement of the movable jaw;

- Guide rods along which the screw “walks.”

- It is rotary, fixing the desired rotation of the tool.

A common configuration of this device is in which the role of a stationary jaw is played by its base, that is, the moving element presses the product to the surface on which the bench vice is fixed. Since the tool often serves as an anvil, it is preferred to be made of steel; other materials (for example, cast iron) are not able to withstand heavy loads.

GOST

For hand-operated bench vices, GOST 4045-75 has been introduced, which applies to models with jaw widths from 63 to 200 mm.

According to technical specifications, the tool comes in the following varieties:

- General purpose.

- With swivel jaw.

- With extra sponges.

The described types of vices may be rotary or non-rotary, and may or may not have a fast idle speed.

For machine vices with manual or mechanized drive, GOST 16518-96 was introduced.

According to this standard, vices are divided into several types:

- With manual drive.

- With pneumatic drive.

- With hydraulic drive.

All of them are rotating or non-rotating.

In turn, the first option may have reinforced fastening and double-sided clamping, and models with pneumatic and hydraulic drives are in addition only equipped with reinforced fastening.

There are only 4 machine vices for performing precision work according to GOST 20746-84.

Their digital designations look like 7200-0301, 7200-0302, 7200-0303 and 7200-0304 (in ascending order of all sizes).

In addition, the accuracy class is indicated by the letter:

- N – normal.

- P – increased.

- B – high.

NOTE:

Accuracy class H is not specified by default. Marking example: 7200-0304 V GOST 16518-96.

How to choose a bench vise?

So, the decision has been made to buy a bench vice, which one is better to choose? To begin with, you need to understand how they will be used: with small parts or large ones, for serious blacksmith work or purely for everyday needs. Once you figure out your goals and read the information above, you can easily determine which type of bench vise is best for you. When choosing a specific model, it is important to pay attention to the absence of play, the possibility of changing lips and key parameters: size and material of manufacture.

Bench vice - dimensions

The two main dimensional characteristics of the device are the width of the jaws and the range of their maximum spreading. These and other parameters are clearly stated in GOST 4045-75 “Hand-operated metalworking vice”:

- The smallest values of these indicators are found in manual vices for small work: their jaws have a width of 6.10 or 16 mm and are set apart by 5.5 or 6.5 mm.

- The standard hand tool is slightly larger: with a width of 36, 40, 50 or 56 mm and an opening range of 28, 30, 40, 50 or 55 mm.

- Ordinary parallel bench vices have the following parameters: jaws of 80, 100, 120 or 140 mm, adjustable by 65, 100, 140 or 180 mm. Moreover, fixed ones, unlike rotary ones, have an even smaller configuration with a width of 60 mm and an opening of 45 mm.

- Large bench vices generally have jaws of 100, 130, 150 or 180 mm, adjustable to 90, 130, 150 or 180 mm.

What material are bench vices made of?

Due to the serious loads on the tool, it is best to choose a metalworker's steel vice. The strongest ones are chair ones, forged from carbon structural steel completely, except for the surface in contact with the product. Tool steel equipped with special notches is used for it. Parallel vices are made lighter by casting their body from cast iron, although the jaws remain steel. Brass or aluminum jaw pads will help prevent dents on the workpiece. Structural and tool carbon steel is also used as material for hand vices.

Types of vices and their prices

Vices are divided into several types according to the design of the clamping mechanism.

The most widespread are mechanical options, where the workpiece is clamped by applying physical force.

In turn, such models are divided into:

Screw

The design provides a lead screw, often with a trapezoidal thread, which runs through the entire length of the vice.

This element rotates using a handle at its outer end.

Quick-clamping

The lead screw passes through a part that is spring-loaded and movable in the transverse direction.

When you press it, the screw disengages and can be moved freely without rotation.

Quick release

Opens and closes without using a screw.

For these purposes, the design of the vice provides a special mechanism with a trigger or lever, which provides quick adjustment of the position of the jaws.

Eccentric

Designed for quickly tightening parts, instead of a screw, an eccentric mechanism with an extended handle is used, while the jaw moves freely until the eccentric is clamped.

In addition to the clamping mechanisms described above, to increase the operating speed and pressing force, the following are used:

Pneumatic vice

The convergence of the jaws is ensured by the special device of the instrument with internal cavities-chambers, valves and diaphragms.

A similar option with a pneumatic drive is connected to an air compressor; parts are clamped in just 2 - 3 seconds without the use of physical force.

In the absence of pressure, the jaws are in the maximum spread position.

Hydraulic

Most often, this is a screw tool with a built-in hydraulic booster system, or options similar in operating principle to jacks, that is, with a built-in or connected hydraulic pump.

I mainly use such models at manufacturing plants, where it is necessary to repeatedly clamp and release workpieces.

The presence of a hydraulic drive makes the work of the master several times easier and faster.

All existing models of vices are divided by design into:

Locksmith

Attached to a table or workbench with bolts in the base.

These are the most common vices listed.

To expand functionality they can be structurally combined with other tools.

For example, most models come with an anvil - a flat platform behind a fixed lip.

Some options have a base with a pipe bender - two fixed rollers.

A movable roller, which adjusts the bending radius and which presses the pipe in the center, is installed on the back of the movable jaw structure.

Price for quality – from 7 thousand rubles.

Tabletop (small)

Designed for fixing small parts, for example, when repairing radio equipment.

In fact, this is a smaller copy of the previous version, but at the base there is a fastening made in the form of a clamp.

Because of this design, these are portable vices, since they can be moved at any time to the other edge of the table, or even worn and carried along with the tool set.

As a rule, mini-vises do not have removable jaws, and therefore, when working with soft materials, rubber or wooden gaskets are installed between the lips and the clamped part.

The minimum cost is 300 rubles.

For high-quality vices you will have to pay from 1000 rubles.

Machine tools

They are used in conjunction with various machines of various sizes.

For fastening to the machine table, the base of the tool has two side projections with long grooves, which allows you to adjust their position relative to the working element of the equipment horizontally.

The movable jaw and the frame itself are made of steel.

Price – from 1 thousand rubles.

Manual

They are used to hold small workpieces that are simply inconvenient to hold in your hands.

In the classic version, these are two steel jaws connected on the reverse side by a jumper, and approximately in the center they have a clamping screw.

These clamping vices resemble pliers.

Another design option is a vice-clamp, which is a snap-on pliers with a lever mechanism and a “dead point” of the levers.

All models are used for processing parts in weight, that is, the vice itself with the clamped workpiece is held in the hand.

The cost starts from 400 rubles.

Carpentry

These are wooden or steel bench vices that are attached to the workbench from below and have guide rods together with a lead screw.

Such a vice is also called a carpenter's vice.

They are equipped with smooth, even jaws with a large surface area, on which wooden pads made of soft wood are installed, which avoids damage to the material being processed.

A carpenter's vice can have either both of its own jaws, or only one movable one, in which case the edge of the table itself acts as a fixed one.

NOTE:

It is normal for a factory-equipped workbench to have a pre-installed built-in vice.

The cost for high-quality models is from 2 thousand rubles.

According to the method of bringing the jaws together, vices are divided into:

Chairs

A rare option that is almost never used anymore.

Initially, these were large forge vices that were attached to a base shaped like a chair.

Now this is the name of any type of instrument whose jaws are brought together similarly to the manual options described above, that is, like tongs.

Parallel

These are almost all modern models, where the movable jaw moves strictly parallel to the fixed one along guides.

In turn, there are rotary (rotate parallel to the base), non-rotary (completely monolithic structure) and reversible (the movable jaw can be moved to the opposite side, and the fixed part has 2 jaws at once).

Special purpose vice

Some vices have a special design for connecting the fixed jaw and the base, which allows you to move the workpiece and tilt it at different angles, from which the following classification follows:

- Inclined - options with a hinged connection to change the angle of location along one vertical axis.

- Globe - as a rule, these are two-axis models that allow you to change the angle of the workpiece vertically and rotate horizontally, and three-axis - with a paired globe mechanism for tilting in two planes vertically and rotating horizontally.

- Hinged - they are based on a ball pressed into a holder, which allows you to rotate the tool in any direction at any angle.

They are also articulated and swivel with a clamp - this name largely reflects the functionality of this model. - Cross (coordinate) - the workpiece can move in two directions horizontally. Cross models have guides located one above the other at right angles.

Machine vices can be universal or specially designed for use in conjunction with one type of machine equipment to perform a specific task:

- Drilling – for clamping workpieces in drilling machines.

- Milling – simplify the performance of milling work. Models for a milling machine are usually capable of rotating and changing angles.

- Patterns – machine tooling made of alloy steel. This is a high-precision vice designed for milling, grinding and measuring work.

- Sine - for processing parts at angles.

- Lathe – for installation on turning equipment.

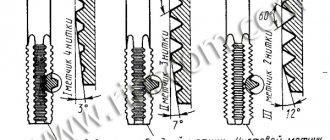

- Prismatic - designed for processing cylindrical parts, they have prismatic jaws, that is, with V-shaped recesses for a round profile.

- Precision - any vice that provides high accuracy of workpiece positioning and low deviation in parallelism of the jaws.

To perform some work where it is impossible to use a standard vice, special variations are used:

- Fishing ones are small models of a special design designed for tying flies. Purpose – fixed fixation of a fishing hook.

- Pipe - options that resemble a “guillotine” type pipe cutter, but instead of a knife, a movable jaw is installed.

There are both folding ones (like a pipe cutter with a clamp latch) and non-folding ones.

- Engraving round – used for engraving jewelry. These small instruments are placed on the table using a vacuum suction cup or a magnet in the base.

- Jewelry (shrabbugels or ball vices) - a heavy steel ball with jaws and guides milled in the upper part. For convenience of working at different angles, the tool is placed on a ring cushion with sand or in the recess of a special stand.

- A vise-stand is reminiscent of a construction sawhorse. These are floor-mounted options with legs, and are also multifunctional, as they are often used in pairs to fix wide products, such as doors. In most cases, such a vice is folding, that is, the legs in the folded position are adjacent to the body for ease of transportation and storage.

- Corner clamps are essentially clamps that allow you to fix 2 parts at a certain angle to each other.

In most cases, we are talking about perpendicular vices, that is, with fixation at 90 degrees. - Self-centering - used to perform similar operations with workpieces of different sizes.

Provide automatic centering of the part during clamping. - Modular - with a flat base and the ability to quickly replace jaws with different profiles of the internal working surface.

- Reinforced – characterized by increased strength.

Chain vice

Another non-standard tool.

They are used for preliminary fixation of pipeline elements to each other before welding.

These mobile vices have a base with V-shaped jaws that rest against the pipe fittings, and instead of an upper lip (as with conventional pipe options) they use motorcycle-style chains that are draped over the joined pipes, each tightened by a cam handle.

Depending on the type of work, vices are distinguished:

- For welding straight pipes - with a straight base.

- For welding bends - with a cut-off base shape.

- For welding inserts - with a carbon base.

- For welding flanges - a straight base with a protrusion for the flange and a hole for attaching it with a bolt.

Some machines are initially equipped with their own clamping elements to hold various tools.

For example, the support of a lathe is, in fact, a movable vice for the cutters.

Types of vices by purpose

Vices are classified according to the nature of the intended actions with workpieces and can be carpentry, metalworking, machine tools, engraving or pipe. There are also tabletop small vices and scrubbers. Let's look at all the categories in order.

Bench vice

This is one of the largest groups of clamping devices. The tool is used in factories and workshops for fixing and processing parts. The vice is fastened to a powerful table or workbench using the provided eyes and bolts.

The lower part of the body is rotatable and allows you to rotate the vice to the left or right on the table for more convenient placement of workpieces. By pressing the discs with a wrench, the position is securely fixed. Because of this feature, the model can additionally be called a rotary model.

Bench vice.

The workpiece itself is clamped using a screw mechanism. It uses a high threaded shaft. Its coils are rectangular or trapezoidal, rather than triangular, which makes them more durable and allows the part to be tightened with force.

The workpiece is installed between two plates called jaws. They are made of steel that has been lightly hardened to give it a strength of 45 HRC. When working with soft materials, the jaws can be replaced with others without damaging the part.

Typically, a bench vise has an additional cast platform. It acts as an anvil - it is easy to level a bent pin, nail or plate with hammer blows, as well as flatten the edge of a rod or tube. The large die-cast design effectively absorbs impacts so the workbench is not damaged.

Let's consider all types of bench vices in terms of configuration, clamping mechanism and functionality. This will help you choose the best option for your workshop, enterprise or garage.

Vice with two movable jaws

A type of bench vice, where the jaws are able to rotate on the shaft on which they are located. Rotation of the working part is possible along the horizontal axis up to 180º in both directions. This expands the possibilities for installing the workpiece and allows you to perform work more conveniently. For example, to make a longitudinal cut at the end of a profile pipe, it can be installed vertically.

There are models with both jaws movable, where the clamping part is double, i.e. available on both sides. From below it is usually of a figured type for fixing round objects. This allows you to grip the round pipe even more securely and not flatten it during tightening.

Like all regular bench vices, they can be rotated on their base. Since both classic models and those with two movable jaws can be called rotating, when purchasing online, you should clarify which method of turning you are talking about.

Bench vice with two movable jaws.

Hand bench vise

Sometimes the size of the workpiece is so small that when installed in a conventional bench vise, it almost does not protrude outward. In this case, use a hand vice. Mini versions come in one of two designs.

Screw ones have two jaws, which are brought together by a transverse screw and a pressure “wing”. There is an option where, instead of a thumb, a handle is used that rotates along its longitudinal axis, which leads to tightening. This type of tool is also called a “jeweler’s” vice. Having clamped the part, it is processed with a file, a small grinder or a drill attachment.

The vice is also used as a universal wrench, grasping the heads of bolts and nuts when a real wrench of the appropriate size is not available. They are also convenient for fixing the tap when cutting threads. The metric tapered thread in such models should not scare off the buyer, since the effort when tightening manual equipment is small.

When choosing a hand vice, pay attention to:

- parallelism of the jaws;

- no play in the tightening handle;

- clamping density without gap.

Hand held mini vise.

The second type of hand vice resembles pliers, which fix the workpiece by snapping a lever mechanism. They have a tension spring with an adjustable distance between the jaws. The part is grabbed and pulled together with a clear fixation of the specified thickness. Typically, the parameter is set slightly less than the thickness of the workpiece to ensure sufficient clamping. To move the sides apart, use an additional lever in the handle, which weakens the grip.

Weiss flu.

Bench bench bench vise

The design consists of two jaws, but they are brought together not in a straight line, but in an arc. For this purpose, both working sides are additionally connected from below by a hinge. The closer the sides are to each other, the higher the convergence point. The vice uses thin, narrow jaws. This form factor allows you to clamp specific parts that do not fit in a regular vice. The maximum spreading distance depends on the size of the model and can be 125, 150, 250 mm.

The device itself can be secured to the edge of a table or chair using two bolts. This is convenient for use not only in the workshop, but also in the field. For example, they can be brought to the garden, installed on any stump and repaired a damaged part of a combine or tractor. This eliminates the need to transport a huge part from the equipment to the workshop. The main area of use of chair bench vices is now blacksmithing.

Bench bench bench vice.

Parallel vice

This is a “classic” type of bench vise marked TSM. They got their name because of the parallel arrangement and movement of the sponges. Typically, in a design, one side is stationary, and the other moves closer and further away from it by rotating the screw. A handle is provided for this action. The base of the vice can be rotary or non-rotary. Installation is carried out on a table, but the device can be used loosely on the floor.

Bench vice TSM.

Globe type vise

The modification has the same movable and fixed jaws, but the body is able to change the angle of inclination. The action occurs using semicircular guides, which is where the instrument got its name. You can fix the specified position using a clamping bolt. Rotating the base to the left or right further expands the possibilities for placing the workpiece in a more convenient position. These versions are called dual-axis.

There are three-axis vices where you can tilt the part back and forth, tilt it left and right, and rotate it left and right in a given position. In this case, the design includes additional semicircular guides located one above the other. The device is installed on a workbench or machine using two eyes and bolts.

Globe type vice.

Angle vise

The tool has a fixed base with two thrust edges. Plates, profile pipes, and metal corners are attached to them. The moving part presses the two sides of the workpiece so that they are brought together at a strictly 90º angle. Due to the open shape of the structure, there is free access to the joint, which facilitates the installation of tack welding. The vice simplifies the quick assembly of frame parts where the connection is made at right angles.

Angle vise.

Holdfast

This type is used exclusively for fixing workpieces made of plastic or wood. In another way, such devices are also called carpenter's vices. The clamping force here is small so as not to leave marks in soft materials, so they are not suitable for fixing iron.

The carpenter's vise design has a lag screw and several smooth metal guides to keep the sides parallel. The device is fixed on the workbench. The jaws here are made of wood, and the steel sealing parts are located much lower than the wooden ones. This is provided to protect the processing tool. When colliding with wooden jaws, the cutting blades do not deteriorate, and the peripheral part of the vice is easy to replace with a new one.

Holdfast.

Carpenter's vice on a workbench.

But besides the usual carpenter's vice, there is another variety.

Vise-stand

This version is structurally different from classic joinery and acts as a free-standing element placed on the floor. The vice has the shape of a construction “goat” and is used in pairs. The workpiece is placed on top of them and work can be done without a workbench or table. The design has a stop and a movable lip with a large stroke (50-100 cm). Rubber pads provide a gentle effect when in contact with wood.

The clamping is carried out by a lever mechanism, so long rotation of the screw is not required. The drive is often foot driven and frees the master’s hands to hold a large workpiece.

In such a vice it is convenient:

- plan the edge sides of interior doors;

- cut window openings in door panels;

- install locks;

- saw timber

Vise stand.

Pipe vise

The round cross-section of the pipes complicates crimping in a vice with even jaws, since the fixation area is very small, and the product can easily slip out when pressed. To securely fasten round pipes, a separate category of vice has been developed. It is convenient to clamp even a short piece of 5-10 cm in them in order to saw off a ring from it or make longitudinal cuts, cut an edge at an angle, etc.

A pipe vise has a vertical frame with an upper movable lip that is moved by rotating a screw. The lower counter part is motionless. The model is secured to the table using bolts. The shape of the jaws with a deep cut inside provides grip and increases the clamping area of the round pipe.

If the part is thick-walled and strong pressure is required, there are jaws with a relief surface. For thin-walled workpieces or soft materials (copper, polypropylene, aluminum), recesses in the jaws with a smooth surface are provided. In addition to this feature, when purchasing, pay attention to the maximum size of the inserted pipe so that it meets the needs of the user.

Pipe vise.

Chain pipe vise

A type of pipe vice that allows you to fix pipes of any diameter. The design of the fixture has a lower semicircular or V-shaped support on which the workpiece is placed. The part is wrapped around a steel chain (like a motorcycle, but larger and stronger) and tightened with an eccentric drive. Due to the chain, the contact area increases even more, which protects the workpiece from dents and ensures reliable retention.

Since the crimping part is flexible, the maximum diameter of the installed pipe depends only on the length of the chain. The device is also practical in the case of gripping not very round parts that are simply physically impossible to install in a conventional vice. Chain vices are also useful for crimping fittings and tees, where protruding elements interfere with the alignment of standard jaws.

Chain pipe vise.

Machine vice

Machine versions of the vice are used as add-ons for main equipment. Common characteristics of the device are steel jaws and a frame, as well as the presence of two long slots in the base. With their help, the vice is attached to the machine and its precise positioning under the spindle or other equipment.

Professional models provide for changing jaws to accurately select the working part to match the shape and material of the workpiece. Here is a classification of machine vices by purpose.

Cross machine vice

The design, in addition to a fixed stop and a movable jaw, has two pairs of guides and screws to move the clamped part back and forth and left and right horizontally. Often there is a scale next to the actuator handles to see the exact values of this displacement.

Thanks to such a vice, a regular drilling machine can be turned into a milling machine, performing lateral processing of workpieces with a gradual offset. This is beneficial for novice craftsmen and starting a business in the garage.

Cross machine vice.

Drilling

The drill press bed has many slots, under which the space is widened for special T-shaped studs. They are used to attach a vice that holds the part during the drilling process. You can move the model to the sides, towards you and away from you, but this is only allowed when adjusting the position. Then the vice is fixed with nuts and then only the working jaw remains movable.

Drilling vice.

Milling

Structurally, they can be installed on milling machines. Since the milling machine bed is movable, the vice is designed to move towards and away from the operator, as well as to change the angle of inclination.

Milling vice.

Patterns

Used on pattern grinding machines. Made from stainless steel to resist corrosion. They have increased accuracy and a scale with metric divisions for the desired positioning of the workpiece.

Pattern vice.

Sinus

They have an additional hinge and guides at the base, allowing you to lift the working part at an angle. This expands the possibilities of processing workpieces at different angles.

Sinus vise.

Prismatic

They have semicircular working edges for fixing pipes and other workpieces with uneven walls in machines. The V-shaped or curved shape of the jaws prevents the part from turning during processing.

Prismatic vice.

Precision

Equipped with a metric scale and have high positioning accuracy. There is no play in the design, and the jaws are strictly parallel to each other. Used for precision machining.

Precision vice.

Engraving vice

They have two significant differences. Firstly, their base is a cast ball that rotates in any direction, being in the seat of the frame. The position is fixed by a lever and becomes motionless. This is convenient for tilting or rotating the workpiece.

Secondly, both jaws are movable and move together at the same time. This ensures that the part is always located in the center, which is convenient for applying point blows and monitoring the symmetry of the cut of the workpiece. Engraving vices are used in artistic processing of metal elements or in weaponry. They are convenient for cutting with a graver or hammer cutters.

Engraving vice.

Shrabkugeli

The base of the vice is a large ball on a wooden stand. Instead of the latter, there may be a leather pillow with pressed sawdust. The ball provides rotation and tilting of the workpiece in any direction. Sponges are usually small and suitable for small parts (coins, tags, jewelry). Often the upper side of the jaws is equipped with holes for installing pins and fixing hollow and cast objects of non-standard shape.

Shrabkugels are held on the table by their mass, which ranges from 5 to 15 kg. This is enough to absorb shock from jewelry cutters and hammers.

Shrabkueli.

Which vice should you choose?

When choosing a vice for your home, you should pay attention to ordinary rotary bench models of medium size.

They can handle almost all household tasks.

When choosing, you should check the method of attaching this tool to the table, as well as for the presence of backlashes that should not be there in the first place.

It is better to choose a vice made of cast iron or steel, but not of powdered metal.

For professional use, when workpieces have to be clamped quite often, it is better to pay attention to quick-release or eccentric models.

It is recommended to choose steel options with an anvil, as they are more durable and can easily withstand impacts.

Important!

Make sure that the jaw pads are removable.

In addition, when choosing a vice, you need to take into account the distance to which the jaws open, because it depends on what parts can be fixed in them.

What other vices are there and where are they used?

To perform different jobs with maximum precision, manufacturers produce different types of tools, which are not limited to differences in drive type, shape and method of clamping workpieces. A separate category of vices are tools that allow you to clamp a workpiece and move it in this form in different directions. These instruments include the following types:

- Inclined - the devices have a swivel joint, due to which the angle of the workpiece fixed in the jaws of the tool changes

- Ball - movable and fixed jaws are connected to the base through a ball, through which rotational ability is provided. The difference between ball and hinge vices lies in the design features of the rotation mechanism

- Globe ones are more modernized versions of devices on which the option of changing the angle of the fixed workpiece in two directions is available - horizontally and vertically. There are even three-axis models that have the ability to change the tilt in two vertical planes and rotate in the horizontal direction

- Cross - provide mobility of the fixed workpiece in two directions - vertically and horizontally. The main feature of such devices is that vertical and horizontal movement is carried out at a right angle of 90 degrees

Vices with rotating properties are usually used where high precision and care are important. That is why such devices are produced in small sizes.

Particular attention should be paid to vice options that are designed to perform specific tasks.

- Drilling - designed exclusively for use with drilling machines. They have adjustable mounting holes for installation on the machine. Sliding jaws allow you to secure workpieces for subsequent drilling of holes in them

- Milling - unlike drilling tools, such models have the ability to rotate and change the angle of inclination. The design of such devices includes metric scales for performing more precise types of work.

- Patterns are universal models of tools that can be used for milling, grinding and measuring manipulations. Alloy steel is used for the manufacture of such devices

- Lathe - intended exclusively for placement on turning equipment

- Sine - with their help, parts are processed at different angles. For this purpose, the devices are equipped with a special mechanism that allows you to change the position of the working part of the tool

- Prismatic - used for processing parts that have a cylindrical shape. The jaws of such devices are V-shaped, thereby increasing the area of contact with cylindrical workpieces. These types are also called pipe types, since they can be used to process pipes

- Precision - designed to ensure high positioning accuracy

All types of vices have characteristic features, and therefore, when choosing them, you need to understand exactly for what purposes you plan to use them.

Standard vices can rightfully be called universal, as they are suitable for securely holding a wide variety of workpieces. However, for convenience and high precision in performing some work, it is recommended to use special-purpose tools. These instruments include the following types:

- Pipe - when it is necessary to fix a pipe for the purpose of its subsequent processing. It is impossible to do this in the jaws of a conventional vice, since strong compression will cause deformation of the workpiece. If you do not squeeze the jaws tightly, then the pipe will slide and move in different directions, making it impossible to drill a hole or perform other types of work. For such purposes, special pipe vices are produced, which are similar in appearance to a guillotine, but instead of a cutting blade, the tool is equipped with V-shaped jaws with steps for increased reliability

- Fishing - for tying flies. Fishing professionals know that vices are also produced for their field of activity. With their help, the hook is fixed in a stationary form.

- Engraving devices are special types of devices that are used to engrave the surfaces of jewelry. These devices are usually attached using a suction cup.

- With a pipe bender - used to bend pipes to the required angle of inclination

- Jewelry - used in jewelry workshops for the manufacture and repair of gold and silver jewelry. Jewelry-type machines are equipped with a ball, through which the fixed workpiece can take a convenient position for the purpose of its subsequent processing

- Angular - used to fix two parts at right angles

- Stand vises are portable devices that are large in size. Outwardly, they resemble the design of a construction trestle with legs, but at their base there are jaws for fixing wide-sized products - these can be doors, sheet materials, etc.

- Self-centering - these vise models are used for carrying out similar manipulations with workpieces of different sizes

- Modular - they have a flat base, which allows you to change the types of cheeks. Designed to work in conjunction with machine tools

- Reinforced vice - have increased strength, which is achieved through the use of special high-strength materials

- Chain - when working with steel pipes, there is often a lack of a third hand, which the devices can fully replace. The special design of the vice allows you to connect two pipes to each other for their subsequent connection by welding. Such tools are called chain tools because chains are used as clamping elements. After tying the pipes with a chain, they are fixed using an eccentric mechanism

Having expanded your horizons about the types and varieties of vices, you can make a brief conclusion that in order to perform the relevant work better, you should use tools that are designed for these manipulations.

What you need to know about vices?

A machine vice is a tool that is almost never used in everyday life.

These are pneumatic or hydraulic models designed for fixing large parts, and they come in both metalwork and machine tools.

Another frequent “guest” of factory floors is the tool vice, which is located next to the grinding machines.

They are distinguished by high perpendicularity of the sides and parallelism of the planes.

This is necessary for precise positioning of the workpiece on the machine.

The difference between machine vices and metalworking vices

Depending on the specifics of use, devices for securing parts can be machine or metalwork. What are their design and functional differences:

- Machine vices

, as the name implies, are used for processing products on drilling, milling, turning and other machines. They can be mounted on a rotating platform of the equipment, which provides the choice of a convenient angle for fixing the part. The design of such a vice is optimal for reliable installation on the machine: the flat bottom part has long side slits for bolting to the surface. Replaceable linings on the jaws of the device often have V-shaped grooves that improve the vertical and horizontal fixation of cylindrical workpieces. - Bench vices

for home and production are relevant when processing parts with hand or electric tools and are installed on a workbench. The device is attached to the surface with a pair of bolts through holes in the base. A bench vise does not need to be as rigid and stable as a machine vice, so they are suitable for working with softer materials - wood or plastic.