May 7, 2021 by Admin

Plastic is one item that has taken over every part of our lives and has penetrated every possible industry. Plastic was initially seen as an invention that truly made life easier and more convenient for us humans. But over the years, the same plastic has become the bane of our existence. To understand the plastics issue as a whole, it is important to understand how plastic is made in the first place.

There are two main ways to synthesize plastics - they can be synthetic or derived from renewable bioproducts. Synthetic plastics are made from crude oil, natural gas or coal. In the most popular scenario, plastics are derived from crude oil, as this is the most cost-effective way to get the job done.

But we should also note that this is also the most harmful way to obtain plastic. Based on how plastics interact with each other, there are mainly six types of plastics: thermoplastics, thermoset plastics, amorphous plastics, semi-crystalline plastics, homopolymers and copolymers.

What is plastic?

Currently, plastics, or plastics, refer to a whole group of materials of artificial (synthetic) origin. They are produced through a chain of chemical reactions from organic raw materials, mainly from natural gas and heavy fractions of oil. Plastics are organic substances with long polymer molecules that consist of molecules of simpler substances connected to each other.

By changing the polymerization conditions, chemists obtain plastics with the desired properties: soft or hard, transparent or opaque, etc. Plastics today are used in literally all areas of life, from the production of computer equipment to the care of small children.

Recycled polymer raw materials

At many enterprises, in order to save money, defective products made from polymer plastics are recycled, ensuring waste-free production. Along with this, there is a whole line of business for processing waste into secondary polymer granules for sale. The process is multi-stage, the entire cycle from collecting and purchasing household plastic waste, sorting, washing, crushing and processing into granules is quite labor-intensive. However, the finished products are practically no different in their properties from the primary raw materials and are successfully used in many industries. The production of recycled polymer raw materials is an important and necessary sector of the national economy, which allows one to save huge amounts of money by eliminating the need to dispose of waste plastics.

How were plastics invented?

The world's first plastic was made in the English city of Birmingham by metallurgist A. Parks. This happened in 1855: while studying the properties of cellulose, the inventor treated it with nitric acid, thanks to which he launched the polymerization process, obtaining nitrocellulose. The inventor named the substance he created by his own name - parkesin. Parks opened his own company to produce parkesin, which soon became known as artificial ivory. However, the quality of the plastic was poor, and the company soon went bankrupt.

Subsequently, the technology was improved, and the production of plastic was continued by J.W. Hite, who called his material celluloid. A variety of products were made from it, from collars that did not need to be washed to billiard balls.

In 1899, polyethylene was invented, and interest in the possibilities of organic chemistry grew exponentially. But until the mid-twentieth century, plastics occupied a rather narrow market niche, and only the creation of PVC production technology made it possible to produce a wide range of household and industrial products from them.

Primary polymer raw materials

Let's consider the main characteristics of some types of primary polymer raw materials.

Polypropylene is synthetic. The substance is white in color and comes in the form of solid granules. It has many modifications, including homopolymer, foaming polypropylene, rubber and metallocene polypropylene. Catalog link: Polypropylene

Polystyrene is a thermoplastic synthetic polymer. Hard, glassy. A good dielectric, resistant to radioactive influences, inert to acids and alkaline solutions (with the exception of glacial acetic and nitric acid). Polystyrene granules are transparent and cylindrical in shape. Used for the production of various products using the extrusion method. Catalog link: Polystyrene

Low-density polyethylene – crystalline, low-transparent granules of high density. Everyone knows the “noisy” HDPE bags that can withstand high loads. Very thin films are blown from it by extrusion. Catalog link: HDPE

High pressure polyethylene – white granules with a beautiful smooth glossy surface. It has a second name - low density polyethylene. Recommended for use in the food industry and for the manufacture of medical products. Catalog link: PVD

Polyvinyl chloride (PVC) is a free-flowing powder with a particle size of up to 200 microns. Easily processed into hard and soft plastics. Used for the production of pipes, films, linoleum and other technical products. Catalog link: PVC (Polyvinyl chloride)

Linear high-density polyethylene - used for the production of thin elastic packaging films and films for lamination. In terms of properties, it occupies a middle position between low-density polyethylene and high-density polyethylene. Work to improve its properties does not stop. Catalog link: Linear Low Density Polyethylene LLDPE

Types of plastics

Currently, the industry produces and uses many types of plastics.

Based on their composition, plastics are divided into:

– sheet thermoplastic masses – plexiglass, vinyl plastics, consisting of resins, plasticizer and stabilizer;

– laminated plastics reinforced with one or more layers of paper, fiberglass, etc.;

– fiberglass – plastics reinforced with glass fiber, asbestos fiber, cotton fiber, etc.;

– injection molding masses – plastics that do not contain other components other than polymer compounds;

– press powders – plastics with powder additives.

Based on the type of polymer binder, plastics are divided into:

– phenol plastics, which are made from phenol-formaldehyde resins;

– aminoplasts made from melamine-formaldehyde and urea-formaldehyde resins;

– epoxy plastics using epoxy resins as a binder.

Based on their internal structure and properties, plastics are divided into two large groups:

– thermoplastics that melt when heated, but after cooling retain their original structure;

– thermosets with an initial structure of a linear type, which acquire a network structure during curing, but when reheated, completely lose their properties.

Thermoplastics can be used repeatedly; to do this, they just need to be crushed and melted. In terms of working properties, thermosets are, as a rule, somewhat better than thermoplastics, but when subjected to strong heating, their molecular structure is destroyed and is not subsequently restored.

Classification of plastics

Depending on the behavior of the binder when heated, plastics are divided into thermosetting and thermoplastic.

Thermosetting plastics, when heated to a certain temperature, soften and partially melt, and then, as a result of a chemical reaction, become a solid, infusible and insoluble state. Thermosetting plastics are irreversible: waste in the form of burrs and defective parts are usually used after grinding only as a filler in the production of press powders.

Thermoplastic plastics soften or melt when heated and harden when cooled. Thermoplastic plastics are reversible, but after recycling the plastics into parts, their physical and mechanical properties deteriorate somewhat.

The group of thermosetting plastics includes press powders, fibers and laminated plastics. They compare favorably with thermoplastic plastics in the absence of cold flow under load, higher heat resistance, and small changes in properties during operation. Thermosetting plastics are processed into parts (products) mainly by pressing or injection molding (Fig. 2).

Rice. 2. Scheme and installation for producing parts from thermosetting plastics

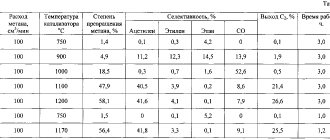

Table 1 lists the properties, applications, and operating temperature ranges of some thermoset plastics. In Fig. Figure 3 shows some thermoset plastic products.

Table 1.

Rice. 3. Products using thermosetting plastics

The technology for manufacturing thermoplastics is quite simple: granules are poured into the chamber of an injection molding machine, where, at the required temperature, they transform into a fluid state, then the molten mass falls into a special mold, where pressing and further cooling occurs (Fig. 4). As a rule, most thermoplastics can be recycled.

Rice. 4. Plastic injection mold

Table 2 shows the properties, applications and operating temperature ranges of some thermoplastic plastics. In Fig. Figure 5 shows some thermoplastic plastic products.

Table 2.

Rice. 5. Products made of thermoplastic plastics

The choice of plastic for the manufacture of a particular product is determined by its operating conditions. The selection criteria are varied and depend on the purpose of the product. The main criteria characteristics of polymer materials are mechanical (strength, stiffness, hardness), temperature (changes in mechanical and deformation characteristics when heated or cooled) and electrical. The latter reflect the widespread use of plastics in the electronics and electrical industries. In addition, tribological characteristics and a number of special properties (fire resistance, sound absorption, optical properties, chemical resistance) have acquired significant importance. Economic conditions are also important (cost of polymer material, product circulation, production conditions).

What are plastics made of?

The raw materials for the vast majority of plastics are coal, natural gas and oil. From them, simple (low molecular weight) gaseous substances are isolated through chemical reactions - ethylene, benzene, phenol, acetylene, etc., which are then converted into synthetic polymers during polymerization, polycondensation and polyaddition reactions. The excellent properties of polymers are explained by the presence of high molecular weight bonds with a large number of initial (primary) molecules.

Some stages of polymer production are complex and extremely environmentally hazardous processes, so the production of plastics becomes accessible only at a high technological level. At the same time, the final products, i.e. Plastics are generally completely neutral and do not have any negative impact on human health.

Introduction to Polymers

Preface

Plastics are materials based on organic natural, synthetic or organic polymers, from which, after heating and applying pressure, they can be molded into products of complex configurations. Polymers are high-molecular compounds consisting of long molecules with a large number of identical groups of atoms connected by chemical bonds. In addition to polymer, plastic may contain some additives.

Plastics processing is a set of technological processes that ensure the production of products - parts with a given configuration, accuracy and performance properties.

High quality of the product will be achieved if the selected material and technological process meet the specified operational requirements of the product: electrical, mechanical strength, chemical resistance, density, transparency, etc.

When processing plastics under conditions of mass production, materials science, technological, scientific, organizational and other problems are solved to ensure high quality products.

Materials science tasks consist in the correct selection of the type and grade of polymer, in such a way as to ensure the possibility of molding a product with a given configuration and performance properties.

Technological tasks include the whole range of issues of polymer processing technology that ensures product quality:

- preparation of polymers for processing,

- development and determination of technological process parameters,

- development of equipment,

- selection of equipment.

The main stages of work on the use of plastics in products are as follows:

- Analysis of product operating conditions, development of requirements for operational properties.

- Selecting the type of plastic according to the specified requirements and performance properties of the product.

- Choosing a method for processing plastic into a product and equipment.

- Selection of a basic brand of plastic and, based on it, a brand with improved technological properties.

- Design, manufacturing, testing and debugging of technological equipment, etc.

Structure of polymers.

Polymers consist of repeating groups of atoms - units of the original substance - monomer, forming molecules thousands of times longer than the length of non-polymer compounds; such molecules are called macromolecules. The more units there are in a polymer macromolecule (the higher the degree of polymerization), the stronger the material and the more resistant to heat and solvents. Due to the impossibility of effective processing of low-melting and sparingly soluble polymers, in some cases, semi-finished products are first obtained - polymers with a relatively low molecular weight - oligomers, which are easily brought to a high molecular level with additional heat treatment simultaneously with the manufacture of the product.

Depending on the composition, groups of polymer compounds are distinguished: homopolymers - polymers consisting of identical monomer units; copolymers – polymers consisting of different starting monomer units; organoelement - compounds with silicon atoms (organosilicon compounds), aluminum boron, etc. introduced into the main chain or side chains. These compounds have increased heat resistance. The shape of the molecules can be:

- linear, unbranched, allowing dense packing;

- branched, more difficult to pack and giving a loose structure;

- sewn - ladder;

- mesh;

- parquet;

- stitched three-dimensional volumetric;

- with a dense network of cross-links;

In organic polymeric materials, the macrostructure is formed either by flexible macromolecules rolled into balls (globules), or by packs-lamellas of more rigid macromolecules, parallelly arranged in several rows, since in this case they have a thermodynamically more favorable shape, in which a significant part of the lateral surface is adjacent to each other to friend. Domains are formed at the folding sites, and the domains create fibrils connected by passage regions. Several domains, connecting along folding planes, form primary structural elements - crystals, from which lamellar structures - lamellas - appear when the melt is cooled. During the process of folding the lamellas, the ends of the molecules can be in different planes; Sometimes these ends of the molecules partially return to the original plane - in this case they create loops.

Properties of polymers.

Polymers in the solid state can be amorphous or crystalline.

When an amorphous polymer is heated, three physical states are observed: glassy, highly elastic, and viscous. These states are established based on the thermomechanical state curve. An amorphous polymer is below the glass transition temperature (Tg) in a solid state of aggregation. At temperatures above Tg the polymer is in a highly elastic state; In this case, molecular mobility becomes so great that the structure in short-range order has time to rearrange itself following a change in temperature, and macromolecules can bend under the influence of external forces. The total deformation in this case consists of elastic and delayed highly elastic deformation. During elastic deformation, the average intercenter and intermolecular distances and bond angles in the polymer chain change; during highly elastic deformation, the orientation changes and the links of flexible chains move over significant distances.

A crystallizing polymer, depending on the cooling rate of the polymer melt, can exhibit two types of structures: amorphous and crystalline. When crystallizing polymers are slowly cooled, the joint stacking of segments of macromolecules forms the structure of macromolecules. This makes it difficult for them to transition from one conformation to another, which is why there is no flexibility of macromolecules and no highly elastic state. During rapid cooling, the crystalline structures do not have time to fully form, so in the supercooled polymer there is a “frozen” - amorphous structure between them. This amorphous structure, when reheated to a temperature above the melting point (Tm), creates a viscous flow state. The polymer structure is characterized by two states: crystalline (up to the melting point) and viscous flow (above the melting point).

The viscous flow state, characteristic of the amorphous and crystalline state of the polymer, mainly provides the necessary deformations during the flow of the polymer through the sequential movement of segments. The viscosity of the polymer increases with increasing molecular weight of the polymer, and the molding pressure of the products also increases.

In conclusion, we note that with an increase in temperature to a certain value, the process of thermal destruction begins in the polymer material - decomposition of the material.

Properties of polymers that determine quality during processing:

- rheological:

- viscous, determining the process of viscous flow with the development of plastic deformation;

- highly elastic, determining the process of development and accumulation of reversible highly elastic deformation during molding;

- relaxation, which determines the relaxation (decrease) of tangential and normal stresses, highly elastic deformation and oriented macromolecular chains;

Viscosity properties of polymer melts.

The molding of polymer products is carried out in the process of their viscous flow, accompanied by plastic deformation. In this case, a thin layer of material in contact with the stationary wall of the tool, due to adhesion to it, has a zero displacement velocity (immobile), the middle layer has the highest displacement velocity V; in steady flow mode, the relationship between shear stress t and shear rate g is linear (Newton's law for viscous liquids): t=h*g, where h is the viscosity coefficient or viscosity. The nature of the dependence of shear rate on shear stress is represented by a flow curve, in which sections are distinguished: 1 – section of linear dependence, characteristic only for low shear stresses; 2 – section with a nonlinear dependence, which is characterized by a decrease in viscosity with increasing shear stress; 3 – area with high shear stress.

Improving the flow of material is facilitated by: an increase in temperature, an increase in shear stress, an increase in the amount of moisture, a decrease in pressure and a decrease in the molecular weight of the melt.

Many properties of polymer materials in products depend on the structure that is formed by the processing process. Depending on the polymer and processing conditions, an amorphous or crystalline structure appears in products.

The structure of a product with an amorphous polymer is characterized by a certain degree of orientation of sections of chain macromolecules and the location of oriented areas along the cross section of the product along the direction of shear (flow) of the material. This leads to anisotropy of properties.

The structure of a product with a crystalline polymer is characterized by a certain degree of crystallinity (from 60 to 95%) and the unevenness of the crystalline regions across the cross section. The properties of such products obtained under different processing conditions, despite the morphological similarity of structure, are different.

Product quality indicators

from polymeric materials depend on the properties, conditions of preparation, processing and physical modification of the material. The appearance of products depends on processing conditions, material purity, and humidity.

Dielectric properties and chemical resistance

depend on the chemical structure and modification of the polymer.

Mechanical properties

- strength, impact resistance, deformation, rigidity, heat resistance - depend on the supramolecular structure, and the coefficient of friction and wear resistance, combustion resistance depend on the chemical structure and modification.

Performance properties

- dimensional accuracy and dimensional stability - depend both on the chemical structure, molecular characteristics, technological properties, and on processing technology and manufacturability of the design.

Thermal stability of polymers

. The main indicator in this case is destruction.

Destruction of polymers

is a change in the structure of macromolecules. Destruction can occur under the influence of heat, oxygen, chemical agents (including water), light, high-energy radiation, mechanical stress, etc., both individually and from a combination of parameters. It is accompanied by a decrease in molecular weight, the release of gaseous and low molecular weight products, a change in color and the appearance of an odor.

Destruction can be accompanied not only by the destruction of macromolecules, but also by their cross-linking (structuring), which causes an increase in the mass and viscosity of the melt. The consequence of this is a violation of all the properties of the material, a decrease in the stability of the properties of products.

When processing polymers, both thermal-oxidative and mechanical destruction can occur, and in hygroscopic materials, hydrolysis can also occur.

Classification of plastics

The characteristics of the classification of plastics are: purpose, type of filler, performance properties and other characteristics. Classification of plastics according to operational purpose:

- by application;

- based on a set of parameters of operational properties;

According to the use of plastics, they are distinguished (rather roughly):

- plastics for the production of food packaging;

- plastics for work in contact with aggressive environments;

- plastics for operation under short-term or long-term mechanical loads;

- plastics for work at low temperatures (down to minus 40-60 C);

- antifriction plastics;

- plastics for electrical and radio engineering purposes;

- plastics for producing transparent products;

- plastics for heat and sound insulation purposes - gas-filled material;

Based on the totality of parameters of operational properties, plastics are divided into two large groups:

- general technical purposes,

- engineering and technical purposes.

Plastics for general technical purposes have lower performance parameters than plastics for engineering purposes. Plastics for engineering purposes retain high mechanical properties not only at normal and elevated temperatures, but can also operate under short-term loads at elevated temperatures. This is not provided by plastics for general technical purposes; they operate in an unloaded or lightly loaded state at normal and medium temperatures (up to 55 C). Plastics for engineering purposes are divided into groups that provide certain properties in a certain range; There are five groups of plastics based on this classification criterion.

According to the value of individual parameters of operational properties

compose a series of plastics for various parameters of performance properties. Classification parameters: mechanical properties, wear properties, linear thermal expansion and others. Depending on the applicability of the filler and the degree of its grinding, all materials are divided into four groups:

- granular,

- powder (press powders),

- fibrous,

- layered.

Technological properties

The technological properties of plastics influence the choice of processing method.

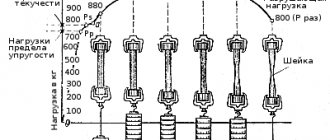

The technological properties of plastics include: fluidity, humidity, curing time, dispersion, shrinkage, tabletability, volumetric characteristics.

Flowability characterizes the ability of a material to viscously flow polymer, extruded for 10 minutes through a standard nozzle under the pressure of a certain load at a given temperature. Thus, for injection molding, materials and processing modes are used in which the melt fluidity is in the range of 2-20 g/10 min, for blow molding - 1.5-7 g/10 min, for extrusion of pipes and profiles - 0. 3-1 g/10 min, for film extrusion - 1-4 g/10 min, for laminates - 7–12 g/10 min. The fluidity of the thermoset is equal to the length of the rod in mm, pressed in a heated mold with a channel of decreasing cross-section. This fluidity indicator, although it is a relative value, allows us to preliminarily establish the processing method: with a Raschig fluidity of 90-180 mm, injection molding is used, with a fluidity of 30-150 mm, direct pressing is used.

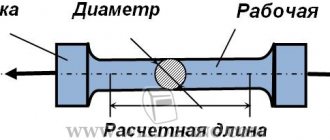

Shrinkage characterizes the change in dimensions during product molding and heat treatment:

U = (Lf-Li) / Lf * 100%; UD = (L-Lt) / Lf * 100%; where Y is shrinkage after molding and cooling; Ud – additional shrinkage after heat treatment; Lф, Lи – size of the mold and size of the product after cooling; L, Lt – size of the product before heat treatment and after cooling.

The shrinkage of thermoset products depends on the method of molding the product and the type of cross-linking reaction: polymerization or polycondensation. Moreover, the latter is accompanied by the release of a by-product - water, which evaporates under the influence of high temperature. The shrinkage process occurs over time; The longer the holding time, the more complete the chemical reaction occurs, and the shrinkage of the product after removal from the mold is less. However, after some holding time, the shrinkage remains constant with its further increase. Effect of temperature on shrinkage: Shrinkage increases in direct proportion to the increase in temperature. Shrinkage after treatment also depends on the humidity of the material and the preheating time: with increasing humidity, shrinkage increases, and with increasing preheating time, it decreases.

Shrinkage of thermoplastic products after molding is associated with a decrease in density when the temperature drops to the operating temperature. The shrinkage of the polymer in different directions relative to the flow direction is different for thermo- and thermoset plastics, i.e. polymers have shrinkage anisotropy. The shrinkage of thermoplastics is greater than that of thermosets.

Moisture and volatile matter content. The moisture content in press materials and polymers increases when stored in open containers due to the hygroscopicity of the material or its condensation on the surface. The content of volatile substances in polymers depends on the content of residual monomer and low-boiling plasticizers, which during processing can turn into a gaseous state.

Optimum moisture content: for thermosets 2.5 - 3.5%, for thermoplastics - hundredths and thousandths of a percent.

Particle size distribution is assessed by particle size and uniformity. This indicator determines the performance when supplying material from the hopper to the heating zones and the uniformity of heating of the material during molding, which prevents swelling and uneven surfaces of the product.

Volumetric characteristics of the material: bulk density, specific volume, compaction coefficient. (Specific volume is a value determined by the ratio of the volume of a material to its mass; bulk density is the reciprocal of specific volume). This indicator determines the size of the loading chamber of the mold, hopper and some dimensions of the equipment, and when processing press powders with a large specific volume, productivity decreases due to the poor thermal conductivity of such powders.

Tabletability is the ability to compress a press material under the influence of external forces and retain the resulting shape after these forces are removed.

Physico-chemical fundamentals of plastic processing

Plastic processing processes are based on physical and physico-chemical processes of structure formation and molding:

- heating, melting, glass transition and cooling;

- change in volume and size when exposed to temperature and pressure;

- deformation, accompanied by the development of plastic (irreversible) and highly elastic deformation and orientation of macromolecular chains;

- relaxation processes;

- formation of a supramolecular structure, crystallization of polymers (crystallizing);

- destruction of polymers.

These processes can occur simultaneously and interconnectedly. Only one process will be predominant at a certain stage.

During the molding process, the polymer is heated to a high temperature, deformed by shear, stretching or compression, and then cooled. Depending on the parameters of these processes, the structure and conformation of macromolecules, as well as the physical, mechanical, optical and other characteristics of polymers can be significantly changed.

When a large number of polymers are cooled, a crystallization process occurs.

Crystallization, depending on the state of the melt, leads to different types of structure. Crystallization from a polymer melt in an equilibrium state without deformation leads to the formation of spherulitic structures. The center of formation of such structures is the nucleus, from which ray-shaped fibrils are formed, consisting of many packed lamellae. Fibrils, growing in the radial direction and in width, form spherical structures - spherulites. Spherulites are formed simultaneously in a large number of crystallization centers. Based on this, spherulites at the points of contact form faces and are polyhedra of arbitrary shape and size. Electron microscopy studies show that the fibril of spherulites is composed of many lamellas stacked on top of each other and twisted around the radius of the spherulite.

Crystallization from a polymer melt occurs when crystallizers - nuclei - are introduced into the polymer material.

If crystallization occurs under high pressure (300...500 MPa) and at high temperature, then a crystalline structure of straightened chains is formed; upon rapid cooling of the same melt, crystallization occurs with the formation of complex chains; macromolecules in this case are in the melt in the form of domains, and rapid cooling does not allow them to transform into a new conformation, i.e. acquire an elongated shape. It has also been established that with increasing pressure the crystallization temperature increases. The practical significance of this property: the possibility of the polymer transitioning directly from the melt without cooling to a quasicrystalline state with increasing pressure; in this case, flow is excluded and relaxation processes are inhibited. As the pressure increases, smaller spherulites are formed and therefore the mechanical strength of the products increases. The size of the crystals also depends on the cooling rate and temperature during the molding process. At a high cooling rate, a fine-crystalline structure is obtained, since there is not enough time for the rearrangement of crystals.

Larger polymer structure can be achieved by increasing the temperature, holding time and slow cooling, or by preheating the melt to a higher temperature before crystallization. The shape of the crystals can be changed. Thus, using crystallization centers and artificial nuclei (1...2% by weight), you can regulate the shape of the crystals. When using a crystallizer substrate, a large number of crystallization centers appear near its surface and a densely packed layer of crystals located perpendicular to the surface is formed. Artificial nuclei are additional centers of crystallization; the shape of the crystal depends on the shape of the crystallization nucleus; spherulite structures grow on small crystals, and ribbon-like structures grow on long needle-shaped crystals. The structure-forming agents (seeds) in this case are aluminum and vanadium oxides, quartz, titanium dioxide, etc. Structure-forming agents usually contribute to the refinement of the spherulitic structure of the polymer.

Unsteady conditions of heat transfer and cooling rates during the molding of polymer products contribute to the production of products with a non-uniform structure (smaller crystals near the surface layers).

If necessary, uniform properties of the product can be ensured by annealing or subsequent heat treatment at a temperature below the melting point. During annealing, the volume of the product decreases and the density increases; Moreover, the higher the temperature and the longer the holding time, the higher the density of the product. Heat treatment is appropriate in cases where increased hardness, elastic modulus, mechanical strength, heat resistance and resistance to cyclic loads are required; at the same time, the relative elongation and impact strength decrease.

The completeness of these processes, in addition to destruction, largely determines the quality of the finished product, and the speed of these processes determines the productivity of the processing method. The quality of the product is significantly affected by the rate of polymer destruction, which is increased by thermal and mechanical effects on the material from the working parts of the tools during formation.

The shape of a thermoplastic product is obtained as a result of the development of plastic or highly elastic deformation in the polymer under the influence of pressure when the polymer is heated. When processing thermosets, product formation is achieved by combining physical formation processes with chemical polymer curing reactions. In this case, the properties of the products determine the speed and completeness of curing. Incomplete use of the polymer's reactivity during curing causes instability of the properties of a thermoset plastic product over time and the occurrence of destructive processes in finished products. The low viscosity of thermosets during formation leads to a decrease in the unevenness of properties, an increase in the rate of stress relaxation and a lesser impact of destruction during processing on the quality of finished products from thermosets.

Depending on the processing method, curing is combined with the molding of the product (during pressing), occurs after the product is formed in the mold cavity (injection molding and thermoset injection molding) or during heat treatment of the molded workpiece (when molding large-sized products, for example, sheets of getinax, fiberglass and etc.). Complete curing of thermosets requires several hours in some cases. To increase product removal from the equipment, final curing can be done outside the molding equipment, since shape stability is acquired long before this process is completed. For the same reason, the product is removed from the mold without cooling.

When processing polymers (especially thermoplastics), macromolecules are oriented in the direction of material flow. Along with the difference in orientation, structural heterogeneity arises in different areas of products that are heterogeneous in cross-section and length, and internal stresses develop.

The presence of temperature differences across the cross-section and length of the part leads to even greater structural heterogeneity and the appearance of additional stresses associated with different rates of cooling, crystallization, relaxation, and varying degrees of hardening.

Heterogeneity in the properties of the material (for the above reasons) is not always acceptable and often leads to defects (due to instability of physical properties, dimensions, warping, cracking). Reducing the heterogeneity of the molecular structure and internal stresses can be achieved by heat treatment of the finished product. However, it is more effective to use methods of directed regulation of structures in processing processes. For these purposes, additives are introduced into the polymer that influence the formation of supramolecular structures and contribute to the production of materials with the desired structure.

Branded assortment of polymers

The branded assortment of polymers was created with the aim of quickly selecting the type and brand of polymer for the manufacture of high-quality products. The brand range includes brands that differ in viscosity and performance properties.

The brand range by viscosity is divided into grades intended for processing by various methods (injection molding, pressing, etc.); with increasing grade number, the molecular weight increases and, as a result, the viscosity increases. These are the brands of the basic range. Viscosity grades are modified to improve technological properties:

- To increase productivity, rapidly crystallizing grades are created;

- for products with complex configurations - brands with lubricants;

- heat-stabilized grades.

Based on the basic assortment of grades based on technological properties, grades with improved properties are created by chemical or physical modification. These brands are developed with such properties that, under recommended conditions, they can produce high-quality products in all respects (accuracy, strength, appearance, etc.). Currently, polymer materials are produced in an assortment and therefore for each product and molding method it is possible to select the appropriate base brand of polymer and, if necessary, a brand with improved technological properties.

In order to produce quality products, basic brands are divided into groups:

- depending on the viscosity of the polymer and the thickness S of the wall of the product;

- depending on the relative length of the product L/S (S-length);

- The entire set of plastic brands contains about 10,000 items.

Choice of plastics

Signs of choice. The main criteria for choosing plastics are operational and technological properties. To speed up the process of selecting a material, special tables are used, each of which shows grades of materials in order of decreasing average value of the presented performance property.

The procedure and algorithm for selecting plastics.

Plastics are selected based on the requirements for the performance properties and geometric parameters of the product. Therefore, first, a type of plastic is selected based on the requirements for its performance properties, and then a basic grade and a grade with improved technological properties, which can be effectively processed using the chosen method. There are two methods for selecting the type of plastic:

- analogy method – qualitative;

- quantitative method.

The analogy method is used when it is impossible to accurately specify the parameters of the operational properties of plastic; in this case, the characteristic parameters of operational properties, purpose, advantages, limitations, recommendations for use and processing methods are used to select; in this case, recommendations for the use of plastics in other types of products operating under similar conditions can also be used for selection.

The procedure for selecting plastics using a quantitative method based on a set of specified values of performance properties comes down to the following:

- identification of the operating conditions of the product and the corresponding values of the parameters of the operational properties of plastics under the basic operating conditions of the product;

- selection of plastic with the required performance parameters;

- checking the selected plastic according to other parameters not included in the main ones.

Injection molding is a method of molding products from polymer materials, which consists of heating the material to a viscous-flowing state and pressing it into a closed injection mold, where the material takes on the configuration of the internal cavity of the mold and hardens. This method produces products weighing from several grams to several kilograms with a wall thickness of 1-20 mm (usually 3-6 mm). To carry out injection molding, plunger or screw injection machines are used (Fig. 1), on which injection molds of various designs are installed (Fig. 2).

Rice. 1. Diagram of an injection molding machine with screw (a) and plunger (b) plasticization of the melt:

1 — hydraulic cylinder of the closing mechanism; 2 — piston of the hydraulic cylinder of the closing mechanism; 3 - movable plate; 4 - half-forms; 5 - fixed plate; 6 — plasticizing cylinder, 7 — screw; 8 — loading window of the plasticizing cylinder; 9 - bunker; 10 — screw drive; 11 — hydraulic cylinder housing of the injection mechanism; 12 — piston of the injection hydraulic cylinder; 13 — auger hydraulic cylinder; 14 - torpedo - melt flow divider; 15 — dispenser; 16 - plunger

Rice. 2. Injection mold:

1 - movable half-mold; 2 - pusher; 3 — ejector plate, 4 — ejectors; 5 — channels of the mold temperature control system; 6 — sprue bushing; 7 - central sprue; 8 — centering sleeve; 9 — centering column; 10 - fixed half-mold; 11 — nozzle of the injection molding machine; 12 — spreading sprue; 13 — inlet sprue; 14 - forming cavity

The main technological parameters of injection molding processes are melt temperature Tr, mold temperature TF, casting pressure RL, pressure in the mold RF, holding time under pressure tvpd, cooling time tcool or curing time in the mold totv for thermosetting materials. Injection molding processes both thermoplastic and thermosetting materials, but the type of material determines the specific physical and chemical processes that accompany the heating and solidification of these types of plastics. The technological flow diagram of the process is shown in Fig. 3. Analysis of the injection molding process can be carried out according to the following components: transfer of the material to a viscoplastic state -> its supply to the dosing zone -> accumulation of the melt -> melt flow in the nozzle-mold system -> melt flow in the channels of the mold and mold cavities -> formation of the structure of the product.

Rice. 3. Technological diagram of injection molding:

1 — car (gondola car, tank); 2 — suspended crane beam; 3 - material warehouse; 4 - vacuum dryer; 5 - injection molding machine; 6 — conveyor; 7 - machining machine; 8 — packing table; 9 - crusher; 10 - extruder; 11 — cooling bath; 12 - granulator

Plastics technology

Polymer is a binder from which plastic is made. In addition, fillers and curing accelerators are used in the production of plastic materials. To make the plastic colored, mineral dyes are added to its composition. The binders are synthetic resins, cellulose derivatives, synthetic rubber - all these substances are high molecular weight polymers.

Some types of plastic can be used several times. Main processing methods:

- the process of pressing, pressure, extrusion when the material is in a viscous fluid state;

- vacuum casting and pneumatic molding, stamping of highly elastic material.

Preface

plastic processing in mass production

- preparation of polymers for processing,

- development and determination of technological process parameters,

- development of equipment,

- selection of equipment.

- Analysis of product operating conditions, development of requirements for operational properties.

- Selecting the type of plastic according to the specified requirements and performance properties of the product.

- Choosing a method for processing plastic into a product and equipment.

- Selection of a basic brand of plastic and, based on it, a brand with improved technological properties.

- Design, manufacturing, testing and debugging of technological equipment, etc.

Properties of polymers

- rheological: viscous, determining the process of viscous flow with the development of plastic deformation;

- highly elastic, determining the process of development and accumulation of reversible highly elastic deformation during molding;

- relaxation, which determines the relaxation (decrease) of tangential and normal stresses, highly elastic deformation and oriented macromolecular chains;