- The surface on which the device is mounted must be able to withstand the maximum lifting capacity of the winch.

The maximum weight of the object to be lifted or held must be half the maximum lifting capacity of the device.

What is not allowed when operating a winch manually?

Each type of lifting and transport equipment has its own characteristics, so always study the passport data before using it. A construction hand winch is a useful and functional mechanism that requires careful handling and compliance with the following rules for safe operation:

- It is forbidden to use a winch with cracks or deformations on the body, or with wear on the gears.

- Do not use a cable that shows signs of obvious wear or broken wires.

- It is forbidden to use the hook if the wear in the throat is more than 10% of the section height, or if the fastening in the cage is broken.

- It is not advisable to winch loads of unknown weight or weights that exceed the lifting capacity of the device.

- It is not allowed to operate the winch if the brakes are faulty or if the cable is wound unreliably on the drum.

DIY hand winch

There are many ways to make a simple mechanism for dragging or lifting loads on your own. As an example, we will briefly describe how a hand-made homemade winch is made from a KamAZ brake ratchet:

- The main component of the future winch is a self-leveling brake adjustment mechanism (ratchet) with a worm gear.

- We remove the ratchet from an old car.

- Carefully knock out the shaft from the ratchet.

- Using a grinder, we lengthen the splines on the shaft.

- We cut the shaft so that it protrudes to the same length on both sides of the device.

- To make coils, cut out 4 washers from metal.

- We put the washers on the pile tightly and brew.

- We get two coils on both sides of the ratchet.

- A handle must be attached to the end of the worm pair.

- We get a gear ratio of 1:20.

- To double the power, you can use a block connection.

- You will get an excellent and inexpensive hand winch for household needs.

Lever winch. We are trying to pull the car out

The lever winch is a manual type mechanism. Having a limited load capacity, they are nevertheless simple and compact, and therefore are used for small lifting and subsequent horizontal movement of cars, heavy machine equipment, pallets with a variety of construction materials and other operations.

Let's start choosing

Of course, models such as LR-15, MTM 1.6 t or devices produced by Zubr are an excellent choice for the motorist. However, do not rush to conclusions or search for relevant advertisements on Avito.

Believe me, Moscow and St. Petersburg offer a fairly large assortment of used and brand new winches. Have I repeatedly scoured various markets in search of the perfect device for all occasions? And you know what I realized? And the fact is that cases are different, and a universal winch is a purely individual concept.

In other words, you should choose the “helper” for yourself. What is needed for this? From personal experience I will say that you should pay attention to several basic parameters.

- Design. A car winch must be of high quality, reliable and strong. Questionable build quality, rusty bolts or any extraneous play should cause only one reaction - a quick escape from such a store. You don’t want to buy a winch that won’t pull the car out and even injure you, do you? The answer is obvious.

- Belt or cable. The motorist must decide for himself what to use. From the point of view of reliability and practicality, a cable is, of course, better. But it is more difficult to install. The belt is less durable. Although let's be honest, you won't pull your car out of the mud every day, will you? Or will you? Where do you live and what do road services do in your region? Well, it's all a joke. Go ahead.

As you can see, lever units can become the optimal solution that will save you from dirt, roadsides and other unpleasant surprises on the road. I can only wish you good luck on your journey and find yourself as rarely as possible “captured” by our excellent communications between populated areas or beyond.

Have you ever found yourself in such situations, have you had to use a winch, and how rational do you think such a purchase is? Be sure to share your opinion in the comments. We will be very interested in communicating with you and answering your questions.

Of course, don't forget to subscribe and tell your friends about us! Motorists, like a big and strong family, must stick together.

( 12 ratings, average: 4.42 out of 5)

The lever winch is a manual type mechanism. Having a limited load capacity, they are nevertheless simple and compact, and therefore are used for small lifting and subsequent horizontal movement of cars, heavy machine equipment, pallets with a variety of construction materials and other operations.

Design and principle of operation

The mechanical devices under consideration are especially effective when working in cramped conditions. In this case, with the existing hook, the lever winch can be attached to any place suitable for these purposes, and the cable can be moved using a special pulling mechanism.

The lever winch consists of the following components:

- Drive.

- Block of pulleys.

- Gear transmission.

- Ratchet braking mechanism.

- Rotary handle.

- Cases.

A manual lever winch differs from other versions of hand winches (drum, worm) in the nature of the movement that must be applied to the control handle in order to cause the load to move. In this case, it is rocking: when the lever is turned forward at a certain angle, the axis of the pulley block (or cable) rotates; when it is turned back - idle - the load is held in place due to the action of the ratchet brake. The stroke of the handle, which depends on its length, determines the performance of the device. If there is a pulley block, the design also provides a clamping mechanism that works with each of the branches alternately.

The manual lever winch operates as follows. When the handle is turned, the torque is transmitted through a gear transmission to the cable-pulling mechanism, which ensures the forceful movement of the load. The design of the device provides a ratchet brake to prevent spontaneous return of the load. It is considered the main component of the lever winch, which is responsible for its efficiency and safety in operation.

A ratchet brake (sometimes called a stop) includes a brake disc, a ratchet gear, a pawl, and a hub into which the handle is screwed. When the handle is turned in a certain direction, the pawl moves away from the convex generatrix of the tooth and allows the wheel to rotate. When you try to turn in the opposite direction at an angle exceeding the pitch of the teeth, the pawl slips into the concave part of the tooth profile and blocks possible rotation of the wheel. To increase the efficiency of the unit, replaceable brake linings made of friction material are installed between the gear ratchet wheel and the brake disc. They not only improve traction, but also reduce wear on the moving parts of the brake.

Drive drum

The drive drum is a hollow tube with cheeks made of durable metal. A toothed gear is installed on it. When the handle is rotated or the lever moves, the gear train begins to move. It drives the shaft with the drive gear. The drive gear comes into contact with the gear, and it also begins to rotate. On the end side of the gear there is a friction clutch assembled from ring trapezoidal pads. There is also a ring groove at the end of the drum, the size of which corresponds to the size of the clutch. After their contact, the drum begins to rotate, winding the cable attached to it, and the load moves.

Small depressions are made on the surface of the drum. They are necessary for uniform winding of the cable, it does not get tangled, and there are no overlaps. The cylindrical shape allows for maximum capacity with minimal dimensions. Ratchets allow you to stop the movement of the cable at any time.

When using metal cable, the diameter of the drum is of great importance. If it is too thin, the wear of the cable increases significantly. But increasing its diameter leads to an increase in the weight and size of the device. Not everyone has the special knowledge to independently calculate the optimal value, so the operation of winches made at enterprises, rather than in a home-made way, is often cheaper, and their reliability is higher.

The subtleties of working with a lever winch

In lever-type lifting manual mechanisms, the main factor for achieving the required torque value is the greatest working force on the handle. It is determined by the duration of continuous operation of the lever winch. If the lever winch is operated for a long time, the force on the handle cannot exceed 10 kg. For short-term work (5 minutes or less), this force can be 16 kg.

If a manual lever winch is equipped with a pulley, the force on the handle is reduced, but at the same time the number of turns of the handle that must be performed to move the load the same distance increases.

In modern designs of these mechanisms, the test force on the handle is usually at least 80 kg, which must be indicated by the manufacturer in the winch data sheet.

The size of a manual cable winch also depends on the force on the handle. The main ones are:

- The arm (radius of rotation) of the handle, which should not be less than 400 mm.

- The center of rotation of the handle should be located at a height convenient for working with a lever winch.

- The length of the control handle for winches with a relatively small load capacity (up to 2 tons) must be at least 300 mm; if the mechanism is of greater power (4 tons or more), then the length of the handle increases to 350...400 mm. Particularly powerful versions of lever winches can be equipped with handles extended to 600 mm; in this case, the mechanism is controlled by two workers. However, for ease of use, a handle length of more than 800 mm is not provided.

- The average operating speed of the user's hand on the handle should not exceed 1 m/s, which corresponds to the angular speed of rotation of the cable on the axis of 60 m/min.

The current rules for the operation of manual lifting mechanisms establish that when two people work on one winch, the non-simultaneous application of working force by them is taken into account. The standard unevenness coefficient φ is 0.8. Thus, the torque on the input shaft can be calculated according to the dependence Min = P×φ×l×m×n, where P is the force developed by the user, l is the length of the handle, m is the number of workers, n is the number of pulley blocks.

Taking into account the fact that almost any lever winch has a gear drive or pulley block, the output torque will be higher: Mout = Mvx×i×η, where i is the gear ratio of the block/gear, and η is the total efficiency of the mechanism drive.

Sometimes, to correctly select the size of a manual lever winch, it is necessary to know the speed of movement of the load v. It can be calculated by the dependence:

v = vp×D/(2×a×i×l), where vp is the speed of the swinging movement of the worker’s hand, D is the diameter of the rope being wound, and is the multiplicity of the pulley (if this device is absent, then a = 1)

Parameters of manual lever winches

The operational parameters of these mechanisms are:

- Method of securing the hook (usually to a fixed base);

- Number of cable branches in the pulley (from two to three);

- Cable length (3...20 m);

- Load capacity (from 0.5 t to 5 t or more).

It should be noted that of all types of hand winches, lever winches have the lowest productivity. Therefore, they are valued mainly for their maximum compactness, ease of operational use (there is no need to fix the winch to any fixed object) and lightness, since the mechanism body is made of high-strength aluminum alloy. The maximum force on the handle of such winches does not exceed 35...40 kg. A number of manufacturers complete devices with additional mounting blocks and hooks, which expands the technological capabilities of the lifting mechanism. Lever winches with a reduced cable length (up to 2...2.5 m) are recommended for use in garages.

The safety of using a manual lever winch largely depends on the rules of its current operation. They boil down to the following:

- Periodically checking the correct reeving of the steel rope.

- Cleaning the internal parts of the mechanism from dirt with a water jet (for this purpose, one or two holes are provided on the body).

- Inspect the cable, which should not have external damage or signs of corrosion.

- Inspection of all components of the device, which should not be deformed, cracked or otherwise damaged.

- Conditions for laying the cable on the axle: before using the device, the number of free turns of the cable must be at least three.

- The moving parts of all winch components must be lubricated.

- The hand lever winch must not be used for lifting persons.

The standard marking of mechanisms is as follows: LR-X, where instead of the letter X the maximum load capacity of the device is indicated in tons.

The price of these devices is determined by the load capacity, the convenience of the handle layout, the diameter of the cable used, and the length of the rope. The price of manual lever winches with a lifting capacity of up to 2 tons is 1000...2000 rubles, from 2 tons to 4 tons - 3000...4500 rubles, more powerful versions, with a double ratchet mechanism - up to 6000 rubles.

Making your own hand winch

If it is expected that the device will be used very rarely, then you can make a mini winch with your own hands. Making a winch with your own hands is carried out in several stages:

- The strong axle is fixed in the guides so that rotation is maintained.

- A lever is welded to the axle and a rope is attached.

When acting on the lever, the cable will be wound around the axle and, accordingly, the load will move.

For ease of operation, the axle can be placed on a platform with brackets; a high-strength hot-rolled channel is perfect for this purpose.

In addition, you can make a recess in the axle to which the gear will be attached - this will provide the ability to wind the cable.

Another way to make a winch with your own hands is to attach a drum to the axle of a wheel, which will become a device for self-pulling the vehicle. When this wheel slips, a cable attached to a stable support will be wound around the drum, which will allow the machine to get out of the mud or deep ditch.

A self-made cable winch can be used to pull out a vehicle, but also to move other loads.

Manual winch for lifting and lowering loads

Using various equipment, you can significantly simplify the process of lifting and lowering loads. Such devices allow you to work with heavy and long objects, and also significantly increase the intensity and efficiency of work. There are quite a large number of different lifting mechanisms, among which hand winches stand out. We will talk about all the features of such devices now.

What kind of load can a hand winch pull?

As the name suggests, requires the physical effort of the operator to lift and lower a load In this regard, this technique is very versatile. There are no requirements for access to electrical power, so the models can be used both outdoors and indoors.

On the other hand, lifting weights requires human muscular strength. As a result, maximum lifting capacity is somewhat limited when compared to electrically powered models.

The question of what kind of load a hand winch can pull cannot be answered unambiguously. There are quite a large number of models that differ greatly in their parameters. Based on this, their carrying capacity also changes. Usually. Such winches are suitable for working with relatively small loads, the weight of which reaches 0.5-3 tons.

Worth noting: At the same time. There are also winches that can lift heavier objects. For example, the MTM 5.4T traction mounting mechanism, which is capable of working with loads weighing up to 5400 kilograms (lifting height reaches 20 m), demonstrates quite good load-carrying capacity indicators.

Thus, you can choose a device that is suitable both for solving simple household tasks and for lifting relatively heavy loads.

Types of winches

If we discuss the types and design of winches, then, first of all, such equipment is divided into manual and electric mechanisms. Manual models deserve special attention, since they can differ significantly in their design features. So, among them we can distinguish winches:

- Lever. The models are well suited for various repair, installation and dismantling work. They are distinguished by their small size and light weight (models weigh 7.5-14 kilograms). The main distinguishing feature is that the devices do not need to be rigidly fixed to the supporting surface. It is the ease of working with this mechanism that made it so popular. Loading capacity reaches 0.6-1.6 tons;

- Drums. The principle of operation is more than simple - the operator operates the handle, due to which the rope is wound onto the drum. The device is very convenient in its operation. The load capacity reaches up to 3 tons, while the price for such mechanisms is the lowest;

- Worm-shaped. It differs from the drum one in its drive (“endless screw”). The mechanism is more efficient, which made it possible to further reduce the size of the winch. At the same time, the drive has many elements that are subject to friction during operation. Thus, this negatively affects the durability of the model.

There is also another group - mounting and traction mechanisms. They are similar to lever winches, but there is no drum, so you can use any length of cable. As a rule, such devices are more massive and also have the highest load capacity.

It is worth noting: it is impossible to say for sure which winch is better. Each model has its own advantages and disadvantages. For example, if you are interested in maximum lifting capacity, then you should take a closer look at mounting and traction mechanisms, but for lifting loads to the maximum height, JHW models are suitable, with a rope length of up to 40 m.

How to lower a load with a hand winch

If you do not know how to use a winch correctly, then before you start working, you need to read the operating instructions for the devices. It is worth noting that different types of equipment are designed for different operations. Thus, winches can pull, raise or lower objects. Some can combine these functions, while others are only suitable for a specific task.

The method of raising/lowering the loads also differs. For example, in the case of the simplest drum winch, in order to change the direction of movement of the object, you just need to start turning the handle in the opposite direction. If we talk about lever devices, MTM, as well as models with a ratchet, then to lower the load you should change the position of the switch.

It is worth noting: It is very important to adhere to the rules for working with cargo. This will help avoid a number of unforeseen situations related to damage to property, as well as the health of the operator and third parties.

Advantages and disadvantages of a manual winch for working with cargo

Among the reasons why hand winches have become so popular are:

- Versatility. Since there is no need to connect the device to an electrical network, you can use the winch absolutely anywhere. There are no restrictions (the only thing is that some mechanisms need to be securely fixed to the surface;

- Affordable price. Prices for such equipment start from 3 thousand rubles. When compared with hoists (electric winches), the cost of manual models is several times lower;

- Compact dimensions and light weight. Since winches do not have a motor, this allows them to significantly reduce their size and weight. Often such models weigh up to 10 kg, so they can be easily moved to any place. At the same time, their dimensions are quite small, as a result of which the mechanism will not take up much free space in the trunk of the car;

- Easy to use. It is very easy to work with such technology. At the same time, the design of hand winches itself is distinguished by its simplicity. As a result, the mechanisms rarely break down and are also easy to repair.

On the other hand, models require constant effort on the part of the operator. This affects not only the fact that the maximum load capacity is severely limited. In addition, they are not suitable for high-intensity work where heavy lifting is constant. But for solving everyday problems, as well as periodically lifting loads in industrial, warehouse and other enterprises, hand winches are perfect.

Hand winch: device, types and principle of operation

Many people do not always appreciate the importance of having a manual mechanical winch.

Understanding the significance of this tool in most cases occurs only in critical situations, when, for example, it is necessary to rescue a car from a mud trap formed on a dirt road. Moreover, such moments can happen to almost every person, regardless of his type of activity and hobbies. There is a huge selection of hand winches on the market. And in this variety, it is often very difficult to decide on the best option that has good performance characteristics and an affordable price.

Design features

The most popular today are drum models and mechanical lever-type manual winches. Although these tools have a similar purpose, however, the principle of their operation is somewhat different.

Drum type equipment

In terms of its external qualities, this type of tool is reminiscent of automobile winches with which special vehicles are equipped. Their design includes a gearbox and a drum. The first is usually a worm or gear type. The drum in this device is designed for winding tape or steel cable around it.

Worm-worm mechanism variations have an undeniable advantage, namely that

their gearboxes have a much simpler system, with the help of which the device is locked at the right moment . Thanks to this, the safety of using this equipment significantly increases. This tool is also distinguished by its high reliability and variety of fastening tactics . Although it also has certain disadvantages:

- The large size of the equipment makes it more comfortable to use in a room like a garage.

- Relatively light weight that this type of equipment can pull.

- Complex operating mechanism.

- The need for ongoing maintenance.

- A kind of “conflict” with dirt.

From the above it follows that this type of winches is not the best option for use on mobile devices.

As for gear devices, their design also includes

a gearbox and a drum , however, unlike worm devices, they are easier to manufacture , and therefore somewhat cheaper .

The cable is attached to them using a ratchet, which has good reliability. The gearbox is characterized by ease of maintenance . A rather important point is the quality of the metal used in the manufacture of gears , therefore, when choosing such equipment, it is not recommended to give preference to cheaper, untested analogues. It is better to choose a well-known manufacturer.

The main disadvantages include the following:

- A method of laying a cable, which often gets into the cavities of the gearbox gears and ceases to perform its functions.

- Small internal diameter of the drum, which causes strong bending of the steel cable. As a result, the latter deteriorates quite quickly.

- Due to the dimensions of the device, the size of the drum is limited, and this, in turn, limits the range of action of the mechanism.

From the above, we can conclude that the process of using drum-type winches in field conditions may not always be comfortable. It is better to use this mechanism in the garage.

Lever type equipment

Winches of this type are most often used in mobile devices. It is these that drivers usually purchase in order to be able, if necessary, to rescue the car from a trap.

The standard structure of the device

includes a frame made of metal, inside which there is a mechanism activated by pressing a lever located on the equipment body . Due to the fact that greater force can be applied to the lever, the device is effective in cases where drum winches would not cope. The traction force of such a mechanism can reach several tons .

Moreover, this figure can be further increased by strengthening the standard lever. Some manufacturers immediately include a special amplifier in the equipment package or manufacture this element using the telescopic method. The main components of the device include a ratchet that secures the cable in a taut state. It is a kind of wheel on which persistent teeth are located. A locking pin rests against them in turn, preventing the wheel from spinning in the opposite direction. This ensures tension in the cable.

In this case, the main load is placed on the equipment frame, as a result of which the latter must be made of durable metal of the appropriate caliber. Otherwise, the device will become deformed. Experts recommend abandoning the option of a winch with a frame whose metal thickness will be less than three millimeters.

The mechanism has small dimensions, so its operation is possible even in very inconvenient places and conditions. And also the lever type of mechanism does not require mandatory fastening of the case. However, when purchasing this modification, you should pay attention to the size of the winding drum, since the smaller it is, the greater the effort required during the work process. You should not opt for a product with a diameter of this element less than 45 millimeters.

Expert commentary

Denis Zagarin, head of the NAMI Test Center

Denis Zagarin, head of the NAMI Test Center

There are no standards and requirements for lugs either here or within the framework of the 1958 Geneva Agreement. There are only requirements for coupling devices, described in Rule No. 55. Accordingly, the strength and ease of use of towing eyes is left to the automakers. But pay attention to the title. Towing is the movement of a vehicle by a tractor, and the weight of the towed vehicle should not exceed the weight of the tractor. In addition, travel under normal conditions, that is, on roads with appropriate coverage and the appropriate category. Of course, the automaker provides a certain margin of safety, including enough to pull out slightly stuck cars. But not those who sat on their bellies or drowned in the swamp.

Have a safe journey on any roads!

Test of the most popular hand winches

Criterias of choice

The design features of the equipment are not the only aspect that needs to be considered when purchasing a tool. There are several other important points that require attention:

- Rope length . Longer parts are more convenient. Although it is quite difficult to find a winch with a cable of more than five meters on the market.

- Traction force . Often sellers claim that five hundred kilograms of traction force is enough. However, in practice, this indicator is often not enough and the equipment does not cope with the task. The optimal weight is considered to be at least a thousand kilograms.

- Cross section of the cable . In this case, a too thick element is not the best option, since a small length of it will fit on the drum. The optimal diameter is six millimeters, which is quite enough, for example, to remove a car from a mud trap.

- Belt or cable . Both of these components can be used on a winch. But which one it is is a personal decision of the owner. The belt is rather short-lived, but easy to use and cheaper. The cable can last much longer, but it is difficult to lay it on the drum. If the equipment will be used infrequently, then it is probably better to acquire the first option.

As a conclusion, we can briefly list the main aspects regarding this equipment:

- For use in a garage, it is better to purchase drum-type winches with a worm gear. And to use the equipment in field conditions, a lever modification is better suited.

- The abutment tooth of the ratchet must be wide enough to prevent unintended slippage of the fastener.

- It is better to choose a winding drum with a diameter of more than 45 millimeters.

- A high-quality lever winch frame is made of metal thicker than three millimeters.

- The equipment will better cope with the assigned tasks if its traction force is at least 1 thousand kilograms.

- The optimal cable thickness is six millimeters.

- It is worth choosing a mechanism with a telescopic lever. Alternatively, this element can be equipped with a special amplifier.

Drum miracle of technology

Externally, this device for a car resembles those winches that are installed on special vehicles and tow trucks. The components are a drum and a gearbox. Moreover, the gearbox can be gear or worm. Accordingly, a worm winch is one of the options to choose from. The drum serves to ensure that the cable, chain or belt component of the mechanism is wound and unwound gradually as it rotates.

Worm

Let's start with the worm type. They have a very significant advantage - the gearbox makes it much easier to organize the winch locking system. That is, the level of security is very high. Let’s not forget about such work qualities as reliability and variety of fixation methods. But the worm mechanism is not without its drawbacks.

- Dimensions. The mechanical worm winch is quite large. It is problematic to store it in the trunk of a regular car. Mainly used in a garage or private home.

- Possibilities. The mechanism is not designed to pull a large mass. Therefore, this option is not suitable for heavy cars.

- Complex design and maintenance. Plus, the “worm” doesn’t like dirt.

The winch is manual. Description, features, types and prices of hand winches

The dragger, the oil tanker, the cable jack, the frog, the Tuapsinka and the Dushanbinka. All these are the names of a hand winch. Some reflect the type of activity, others a feature of appearance, and still others the place of production.

In particular, in Soviet times, winches were supplied by factories in Tuapse and Dushanbe. Hoists were also produced there. Both in appearance and in structure they are similar to winches. The article is devoted to the latter. But first, let’s look at the differences from hoists.

Ratchet mechanism

To ensure safe operation, hand winches are equipped with a ratchet. It is a gear mechanism with intermittent movement. The ratchet converts the reciprocating movements in the system into intermittent rotational movements, that is, produced in only one direction.

The ratchet is made in the form of a gear, which has asymmetrical teeth. The support for them is provided only on one side. When you try to turn the drum in the other direction, a metal limiter called a pawl appears in the path of the shaft movement. When rotating in a given direction, the pawl is pressed by a spring or its own weight against the gear and does not interfere with movement.

This braking system, despite its simplicity, is very reliable. During work, there is no fear of the rope unwinding arbitrarily, which will lead to the fall of the object being moved.

The winch can also be equipped with a hand brake that directly blocks the drum.

Description and characteristics of the manual winch

A manual winch is a device for moving loads horizontally. Hoists move weights vertically, that is, from bottom to top. However, there are combined models in which two mechanisms are combined.

The structure of the winch is based on a drum with a rope wound around it. There are loads being pulled for him. The minimum load for winches is 150 kilograms, and the maximum is 10 tons. How long a particular model can withstand can only be verified experimentally.

Manufacturers declare the lifting capacity of winches. But the same experience suggests that Chinese installations, for example, tend to withstand less than the norm. In accordance with the manufacturer's application, as a rule, Russian winches are used. They are mainly supplied by the Armavir plant.

At the load limit of the winches, the cable breaks. To be on the safe side, avoid its metal variants. If they tear and spring back, they can cause serious injuries.

Wire ropes are preferred. Their length also varies in winches of different models. Minimum – 1.5 meters, maximum – 10.

The drum with the cable in the winch is accompanied by a transmission in the form of a gear drive, a lever with a ratchet, or a screw mechanism. They reduce the load on the cable.

The transmission elements and the drum are attached to the frame. It has grooves for a chain that is pulled to a fixed support and secured to it. There are also frames with bolted connections for fastening.

Unlike an electric winch, a manual winch is completely autonomous. In addition to factory options, there are simplified home-made ones. Fans of cross-country driving, for example, carry a half-meter piece of pipe with them.

It is driven into the ground. A cable is attached to the top of the pipe. The improvised winch is activated by the handle of a shovel or a crowbar. The grip is carried out between the pipe and the cable.

The force applied is greater than with the factory settings. However, even with the simplest winch the efficiency is many times greater than without mechanical assistance.

A manual winch, made with your own hands, works only for traction. Among the factory settings there are also those capable of smoothly lowering the load. If the design is designed not only for traction on the ground, but also for lifting, their power varies.

It is easier to move horizontally than vertically. Does the packaging indicate 2/0.8 t? This means that the winch is capable of pulling 2000 kilograms on the ground, but lifting less than 1000.

We are experiencing

For the test, we purchased seven manual winches at prices ranging from 1,100 to 3,600 rubles. Generally speaking, the target products for pulling out a car are mainly lever winches - we covered almost the entire range. But for fun, we also took a drum drum.

Avtodelo 43151, China. Lever winch approximate price 1200 ₽ Lever winch of pulley type. Weight - about 2.3 kg. The measured stroke is 1.9 m (with a chain hoist - half as much). The cable with a diameter of 4 mm broke. The drum was also dented. Rated "Poor". |

Service key article 71070, China. Winch 0.75 t / 1.5 t approximate price 1100 ₽ Lever winch. Weight - 2 kg. There is no pulley block. The actual stroke is 2.1 m. The cable diameter is 5 mm. Our sample was missing the boss that secures the cable in the drum. During testing, the frail arm was bent in half. Rated "Poor". |

Service key article 75066, China. Winch 0.8 t with worm gear approximate price 2000 ₽ Drum type winch. Weight - 2.7 kg. Travel - 6.7 m. No pulley block. The diameter of the cable is 5 mm. There is no cable guide. The worm gear mentioned in the description was not found - it turns out that we were deceived. It’s not very convenient to use, but the product is well made: in any case, nothing broke during testing. Rating "Satisfactory". |

Cable puller RockForce TRK8021, no name. Winch approximate price 2500 ₽ Lever winch with pulley system. Weight - about 2.8 kg. The actual travel is about 2.7 m (without a pulley). The diameter of the cable is 5 mm. A good cable guide with springy wings. I liked the sealing of the hooks. Powerful M8 coupling bolts are used, but the nuts are not locked. Rated "Good". |

Falco 737012, China. Manual lever winch approximate price 1100 ₽ Lever winch with chain hoist. Weight - 2.1 kg. Actual travel - 1.7 m. Cable - 4.5 mm. During testing, the handle was deformed. Rated "Poor". |

Matrix Winch 52225, China. Lever winch approximate price 3600 ₽ Lever pulley winch. Weight - 5.4 kg. Actual travel - 2.9 m. Cable - 6 mm. Body parts made of 4 mm steel - can be recommended for crossovers. The pulley can be conveniently disconnected using a standard hook. No comments. "Excellent" rating. |

Matrix Winch 52260, China. Lever winch approximate price 1100 ₽ Lever pulley winch. Weight - 2.9 kg. Actual travel - 2.1 m. Cable - 4.5 mm. Convenient chain hoist switching. Body parts are made of three-millimeter steel. Rated "Good". |

The purchased cable must be sealed humanly. We used special clamps, which would also be a good idea to buy in advance.

The purchased cable must be sealed humanly. We used special clamps, which would also be a good idea to buy in advance.

We remind you that the results of our tests relate to specific product samples and cannot be the basis for judgments about the quality of products of a particular company as a whole.

We loaded each winch according to the force declared by the manufacturer. To do this, the ratio of the radius of winding the cable on the drum and the length of the working handle was determined. No matter how many times the handle is longer, the force on it is less than the force applied to the eye of the car. Therefore, to create the required cable tension, we pulled the winch handle using a calibrated dynamometer.

In addition, the nuances of the design were assessed: the diameter and length of the cable, the presence of a pulley, the thickness of the metal, the quality of the cable seal.

The cable of the Avtodelo 43151 product turned out to be the weakest in our sample.

The cable of the Avtodelo 43151 product turned out to be the weakest in our sample.

The shame of testing: the handle of the product “Service key article 71070” folded in half

The shame of testing: the handle of the product “Service key article 71070” folded in half

A clear disadvantage of the drum-type winch “Service Key Article No. 75066” is that it simply cannot be used without an additional cable.

A clear disadvantage of the drum-type winch “Service Key Article No. 75066” is that it simply cannot be used without an additional cable.

Matrix Winch winches easily allow you to switch from a pulley connection to a conventional one. In the first case, we gain in strength, in the second - in distance.

Matrix Winch winches easily allow you to switch from a pulley connection to a conventional one. In the first case, we gain in strength, in the second - in distance.

Types of hand winches

In fact, dividing models into home-made and factory-made, imported and domestic are classifications of winches. They can also be divided according to the type of fastening.

There are devices that are fixed on walls, on the ground, and combined ones. But, the main classification is related to the structure and type of winch mechanism:

No. 1 The lever mechanism can operate without fixation. Accordingly, there is no need to look for a base that, like a winch, can withstand a significant load.

Plus, the free mounting allows you to use the device both horizontally and vertically. The main lever in the design. He triggers a ratchet mechanism that rotates the shaft in only one direction.

The disadvantage of the design is the small winding of the cable on the drum. You won’t find more than 6 meters in models of this class. But the manual lever winch is a record holder for lifting capacity. It is among the devices with levers that there are 10-ton towing ones.

Such winches are large in size and are used in industry and construction sites. Most lever samples are miniature and purchased for household needs.

A subtype of a lever winch is considered to be an assembly-traction winch. It does not have a drum. This makes the models compact and removes restrictions on rope length. There are proposals with 20-25-meter cables.

They are clamped with cams on the body. The clamps are located opposite each other, ensuring an even load on the cable. Ultimately, it lasts longer. In addition, there is a function for locking the cams with a lever.

The latter is protected by a shear pin. The device is more advanced than other lever winches and is gaining popularity.

No. 2 The drum mechanism works only from the support. Designed for horizontal movement of cargo. If you need to move them at an angle of 45 degrees, the manual drum winch is mounted at a height of 15 centimeters from the ground.

It's minimum. If the load has to be moved at a large angle, the device is raised by 65 centimeters. In addition to the support, the handle, gearbox and drum work.

The latter usually has tens of meters of cable. Therefore, the series models are also called cable models. Instead of a lever, the movement is set by a rotating handle.

Through the gearbox, it transmits the impulse to the drum, which sets the traction force. If it is excessive, the stopper is activated. This will protect you in moments of sudden drop of loads. They can weigh from 250 kilos to 5 tons.

The subclassifications of manual cable winch are due to different types of drive. The least reliable is considered:

-Worm. It has a helical gear and a main gear. The latter is mounted on a drum and rotates with a screw. The mechanism has an auto-stop and allows you to move the load in any direction; in other words, it works in reverse motion. The drive strength and the compactness of the mechanism are also pleasing. But the advantages are outweighed by rapid wear due to active friction in the worm pair. Reducing the load, you have to constantly lubricate it. Without lubrication, worm drives often jam.

-Single-speed gear drive consists of a large gear on the drum and a small transmission gear next to it. The design is also called gear. The gear ratio is calculated from the number of teeth on the gears. The leading one is monolithically fastened to the shaft, and the handle is fixed to it.

If her shoulder is long, the pull requires minimal effort. Short handles make you sweat. But the mechanism is reliable and durable, it pulls 2-3 tons horizontally, and several hundredweight vertically.

-Multi-speed gear drive. This one has several pairs of gears. Considering that each increases the force coefficient tens of times, the drive is the most powerful. But the rotation speed of the drum, characteristic of the first pair of gears, is lost.

An acceptable rhythm is gained with heavy loads weighing over a ton. If you plan to lift a bucket of gravel, the process will be protracted. The gear locking feature helps. You can stall certain pairs. Taking this into account, a manual chain winch with a multi-speed drive is the pinnacle of perfection in its class.

As you can see, the scope of its application depends on the nuances of the winch structure. There is even a separate classification based on the purpose of installations. We will consider it in a separate chapter.

Types of winches

Drum-type devices for lifting heavy objects differ in the way they transmit torque. We will consider the main types of hoists according to the method of converting forces.

Gear

These winches are the most common. They work due to the efforts made, i.e. are manual. In turn, gear winches can be divided into two types.

The design of such a hoist is quite simple: the main gear is attached to the drum, and a small drive gear is attached to it. In a single-speed gear winch, the quality of the parts is very important, since during operation the main gear bears the entire load and if the metal does not meet the strength standard, the device will quickly fail.

This design includes two or more pairs of gears, each of which provides a gain factor of several times. During operation, the sequential transmission of torque increases the force many times over.

Worm

The worm gear is a helical gear that rotates the main gear mounted on the drum. In this design, the shafts are positioned perpendicular rather than parallel to the ground.

The main advantage of such a winch is its high gain - this significantly increases work efficiency. The disadvantages include the heavy load on the transmission, due to which the device requires constant technical maintenance.

Chain

The design is based on a chain drive; it can be compared to a bicycle drive. It is easy to assemble such a winch yourself, since it is not intended to use complex structures made of hard-to-find materials.

Application of hand winch

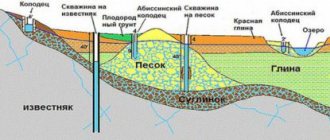

Most often a hand winch is needed for a car . This is considered domestic use. It is customary to put lever models in cars. Their compactness and ability to work without fastening are convenient.

In contrast to models with electric drives, there is lightness and resource saving of the engine from which the winches take energy. In addition, manual installations are several times cheaper than electric ones.

Household winches are called small-sized, since compact models are sufficient for household needs.

They are used not only in cars, but also on private construction sites, in garage work, and when stringing wires. Other types of installations are highly specialized. So:

- Scraper winches are used by miners to move cradles of rock.

- Shunters help move railway cars. This need arises in unloading areas and in the enterprise.

- Traction winches are also industrial, but are aimed at various loads moved in enterprises, warehouses, and construction sites.

- Mounting models are used for assembling and dismantling various equipment. Class winches help move and hold its parts suspended.

Hand winches are made from strong alloys. Their combination with the design of the devices allows the mechanisms to be used in any conditions, be it hot, cold, indoors or outdoors.

For open-air work and trouble-free storage of winches, they are coated with anti-corrosion compounds that prevent rust.

Prices for hand winches

The price of a manual winch is determined by its type, length and diameter of the cable, and production. Thus, it is possible to buy a Chinese-assembled lever installation for 1200-2000 rubles.

Domestic samples will cost 3 times more. But there is no “demolition” for Russian winches. European models also boast about this. However, they are even more expensive than domestic ones.

In this situation, many people prefer more powerful electric winches. The price is the same for many, but there are more opportunities.

For those who do not understand winch drives, the offers of drum models with a worm drive may seem advantageous. The catch, as stated in the article, lies in their unreliability.

However, for domestic needs such installations are acceptable and even advantageous. A worm drive is unlikely to handle industrial loads.

Multi-speed gear models and some lever options are ideal here. However, in factory conditions, electric winches are more often used. We will devote a separate article to them.

Hello, our dear friend! Since you are here now, then probably not the most pleasant thing happened to you when the car got stuck, and no attempts to get it out on your own were successful. This is a familiar situation for many motorists. The way out of it is considered to be a manual winch, which easily fits into the trunk of a car and allows you to free your four-wheeled horse from the tenacious paws of a ditch or our wonderful road, consisting of mud and asphalt residues.