The water that ends up in the sewer system may contain some fat or oil. Over time, this fatty mass is deposited on the walls of the pipeline, septic tank or cesspool. As a result, a blockage forms in the pipes, the cesspool begins to fill up faster and you have to call the vacuum cleaners more often.

A special device – a grease trap – can prevent this situation. It is installed before the juices are discharged into the riser and does not allow fatty inclusions to enter the sewer system. Used in industrial enterprises and catering establishments. However, for an ordinary kitchen, the presence of such a device will not be superfluous.

Design and principle of operation of the device

The main function of a grease trap is to filter sewage from grease, oil and solids that pollute the environment.

The equipment consists of a number of elements, these are:

- compartment of the device in which fat and oil are collected;

- a flask of 2-3 compartments, designed for settling wastewater;

- outlet pipeline connected to the sewer system;

- inlet pipe;

- airtight removable lid that prevents the occurrence of unpleasant odors.

The sewer grease separator consists of a one-piece sealed housing with a lid. The removable cover allows for preventive maintenance or manual cleaning of the tank when necessary.

There are 2 pipes connected to the body - inlet and outlet. The tank is divided into 2 or 3 compartments, which communicate with each other and are designed to separate oil, fat, and solids.

From the last compartment, defatted and treated wastewater is discharged into the sewer pipeline.

The simplest, inexpensive grease trap models have 1 chamber and are installed under the sink

Any model of grease trap for sewerage works on the principle of gravity. Particles of fat and oil accumulate on the surface of the filter, since they are much lighter than water.

Then they fall into a special settling tank, from where they are easily removed manually, using special equipment or special equipment.

Special enzymes are usually added to the device to break down accumulated fat. They allow you to significantly increase the time between cleaning the device.

Advantages of installing a grease trap in the sewer system

- The passage openings of the sewer pipes, becoming clogged with grease, become narrower. Problems arise with the drainage of wastewater into the sewer system. Installing a grease trap allows you to forget about frequent blockages, which are caused by grease deposited on the walls of the pipes;

- Decomposing sediments emit an unpleasant odor. The grease trap will also relieve its owners from it;

- The pipes will also be cleared of other large particles;

- The sealed body of the grease trap prevents debris and foreign liquids from entering the device;

- Deposits provoke the formation of an aggressive environment that affects the pipe material. The fat trap neutralizes this harmful effect;

- Grease traps for sewerage are easy to install on your own;

- The device can be used for a very long time, subject to regular preventive cleaning;

- The equipment does not require power supply;

- The materials from which the grease trap is made are durable and reliable;

- A sensor can be installed inside the chamber to monitor the level of accumulated fat;

- The design of the trap is simple, and therefore the cost of the product is low.

Note: Fat deposits accumulate especially intensively inside metal pipes, so for such waste systems the presence of a grease trap is very desirable.

Purpose and advantages of grease traps

More complex models of grease traps are used in large enterprises and are designed to effectively purify wastewater from solid particles, fat-containing and oil impurities.

According to sanitary standards in meat and dairy production and in public catering establishments, the installation of grease collection equipment in the sewer system is mandatory.

Industrial devices are installed at the outlet of a treatment structure that performs primary wastewater treatment.

Installing a grease trap will protect the sewer system of any catering establishment or production facility from contamination with fat and oil inclusions

Industrial devices are developed by manufacturers to ensure that clean water, purified from foreign impurities, enters the sewer system by separating and further removing the fatty component of the waste mass.

Installing a grease trap will help prevent sewerage failure due to the effects of grease deposits. It also protects the environment from the release of harmful impurities that can cause irreparable damage to the environment.

Such separators are indispensable not only in production, but also in everyday life. They reliably protect sewer pipes from the occurrence of grease valves or blockages. At the 1st stage, the device receives household water and separates fat and oil accumulations.

At the 2nd stage, the final separation of fat deposits and the removal of effectively purified water into the sewer system is observed. The device traps non-emulsified fats and removes them from wastewater.

A grease trap installed under the sink is often used in home kitchens, cafes, restaurants, pastry shops and fast food establishments.

The use of grease removal equipment has a number of advantages:

- Equipment tightness . Due to the tightness of the housing, the possibility of foreign liquid entering the filter is excluded.

- Practicality and versatility . Installation of various additional devices is possible. The sensor for the accumulation of harmful substances is in particular demand.

- No unpleasant odors . Due to the tightness of the housing, odors that usually arise during the breakdown of fats do not penetrate into the room.

- Easy to install . Installing indoor grease traps does not require any special skills and is carried out in 4 stages.

- Ease of maintenance. Cleaning most models of grease traps does not require much effort; it can be done manually using available tools.

- Reasonable price . The devices have a low price compared to other types of filters.

In addition to these advantages, the device that collects fat also has a long service life. All equipment is made of high-quality and wear-resistant materials, which guarantees its durability.

An important advantage of using a grease trap is the preservation of the environment, which is especially important in modern times.

Modifications of grease traps are different for each case:

Three main types of grease traps for sewage (each, in turn, is divided into several modifications)

Small grease traps for catering

The most common type of grease trap for sewerage. Currently present in almost every establishment. These are basically small grease traps installed directly under or next to wash tubs. Hence the common name - “grease trap under the sink”

And this is what it looks like in reality -

Today they can be found in almost every cafe, restaurant or canteen. The compact dimensions of grease traps for sewerage allow connection to be made almost anywhere, while at the same time, the high efficiency of the equipment guarantees stable operation of the building’s internal sewage system.

Installation is extremely simple and does not require the involvement of specialists.

Products are available in all sorts of color variations, with different locations of pipes and other specific features. One way or another, they always look good, which is important when it comes to making the necessary changes to the interior of the kitchen workspace.

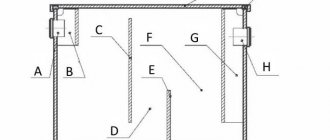

Workshop grease traps - above ground

Grease traps for workshop sewerage are installed in technical rooms (basements), which is where the name came from. Schematic diagram of workshop grease traps:

And this is what it looks like.

The essence is the same as “under-the-sink” grease traps (described above), but they have significantly larger dimensions. High performance allows you to combine the entire system and “close” the entire sewer system (all sinks, bathtubs, dishwashers, etc.) to one grease trap, which leads to a significant reduction in cost at the initial stage and significantly reduces operating costs in the future.

Workshop grease traps for sewage are made exclusively from polypropylene - a completely inert material with practically no limited service life. Steel profiles around the perimeter ensure high rigidity of the grease trap, protecting it from accidental mechanical damage. Taken together, the technology for manufacturing grease traps makes it possible to produce equipment with an unlimited service life, guaranteeing flawless operation of the sewage system throughout the entire life of the enterprise.

At the Customer's request, workshop grease traps for sewage can be made with pipes with a diameter from 110 to 315 mm - PP, PE, PVC-U, Pragma or Korsis.

Underground high-performance grease separators for sewerage

Equipment with a working volume of up to 100 cubic meters.

Connection to the sewerage system is made exclusively underground. The technological scheme is the same as the previous ones, however, the specifics of operation impose additional requirements on the strength of products. They are made cylindrical, since this shape provides the greatest rigidity of the body, which is the main requirement for underground installation.

They are divided into two main types - vertical and horizontal.

Diagram of vertical grease separators:

They are produced in three versions:

Version “A” - with a removable technical well

Advantages

- the removable neckline is cut on site, allowing you to accurately set the final height of the product. In addition, this approach minimizes forwarding costs. Recommended for small depths - up to 1500 mm. When connecting to a sewer “under a manhole”, the neck is additionally equipped with a 580 mm adapter.

Grease traps for sewerage “B” and “C” - in a single housing, with a ladder for maintenance

Design advantages

— a large-diameter technical well (equal to the diameter of the grease trap) with a platform (only in version “C”) provides the most convenient and

safe

sequential pumping when installing the grease separator at great depths. The presence of separate stairs facilitates access to each chamber of the grease trap for sewerage. Obviously, grease traps in Designs B and C are preferable in cases where the h2 value exceeds 1500 mm. A neck with a diameter of 580 mm as a standard allows installation under a road hatch, without the need for additional transitions. Stairs are installed by default.

Schematic diagram of horizontal grease traps for sewerage:

Horizontal grease traps are also not the same. They may differ in the number of technical wells (necks) for maintenance, the general layout and the presence of additional equipment. Underground grease separators A Underground grease separators B

The operating principle is the same as those described above. The design feature allows the grease trap to be connected to the sewer without significant recesses, however, they require more free space for installation. The basic principles of operation and types of grease traps are briefly outlined above, on the basis of which we can briefly summarize: There are many different grease traps, but they all have similar results, provided that the production technology is followed.

The following indicators were obtained during equipment testing:

- degree of fat content at the inlet (mg/liter) - 4200

- output quantity - 18.12

Conclusion - the equipment can be used to prepare wastewater for discharge into the citywide network, subject to the most stringent requirements for the mass fraction of fats in its composition.

In fairness, it is worth noting that the specified test results for grease traps are achievable only under ideal conditions. In reality, the quality of wastewater at the sewer outlet is influenced by many additional factors - such as the temperature of the wastewater entering treatment, the type of detergents, volley discharges and their frequency, etc.

Recently, in Russia as a whole, and in certain regions in particular, there has been a tightening of standards for the content of fatty products in wastewater from enterprises. For example, in Astrakhan, the water utility applies the requirements of no more than 8.6 mg/liter. Such indicators are unattainable for any grease trap, regardless of volume or type.

In such cases, the solution may be to equip the grease trap with a sorption filter. The sorption filter can be installed directly after the grease trap in the sewerage system. In this way, a fat content in the output of less than 1 mg/liter can be achieved. More information about this equipment can be found in the corresponding section of the site.

Additionally, all underground grease traps for sewage, regardless of type and design, can be equipped with the following equipment:

- Fat level sensors (with alarm unit)

- Sludge (sediment) level sensors

- Overfill sensors

- Automatic grease collection and removal systems

- Systems for agitation and automatic removal of sediment (sludge)

- It is possible to produce insulated grease trap housings for use in cold regions with slight depth.

Grease trap for sewerage – many options, difficult choice?

Based on the above, it can be argued that the efficiency of grease traps, first of all, depends on its volume. The higher it is, the lower the flow speed and, accordingly, the faster its temperature decreases. We get the natural identity “size = throughput”. The opposite statement is also true - increasing the size of the grease trap, while maintaining the rate of waste flow, entails an inevitable increase in efficiency in absolute terms.

You have chosen a grease trap, how to install it?

Despite their external similarity, they are connected to the sewer system in different ways.

Small grease traps “under the sink” can be installed independently, without the involvement of specialists. It happens like this - However, not always. Often, owners of small catering establishments have to work with what they have, and they have no opportunity to change the internal space of the workroom properly. Not everywhere can a sewer grease trap be simply installed under a sink without spending even ten minutes on it - since washing equipment is installed in very cramped spaces.

In such cases, it is still necessary to involve specialists who are able to make the necessary design changes to the washing equipment used, optimize it and find the possibility of connecting the grease trap to the internal sewerage system.

In NPO Industrial Water Treatment, it is for such cases that there is its own service department, capable of solving any, even the most complex and non-standard problem, so that you have the opportunity to carry out your professional activities without thinking about the peculiarities of the operation of your sewerage system. One way or another, in the end, connecting compact grease traps is not a very difficult task.

With the connection of underground grease traps, everything is different.

A short excerpt from a typical grease trap data sheet (recommendations for connecting to the sewerage system)

The grease trap is mounted and connected to the exit point of the building's internal sewage system, which has a ventilated riser in its design.

If there is no riser, it must be installed with an exit point under the ridge of the building. It is necessary to agree with specialists on the need for ventilation equipment for the grease trap; if this is not available, plug the pipe on the product.

The design, installation, and use of treatment facilities must take into account the requirements of SNiP 2.04.03-85, SNiP 2.04.01.-85, SanPiN 2.1.5.980-00 and other relevant building codes and regulations, and in the conditions of the Moscow region - also TSN ViV-97MO.

When planning the system, it is necessary to take into account the following factors: the composition of the soil, its filtering capacity, sanitary zones, the presence of water sources for drinking purposes, the presence of karst rocks, the protection of the underground aquifer, the height of the groundwater (taking into account the period of spring snowmelt and heavy rainfall), the requirements of the SES of this area, accessibility for maintenance. (SanPin 2.1.5.980-00 “Hygienic requirements for the protection of surface waters”).

When choosing an installation location, consultation with specialists is necessary.

Requirements for a place to install a grease trap:

- When choosing a location for installing a grease trap, you should follow the recommendations:

- If possible, the equipment should be located below the building, along the natural slope of the area.

- Provide for the possibility of access to the grease trap for a sewage disposal truck for pumping. The recommended distance is no more than 4-5 m (the length of a standard sewer hose is 7 m, taking into account the downward movement).

- Locate the installation as close to the building as possible. The optimal distance is 3-5 meters. It is also necessary to take into account that increasing the length of the sewer route to the insertion point leads to more difficult cleaning in the event of a blockage. A route longer than 15 meters must be completed with an intermediate well.

- The sewerage route from the building to the installation must be straight. If it is impossible to organize a straight route, repeat wells are installed at the bends.

- The area for the grease trap should be located at a distance of at least:

- from the boundary of the ground, road -5 m

- from the reservoir, stream –10-30 m

- from the source of drinking water -50 m

- from trees -3 m

- from a residential building -5 m.

Pit preparation

Construction of a pit for a grease trap

The trench for the pipe leading to the grease trap from the outlet of the house is made with a slope of 2% (20 mm per 1 meter). A leveling bedding is made at the bottom of the trench.

The pit for installation must have plan dimensions 500 mm wider than the product on each side to ensure the possibility of carrying out work on equipping the grease trap.

Types of grease traps by purpose

Equipment for household purposes is installed under the sink in residential buildings, apartments and small catering establishments - bars, restaurants, cafes, confectionery shops and canteens.

There are 2 main types of fat traps:

- household appliance;

- industrial.

They are mandatory elements of the sewerage systems of restaurant-type establishments. The devices filter the grease that forms after washing dirty dishes.

Household grease traps are cleaned manually and used with a liquid flow rate of up to 1.5 cubic meters per hour. Industrial grease traps are installed in industries whose wastewater contains a significant amount of fat, oil and other foreign impurities.

The use of an industrial device for catching grease is mandatory in large enterprises if the water flow is more than 2 cubic meters per hour. Their cleaning is carried out automatically - using special mechanisms.

Kinds

Effluents can be treated in three ways:

- Mechanical is the most common (the option is described above and has disadvantages: low level of cleaning, the need for regular cleaning).

- Gravity - similar in design to the previous one, but there is a difference in technology. The wastewater settles (within 24 hours), almost all fatty impurities collect near the surface. The purification level is close to 98%, but the fat must be removed and disposed of manually.

- Biological - with the help of destructors. Special microorganisms added to the wastewater convert the fatty component into a neutral sediment.

It wouldn’t hurt to install special devices on kitchen hoods. The fat vapors settled there reduce the level of pollution in ventilation systems. Grease traps for sewerage can be distinguished according to the criteria shown in the table:

CLASSIFICATION OF DEVICES

| Material of manufacture | Plastic or propylene | Serves up to 30 years; Harmless to people and the environment |

| Fiberglass | For industrial separators, durable, reliable, chemically resistant | |

| Galvanized steel Stainless steel | Affordable price Expensive, corrosion resistant, aesthetic appearance | |

| type of instalation | Under the sink | Easy to install and clean |

| In the basement | Costs for excavation and concreting | |

| In a separate room | For a large number of points | |

| Type of fat removal | Manually | Inside apartment kitchens |

| Automatically | In industry, using special equipment and pumps |

Sewage separators differ in the way they receive wastewater: volley discharge or uniform intake of wastewater.

Important! In all options, you can use Custom GT grease trap tablets; when they decompose, they remove unpleasant odors and make the cleaning process easier.

How to choose the right grease trap?

Each buyer independently chooses a grease trap model depending on the requirements for the device and financial capabilities. Regardless of the model you like, it will be possible to solve the current problem of the accumulation of fat and oil impurities, which can lead to clogging of the sewer system.

Grease traps by installation type

There are several criteria for choosing a special grease trap.

According to the installation method, separators are divided into 2 types:

- installed outdoors;

- used indoors.

There are separate models for each installation method. It is rare to find “mixed” solutions that are installed both outdoors and indoors.

Grease traps of any type are installed in the sewer system. In catering establishments and in the meat, dairy and fish processing industries, the use of separators for separating fat is a prerequisite.

Devices intended for indoor use are easy to install and affordable

Household grease separators can be installed in various ways:

- in a separate room;

- under plumbing fixtures;

- in the basement.

The choice of the optimal option depends on several criteria: the dimensions of the equipment and the ease of use.

Outdoor grease traps are made from more durable materials, as they must effectively resist external soil pressure.

Installation of such a fat separator is a complex and multi-step process. At the first stage, earthworks are carried out, then the site is concreted, and only then can we proceed to installation.

Therefore, to install grease traps, they usually turn to specialized companies.

The throughput capacity of outdoor grease separators is much greater than that of grease separators installed indoors

What material is the equipment made from?

The body of grease traps can be made of plastic, fiberglass or stainless steel.

Plastic grease traps are characterized by the following properties: attractive appearance and low throughput. They are mainly intended for domestic use, so they are installed indoors.

Advantages of plastic fat separators:

- Environmental friendliness of the material . Plastic is considered safe for the environment and people.

- Practicality . The material allows manufacturers to produce devices of standard sizes and tailored to individual customer requirements.

- Easy to maintain . Equipment can be cleaned manually using available tools.

- Durability . Plastic has a long service life; the device can last up to 30 years.

For the correct operation of grease traps, it is recommended to use a fat and oil deposit level sensor or other additional devices

Plastic fat separators are distinguished by their aesthetic appearance and compactness. They can be installed in premises of any purpose

Fiberglass is made from glass fiber and a polymer binder. Fiberglass grease traps have excellent strength characteristics. Due to this, they can be installed both indoors and outdoors.

The main advantages of a fat separator made of reliable fiberglass:

- Resistance to aggressive environments . The devices are resistant to extreme weather conditions and harmful chemicals.

- Increased strength . Grease traps made of fiberglass have proven themselves to be durable and reliable equipment.

- Light weight and easy to care for. Fiberglass grease separators are easy to clean.

The design of fiberglass grease traps can be horizontal or vertical

The fat layer accumulates inside the device to a certain level and is easily pumped out through the hatch

Fat separation equipment made of durable stainless steel is the most expensive among different models. It can be installed outdoors and indoors.

Some manufacturers make separators for fat impurities from galvanized steel. The quality characteristics of such devices are lower than those of stainless steel devices.

A stainless steel fat separator installed indoors looks aesthetically pleasing. The equipment not only effectively performs its direct functions, but also stylishly decorates the interior

Grease traps made of stainless steel are distinguished by high hygienic properties, excellent performance characteristics, and a long service life. It is also worth noting the high anti-corrosion qualities of stainless steel separators.

Image gallery

Photo from

Plastic grease trap for sink

Industrial grease trap made of fiberglass

Stainless steel separator

Homemade bucket separator

Tips for choosing

Correct operation of the device and reliable protection of sewer pipes and from grease deposits and blockages depends on the correct choice of a grease trap.

How the device works

For domestic use, it is enough to purchase a device whose productivity ranges from 0.1 to 2 l/sec. Large restaurants and enterprises producing fat-containing food products are equipped with large grease traps. Here they focus on the specifics of production. Thus, at enterprises producing dairy products, grease traps are equipped with tank filling sensors and pumps that pump wastewater into the tank.

Cleaning the tank

You can get rid of a specific unpleasant odor in a catering area by installing an automatic, compact grease trap. Place it directly under the sink. Modification of many models provides for the output of wastewater to a separate receiver. Maintenance of such devices does not require much time - it is enough to periodically clean the pipes from large particles, and use any detergent to remove sediment.

Compact device for a small dining room

To prevent the formation of blockages, sewer pipes are periodically washed with hot water.

Varieties

Conventionally, grease traps can be divided into several categories depending on the manufacturer, parameters for using the equipment, the method of its installation and materials of manufacture.

For the manufacture of grease traps, stainless steel, plastic and fiberglass are used. The advantages of plastic products are as follows:

- Tanks can be manufactured to order that meet certain criteria - with a certain throughput, dimensions and shape;

- the PVC product is easy to use and maintain - it is enough to periodically clean the tank;

- The material is environmentally friendly and has a long service life.

Plastic product

Products made of fiberglass are often used for industrial purposes, since the material is particularly resistant to chemically active environments. The equipment assumes both internal and external types of installation - the body is durable, not afraid of environmental influences, easy to clean and lightweight.

Fiberglass tanks

Large enterprises use grease traps with a steel casing. Such equipment has a high cost, but it is justified by the performance properties of the material. It is characterized by high anti-corrosion properties, universal installation - inside and outside, and a long service life.

Stainless steel product

Performance properties of separators

Grease traps vary significantly in power and performance. Devices with a capacity of 0.1 to 2 l/s are considered household equipment.

All devices with a capacity of more than 2 l/s belong to industrial devices. Fat separators provide effective wastewater treatment from fats up to 20 mg/l.

Full operation of the fat separator is possible if the performance of the device corresponds to the amount of wastewater coming from the sewage system

The performance of the equipment must correspond to the amount of sewage entering the device or be higher than this value.

Grease traps also differ in how they are cleaned. There is equipment:

- manual cleaning;

- mechanized cleaning.

In most cases, grease separators are manually cleaned with low throughput, intended by the manufacturer for indoor installation.

They are under constant control; filters are cleaned manually using available means.

Grease traps for mechanized cleaning are, most often, industrial fat separators, characterized by high productivity. Typically, devices are equipped with sensors that signal the need for cleaning.

The cleaning procedure is carried out using pumps or specialized vehicles.

How to make a grease trap yourself

If you wish, you can make a grease trap for your sink with your own hands. The advantage of this approach is that you can choose the optimal housing size for convenient placement under the sink. In addition, it is possible to calculate the required throughput of the device. Well, saving money is also important for some people. Let's take a step-by-step look at how to make a fat catcher yourself.

Making a grease trap

We will need the following materials:

- sheet plastic;

- a piece of plastic pipe with a diameter of 5 cm;

- PET elbow for inlet pipe with a diameter of 5 cm;

- silicone sealant;

- glue for plastic;

- PET tee for outlet pipe with a diameter of 5 cm.

Device manufacturing procedure:

- Using a hacksaw, blanks are cut from plastic sheets to the size of the bottom and walls of the box.

- The walls and bottom are glued together into a single structure.

- 2 partitions are cut out, which must correspond to the width of the grease trap body.

- The first partition is glued inside the body, the upper edge of which corresponds to the level of the walls. The partition should be located above the bottom. Water will flow underneath it into the second chamber.

- A second partition is mounted, which fits closely to the bottom. Its height should be one third less than the height of the walls. Water will pass over this partition.

- A hole is made in the front wall of the housing for the inlet pipe. This hole should be 4-5 cm above the outlet.

- A PET elbow is inserted into the inlet hole and sealed with silicone sealant. The elbow will connect to the sink drain a little later, so think about the connection method in advance.

- An outlet hole is made on the opposite wall of the housing, into which a PET tee is inserted from the inside. A plastic pipe is attached to the tee on both sides. One end of it should be near the bottom, and the other should rise to the lid itself.

- A cover is cut out of plastic according to the dimensions of the case. It should provide a tight seal, but can be easily removed for cleaning.

- The tightness of the device is checked. To do this, water is poured into the grease trap to such a level that it begins to pour out through the outlet pipe.

After checking, the device is connected to the drain line.

Design of a homemade grease trap

Inserting a device into the system

First of all, you need to decide where to install the grease trap. If a household appliance is installed, it is usually located under the sink or near the sink. The grease trap is cut into the drain pipe immediately after washing, before exiting into the sewer.

Tip: If there are several drain points, it is recommended to install the separator at the outlet of the last drain point. This will ensure complete separation of fats from all sinks in the house.

It is necessary to make sure that the grease trap is installed strictly horizontally, without tilting. Otherwise, water will overflow over the edge of the housing.

All connections between the grease trap pipes and the drain are sealed with silicone sealant.

Checking the device operation

After installation is completed, it is necessary to check the quality of separation of fat from water. To do this, you need to open the water supply and then pour about 50 g of vegetable oil into the sink. After a while, remove the grease trap cover and make sure that the oil remains inside the device. In this case, the device is considered to be operating normally.

The catcher needs to be serviced periodically. To do this, remove the top cover, after which the layer of fat accumulated inside the device is removed.

Manual cleaning of the grease trap

By installing a homemade grease trap in your home, you will ensure clean drainage. By these actions you will not only improve the ecological state of the environment, but also get rid of blockages in sewer pipes.

Equipment installation technology

The installation process of a fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the grease trap. Let's consider several options for installing separators.

Installation of an outdoor grease trap

The installation procedure for an industrial grease trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to carry out the installation yourself, it is necessary to carry out a number of preparatory work:

- We select a place for installation . When choosing, you should take into account the layout of the site, as well as the possibility of performing landscaping work in the future.

- We determine the size of the pit for mounting the device - its depth should be such that the grease trap cover is approximately 4 cm higher than the surface of the ground.

- We dig a hole . At the very bottom we will equip a solid formwork into which we will pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1:5 is optimal.

- We wait until the solution hardens , at least 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of the equipment. To do this, we install the grease trap body on a concrete base and securely fasten the device to the hinges embedded in a homemade concrete slab during the pouring period. If you forgot to install the hinges, they can be secured with anchor bolts.

Now we are constructing unique plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If you plan to operate the separator in a cold climate, then it must be covered with heat-insulating material. Mineral wool or polystyrene foam is suitable for this.

All that remains is to connect the grease trap to the communication networks. To do this, the outlet pipe of the equipment must be connected to the drainage system. The joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. Coat the joints of the elements with sealant.

We fill all the free space created between around the grease trap body with soil. Usually backfilling is used, during which the soil dug out from this place during the hole digging stage must be filled into the opening.

We must not forget about the need to install a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a large load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

Outdoor grease traps are often cleaned by specialists from specialized companies using pumps or special equipment

It is recommended that the installation and installation of industrial grease traps be carried out with the assistance of professional installers. They must have permits to carry out the full range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

Installing a grease trap indoors

Installing a household separator under a sink is a simpler process than installing equipment outside. To do this, you first need to choose the optimal location for installing the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing equipment.

It remains to perform a number of sequential actions:

- We bring the outlet pipe of the equipment into the sewerage system. At the connection point you need to install a rubber gasket, which comes with the device.

- We connect the inlet pipe of the trap to the outlet pipe of the sanitary equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to install a special gasket.

- We fill the grease trap with the required amount of water to check the device for leaks.

If the test is successful, you can install the lid on the grease trap. Once the cover is installed, the installation of the equipment can be considered complete.

Image gallery

Photo from

Step 1 - Disconnecting the Flexible Sewer Hose

Step 2 - connecting the grease trap and drain

Step 3 - connecting the grease trap to a flexible hose

Step 4 - connecting the device to the sewer

For more information on how to choose and install a grease trap under a sink, read this material.

Installation

In fact, installing a grease trap is a simple process.

You can do without calling a specialist and actually handle the installation yourself. The best place for installation is under or next to the sink. Often, sewer separators are built into kitchen sinks. To install a grease trap under the sink , the device is connected to the sewer. The kit contains everything you need for this purpose.

During installation, the device must be placed on a hard and level surface. The main requirement for the separator is that the container must be accessible for regular cleaning.

Sequence of work:

- the sink drain hose is connected to the inlet pipe, the rubber gaskets are lubricated with silicone sealant;

- the drain pipe is connected to the sewer using a corrugated hose with the same diameter using rubber seals;

- the container is filled with water to check how tight the structure is (if there is even the slightest leak, it is eliminated);

- after closing the top cover, the device will be ready to receive waste;

- All that remains is to install the outer part of the household grease trap, connecting it to the sewer.

Professional installation of a grease trap at an industrial enterprise is carried out by specialists who are required to instruct the process personnel in detail regarding the correct operation and cleaning of the grease trap.

Review of popular grease trap manufacturers

The modern market offers a wide range of fat separators made by foreign and domestic manufacturers. It should be noted that there are no significant differences in the equipment of different companies.

Devices of any brand work on the same principle - they function due to the force of gravity. Many manufacturers offer additional equipment in addition to traps, such as a stand.

The stand is designed for use with grease traps that are installed directly under the sink in restaurants, canteens, cafes and cutting shops of large supermarkets

When choosing the optimal model, you should focus on the purpose of the grease trap, as well as the prestige and reputation of the manufacturer.

Grease traps from the following companies are in particular demand:

- Helyx;

- Wavin Labko;

- Evo Stock;

- flotenk;

- UE "Polymerkonstruktsiya"

Helyx is a popular manufacturer that produces mainly industrial vertical and horizontal grease traps. The separator is used as the initial treatment system.

It is installed at the site of industrial sewage discharge, which contains contaminated and greasy wastewater.

Wavin Labko is a Finnish developer and manufacturer of innovative electronic fat accumulation meters and traps made of fiberglass and polyethylene.

Wavin-Labko's EuroREK grease traps are used in restaurants, cafes, canteens, gas stations, meat processing plants and slaughterhouses.

The Russian manufacturer Evo Stok produces equipment for various purposes from heat-resistant reinforced plastic that is resistant to corrosion.

The devices are equipped with hermetic seals that effectively prevent unpleasant odors from entering the room.

Flotenk produces industrial and household devices from durable fiberglass reinforced plastic .

The advantages of grease traps from Flotenk are aesthetics, the presence of a level alarm, a degree of purification of up to 50 mg/l, and durability. The manufacturer produces vertical and horizontal grease traps.

The grease catcher from Polymerkonstruktsiya Unitary Enterprise is a container made of a spiral pipe, with inlet and outlet pipes.

The outlet pipe is located at a considerable depth, which prevents fat from leaking through.

Device Features

What is a grease trap? It is a container that is located in the path of wastewater from catering establishments: restaurants, canteens, cafes, pasty shops, food production facilities, private houses and apartments, rushing into the sanitary sewer.

Purpose of the tank:

- separation, collection and removal of oil and grease from wastewater;

- protection of sewerage and treatment tanks from possible grease plugs;

- savings on sewer system maintenance.

It is enough to connect the grease trap to the waste pipe, you can avoid many problems inherent in catering establishments and industries related to the production of food products.

Purchasing this simple device that separates grease waste from water will save money on cleaning drainage pipes.

Attention! The cheaper the device for collecting fat, the greater the effort, financial and time costs its maintenance will require.

The right grease catching and drain protection products can help those who are concerned about clogged sewer pipes and related problems. Without such equipment, a catering outlet cannot be opened; a large amount of fatty waste water damages the sewage system.

Outdoor installation

To properly install a grease trap for external sewerage, you will have to put in a lot of effort. Of course, all problems can be avoided by using the services of experienced specialists - but this option, of course, will cost an order of magnitude more than installing it yourself.

Before installing the grease trap, you need to perform several preparatory steps:

- First of all, you need to find a place suitable for the separator. In the selection process, it is worth starting from the characteristics of the site and the need for any work to be carried out subsequently.

- The next step is to determine the dimensions of the pit for laying the equipment. The depth of the pit is calculated so that the upper part of the grease trap (where the lid is located) protrudes from the ground by about 4 cm.

- Next you need to start digging a hole of the selected size. At the bottom of the pit, a solid formwork is formed, which is subsequently filled with a sand-cement composition (for sandy soil and loam, a ratio of 1:5 can be used).

- All you have to do is wait until the solution hardens completely. This usually takes at least two weeks.

Having finished with the preparation, you can begin installing separator equipment, which involves performing the following operations:

- The grease trap body is installed on the prepared site. To fix the device, loops are used, which must be embedded in the concrete during pouring. However, if there are no loops, you can use an anchor fastening.

- You need to install plywood walls around the perimeter of the device. The role of these walls is to prevent soil from shedding during operation of the device. If the region where the equipment is installed has a harsh cold climate, then the grease trap must also be covered with a layer of thermal insulation. It is best to use mineral wool or polystyrene foam as a thermal insulation material.

- The next stage is connecting to communications so that the principle of operation of the grease trap can be demonstrated in practice. The outlet pipe is connected to the drainage system, and the input pipe is connected to the sewerage system. All joints must be treated with sealant to create a solid structure. The cavity between the device body and the edges of the pit is filled with soil. There is no need to look for new soil for this - it is best to use the one that was previously in the prepared hole.

- The last stage is the installation of a vent riser, which is necessary to remove gases accumulating in the sewer system. You need to choose the diameter of the pipe and their number depending on the load on the sewer system. It is best to read the corresponding article about the installation of a drain pipe and the features of this work.

And yet, the best option would be to involve professionals who understand what the concept of a grease trap looks like and can implement it. In addition to skills, an experienced team also has a set of tools that allow them to complete all the work quickly and efficiently.

Why is it needed?

If a local sewer system is being installed, then it makes sense to use all the possibilities that increase the efficiency of the system and its durability. A household grease trap installed at the beginning of the system will eliminate the risk of pipe clogging, narrowing of their diameter, and the appearance of an unpleasant odor.

Advice! Fat deposits that form on the walls of pipes are a favorable environment for the growth of bacteria, and this contributes to the appearance of an unpleasant odor from the sewage system.

The installation of grease traps in public catering wastewater systems is mandatory. But is it worth installing equipment in a private home? Each owner can decide this question independently, having previously assessed the benefits of using grease traps. This:

- Keeping pipes clean. Fatty impurities, once in a cold environment, turn into flakes that settle on the walls of the pipes. Over time, the fat covers the walls of the pipes in a fairly thick layer, gradually reducing the diameter of the pipe. Over time, a fatty plug can completely block the lumen of the pipe, which will lead to a shutdown of the sewage system.

- Eliminate odor. Fats are decomposed by bacteria to form substances with an unpleasant odor. Therefore, one of the reasons that the sewage system begins to spread a stench is that the pipes become overgrown with fatty deposits.

- Increased pipe life. When fat decomposes, not only unpleasant-smelling gases are formed, but also caustic substances that gradually destroy the pipes. Regular sewer cleaning using chemicals does not contribute to the longevity of the pipeline. And such cleaning will need to be done regularly so that the sewer system does not become clogged with grease.

All of the above suggests the advisability of installing household grease traps even in apartments, but it is especially important to use the device if an autonomous sewage system is used in a private household. Moreover, it is quite possible to install a grease separator yourself.

Selecting a grease trap

Choosing a suitable fat trap is always an individual matter. When choosing, you need to take into account a number of parameters, starting from the purpose of the device and its operating conditions to the set of additional functions. However, one thing is for sure - if the equipment is suitable for a specific situation, then its effectiveness will be quite high.

Installation methods

Depending on the installation features, all fat traps are divided into two categories:

- Outdoor, intended for installation outside the building;

- Home ones, which are installed exclusively indoors.

There are also combined solutions suitable for installation in any conditions - but such devices are practically not found on sale. However, the range of standard models is so wide that choosing the best option for specific operating conditions is not difficult.

Regardless of the type, grease separators are installed directly in the sewer system, but the specific installation point may vary. For example, household equipment can be mounted either directly under the plumbing or in the basement. Sometimes grease traps are installed in a separate room. Of course, when installing in a building, you need to take into account the size of the equipment and how convenient it will be to maintain.

With external separators the situation is more complicated. For the manufacture of such devices, more durable materials are used, since the equipment must withstand greater load and exposure to external factors. Outdoor grease traps must be installed underground. This process is quite complicated - you first need to prepare the site, concrete the area, and only after that can the separator be installed. For such work, it would be best to involve specialists.

How does a grease trap work?

The grease trap well for sewage is quite simple in design - this device is made on the basis of a sealed housing and has two pipes. One of which goes to the entrance, and the second to the exit. A removable cover is installed on the body, through which it is easy to clean the tank and prevent it. The device body is divided into several compartments connected to each other. In each of them, fat is separated from other wastewater particles. After passing through the last compartment, wastewater that no longer contains fat enters the sewer system. For an apartment, you can also purchase a model with just one compartment.

The operating principle of a sewer grease trap is based on the density difference between water and fat. The latter are lighter than the former, so they rise to the top.

When water enters the first compartment, it begins to slowly rise, and the resulting fat flows into the tray or floats on the surface. Little by little, water without fat enters the second compartment. Here the cleaning process is identical. That is, in each tank of the device, wastewater is purified from harmful fat deposits. And the greater the number of compartments, the cleaner the water will enter the sewer.

In addition to cleaning, solid waste accumulates in the first compartment. This process is accompanied by the appearance of a large amount of garbage. Accordingly, this compartment most needs manual cleaning. Also, some models are equipped with an additional filter, which is installed in front of the first compartment and serves for rough cleaning.

How to install?

Installing a grease trap is not difficult; this work can be done independently. When performing installation, you must adhere to certain rules:

- First decide on the installation location and check whether there is enough space for installation. So, placement under the sink may be hampered by plumbing. Keep in mind that the grease trap will need to be cleaned periodically, so it must be easily accessible;

- prepare the horizontal surface where the grease trap will be installed;

- check the completeness; all pipes and fastening elements necessary for assembly must be present;

- Now you can install and connect the grease trap, following the instructions;

- during the installation process, it is necessary to seal all joints using plumbing sealant or sealing tape;

- carry out tests to ensure the installation is leak-tight.

How to choose a grease trap?

When searching for any ideal device, it is always evaluated from all sides. How to choose a grease trap? In this case, the following factors are taken into account:

- diameter of sewer pipes;

- tank performance;

- availability of free space;

- the materials from which it is made;

- installation location (house/apartment or street);

- the total number of plumbing fixtures (when installed in the basement, outdoors);

- main characteristics of the grease trap (volume, frequency of use, cleaning);

- fame, reputation of the manufacturer, number of positive reviews about specific models.

After defining the main criteria, we need to dwell briefly on the most important of them.

Trap performance

Industrial equipment must have high power ratings. For household appliances that are usually installed under the sink, this requirement is unnecessary. As a rule, the optimal flow rate is from 0.14 to 2 liters per second, or from 0.5 to 1.5 m3/h.

Peak reset

When examining the issue regarding performance, one cannot fail to mention one more parameter, which is always indicated in the technical data sheet of trap products. All washers can operate in 2 modes: both flow-through and storage devices.

- Normal use. This type of operation of flow devices is used more often. The liquid does not linger in them for a minute, but flows into the grease trap by gravity, simultaneously leaving suspensions and fat in the equipment. In this case, the performance of the crane is important: the maximum value is 0.15 l/s.

- The sink is a temporary reservoir. Choosing a device for storage tanks is a little more complicated. In this case, water is first drawn into the sink, and then “in one gulp” is sent to the drain. It is for plumbing installations operating in this mode that the peak discharge for grease traps must be taken into account.

All models require the use of a plug to close the drain and outlet. If owners sometimes use a plumbing fixture as an “artificial source,” then it is important for them to match the capacity of the sink and the grease separator. By ignoring it, the owners risk arranging a “surprise” for themselves.