Main purpose

Machines of this type are used primarily, of course, for boring holes of different diameters in workpieces. But if necessary, they can also be used for:

- turning the external surfaces of cylindrical parts;

- machining the ends of workpieces;

- countersinking and reaming of holes;

- thread cutting;

- milling.

Types of boring machines

Equipment of this type can be classified according to several criteria. According to the scope of application, such machines can be:

- universal turning and boring machines;

- specialized.

The machines of the second group are in turn divided into the following varieties:

- horizontal boring;

- coordinate boring;

- diamond boring.

Recently, CNC boring machines have become very widespread in enterprises.

Information about modifications 2A622F4 and 2A622

This is a new type of CNC horizontal boring machine, replacing obsolete analogues.

The devices are designed to process parts in a cantilever manner, even with large-sized housings. Their weight can reach up to 4 tons. Processing should not be a hassle, even if there are holes that require precise parameters. And when certain dimensions are saved for connecting the axes. Sometimes products with the number 2L614 are designed this way.

An obligatory part of the equipment is a rotary table and a front stand that maintains a fixed position. But the table itself moves, lengthwise or crosswise. On machines of this series it is easy to mill workpieces following an octagonal contour. Let's assume an option with a circular table feed. One of the available modifications is is2a636f1.

The design also includes a retractable spindle with a diameter of 110 millimeters. The plates are mounted in one position on the spindle headstock, at the end of the wall. This is how the horizontal boring machine model 2a614 works.

Among the main characteristics it is worth noting high rigidity and the ability to resist vibrations. Due to this, the service life of the spindle device is increased. Console technology increases efficiency. Machining the end surfaces of parts is made possible thanks to a removable faceplate. Boring large diameter holes is simplified. The 2L614 variants have this property.

The type of design determines the presence of certain additional parts:

- CNC option.

- Digital identification technologies.

- Coordinate readings are in digital form, this is important for the processed part.

What can a jig boring machine be like?

Equipment of this type is intended primarily for the most precise processing of workpieces. Coordinate boring machines can be:

- single-post;

- two-post.

The design of such machines includes:

- bed;

- rack;

- table with slide;

- boring head.

Also, the design of such equipment includes a traverse.

Features of working on a coordinate boring machine

When using this type of equipment, the workpiece being processed is first secured on the work table. Next, the required cutting tool is installed in the spindle. The work is then done in the following order:

- depending on the height of the workpiece, adjust the traverse and boring head;

- set the spindle to the specified coordinates.

The last operation on equipment such as a jig boring machine, depending on its type, can be performed in different ways. On a single column model, the spindle is installed properly by moving the work table in two perpendicular directions. On two-rack equipment:

- the table is moved longitudinally;

- the boring head is moved in the transverse direction along the traverse.

Model range of jig boring machines

Many manufacturers produce such equipment today. But most often, enterprises use jig boring machines:

- 2E450. This single-column model has table dimensions of 630 x 1120 mm and is equipped with an optical measuring system complemented by an on-screen readout. This boring machine also has an automatic slide stop function. Another addition to this model that increases ease of use is the device for pre-setting coordinates.

- 2D450. This model also has table dimensions of 630 x 1120. The optical device included in its design can measure both whole and fractional parts of coordinates.

Of course, other coordinate boring machines can also be used in enterprises. Models 2A450, 2L450AF11-01, for example, are also in great demand today.

Horizontal boring machines

Such equipment is also used quite often in enterprises and workshops. Its main distinguishing feature is that the spindle in it is located horizontally. The main movement of the latter is rotational-translational relative to the axis. In this case, during turning, both the feed of the workpiece and the movement of the working tool itself can be carried out.

Moving the spindle head on equipment such as a horizontal boring machine is an additional movement.

Horizontal boring models

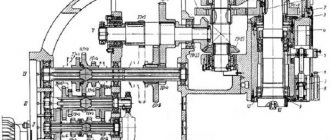

The main design feature of this type of machine is that the spindle is located in a horizontal position and can be extended. This allows you to make holes even in the most difficult to reach places, including large parts (booms, frames, metal structures).

The main movement of horizontal boring models is rotational-translational. It is performed by a spindle. Not only the tool itself moves in such machines, but also the workpiece. If necessary, you can switch feeds and speeds during operation. In some cases, feeding is carried out using a special substrate.

Depending on the configuration, in addition to the main movements, such machines may have auxiliary ones:

- spindle head along the vertical axis;

- table at given coordinates.

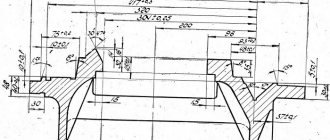

Also, the design of some models allows for the possibility of moving the rest and rear pillar. Below is a diagram of this type of boring machine. Horizontal models can be used for processing parts made of cast iron or cast steel.

What models can be used

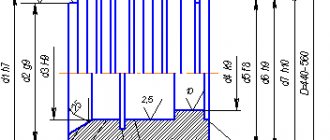

Equipment of this type can be supplied to the market today, both ordinary universal with a spindle with a diameter of 110-130 mm, and heavy. The machines of the latest variety are usually additionally equipped with a slider and a movable column.

Manufacturers also produce many models of such equipment. For example, units of the VFC and FORT lines are very popular among consumers

The VFC horizontal boring machine can be designed for processing workpieces weighing up to 10 tons. Such machines are used mainly for boring parts made of cast iron and steel. These models are built on a modular basis and have a rotary table.

FORT series machines are also presented on the market in a very wide range. They can have a classic design with a cross-shaped table or with a movable column. The table dimensions of FORT horizontal boring machines vary from 1250 x 1400 mm to 4000 x 4000 mm. The spindle diameter can be 100-260 mm.

Diamond boring machines

Equipment of this type is intended mainly for fine finishing of workpieces. The tools in such machines, as can already be judged by their name, are either diamond or carbide. A boring machine of this type can be used for processing workpieces made of both steel and cast iron, as well as alloys of non-ferrous metals, hard rubber, textolite, rubber, etc. In some cases, diamond boring can even replace grinding.

Cutting on such equipment is carried out at a significant speed and at the same time with a small depth of material removal. Depending on the location of the spindle, diamond boring machines can be horizontal or vertical.

Classification of boring machines

Boring machines are most widely used in individual, small-scale and mass production. This equipment processes complex body parts with many holes, groove necks and ledges. According to their layout, horizontal boring machines are divided into three groups:

Machines with spindle diameter up to 125 mm. designed for mechanical processing of medium and small workpieces;

Machines with a spindle diameter of 100 - 200 mm. Designed for mechanical processing of medium and large-sized workpieces;

Machines for machining particularly large parts have a spindle with aisles of 125 - 320 mm.

Boring machines of the first group have a fixed column and a work table that moves along two axes in a horizontal plane. The spindle with the rotating tool is located in the boring head, which can move in the vertical direction along the column. For machines of the second group, the work table can only move in one direction. A movable column can move perpendicular to it along the guides. For machines of the third group, the table is motionless.

Turning and boring machines

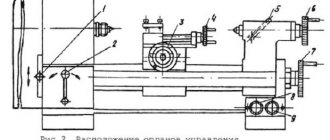

The main feature of this type of equipment is the very high spindle speed. A boring and turning machine can be used to process both flat and cylindrical parts.

When working on such equipment, the workpiece is mounted on the table. In this case, the spindle makes a rotational-translational movement.

Modern industry also produces large-sized turning and boring machines. The turning diameter of such equipment can be equal to 4 m. At the same time, the machine can process parts up to 32 m long. The most popular model of turning and boring machine at the moment is 2A656RF11.

Design features and benefits

The main purpose of horizontal boring machines is deep boring of holes. Most often, they are used to manufacture gearbox and turbine housings, gearboxes and cylinder blocks, electric motors and other similar samples of parts and components for various branches of mechanical engineering.

Speaking about the features of universal models of horizontal boring machines, it is worth noting the retractable spindle design and a cross-shaped rotary table. The retractable spindle has a more rigid structure than other similar types of milling equipment. This makes it possible to successfully perform high-precision machining of complex-shaped workpieces - cylinder blocks or beds - simultaneously along the entire length of a large part. The presence of a rear support post makes it possible to achieve excessive runout of the cutting tool, thereby compensating for the decrease in the intensity of its impact due to the maximum extension length of the spindle in the working position. This is especially important in the process of manufacturing seats for shaft bearings, gearboxes, housings and gearboxes, where it is necessary to ensure the same impact along the entire length of the workpiece.

To increase the functionality of the machines, a cross table of a rotary design is installed on them. Thanks to the presence of a rear stand, this technological solution allows you to simultaneously bore holes, for example for bearings, on opposite sides of the body workpiece when it is rotated 180 degrees. It was possible to cope with the problem of some loss of accuracy when moving the workpiece thanks to the technology of Hirth fastening on curved teeth and a two-gear system for rotating the table with pre-tensioned gearing.

An important advantage of universal machines is their adequate cost, which can be quickly compensated for in both small-scale and individual production, where non-standard models of parts, tools and structures are manufactured, and their repairs are also carried out. The only requirement that must be met when working on this equipment is the presence of highly qualified boring workers on the company’s staff. Otherwise, it is recommended to use CNC machines, which minimize the impact of the human factor.

CNC equipment

CNC can be complemented by both diamond and horizontal, turning or jig boring machines. Modern electronics, of course, greatly increases the ease of use of this equipment. The turner controls the operation of a CNC machine not manually, but through a computer. This allows you to achieve the highest precision drilling or cutting and maximum productivity.

CNC boring machines can be used for both roughing and finishing machining of workpieces. They cost, of course, much more than conventional models. Only turners who have undergone requalification under the appropriate program can work on such machines.

CNC boring machines

Models of this variety have many advantages compared to conventional ones. Their work is controlled by a computer with a program embedded in it. This allows for high processing precision and maximum productivity. The program is written in special codes specified in the description of the machine. This modern equipment can be used for both roughing and finishing of parts.

Boring machines are equipment that is truly in demand and in many cases irreplaceable. Especially when you need pinpoint precision or maximum performance. If an enterprise has a need for equipment of this type, finding a suitable model on the modern domestic market will not be difficult.