Rules for soldering copper parts

The soldering iron is used only for connecting small parts, and the soldering process itself is carried out at a temperature of +350 ℃. Large workpieces, due to their increased thermal conductivity, need to be soldered only with torches.

As for baths and stoves, there are two positions that differ from each other in filler. It could be solder or salt. It should be noted that salts perform two functions: a heating element as a source of temperature, and a flux.

That is, in technologies that use salt furnaces or baths, fluxes are not used.

In principle, regardless of the metal of the workpieces, the joining process itself is the same for all materials. And it is divided into six stages:

cleaning copper blanks mechanically to remove the oxide film;- degreasing;

- introducing flux into the soldering zone;

- heating zone.

- adding solder;

- cleaning the joint from flux and solder material.

Bronze soldering is also carried out. The main difference is the required brand of solder and flux. Since bronzes are an alloy of copper, tin and some other elements, choosing a solder is not difficult .

Bronzes also include alloys of copper and cadmium, copper and beryllium, alloys with lead and aluminum. It is necessary to pay attention to the composition of bronze, depending on which the properties of the material change.

Connecting wires

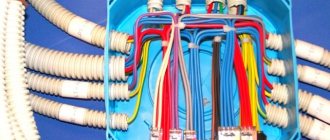

Before connecting the wires in the junction box, we advise you to study the rules for their installation.

After all, it is important not only to properly connect the wires to each other, but also to correctly insert them into the junction box, and also conveniently position them for possible inspection or repair

Rules for installing wires in a junction box

First of all, let's look at the rules for the arrangement and installation of wiring in the distribution network. After all, it is with this factor that any installation begins.

- First of all, you should remember that no more than eight groups of wires can be laid in one groove, box or pipe.

- All connections must be made in accordance with clauses 2.1.17 - 2.1.30 of the PUE. These clauses provide for a whole range of restrictions. First of all, remember that the wire in front of any contact must have a reserve sufficient for at least one reconnection.

- Before connecting the wires in the junction box, make sure that they are free of tension. Or that this tension will not occur due to temperature changes.

- Any wire connection points must be accessible for repair and inspection. At the same time, these places should be organized so that inspection is not hampered by structural elements.

- Any connection must be insulated. In this case, this insulation must correspond to the level of the main insulation. To achieve these parameters, it is better to use electrical tape or heat shrink.

- The distribution boxes themselves must be made of fireproof or fire-resistant materials. like in the video. This is especially true for the installation of wiring on combustible structures, which are subject to additional requirements.

Options for connecting wires in a junction box

First, let's look at how to connect the wires in a junction box. After all, it is the contact connections that are often the most vulnerable point of any electrical network and any shortcomings appear very quickly.

According to clause 2.1.21 of the PUE, all connections of wires and cables must be made by welding, soldering, crimping, screw or bolt compression. Other connection methods, especially twisting, are not allowed. Based on this, let's look at each of the possible connection methods separately.

The most reliable connection of wires is considered to be the welding method. It has the lowest transition resistance, resulting in virtually no increased heating. In addition, over time, such a compound does not lose its properties.

Welding of wires in the junction box is carried out using a special welding transformer and a carbon electrode. The cost of such products is high enough for a simple replacement of wiring in an apartment, so you can often find homemade devices. Typically these are transformers up to 600 W and voltage 9 - 36V.

The second place in reliability is the connection using the soldering method. This method is more accessible for home use because it does not require special equipment other than a regular soldering iron.

Connecting wires by soldering

Soldering of wires in the junction box is carried out using conventional technology and does not impose any special requirements.

The only point worth paying attention to is the quality of such connections. After all, if heated, the tin will heat up quickly enough and the contact will disappear. To prevent this, soldering is often combined with a twisted connection.

To prevent this, soldering is often combined with a twisted connection.

Wire crimping has recently become increasingly popular. After all, a large number of fairly cheap tools for crimping wires have appeared on the market, and the price of consumables for this method is quite low.

But the most common method is still the screw or spring clamp method. A huge number of buses and terminals currently on the market allow for a fairly reliable connection of wires.

Note! Screw terminals should be used to clamp single-core wires. If you use stranded copper wire, then you need to purchase special tips that will prevent the screws from breaking the strands of the stranded wire when clamping. These lugs are attached to the wire using the crimping method.

These lugs are attached to the wire using the crimping method.

Selection of solder and flux

When soldering copper alloys at low temperatures, tin-lead and lead-silver solders are used.

Either rosin dissolved in alcohol or zinc chloride is added to the soldering zone. These are fluxes. Unfortunately, tin and lead additives are highly brittle compounds, which are formed due to the so-called intermetallic compounds. At low soldering temperatures, cracks form in them.

Therefore, to connect copper, solder materials are used that contain no more than 15% tin. The lead component increases the impact strength of the joint.

And if the material contains silver, then the copper compound becomes cold and heat resistant. But it is also necessary to take into account the fact that silver reduces the strength of the connection.

In diffusion soldering, solder for copper is made up of several metals: tin, lead, indium and gallium. If a low temperature process is carried out, high joint strength cannot be guaranteed. It is not higher than 70 MPa.

Capillary soldering can also be carried out with these solders. But with one condition - the gap between the workpieces should not exceed 0.5 mm, and the soldering temperature should not exceed +900 ℃.

For soldering tin bronze, silver, tin-lead and copper-zinc solders are used. When the tin content in the alloy is high, copper-zinc material is undesirable. During the soldering process, bronze should be heated gradually and the metal should be thoroughly fluxed.

Correct procedure

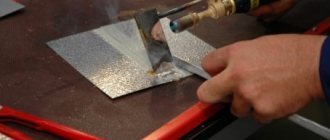

Wires should be tinned using a soldering iron in accordance with an algorithm verified by many years of practice. At the very beginning of work, you need to carefully remove the outer insulating layer of the wires with a knife or pliers. It is advisable to remove at least 10 mm and maximum 50 mm from the polymer coating from each connected end.

After this, use the same knife to clean the surface to a shiny state. This will eliminate the presence of remnants of the insulating sheath and remove oxide deposits from the wires.

Thick wire is easier to hold and clean. If the cable includes several thin wires, it is advisable to fray them, separate them, strip them on all sides, and then twist them again.

Then you can heat up the soldering iron, first checking the cleanliness of the tip. The surface will only be well maintained if it is absolutely clean.

Using a heated soldering iron, you should heat the prepared, thoroughly stripped ends of the wires, dipping them in rosin. The rosin needs to coat the wire well.

Use the soldering iron tip to take the solder and evenly distribute the mixture along the cut of the wires, which are fixed with tweezers or ordinary pliers. To ensure complete application of the mass of molten consumables, the wires should be rotated around their own axis.

Copper wire can be treated not only with rosin, but also with acidic flux. Some people prefer to use something that is always commercially available. A special flux is provided for tinning aluminum wires.

Some types of solders

Cadmium solders when soldering copper and steel require certain skills to work with them. Because the manufacturability of these materials is lower than that of previous ones.

It should be noted that such a connection is heat-resistant (up to +350 ℃), but not cold-resistant. In addition, a cadmium alloy joint will not be very strong.

Zinc solder materials are rarely used for soldering copper because the metal itself quickly dissolves into the solder material. This weakens the joint, hence the low tensile strength - up to 15 MPa.

Zinc solders alloyed with silver or copper also have low fluidity. Although these materials are doped with cadmium or tin, they have good fluidity, but the strength of the compound itself decreases greatly.

Copper-phosphorus grades with the addition of silver are a good option for soldering. The connection can withstand high loads, up to 300 MPa, and temperatures up to +800 ℃. But solder metal bonded to copper is not ductile. This means that it has low bending strength.

Silver solder materials have proven themselves well in high-temperature copper soldering conditions. True, they show their qualities if soldering is carried out with acetylene or in special furnaces where corrosive fluxes are used.

Solders with a high silver content are used in the process of joining copper blanks in a vacuum or when heated with argon. If the process is carried out under pressure, then either foil (silver) or silver coating is used for the connection.

Solder materials with a high copper content and a low silver content are used rarely and in exceptional cases. Because it is a refractory alloy that requires high heating temperature.

As for pure lead solders, the connections made with them are not strong enough, but they have high ductility. For example, such joints after soldering can be bent up to an angle of 130°, and in tension they can withstand up to 140 MPa.

Is it possible to solder stainless steel to copper?

Soldering copper to stainless steel, although it is a rather complicated process, is still possible. The fact is that the connection of stainless steel to stainless steel and copper to copper occurs much more often, since the final quality of the connection is much better. But in various situations, when you need to make such a connection, you have to compromise on quality. Especially for such cases, special solders are produced that allow you to make a reliable connection that meets operational requirements. While for other types of soldering the use of flux is not always necessary, here it is necessary to carry out a full range of procedures, including tinning, and also to use all additional materials.

This group includes solders based on silver and copper. Copper-zinc solders are used to connect parts with static loads because they have a certain fragility.

The process of soldering copper with brass is carried out using solid copper-phosphorus solder.

Silver types of solders are among the highest quality materials. Such alloys may contain, in addition to silver, zinc and copper. These solders are used for joining workpieces that operate under conditions of shock and vibration.

Use of borax

Soldering brown copper has always been considered the easiest way to connect copper pipes. Essentially, borax is a high-temperature flux in the form of a paste.

When heated to 700-900 ℃, it begins to melt, turning into a glassy mass. With its help, not only copper blanks are connected, but also copper and iron, for which solders made of copper, silver, gold or brass are used, that is, medium-melting alloys.

The only thing you need to pay attention to is the salts that are formed during the process of soldering copper with borax.

High-quality borax-based flux can be made at home, which is what most craftsmen do.

To do this, they mix boric acid and borax in equal proportions. Add water to it, mix and evaporate. The result is boron flux. To increase quality, chloride or fluoride salts can be added to the mixture.

The technology for soldering copper tubes is practically no different from the standard process. But it also has its own nuances.

For example, borax is applied both on top of the tubes and on its internal surfaces. Then the two pipes are heated for 15 seconds, and only after that solder is added to the heating zone.

Foil soldering method

Foil can successfully replace solder. This is a thin aluminum film that requires minimal thermal energy to melt. This soldering method is convenient for connecting thin wires that Chinese manufacturers use in their many electrical and electronic products. Proceed as follows:

- the wires are cleared of insulation along the ends of 1.5-2 cm;

- the veins are twisted;

- the twist is covered with a thin layer of solder paste and wrapped in foil;

- the resulting compound is heated with a gas lighter or a candle flame;

- within 1 minute a strong soldered connection of wires is formed.

How to solder copper wire

At home, you often have to solder copper jewelry. Despite the apparent simplicity of the process, it is actually not simple. Firstly, you need to use a file to process the copper wire so that the connection of its two parts passes along a larger plane. It is imperative to secure the parts to be connected relative to each other so that mixing does not occur during the soldering process.

Liquid flux is added to the joint, after which the joint is heated with a burner. Next, solder is supplied to the heating zone. It is better if these are small pieces that are installed end-to-end with tweezers. You can lay them down before heating the copper wire.

Soldering of edible and non-edible copper is a standardized process based on two documents - GOST 1922249-73 and GOST 16038-80. That is, the norms and rules stipulate specifically how to carry out the work, with what and under what conditions.

Soldering order

The soldering technique is directly related to the type of connection formed, which can have the following designs:

- ordinary twisting, most often found in distribution circuits;

- a docking station made of wires of various classes (copper and aluminum, in particular);

- twisted joints arranged in apartment distribution boxes and other types of connections.

When soldering conventional twist, special attention should be paid to the cross-sections of each of the wires, which may have a significant difference in thickness. If one of them is thick and the other is incomparably thinner, their twist is formed in a special way

To obtain a reliable solder connection in this case, you should wind a pre-tinned thin wire around the well-stripped bare part of the thick one, and then bend it in any convenient direction. Only after this should you carefully solder the area from the joint along the entire length of the exposed part (after first applying a rosin solution to this place).

To remove insulation from conductors, you can use a regular lighter, under the flame of which the protective film is first burned, after which its remains are scraped off with a knife or scalpel.

Thus, the entire soldering process can be conditionally divided into two stages, at each of which the following actions are carried out.

Firstly, preparation (removal of varnish from the surface) and tinning of the wires themselves. And secondly, their reliable sealing at the point of contact. When connecting the cores in parallel (without twisting), it is necessary to lay them closely on the working area of the table and, holding them with one hand, take the soldering iron with the other and iron the contact point with the tip.

Why do you need solder paste?

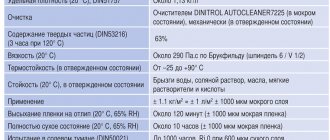

Solder paste is a pasty mass consisting of small particles of solder, flux and special additives. Flux paste is used in industry when soldering elements on printed circuit boards. The paste is selected according to certain conditions:

- after application there should be easily removable particles;

- the substance must maintain viscosity and stickiness;

- do not have a negative impact on the surface being treated;

- do not leak onto clothing during melting.

How to work with the paste depends on the type and size of solder contained in its composition. The material also differs in the type of flux (rosin, water-washable, no-clean). It is necessary to hold small parts in place and facilitate the joining process.