About the types of workbenches

Car owners regularly face the need to perform a variety of repair work. For everyone involved in carpentry and plumbing (no matter at a professional or amateur level), proper equipment of the workplace helps to allocate energy and time more economically, and also ensures better results. A workbench is suitable for the role of universal equipment suitable for use in garage conditions.

Initially, the workbench arose as a carpenter's workplace intended for processing wood. With the advent of various (including electrical) equipment and the division of professions, the workbench began to specialize. Today, in addition to carpentry, there are carpentry and metalworking workbenches, as well as combined varieties.

Great-grandfather of modern models Source pinterest.com

Basic equipment

A workbench in a garage is an equipped workbench consisting of various modular elements, which include:

- Metal frame (table). Its design is designed for a significant weight, from 70 to 300 kg (depending on the model). Tables designed for working with heavy and large parts (for example, wheels) are strengthened with additional diagonal connections.

- Tabletop for carpentry and plumbing work. Depending on the functions performed, it can be made of galvanized or stainless steel, chipboard, or plywood. The safety margin of the tabletop is designed to withstand dynamic and shock loads, and contact with chemically active compounds.

- Accessories. The workbench serves not only as a work area, but also as a place to store tools, spare parts and other equipment. Therefore, the mandatory components of the design are cabinets, screens, drivers (drawers), shelves, and hanging holders.

Every thing in its place Source interstroy.info

Preparation for design

The optimal size of the tabletop width is 60–75 cm. The length is selected based on the free space. The minimum is 70 cm, the maximum is 2.5 meters. The edges of a standard tabletop are made 0.5–1 cm wider than the base.

Garage design

Materials you will need:

- Boards 5–6 cm thick.

- Sheet iron for table top.

- Plywood for walls, boxes, wall panels.

- Steel strips of 0.4 cm each. Guides and brackets are made from them.

- Metal corners measuring 40x40x3 mm. They are needed for the power frame, tabletop limiters, and back wall.

- Tetrahedral pipes with a cross section of 50x50x3 mm, intended for the frame.

- Anchor bolts, screws, self-tapping screws.

- Varnish, paint, antiseptic solution.

Plank option

The following tools will be required:

- welding, electrodes;

- roulette, level;

- drill, screwdriver;

- jigsaw;

- Bulgarian;

- discs (for metal and for grinding).

Product with a long tabletop

The parts are cut out according to the dimensions of the drawing, where the standard height of the workbench in the garage must be taken into account. Next, the metal elements are cut. The workbench can be made with built-in jacks, screw or nut, to change the height.

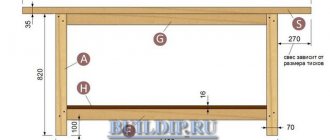

Standard parameters for height 185 cm:

- total height of the workbench – 95 cm;

- tabletop thickness – 6+2 (change in distance during welding) cm;

- frame height – 87 cm;

- tabletop length – 220 cm;

- width 60–75 cm;

- The width for the side cabinets is no more than 75 cm on each side.

Graphic representation of the product

Selection criteria: wood or metal

For many car enthusiasts, the garage is a second home, so they approach its arrangement with due attention. A particularly important point is the purchase of a workbench; the selection criterion may be the purpose for which it is intended. In most cases, such equipment is installed to perform the following work:

- For regular inspection and maintenance of the vehicle.

- For minor plumbing work, minor repairs, correction of defects related to the maintenance of the house and garden area.

- If plumbing or carpentry is part of your hobby.

The first question that arises when choosing is the material of manufacture. There are wooden (most often homemade) and metal workbenches offered by various manufacturers, both domestic and foreign.

Workplace for the soul Source nw1ab.ru

Wooden workbenches

A wooden workbench for the garage, made entirely or partially from wood, is suitable for periodic and short-term work with simple parts; it is not well suited for machining complex metal components. The frame of such models is made of strong wood (beech or oak) and secured with self-tapping screws. The stability of the table is ensured by additional spacers, transverse or x-shaped. Wooden models are usually equipped with shelves or drawers for storage. The wooden tabletop is trimmed with metal along the edge.

A common model is a design of two massive cabinets connected by a tabletop. This option looks quite practical, since it solves most of the problems associated with the placement of tools. Despite the relative cheapness and good (albeit somewhat limited) functionality, many believe that a workbench in a wooden garage has significant disadvantages:

- A wooden bench is not designed to withstand heavy loads.

- With increased use, the service life of the frame is significantly reduced.

Wooden workbench Source whilesafe.blogspot.com

See also: Most Popular Garage Projects.

- The table area does not allow placing several types of equipment at the same time.

- The wooden surface of the countertop under the influence of chemical agents (paints, solvents) and metal dust becomes unusable over time, and traces of oils remain forever.

- Wood is a fire hazardous material; in combination with the collection of chemical substances located nearby, this property increases many times over.

Metal workbenches

To assemble a functional metal bench, you will need special equipment and skills in working with metal (the fragments are connected by welding). Metal models, assembled in workshop conditions, have a durable construction and modern design. Despite the higher price due to the cost of metal and a more complex assembly process, metal equipment has many advantages, including:

- Long service life. Stainless steel models boast an impeccable service life of 50 years.

Metal workbench Source shkaf-nsk.ru

Step-by-step instructions for making a workbench for a garage

Assembling the support frame

Let's look at an approximate procedure for assembling a metal workbench. The following operations must be performed:

- According to the assembly drawing, parts of the appropriate length are cut to assemble the support frame. A rectangular pipe, angle steel or other types of rolled products selected for this purpose are used.

- The frame is being welded. First, the support platform for the tabletop is welded, then it is turned over and the supports and frame of the cabinet are welded. Drawer guides are installed and side panels are attached.

- Weld seams are cleaned using a grinder, burrs and sharp edges formed during metal cutting are removed.

- The workbench is turned over and installed in a pre-selected place. The required number of boards to cover the table top is cut from sheet material or cut to length. Installation and surface finishing are carried out,

- Depending on the type of construction, a back wall is attached to the rear edge of the worktop to prevent tools or parts from rolling off and falling behind the workbench. In a garage, this is very important, since it will be extremely difficult to find a rolled small screw.

- The instrument panel is assembled and hung on the wall. Typically a sheet of plywood is used with rows of holes into which rods are inserted to hang the tool.

- The racks are assembled in a similar way: welding the frame, installing the planes and hanging them on the walls or installing them with fixation to them. All edges are carefully processed and cleaned, sharp corners are rounded.

- The finished structure is painted, after the paint has dried, lighting is installed, tools are placed, a vice, emery and other necessary equipment are attached.

The listed operations refer to the basic, most necessary actions. Depending on the type of structure and the presence of additional elements, other assembly steps may be required. In order to avoid mistakes, it is recommended to think through the order of work when creating a working drawing. It is necessary to follow the points of the plan to increase the speed of work and eliminate confusion in assembling the structure.

Video: The process of creating a workbench

Workbench options

To determine the size of the workbench, you need to understand how much space in the garage you are willing to allocate for a workplace. The choice of design for arranging a garage is based on several indicators:

- Depth. Most garages have modest dimensions. Taking into account this limitation, for use at home, workbenches with a tabletop depth (width) not exceeding 0.5-0.6 m are preferable.

- Length. An important parameter that should not be reduced unless absolutely necessary. The longer the tabletop, the more convenient it is to perform metalwork work on it and install auxiliary tools. If you intend to use a circular saw or an electric jigsaw, you will also have to allocate part of the countertop for this work. In practice, most garage owners prefer to install workbenches about 1.5-2 m long.

Compactness is one of the advantages Source koffkindom.ru

Durable and reliable DIY garage workbench

Dear visitors to the site “Visiting Samodelkin,” in the material presented you will be shown how to independently make a durable and reliable workbench for your workshop or garage. There’s no way you can do without a workbench in the garage; something constantly needs to be repaired, disassembled, assembled, and where to do this if not on a workbench, the vice is screwed to the tabletop and all the necessary tools are always at hand.

The workbench is designed for metalworking work, has a metal frame made of angle and corrugated pipe, as well as convenient drawers for storing small tools, bolts, nuts and other useful little things, there are also convenient shelves, and the tabletop itself must be trimmed with 1.5-2 mm iron thick. In addition, a panel for tools is attached to the back of the table, which is also very convenient because the necessary things will hang right in front of you, it is also advisable to display a socket or tee on the panel so that you can connect a power tool.

It is necessary to protect metal surfaces from corrosion, namely, cover them with an anti-corrosion compound and paint, so the table will always look neat and will serve you for many years.

So, let's look at what exactly is needed to make a workbench?

Materials

1. professional square pipe 2. angle 40x40 mm 3. metal sheet 2 mm 4. plywood 5. metal screws 6. paint 7. wood impregnation 8. wood screws 9. anti-corrosion coating 10. metal plate 11. furniture guides for boxes

Tools

1. welding machine 2. grinder (angle grinder) 3. drill 4. tape measure 5. wood saw 6. jigsaw 7. brush 8. hammer 9. screwdriver 10. ruler 11. marker 12. level 13. corner 14. sandpaper 15 . Sander

Step-by-step instructions for creating a workbench with your own hands.

Assembling and installing this table in a garage or workshop is a serious and responsible matter. When making it, you must first of all know that it must be stable and withstand a load of about 200 kg, check with a level to see if there are any distortions, because it is desirable for the table to end up smooth. Before starting work, you should study the drawings and diagrams provided by the author.

I thoroughly cleaned the welding areas using an angle grinder.

I welded metal corners to the back of the table; a panel for the tool will be attached to them.

Then the area under the countertop is strengthened, namely, additional pipes are welded.

The tabletop itself will be made of 50 mm boards and the author made a frame from a corner to accommodate it.

After which all joints must be reinforced with metal plates.

Spacers are welded into the corners.

The workbench will be subject to various loads: weight, shock, vibration, etc., at the creation stage, all these points must be taken into account and be on the safe side.

For the convenience of storing small tools, spare parts, bolts and nuts, the master made special boxes from plywood.

The surface of the workbench is painted.

Furniture guides are screwed onto the sides of the drawers.

The author makes the tabletop from wood, the board is 50 mm, if you don’t have a long board, you can lay short ones across.

The tree will take some of the load from shock, vibration and weight.

The resulting surface should be sanded well; for this, the master used an angle grinder (angle grinder) with a grinding wheel.

In order for the wood to last a long time and not rot under the metal, it should be treated with a special impregnation for wood.

The author used "Barrier"

After that, a 2 mm sheet of metal is cut to the size of the tabletop.

The metal must be treated on both sides with an anti-corrosion compound so that the metal sheet does not rust.

The drawers are installed in the table cavity where the craftsman has installed a slide under each drawer.

This way the drawers will be easy to open and close.

There is a handle screwed into the front of each drawer for easy opening.

For example, you can place emery on a finished workbench by bolting it to the tabletop.

There are open shelves at the bottom where you can store power tools.

It is very convenient to work when you have everything at hand and collected in one place.

You can also install a vice on the workbench, which is also screwed to the tabletop with bolts and tightened with nuts.

After which the author proceeds to create a panel for tools, cuts plywood to size and coats it with a protective composition for wood.

Next, screw it to the corners with bolts and tighten it with nuts.

The result is a convenient panel for various tools.

Then you need to screw in self-tapping screws or make special hooks so that the tools can be easily hung.

This is what actually happened as a result of the work done.

A workbench in a workshop or garage is simply irreplaceable, and you can make it yourself, which our author actually proved with a clear example. The master tried to do everything as efficiently and reliably as possible, because he did it for himself. Many will say a lot of metal was spent, yes it is, but quality is above all.

As you can see, if you want, you can do everything yourself, you have instructions and an example, so let’s take it and do it. Be brave, friends!

This concludes the article. Thank you all very much for your attention! Come visit often and don't miss out on new items in the world of homemade products!

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Workplace organization

The average garage doesn't have a lot of free space. In addition to compactness, the criterion that influences the parameters of a desktop is the amount of work to which you are going to devote your time. If you expect that you will not only drill and hammer nails, but also do more complex manipulations, you should think about a larger table. It is more convenient to carry out periodic processing of parts or workpieces if the vice and the sharpening or drilling machine are in assembled condition. The garage owner will have to find a solution for several more problems:

- Storage. Due to limited space, the workbench has another important task - providing convenient storage conditions. The right workbench is used not only as a work desk, but also as a convenient container for consumables, spare parts and tools.

When everything is at hand Source tr.pinterest.com

- Choosing a location. A specific garage task is choosing a place for a workbench. Two conditions must be met. Firstly, the distance between the car and the workbench and shelves in the garage must be at least one meter. The second condition is that you must be comfortable working near the machine without the risk of damaging it.

- Electrical connections. Electrification must be safe, taking into account the influence of dampness and aggressive liquids common in garage work. Electrical wiring must be laid in fireproof corrugation or hidden in grooves. If your electrical panel has a metal casing, it must be grounded.

The car should not be a hindrance Source yasminroohi.com

- Lighting. Considering that there are always shadow areas in the garage (from the car, shelves and racks), a combined system of several light sources designed for different tasks would be a practical option. Above the workbench, in the work area, it is convenient to install a bright turning lamp, protected by a lampshade. The lamp can be made removable; It’s also convenient to integrate it into a workbench, rather than attaching it to the wall—if you want to move the table, there won’t be any problems with electrification.

Features of the workbench design

A workbench for a garage is often compared to a desk because it provides convenience for a variety of tasks and makes it possible to keep all the necessary tools at hand. Thus, in addition to the tabletop, it has a large number of shelves and drawers. The design of the workbench consists of the following elements:

- The supporting element is a frame with legs. Everything else rests on it.

- Tabletop. Presented as a thick and powerful surface that can withstand hammer blows. Made from sheet metal or thick board.

- Nightstand. There may be one or two and they are located at the edges of the tabletop. They are equipped with shelves, drawers, or both. They usually store small tools or spare parts.

- Additional shelf. It is mounted under the countertop and is most often used for storing various fixtures, tools and other necessary things that may be needed during repair work.

The workbench must be well lit. To do this, install a stationary rotating lamp, which is plugged into an outlet. It can be installed on the wall, near the workbench, but it is much more practical to build electrical equipment directly into it. In this case, there will be no problems with electrification if you need to install the table in a new place.

Workbenches for garage

Features of the models

Mass-produced workbenches are convenient in that their characteristics are set during production and correspond to their purpose. Depending on the technical conditions under which a particular workbench will operate, different models may have the following parameters:

- Table top material. Moisture-resistant plywood or MDF coated with galvanized metal. The thickness of the tabletop varies between 24-30 mm.

Professional approach Source extxe.com

- Permissible load on the tabletop. Serial models allow a load of 300-350 kg. The reinforced series workbench is designed for 400 kg or more.

- The permissible load on a shelf in a cabinet is 20-30 kg, on a bench shelf - up to 40-50 kg.

- Protection. A lock, key or high security (pin) can be installed on the cabinet.

- Accessories. A variety of shelves, holders, screens and hooks.

Factory-made workbenches are supplied unassembled; By design they can be divided into three groups:

- Without pedestals. The ideal small workbench for a modest sized garage. The easy-to-assemble design is characterized by a sufficient size of the working surface, which can be folded if necessary (folding workbench). Stability is provided by adjustable legs. Baseless models can be additionally equipped with drawers on bearing guides.

Required tools and materials

To create a metal workbench with your own hands you will need:

- Grinder with cutting and grinding wheels;

- Welding machine;

- Tape measure, ruler, square;

- Pencil or scriber;

- Construction level, laser level or level;

- Electric drill or screwdriver;

- Jigsaw for cutting sheet materials (chipboard, MDF, plywood, etc.).

From the materials you need to prepare:

- Metal corner 50 to 50;

- Rectangular pipe 60 by 40;

- Steel strip and steel sheet for the manufacture of guides for drawers, shelving, upper tier, tool board;

- Boards or sheet materials for the countertop;

- Boxing;

- Self-tapping screws, screws, bolts with nuts, other fasteners;

- Paint, brushes, solvent.

Depending on the chosen design, other parts or materials may be required; only the most necessary elements are listed.

Video description

About the organization of the workplace in the following video:

- Single pedestal. Reliable prefabricated structure with a reinforced table top and a weight of 96-105 kg. This workbench is equipped with both a comfortable work surface and a cabinet with drivers (drawers on ball guides of different heights) or adjustable shelves. The drawers are locked with a central lock. Some models are equipped with a dashboard.

- Double-pedestal. The weight of such models is 100-115 kg; They are equipped with two drivers with drawers of different heights. The maximum permissible load on each drawer (if evenly distributed) is 30 kg. The kit may include a perforated screen - a panel designed to accommodate holders and hooks.

Combination workbench Source searsoutlet.com

What types of workbenches are there?

Workbenches can be divided into the following types: carpentry, metalworking, universal, for tools, construction sawhorses.

Folding workbench, extendable for carpentry work

Wooden carpentry workbench, stationary

Carpentry

This type of workbenches is used for processing wood; the surface can be wooden, chipboard, or plastic.

Many models have a vice installed for fixing objects; clamps are also included as an additional fastening. Suitable for making wooden stairs, cabinets, shelves, furniture and other household items.

Table for metalwork

Workbench Workbench MECHANIC-M20.01PPS16E2S – four-pedestal

Locksmith

The metalworker type of workbenches is designed for straightening, cleaning, and grinding metal products. Unlike carpentry, it has significant strength, is made of metal and coated with anti-corrosion paint. To handle heavy objects, the design itself is reinforced.

The workbench also has many accessories, including drawers for storing tools and various shelves.

If you make a workbench yourself, the tabletop can be made of wood, but be sure to cover it with a metal sheet or galvanized steel.

Workbench BOSCH PTA 2400 – for miter saws

Workbenches for tools

Also indispensable for fixing, processing wooden workpieces and fastening tools such as a miter saw, jigsaw and others.

Here, as in carpentry, you need to pay attention to the maximum load, the sliding surface, the height of the workbench and the length of the working surface.

Elmos sawmill for sawing wood

sawing sawhorses

Most often they are used for cutting workpieces, firewood and serve as stands for cutting materials with chainsaws, miter saws, processing with grinders and other tools.

Of these, we can distinguish folding ones made from metal profiles, both steel and aluminum, and solid (stationary) wooden racks without the ability to fold.