Principles of dimensional RCD

During dimensional processing, the usual mechanical cutters and abrasives act as a direct tool of influence. The key difference between this method is the energy source that powers the tool. An ultrasonic current generator operating at frequencies of 16–30 kHz acts in this capacity. It provokes vibrations of the same abrasive grains at an ultrasonic frequency, which ensures the characteristic quality of processing. Moreover, it should be noted that there are a variety of types of mechanical effects. This is not only the usual cutting and grinding elements, but also deformation of the structure while maintaining its volume. Moreover, ultrasonic sizing ensures minimal removal of workpiece particles even during cutting. The grains that impact the material punctuate microparticles that do not affect the design of the product. In essence, the destruction of the structure by extraction does not occur, but uncontrolled propagation of cracks may occur.

Educational materials

Ultrasonic processing of materials - a type of mechanical processing - is based on the destruction of the processed material by abrasive grains under the impacts of a tool oscillating at an ultrasonic frequency.

The energy source is ultrasonic current generators with a frequency of 16 ... 30 kHz. The instrument receives vibrations from an ultrasonic transducer with a core made of magnetostrictive material. Nickel, iron-nickel alloys (permendur), iron-aluminum alloys (alfer), and ferrites have a magnetostriction effect.

In a core made of magnetostrictive material, in the presence of an electromagnetic field, the domains rotate in the direction of the magnetic field lines, which causes a change in the cross-sectional size of the core and its length. In an alternating magnetic field, the frequency of change in the length of the core is equal to the frequency of current oscillations. When the frequency of current oscillations coincides with the natural frequency of oscillations of the core, resonance occurs and the amplitude of oscillations of the end of the core reaches 2 ... 10 μm. To increase the amplitude of oscillations, a resonant waveguide of variable cross-section is fixed to the core, which increases the amplitude of oscillations to 40 ... 60 μm.

A working tool-punch is fixed to the waveguide. A workpiece is placed under the tool and an abrasive suspension consisting of water and abrasive material is fed into the treatment area by irrigation or under pressure. Boron carbide, silicon carbide, and electrocorundum are used as abrasive materials. The highest productivity is obtained when using boron carbides. The tool is pressed against the workpiece with a force of 1…60N.

Workpiece 3 is placed in bath 1 under tool 4 (Figure 4.12). The tool is mounted on a waveguide 5, which is fixed in a magnetostrictive core 7, mounted in a casing 6, through which water is pumped to cool the core. To excite oscillations of the core of the magnetostrictive transducer, an ultrasonic frequency generator 8 and a direct current source 9 are used. The abrasive suspension 2 is supplied under pressure through the pipe 10 by a pump 11, which takes the suspension from the reservoir 12. Pumping the suspension with a pump prevents the abrasive powder from settling to the bottom of the bath and ensures supply to the zone processing of abrasive material.

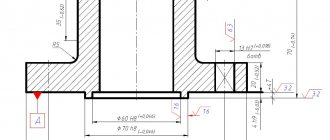

Figure 4.12 – Diagram of an ultrasonic machine

Cavitation phenomena in a liquid contribute to the intensive movement of abrasive grains under the tool, the replacement of worn grains with new ones, as well as the destruction of the material being processed.

The ultrasonic method is used to process brittle hard materials: glass, ceramics, ferrites, silicon, quartz, precious minerals, including diamonds, hard alloys, titanium alloys, tungsten.

The method is used for profiling external surfaces, engraving, and manufacturing parts of complex shapes. The feed movements for these types of processing are the vertical feed of the tool when processing holes and cavities, the longitudinal feed of the workpiece when cutting it into pieces, the longitudinal and transverse feed of the workpiece when cutting it along a complex contour. To control the movements of the workpiece and the vertical feed of the tool, program control systems are used.

Methods of processing structural materials > Theory according to TCM >

Differences from plasma processing technology

In terms of processing quality, ultrasonic and plasma methods have many similarities, providing the possibility of high-precision cutting. But there is also a significant difference between them in the principle of operation. Thus, if ultrasonic treatment involves intense impact on abrasive powder from a trimming tool with the energy support of an electric wave generator, then the plasma processing method uses ionized gas charged with ions and electrons as a working medium. That is, ultrasonic and plasma processing technologies equally require the support of a sufficiently powerful energy generator. In the first case, this is an ultrasonic electrical device, and in the second, high-temperature gas or isothermal installations capable of raising the temperature of the working environment to 16,000 °C. An important component of plasma processing is the use of electrodes and plasma-forming substances that provide high power to the cutter's guided arc.

Ultrasonic processing devices

Now it’s worth taking a closer look at the equipment that is used in the implementation of RCD. In large industries, for such purposes, machines are used that are equipped with a generator set to generate alternating current of ultrasonic frequency. The generated current is directed to the winding of the magnetic converter, which, in turn, creates an electromagnetic field for the working element of the installation. Ultrasonic machining begins when the machine punch begins to vibrate while in an electromagnetic field. The frequencies of this vibration are set by the generator based on the established parameters that are required in a particular case.

The punch is made of magnetostrictive material (an alloy of iron, nickel and cobalt), capable of changing in linear dimensions under the influence of a magnetic transducer. And at the final important stage, the punch acts on the abrasive powder through vibrations directed along the waveguide-capacitor. Moreover, the scale and power of processing may be different. The equipment considered is used for industrial metalworking with the formation of massive structures, but there are also compact devices with a similar principle of operation, on which high-precision engraving is performed.

Ultrasonic treatment. Design and operation of ultrasonic installations.

1.2. Design and operation of ultrasonic installations

The main elements of the oscillatory system are a source of ultrasonic vibrations (USV), an acoustic speed transformer and fastening parts.

of sources of ultrasonic vibrations : mechanical and electrical.

Mechanical sources of ultrasonic vibrations include ultrasonic sirens and whistles, the operation of which is based on the conversion of mechanical energy (for example, the speed of movement of liquids or gases). Electrical sources of ultrasonic vibrations convert electrical energy into mechanical elastic vibrations of a certain frequency. Various transducers are used for these purposes: electrodynamic, magnetostrictive, piezoelectric. The most widely used are magnetostrictive and piezoelectric transducers.

The operation of magnetostrictive converters is based on the longitudinal magnetostrictive effect, which manifests itself in a change in the length of a metal body made of ferromagnetic materials (without changing their volume) when exposed to a magnetic field. The magnetostrictive effect is different for different metals. Nickel and permendur have the greatest magnetostriction; they are widely used in the production of magnetostrictive converters.

Rice. 1.1. Magnetostrictive transducer circuit

The magnetostrictive transducer package is a core made of thin plates on which a winding is placed to excite an alternating high-frequency electromagnetic field in it. With the magnetostrictive effect, the sign of the core deformation remains constant even when the direction of the electromagnetic field is reversed. The frequency of change in deformation is 2 times greater than the frequency of change in the alternating current passing through the winding of the converter, since deformation of the same sign occurs in both half-cycles.

In Fig. Figure 1.1 shows a diagram of a magnetostrictive transducer. Winding 5 of the converter 4 core is powered by high frequency current generator 1. Under the action of electromagnets 3 and 6, powered by rectifier 2, a constant magnetic field arises. It creates a state of initial magnetization in the core of the converter 4 - polarization. Due to magnetostriction, core 4 in a constant magnetic field will change its length to the value l1. When winding 5 is connected to generator 1, a high-frequency alternating current flowing through it creates a magnetic field of the same frequency, as a result of which two magnetic fluxes will pass through the system: constant with induction Bo and alternating with induction Bp. At any time, the resulting magnetic flux

Вр = Во+ Вп.

In the case of a consistent direction of flows, when Вр ≠ 0, the core has a length l1; when the flows have the opposite direction and the resulting flow Вр ≈ 0, the core length is l2 ≠ l1. Thus, with the help of generator 1, rectifier 2, concentrator 7 (acoustic speed converter), electrical energy is converted into the energy of mechanical vibrations of the technological converter 8, which acts on the surface of the workpiece 10. Through the hose 9, working fluid is supplied to the processing zone.

The main disadvantages of magnetostrictive converters are: the presence of losses due to magnetization reversal of the core; significant current consumption for magnetization; low efficiency, low efficiency.

The operation of piezoelectric transducers is based on the ability of certain substances to change their geometric dimensions (thickness and volume) under the influence of an electric field. The piezoelectric effect is reversible, that is, if a plate of piezomaterial is subjected to compressive or tensile deformations, then electric charges will appear on its edges. If a piezoelectric element is placed in an alternating electric field, it will deform, exciting ultrasonic vibrations in the environment. The most widely used piezoelements are those based on barium titanate and lead zirconate titanate (PZT). An oscillating plate made of piezoelectric material is an electromechanical transducer.

An example of a technical application of a piezoelectric transducer is installations for sonicating solutions for the purpose of homogenizing them (Fig. 1.2). The solution flowing through the channel or located in the vessel is irradiated for a calculated time in the sound field, which significantly accelerates the dissolution of the components.

Acoustic speed transformers (concentrators of longitudinal elastic vibrations) are designed to match the parameters of the converter with the load, to install an oscillatory system and introduce ultrasonic vibrations into the processing zone. Concentrators are rods of different sections, made of corrosion-, cavitation- and heat-resistant materials, resistant to aggressive environments, abrasion, etc.

Various forms of acoustic speed transformers (Fig. 1.3) are characterized by corresponding vibration concentration coefficients. They (coefficients) are determined by the ratio of the cross-sectional area of the larger end of the concentrator (connected to the vibrator) to its small output end (connected to the tool).

Rice. 1.2. Design of a multilayer piezoelectric transducer : 1 - bath with solution; 2 - bottom of the bath; 3 - adhesive composition; 4 — top pad; 5 — disk from the central heating system; 6 — lower reflective pad

Rice. 1.3. Shapes of acoustic speed transformers

The increase in the amplitude of oscillations of the end with a small cross-section compared to the amplitude of oscillations of the end of a larger cross-section is explained by the fact that with the same oscillation power in all sections of the speed transformer, the intensity of oscillations of the small end is k times greater.

The power source of ultrasonic installations is used to convert electrical energy of industrial frequency into alternating current energy of ultrasonic frequency to excite the converter. The following requirements are imposed on them: stability of the generated frequency and the ability to regulate it within specified limits; power regulation; low cost, weight and size; reliability and ease of use.

There are also ultrasonic generators based on transistors and thyristors, machine ones, etc.

1.3. Technological features of the use of ultrasound

The use of ultrasound in industry is carried out in three areas: force on the material; intensification of technological processes; ultrasonic testing methods.

The forceful effect of ultrasound on the processed material is used for mechanical processing of hard and superhard alloys, dispersion and emulsification, removal of films, contaminants, etc.

A schematic diagram of ultrasonic dimensional processing by piercing (chiselling) is shown in Fig. 1.4. With this processing method, the directed destruction of hard and brittle materials is carried out using a tool 3 oscillating at an ultrasonic frequency. In this process, it exerts an impact on the surface being processed 1, which is achieved through the smallest grains of abrasive powder 9, introduced in the form of a suspension into the gap 8 between the end of the tool and the product.

Rice. 1.4. Scheme of ultrasonic dimensional processing by stitching : 1 - workpiece; 2 - bath; 3 - tool; 4 - acoustic speed transformer; 5 — magnetostrictive transducer; 6 — housing with cooling; 7 - ultrasonic generator; 8 - gap; 9 - abrasive particles

Although the productivity of each blow is negligible, the overall productivity of ultrasonic processing is relatively high, which is due to the high vibration frequency of the tool (16-30 kHz) and the large number of abrasive grains (20,000-100,000 per 1 cm3) striking the workpiece surface. Under the impact of abrasive grains, small particles of the product material are chipped.

Dispersion and emulsification occur under the influence of intense ultrasonic waves, causing the grinding effect of cavitation and turbulent movement of liquids. This method makes it possible to obtain stable emulsions of liquids that are immiscible by conventional methods, such as water and oil, mercury and water, benzene and water, etc.

Obtaining suspensions by dispersing the solid phase using ultrasonic waves makes it possible to significantly increase the productivity of the process. For example, the use of ultrasound reduces the duration of the process of preparing a suspension of magnesium oxide in carbon tetrachloride from 25 hours to 40 minutes.

Using the ultrasonic method, it is possible to clean various metal parts from scale, pastes, resins, corrosion products, degrease, remove burrs, etc.

The equipment used for ultrasonic treatment includes a bath with a solvent for basic cleaning, an ultrasound source with a device for supplying vibrations to the working area; bath for rinsing products that have undergone ultrasonic cleaning.

Ultrasonic cleaning achieves the greatest effect when removing contaminants from hard-to-reach cavities, recesses and small channels, when cleaning small parts of complex configurations, optical products, etc.

Intensification of technological processes.

Ultrasonic vibrations significantly change the course of traditional chemical processes. In particular, ultrasonic treatment significantly accelerates the polymerization of vinyl acetate, styrene emulsions, acetaldehyde, etc. Moreover, the intensification of the polymerization process is observed only at a certain ultrasound strength. When it decreases, the reverse process may begin—depolymerization. This property of ultrasonic vibrations is used to control polymerization reactions. By changing the parameters of ultrasonic vibrations, the reaction speed can be significantly increased. In metallurgy, during the production of metals, the introduction of elastic vibrations of ultrasonic frequency into melts leads to crystal refinement, a decrease in porosity, an increase in the mechanical properties of solidified melts and a decrease in the gas content in metals. For example, lead and aluminum do not mix in liquid form. The application of ultrasonic vibrations to the melt ensures the “dissolution” of one metal in another.

Ultrasonic testing methods.

Using ultrasonic vibrations, you can continuously monitor the technological process without carrying out laboratory analyzes of samples: knowing the dependence of the parameters of the sound wave on the physical properties of the medium, and then recording the amplitude of particle vibrations, the intensity of ultrasonic vibrations or the speed of sound, you can judge with high reliability the state of the medium and its changes.

Ultrasonic testing is performed using low-intensity ultrasonic vibrations. Depending on the physicochemical properties of the medium, the speed of ultrasound in it will be different. By recording the speed of sound, you can find out about the physical and chemical changes that have occurred in a given environment, control its concentration, determine the presence of impurities, and monitor the progress of the process.

It is known that any elastic medium has a certain viscosity and when sound waves propagate in the medium, a noticeable loss of energy occurs. When moving away from the source of oscillations, the amplitude of oscillations of a plane wave changes according to the law

A = Ao e -ah,

where Аo is the amplitude of oscillations at the point x = 0; a is the absorption coefficient of the medium.

By changing the energy of an ultrasonic wave, it is possible to control the composition of various mixtures in a substance. The speed of ultrasound in such media remains unchanged, and the presence of suspended matter impurities affects the absorption coefficient of sound energy. This makes it possible to determine the percentage of impurities in the starting material.

When a sound wave passes the boundary of two media, the wave is partially reflected. The difference between the energy of the wave passing through the interface and the reflected wave will depend on the ratio of the acoustic resistances of different media. By the back reflection of sound waves at the interface between media (“transmission” with an ultrasonic beam), it is possible to determine the presence of impurities in the monolith and use methods and devices for ultrasonic diagnostics of parts on this principle.

The ultrasonic processing method is one of the methods of mechanical action on a material using electric current. Ultrasound is mechanical elastic vibrations that can propagate only in an elastic medium, in contrast to electromagnetic vibrations. The speed of propagation of a sound wave depends on the density of the medium in which the wave moves: the stiffer and lighter the material of the medium, the greater the speed of the wave.

The advantages of ultrasonic processing include: the ability to obtain ultrasound using various technical techniques; a wide range of technological applications of ultrasound (dimensional processing, welding, soldering, etc.); ease of operation of industrial installations. The disadvantages of this method include the need to manufacture special ultrasonic vibration generators.

An electromagnetic field can not only have a mechanical effect on objects surrounding it, but also change their position in space. Technological processes that use this phenomenon are called “electron-ionic”. We'll get to know them in the next chapter.

Technique for performing dimensional RCD

After installing the equipment and preparing the target material, an abrasive suspension is supplied to the operation area - that is, to the space between the surface of the product and the oscillating end. By the way, silicon or boron carbides are usually used as the abrasive itself. Automated lines use water for powder delivery and cooling. Direct ultrasonic processing of metals consists of two operations:

- Impact penetration of abrasive particles into the intended surface of the workpiece, as a result of which a network of microcracks is formed and microparticles of the product are punctured.

- Circulation of abrasive material in the processing zone - used grains are replaced by streams of new particles.

An important condition for the effectiveness of the entire process is to maintain a high pace in performing both procedures until the cycle is completed. Otherwise, the processing parameters change and the accuracy of the abrasive direction decreases.

Ultrasonic finishing of metal surfaces

The productive life of ultrasonic processes depends on the accuracy of the basic processes that make up the ultrasonic processing of metals. The first intensive process is the introduction of abrasive particles under impact loads, which cause the removal of a thin layer from the surface of the workpiece. The second mandatory process is the regular circulation and replacement of the abrasive substance directly in the processing sector. Violation, reduction in intensity, of one of the listed processes leads to a decrease in the level of effectiveness of the entire ultrasound treatment.

Ultrasonic metal machining began to spread in the metalworking industry in the sixties. Thanks to the introduction of this method of processing materials into production processes, it has become possible to facilitate the technological process of producing shaped products from brittle and hard metal. Also, the ultrasonic process of manufacturing products significantly reduces the time period for carrying out technical tasks. The only drawback of this method of working with metal bases is a decrease in productivity indicators with increasing thickness of the layer removed from the workpiece. To process materials with ultrasound, specialized machines are used, which are universal ultrasonic units for industrial and private production.

Process characteristics

Processing parameters that are optimal for a specific task are pre-set. Both the configuration of the mechanical action and the properties of the workpiece material are taken into account. The average characteristics of ultrasonic treatment can be presented as follows:

- The frequency range of the current generator is from 16 to 30 kHz.

- The amplitude of vibration of the punch or its working tool - the lower spectrum at the beginning of the operation is from 2 to 10 microns, and the upper level can reach 60 microns.

- The saturation of the abrasive suspension is from 20 to 100 thousand grains per 1 cm3.

- The diameter of the abrasive elements is from 50 to 200 microns.

Varying these indicators allows you to perform not only individual high-precision linear processing, but also accurately form complex grooves and cuts. In many ways, working with complex geometric shapes has become possible thanks to the perfection of the characteristics of the punches, which can influence the abrasive composition in different models with a thin superstructure.

Operating principles of main emitters

The essence of magnetostriction is that a ferromagnetic rod placed in an alternating magnetic field is capable of modification. The change in the geometry of the rod is caused by the influence of acoustic waves. The greatest amplitude of oscillations can be achieved if the frequency of the magnetic field coincides with the oscillation frequency of the element placed in this field (an acoustic resonance is formed).

The amplitude of the rod’s vibrations directly depends on its characteristics, such as physical properties. These indicators are insignificant, but they are sufficient for the production of high-tech ultrasonic installations.

It should be noted that the best ferromagnetic metal is nickel.

The operation of a piezoelectric emitter is based on the inverse piezoelectric effect. This means that when an electric field is applied to a crystal, it becomes deformed. In this way, a large spectrum of ultrasonic frequencies is generated. Such devices create acoustic vibrations with a frequency reaching 100 MHz.

The main element of the piezo emitter is a solid plate made of quartz, tourmaline, barium titanate and other materials.

Deburring using RCD

This operation is based on increasing the cavitation and erosion activity of the acoustic field when introducing ultra-small particles from 1 micron into the abrasive flow. This size is comparable to the radius of impact of a shock sound wave, which makes it possible to destroy weak areas of burrs. The working process is organized in a special liquid medium with a glycerin mixture. A special equipment is also used as a container - a phytomixer, the glass of which contains suspended abrasives and a working part. As soon as an acoustic wave is applied to the working medium, the random movement of abrasive particles begins, which act on the surface of the workpiece. Fine grains of silicon carbide and electrocorundum in a mixture of water and glycerin provide effective removal of burrs up to 0.1 mm in size. That is, ultrasonic treatment ensures accurate and high-precision removal of microdefects that could remain even after traditional mechanical grinding. If we are talking about large burrs, then it makes sense to increase the intensity of the process by adding chemical elements like copper sulfate to the container.

Cleaning parts using RCD

The surfaces of working metal workpieces may contain various types of coatings and contaminants that cannot be removed by traditional abrasive cleaning for one reason or another. In this case, the technology of cavitation ultrasonic treatment in a liquid environment is also used, but with a number of differences from the previous method:

- The frequency range will vary from 18 to 35 kHz.

- Organic solvents such as freon and ethyl alcohol are used as a liquid medium.

- To maintain a stable cavitation process and reliable fixation of the workpiece, it is necessary to set the resonant operating mode of the phytomixer, the liquid column in which will correspond to half the length of the ultrasonic wave.

Ultrasound-assisted diamond drilling

The method involves the use of a rotating diamond tool, which is driven by ultrasonic vibrations. The energy costs for the processing process exceed the amount of resources required with traditional methods of mechanical action, reaching 2000 J/mm3. This power allows drilling with a diameter of up to 25 mm at a speed of 0.5 mm/min. Also, ultrasonic processing of materials by drilling requires the use of coolant in large volumes up to 5 l/min. Liquid flows also wash away fine powder formed during the destruction of the abrasive from the surfaces of the equipment and workpiece.

Prerequisites for the use of ultrasound

Acoustics, as a branch of physics that studies the theoretical aspects of ultrasound, received significant development already in the 19th century. The fundamentals of the theory of oscillations and nonlinear acoustics were developed by J. W. Rayleigh. Further study of ultrasonic vibrations became possible after the discovery of the effect of magnetostriction (J. P. Joule) and piezoelectricity (P. Curie).

The sources of ultrasonic vibrations used in processing are gas and hydro-jet emitters, dynamic sirens, electromechanical, piezoelectric and magnetostrictive transducers.

Monitoring the implementation of RCD

The technological process is under the control of the operator, who monitors the parameters of the influencing vibrations. In particular, this applies to the amplitude of vibrations, the speed of sound, and the intensity of the current supply. Using this data, control of the working environment and the impact of abrasive material on the workpiece is ensured. This feature is especially important for ultrasonic processing of tools, when several operating modes of equipment can be used in one technological process. The most advanced control methods involve the participation of automatic means of changing processing parameters based on readings from sensors that record product parameters.

Ultrasound-based processing technologies

The following technological operations are carried out using ultrasound (the list is not exhaustive).

Solids Processing

- Ultrasonic welding is a method of combining different materials in a solid state using ultrasonic vibrations. This type of welding is used to join parts that are difficult to heat, or when joining dissimilar metals or metals with strong oxidizing films (aluminum, stainless steels, permalloy, etc.). This type of welding has found application for producing welded joints and polymer sheet materials;

- Ultrasonic soldering is used for soldering and tinning of metals, such as aluminum, titanium, molybdenum. Ultrasound destroys oxide films on the surface of parts and improves the process. Using ultrasound, you can tin and then solder ceramics, glass and other non-metallic materials. Ultrasound is applied by a waveguide concentrator to solder placed in a bath or applied to the surface of a part.

- ultrasonic abrasive-pulse processing - surface treatment of fragile materials by pulsed action of abrasive particles. In the process of abrasive-pulse processing, a suspension is pumped into the processing zone - abrasive particles (diamond, boron carbide) suspended in a liquid. Acquiring movements from the ultrasonic vibration concentrator, they cut the material, copying the shape of the working part of the concentrator on its surface. Used primarily for forming holes, cavities, shaped surfaces and grinding;

- ultrasonic strengthening is a method of surface plastic deformation, the essence of which is that the surface is subjected to impact from the spherical head of the tool, vibrates at the ultrasound frequency in the direction normal to the surface and causes its plastic deformation. At the same time, strain hardening occurs in the surface layer, which improves the physical and mechanical properties of the surface layer of the parts;

- Ultrasonic cleaning – cleans the surfaces of products from dust, chips, grease and other contaminants. Some parts with complex shapes and hard-to-reach places can only be cleaned using ultrasonic treatment. Cleaning is usually carried out in baths with built-in electroacoustic emitters; Surfactants are added to the working fluid. To remove burrs from parts, abrasive particles are introduced into the liquid, which speed up processing several times.

Liquid Processing

- Ultrasonic impregnation in a liquid medium is one of the high-performance and high-quality methods of impregnation of various porous-capillary products. Ultrasonic impregnation has found application in impregnation technologies for winding electrical products: relay windings, electric motors, transformers and chokes, tapes made of fibrous and woven materials, slopes, cardboard and paper, wood products.

- ultrasonic degassing is the process of reducing the gas content in a liquid, either in a dissolved state or in the form of bubbles, under the influence of acoustic vibrations in the ultrasonic range. The effect of ultrasonic degassing is used in industrial practice in the production of metals, glass, resins, viscose, oils, etc. The greatest efficiency of degassing in these environments is observed in high-intensity ultrasonic fields with active acoustic cavitation. The same technology is used in ore enrichment using the flotation method - gas bubbles settle on the surfaces of mineral particles and float up with them.;

- ultrasonic atomization is the process of producing aerosols using ultrasound. The acoustic method of producing aerosols has a number of advantages over the existing ones - chemical (condensation) and mechanical (dispersion), since modern ultrasonic equipment for spraying can significantly intensify the process, improve the quality of the product, and replace bulky devices with more compact ones. At the same time, at a high aerosol concentration, a monodisperse and homogeneous in composition spray plume with a given particle size is obtained;

- ultrasonic emulsification is the process of emulsifying a material under the action of an ultrasonic vibration generator.

Processing of gas-liquid media

- Acoustic (ultrasonic) coagulation is the process of bringing together and enlarging small solid particles, liquid droplets or gas bubbles suspended in a gas or liquid under the influence of acoustic vibrations. During coagulation, the dispersion of media, assessed by the total surface of particles per unit volume, and the number of particles in the dispersed system decrease. As a result of coagulation, suspended particles are deposited in a gas or liquid. Acoustic coagulation is used to sediment industrial dusts, fumes, and mists. Coagulation in liquids is carried out in the ultrasonic range and is practically used for the purification of liquids in the chemical and food industries, for example, in the processing of wine;

- ultrasonic absorption is a phenomenon of mass transfer that occurs between the liquid and gas phases. One such process is gas absorption. In addition, processes such as desorption, rectification, adsorption, catalysis, which are either fundamentally little different from absorption, or are processes in which absorption is one of the determining stages. The application of ultrasonic vibrations to a two-phase system is known to promote turbulization of local flows, improve local mixing and thereby significantly accelerate the absorption of gases by liquid;

- acoustic (ultrasonic) drying - removal of moisture from a material under the influence of intense acoustic vibrations. To a large extent, the effectiveness of ultrasonic drying is associated with the acceleration of heat transfer processes in the ultrasonic field. The advantages of ultrasonic drying include the ability to speed up the process by 2-6 times without significantly increasing the temperature of the material, which is especially important when drying heat-sensitive substances prone to oxidation. Ultrasonic drying is suitable for fine materials in suspension or in a state of continuous mixing.

Benefits of Ultrasound Technology

The use of RCD technology provides a number of advantages, which manifest themselves to varying degrees depending on the specific method of its implementation:

- The productivity of the processing process increases several times.

- The wear of the tool used for the ultrasonic processing method is reduced by 8-10 times compared to conventional machining methods.

- When drilling, processing parameters in depth and diameter increase.

- The accuracy of mechanical action increases.

What is ultrasound?

Ultrasound (US) is elastic vibrations and waves, the frequency of which is higher than 15...20 kHz. The lower limit of the ultrasonic frequency region, separating it from the region of audible sound, is determined by the subjective properties of human hearing and is conditional. The upper limit is due to the physical nature of elastic waves, which can propagate only in a material medium, that is, provided that the wavelength is significantly greater than the free path of molecules in gases or interatomic distances in liquids and solids. Therefore, in gases, the upper limit of ultrasonic frequencies is determined from the condition of approximate equality of the sound wavelength and the free path of molecules. At normal pressure it is 109 Hz. In liquids and solids, the determining factor is the equality of the wavelength to interatomic distances, and the cutoff frequency reaches 1012-1013 Hz. Depending on the wavelength and frequency, ultrasound has specific characteristics of radiation, reception, propagation and application, therefore the ultrasonic frequency range is conveniently divided into three sub-regions:

- low - 1.5–10...105 Hz;

- average - 105...107 Hz;

- high - 107...109 Hz.

Elastic waves with frequencies of 1·108…1·1013 Hz are commonly called hypersound.

Sound wave theory

Ultrasound as elastic waves

Ultrasonic waves by their nature do not differ from elastic waves in the audible range, as well as from infrasonic waves.

The propagation of ultrasound obeys basic laws common to acoustic waves of any frequency range, usually called sound waves. The basic laws of their propagation include the laws of reflection and refraction of sound at the boundaries of various media, diffraction and scattering of sound in the presence of obstacles and inhomogeneities in the medium and irregularities at the boundaries, and the laws of waveguide propagation in limited areas of the medium.

Specific features of ultrasound

Although the physical nature of ultrasound and the basic laws governing its propagation are the same as for sound waves of any frequency range, it has a number of specific features that determine its significance in science and technology. They are due to its relatively high frequencies and, accordingly, short wavelength.

Thus, for high ultrasonic frequencies the wavelengths are:

- in the air - 3.4⋅10-3...3.4⋅10-5 cm;

- in water - 1.5⋅10-2...1.5⋅10-4 cm;

- in steel - 1⋅10-2 ... 1⋅10-4 cm.

This difference in the values of ultrasonic waves (USW) is due to different speeds of their propagation in different media. For the low-frequency region, ultrasonic wavelengths do not exceed several centimeters in most cases and only reach several tens of centimeters in solids near the lower limit of the range.

Ultrasonic waves attenuate much faster than low-frequency waves, since the sound absorption coefficient (per unit distance) is proportional to the square of the frequency.

Another very important feature of ultrasound is the ability to obtain high intensity values at relatively small amplitudes of oscillatory displacement, since at a given amplitude the intensity is directly proportional to the square of the frequency. The amplitude of the oscillatory displacement in practice is limited by the strength of the acoustic emitters.

The most important nonlinear effect in an ultrasonic field is cavitation—the appearance in a liquid of a mass of pulsating bubbles filled with steam, gas, or a mixture of them. The complex movement of bubbles, their collapse, merging with each other, etc. generate compression pulses (microshock waves) and microflows in the liquid, causing local heating of the medium and ionization. These effects have an impact on the substance: destruction of solid bodies in the liquid occurs (cavitation erosion), various physical and chemical processes are initiated or accelerated (Fig. 1).

Rice. 1

By changing the conditions for cavitation, you can strengthen or weaken various cavitation effects. For example, with increasing ultrasonic frequency, the role of microflows increases and cavitation erosion decreases; with an increase in hydrostatic pressure in the liquid, the role of microimpact influences increases. An increase in frequency usually leads to an increase in the threshold intensity value corresponding to the onset of cavitation, which depends on the type of liquid, its gas content, temperature, etc. For water in the low-frequency ultrasonic range at atmospheric pressure, it is usually 0.3-1 W/cm3.

Ultrasound sources

In nature, ultrasound is found in many natural noises (in the noise of wind, waterfall, rain, in the noise of pebbles rolled by the sea surf, in the sounds accompanying lightning discharges, etc.), as well as in the world of animals that use it for echolocation and communication.

Technical ultrasound emitters used in the study of ultrasound and their technical applications can be divided into two groups. The first includes emitter-generators (whistles). Oscillations in them are excited due to the presence of obstacles in the path of a constant flow - a stream of gas or liquid. The second group of emitters are electroacoustic transducers: they convert already given electrical vibrations into mechanical vibrations of a solid body, which emits acoustic waves into the environment.

Ultrasound Applications

The diverse applications of ultrasound, in which its various features are used, can be divided into three areas. The first is associated with obtaining information through ultrasound, the second with the active influence on matter, and the third with the processing and transmission of signals (the directions are listed in the order of their historical development).

Principles of ultrasonic cleaning

The main role in the influence of ultrasound on substances and processes in liquids is played by cavitation. The most widely used ultrasonic technological process, the cleaning of solid surfaces, is based on cavitation. Depending on the nature of the contaminants, various manifestations of cavitation, such as micro-impact effects, micro-flows, and heating, may be of greater or lesser importance. By selecting the parameters of the sound field, the physicochemical properties of the washing liquid, its gas content, and external factors (pressure, temperature), it is possible to control the cleaning process within a wide range, optimizing it in relation to the type of contaminants and the type of parts being cleaned. A type of cleaning is etching in an ultrasonic field, where the action of ultrasound is combined with the action of strong chemical reagents. Ultrasonic metallization and soldering are actually based on ultrasonic cleaning (including removal of oxide film) of the surfaces being joined or metallized. Cleaning during soldering (Fig. 2) is caused by cavitation in the molten metal. The degree of purification is so high that compounds are formed that cannot be soldered under normal conditions, for example, aluminum with other metals, various metals with glass, ceramics, and plastics.

Rice. 2

In the processes of cleaning and metallization, the sound-capillary effect is also essential, ensuring the penetration of the cleaning solution or melt into the smallest cracks and pores.

Cleaning and washing mechanisms

Cleaning in most cases requires that contaminants be dissolved (in the case of dissolved salts), scraped off (in the case of insoluble salts), or both dissolved and scraped off (as in the case of insoluble particles embedded in a layer of fatty films). The mechanical effects of ultrasonic energy can be useful in both accelerating dissolution and separating particles from the surface being cleaned. Ultrasound can also be used effectively in the rinsing process. Residual chemicals from cleaning media can be quickly removed by ultrasonic rinsing.

When removing contaminants by dissolution, the solvent must come into contact with the contaminating film and destroy it (Fig. 3, a). As the solvent dissolves the contaminant, a saturated solution of the contaminant in the solvent appears at the solvent–contamination interface, and dissolution stops because there is no delivery of fresh solution to the surface of the contaminant (Fig. 3b).

Rice. 3

Exposure to ultrasound destroys the layer of saturated solvent and ensures the delivery of fresh solution to the surface of the contamination (Fig. 3, c). This is especially effective in cases where “irregular” surfaces with a labyrinth of sinuses and surface relief, such as printed circuit boards and electronic modules, are subject to cleaning.

Some contaminants are a layer of insoluble particles firmly adhered to the surface by forces of ionic bonding and adhesion. These particles only need to be separated from the surface to break the forces of attraction and transfer them into the volume of the washing medium for subsequent removal. Cavitation and acoustic currents tear off contaminants such as dust from the surface, wash them away and remove them (Fig. 4).

Rice. 4

Contaminants, as a rule, are multicomponent and may contain soluble and insoluble components in combination. The effect of ultrasound is that it emulsifies any components, that is, it transfers them into the washing medium and, together with it, removes them from the surface of the product.

To introduce ultrasonic energy into the cleaning system, an ultrasonic generator, a converter of the generator's electrical energy into ultrasonic radiation, and an acoustic power meter are needed.

An electric ultrasonic generator converts electrical energy from the network into electrical energy at an ultrasonic frequency. This is done by known methods and does not have any specifics. However, it is preferable to use digital generation technology, when the output produces rectangular pulses of alternating polarity (Fig. 5). The efficiency of such generators is close to 100%, which makes it possible to solve the problem of the energy intensity of the process. Using a square wave signal results in acoustic emissions rich in harmonics. The advantages of a multi-frequency cleaning system are that no “dead” zones are formed in the interference nodes in the volume of the washing medium. Therefore, multi-frequency ultrasonic irradiation makes it possible to locate the cleaning object in almost any zone of the ultrasonic bath.

Rice. 5

Another technique for getting rid of “dead” zones is to use a frequency-swinging generator (Fig. 6). In this case, the nodes and antinodes of the interference field move to different points of the cleaning system, without leaving any areas for cleaning without irradiation. But the efficiency of such generators is relatively low.

Rice. 6

There are two general types of ultrasonic transducers: magnetostrictive and piezoelectric. They both perform the same task of converting electrical energy into mechanical energy.

Magnetostrictive converters (Fig. 7) use the magnetostriction effect, in which some materials change linear dimensions in an alternating magnetic field.

Rice. 7

The electrical energy from the ultrasonic generator is first converted by the magnetostrictor winding into an alternating magnetic field. The alternating magnetic field, in turn, generates mechanical vibrations of ultrasonic frequency due to the deformation of the magnetic circuit in time with the frequency of the magnetic field. Since magnetostrictive materials behave like electromagnets, the frequency of their deformation oscillations is twice as high as the frequency of the magnetic, and therefore the electric, field.

Electromagnetic converters are characterized by an increase in energy losses due to eddy currents and magnetization reversal with increasing frequency. Therefore, powerful magnetostrictive transducers are rarely used at frequencies above 20 kHz. Piezo transducers, on the contrary, can radiate well in the megahertz range. Magnetostrictive transducers are generally less efficient than their piezoelectric counterparts. This is due, first of all, to the fact that a magnetostrictive converter requires a double energy conversion: from electrical to magnetic and then from magnetic to mechanical. Energy losses occur at every transformation. This reduces the efficiency of magnetostrictors.

Piezoelectric transducers (Fig. convert electrical energy directly into mechanical energy through the use of the piezoelectric effect, in which some materials (piezoelectrics) change linear dimensions when an electric field is applied. Previously, piezoelectric transducers used such piezoelectric materials as natural quartz crystals and synthesized barium titanate, which were fragile and unstable, and therefore unreliable. Modern transducers use more durable and highly stable ceramic piezoelectric materials. The vast majority of ultrasonic cleaning systems today use the piezoelectric effect.

convert electrical energy directly into mechanical energy through the use of the piezoelectric effect, in which some materials (piezoelectrics) change linear dimensions when an electric field is applied. Previously, piezoelectric transducers used such piezoelectric materials as natural quartz crystals and synthesized barium titanate, which were fragile and unstable, and therefore unreliable. Modern transducers use more durable and highly stable ceramic piezoelectric materials. The vast majority of ultrasonic cleaning systems today use the piezoelectric effect.

Rice. 8

Ultrasonic cleaning equipment

The range of ultrasonic cleaning equipment used is very wide: from small tabletop units in dentistry, jewelry stores, and the electronics industry to huge systems with volumes of several thousand liters in a number of industrial applications.

Selecting the right equipment is paramount to the success of ultrasonic cleaning applications. The simplest application of ultrasonic cleaning may require only heated cleaning fluid. More complex cleaning systems require a large number of baths, the last of which must be filled with distilled or deionized water. The largest systems use submersible ultrasonic transducers, the combination of which can irradiate baths of almost any size. They provide maximum flexibility and ease of use and maintenance. Ultrasonic baths with heated cleaning solution are most often used in laboratories, medicine, and jewelry.

Ultrasonic cleaning lines (Fig. 9), used in large-scale production, combine electric ultrasonic generators, ultrasonic converters, a transport system for moving cleaning objects through baths and a control system in one housing.

Rice. 9

Ultrasonic baths can be included in a chemical-galvanic metallization line using modular submersible ultrasonic transducers.

Ultrasonic cleaning systems

When choosing a cleaning system, it is especially important to pay attention to those characteristics that allow you to use it most effectively. First of all, it is important to determine the intensity factors of ultrasonic cavitation in the washing liquid. Liquid temperature is the most important factor determining the intensity of cavitation. Changes in temperature lead to changes in viscosity, solubility of gas in liquid, rate of diffusion of dissolved gases in liquid, and vapor pressure. All of them affect the intensity of cavitation (Fig. 10, 11).

Rice. 10

Viscous fluids are inertial and cannot react quickly enough to form cavitation bubbles and strong acoustic currents. For most effective cavitation, the cleaning liquid should contain as little dissolved gas as possible. Gas dissolved in the liquid escapes during the bubble phase of cavitation growth and weakens its explosive effect, which is necessary for the expected effect of ultrasonic influence. The amount of dissolved gas in a liquid decreases with increasing temperature. The rate of diffusion of dissolved gases in a liquid also increases at higher temperatures. Therefore, preference is given to cleaning in heated washing solutions. Vapor cavitation, in which cavitation bubbles are filled with liquid vapor, is the most effective.

Rice. eleven

The intensity of cavitation is directly related to the power of ultrasonic irradiation. Usually it is set above the cavitation threshold. The intensity of cavitation is inversely proportional to the ultrasonic frequency: with increasing ultrasonic frequency, the size of cavitation bubbles and their resulting effect on the surface being cleaned decrease. The decrease in the intensity of ultrasonic exposure with increasing frequency can only be compensated by increasing the irradiation power.

Ensuring maximum cleaning effect

A successful choice of cleaning media is the key to success in the ultrasonic cleaning process. First of all, the selected composition must be compatible with the materials of the surfaces to be cleaned. Aqueous solutions of technical detergents are most suitable for this. As a rule, these are ordinary surfactants (surfactants).

Degassing of cleaning solutions is extremely important in achieving satisfactory cleaning results. Fresh solutions or solutions that have been cooled the day before must be degassed before the cleaning process. Degassing is performed by heating the liquid and pre-irradiating the bath with ultrasound. The time set for degassing the liquid ranges from a few minutes for small tanks to an hour or more for a large tank. An unheated tank can degas for several hours. A sign of completed degassing is the absence of visible gas bubbles moving to the surface of the liquid and the absence of visible bubble pulsations.

The power of ultrasonic irradiation should be compared with the volume of the bath (Fig. 12). Cleaning objects that are massive or have a high surface-to-mass ratio may require additional ultrasonic power. Excessive power can cause cavitation erosion or a “burning” effect on soft surfaces. If objects with dissimilar surfaces are being cleaned, it is recommended to set the irradiation power to the less durable component.

Rice. 12

It is important to place the objects to be cleaned correctly in the bath. Submersible devices must not shield objects from the effects of ultrasound. Solid materials usually have good sound conductivity and do not shield the object being cleaned. However, cleaning objects must be constantly oriented or rotated during cleaning so that internal sinuses and blind holes are completely cleaned.

Properly used ultrasonic technology provides greater speed and high quality cleaning of surfaces. Refusal to use solvents through the use of aqueous media reduces the cost of the process and most effectively solves environmental problems. Ultrasound is not a technology of the future, it is a technology of today.

Arkady Medvedev, [email protected]

Disadvantages of technology

A number of disadvantages have so far hampered the widespread use of this method. They are mainly related to the technological complexity of organizing the process. In addition, ultrasonic processing of parts requires additional operations, including the delivery of abrasive material to the working area and the connection of water cooling equipment. These factors can also increase the cost of work. When servicing industrial processes, energy costs also increase. Additional resources are required not only to ensure the function of the main units, but also to operate the safety systems and current collectors that transmit electrical signals.