One option for stripping metals is electrical discharge machining. The principle of operation of the technology is simple. A direct current source is connected to the workpiece and the electrode, which generates short-term pulses passing through the electrodes. Electricity in the core creates an electronic arc that easily burns through a metal surface. The arc lasts a short period of time, so it does not deform the metal, does not leave marks, and maintains the integrity of the electrode.

Electrical discharge machining of metals is usually performed using special machines, which have many advantages - high power, versatility, ease of use. But how does this metal processing happen? In what operating modes can erosion machines operate? And what do you need to know when choosing them? These issues will be discussed in the article.

Physical and chemical basis of electrical erosion

Electrical discharge machining (EDM) is a technology that destroys the surface of metal products using electrical discharges. The phenomenon of electrical erosion is based on the destruction of electrodes under the influence of electric current passed through the electrodes. The technology was invented by Soviet engineers and scientists B. Lazarenko and N. Lazarenko in 1943.

Electroerosion technology allows you to change the size and shape of metal parts - it can be used to create holes, for grinding, for processing shaped cavities, for creating recesses, and so on. The technology is very accurate and reliable, which allows it to be used for high-precision metal processing.

At the physical level, EEE looks like this:

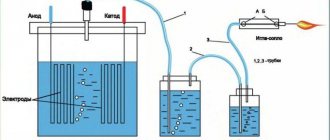

- For electrical erosion, machines are used that have approximately the same design. Their main element is the processing tool-electrode, which acts as a cutter. The second important element is the workpiece itself. The third element is a direct current source to which the electrode and the workpiece are connected.

- To avoid overheating of parts, processing is performed in a liquid environment. The liquids are dielectrics that conduct current poorly (kerosene, mineral oil). For ease of operation, the machine can be equipped with additional parts (rheostats, capacitors, etc.). Most modern machines are also equipped with an electronic control panel.

- The installation can operate in two modes - electric spark and electric pulse. In the case of the electric spark mode, the current is supplied in such a way that the electrode acts as a minus cathode, and the part itself acts as a plus anode. During operation, the electrode generates an electric arc, which ionizes the surface of the metal workpiece. The ions have a very high temperature, which causes the metal to melt and form a small crater. To avoid melting the cathode electrode, electricity is supplied in short pulses. The duration of electricity supply to generate 1 pulse is 0.001 seconds. During electric spark machining, a small amount of metal is cut off, so this technology is used for final processing of the workpiece.

- In the case of electric pulse operation, the electrical polarity changes. A positive current is supplied to the electrode, and a negative current is supplied to the part. This also results in the formation of ionized plasma, which burns through the metal to form a crater. However, due to the characteristics of the crystal lattice of metals, a more powerful flow of ions is generated, therefore the electric pulse mode is 10-11 times more powerful than the electric spark mode. To protect the electrode from melting, current is supplied in small portions, where the duration of 1 pulse is 0.001 seconds. Due to its increased power, the electric pulse mode is used for roughing, as well as for cutting heavy-duty metal alloys.

Metal particles that are cut off by the ion flow fall into the dielectric liquid. They do not dissolve, but are present in the dielectric in the form of a fine suspension. At first the particles have a very high temperature, but upon contact with liquid they quickly cool down, reaching ambient temperature. After carrying out the work, it is not recommended to use the “solution” for its intended purpose, since the metal suspension can deteriorate the technical properties of the device in use.

Choosing an electrical discharge machine

Electrical erosion is the destruction of metal surfaces under the influence of electrical charges. This technology is based on the work of Soviet scientists N. I. Lazarenko and B. R. Lazarenko.

Using this method, you can easily change the dimensions of metal products and create holes of various shapes and depths in them. Excellent results are obtained by electrical discharge machining of profile grooves and grooves, shaped cavities in machine parts and mechanisms.

Such equipment is especially in demand for the manufacture of parts made of hard alloys, where conventional machining is difficult.

Electroerosion machines have universal capabilities in processing materials with a dense surface structure. This type of material processing compares favorably with other methods of changing the shape and size of parts, since the labor intensity of operations thanks to electrical erosion technology is sharply reduced.

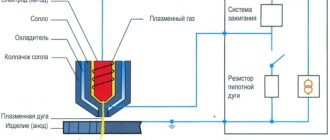

The operating principle of an electrical discharge machine is shown in the diagram below. Under the action of a pulsed electric generator, spark discharges or other electrical interaction are formed in the gap between the electrode and the surface of the part.

The spark gap space is continuously washed by a flow of coolant, due to which the destroyed metal is removed from the treated surface. Under the control of the CNC unit, the process proceeds in the specified direction and in the required quantity.

Brass wire is most often used as an electrode, which, as it is consumed, is fed into the electrical discharge processing zone. A more modern consumable material for electroerosion is molybdenum wire, the consumption of which for processing one part is negligible.

However, these machines also have significant limitations compared to devices for machining parts. After all, they are suitable for processing only conductive metals and their alloys.

It is possible to influence metal by electroerosion in various ways: by applying both electrical discharges and parametric pulses to the spark gap.

Depending on the required processing result, a more suitable path for its implementation is selected.

A very important element of this effect on metal surfaces is that with it it is possible to process the workpiece in different directions at the same time.

Among the methods of electrical discharge processing of products there are:

- electric pulse;

- electric spark;

- electrical contact;

- anodomechanical.

Technological operations that are performed by electroerosion include:

- structural strengthening;

- grinding;

- marking;

- cutting;

- finishing;

- volume copying;

- fine-tuning

Using electrical erosion on these machines, it is possible to make various blind openings, recesses and holes of non-geometric configuration. It is also possible to make threads of any profile on the surface of holes.

The machines are capable of removing metal from the inner surface of products to a given depth, thereby performing operations that replace milling and turning.

Electrical erosion technology is used in the processing of metals that are difficult to treat with classical mechanical machine tools. These include, in particular, titanium and its alloys.

It is quite acceptable to buy a used machine to perform certain technological operations in a workshop, having first checked its performance.

Practice shows that even with a large number of hours of operation, equipment for electrical discharge machining is almost not subject to wear.

Electrical discharge machining of metals

Electrical discharge machining is suitable for processing any metals and their alloys (cast iron, steel, brass, aluminum, and so on). The temperature of the ionized plasma is very high (more than 10 thousand degrees), which makes it possible to work with all types of metals. Plasma has a short lifetime, so it does not damage the metal part, and controlling the power of the ion flow is not too difficult. The technology is in demand in high-precision industries; In small-scale and home production, EDM machines are rarely used due to their high cost.

In practice, EDM technology is usually used for processing complex facade structures, as well as when working with heavy-duty parts for aircraft, cars, ships, and electronic devices. If the equipment is used correctly, microcracks and microdamage to the metal workpiece do not occur, which has a positive effect on the quality of processing. Graphite, tungsten, aluminum or brass are used to create the electrode. These materials do not collapse upon contact with heated plasma and retain their shape. EDM allows you to change the shape, size, and roughness of the original part.

Operating principle of an electrical discharge machine

After the design aspects of existing electrical discharge machines have been discussed above, it is necessary to understand the principle of their operation. It is impossible not to mention that the procedures for processing parts that are used on devices of this type allow one to achieve simply amazing results.

First, a few words about what electrical erosion is, because as the reader might have already guessed from the name of the machine, it is this reaction that is the basis of the operation of such devices.

The destruction of the top layer of the surface of a material under the influence of external influences carried out by electrical discharges is called electrical erosion. It was this process that became the basis for processing various materials and parts, which is called electroerosive.

Electrical discharge machining itself is carried out by changing the size, shape, roughness and surface properties of the workpiece under the influence of electrical discharges as a result of electrical erosion affecting the workpiece during processing.

Due to the fact that very high temperatures operate in the discharge zone (8000 - 12000 degrees Celsius), the metal undergoes the following changes: heating, then subsequent melting and even partial evaporation. In order to obtain such high temperatures in the discharge zone, a large concentration of energy is created, which is achieved thanks to an electrical pulse generator. The electrical discharge machining process itself takes place in a working fluid, namely distilled water. It fills the space between the existing electrodes. One of these electrodes is the workpiece itself, and the second is the tool electrode (tubular electrode).

Under the influence of forces that arise in the discharge channel, as well as due to the fact that the electrode rotates rapidly, liquid and vaporous metal is released from the discharge zone into the surrounding working fluid, and then it solidifies in it with the formation of separate small parts. A hole is formed in the workpiece under the influence of a current pulse. In addition, you can observe the waste of the electrode-tool, which occurs parallel to the formation of the hole.

It should be noted that the electrode tool must be made of a material with high erosion resistance. Such materials that have such an important quality and that can ensure the stability of the electrical erosion process are: tungsten, graphite, aluminum, brass, copper and graphite materials. Typically, these machines use copper or brass tubular electrodes.

Advantages

EEE technology has both advantages and disadvantages. Let's first consider the advantages of EEE technology:

- Versatility (for metals). The heated plasma stream has a very high temperature, and with its help you can burn through any metal alloy. Using heated plasma, you can create a hole, cut a part, perform high-precision grinding, and create a recess. This makes EEO machines universal and easy to use.

- High cutting quality. The thickness of ionized plasma is less than 1 millimeter, so it can be used to perform precise machining of metal parts. The heated plasma cools quickly, so the edges of the workpiece remain smooth, strong, and without melted parts. The electric arc does not evaporate the dielectric solution, so the protective liquid can be used for a long time (liquid loss from evaporation is less than 0.1%).

- Easy to use. EEO machines are easy to use and do not require special care. Almost all models are equipped with an electronic panel that allows you to control the operating mode (discharge power, pulse duration, plasma supply depth, etc.). During work, harmful fumes and gases are not generated, so the worker does not need to wear protective clothing.

- Several operating modes. The main modes are electric spark and electric pulse. The first technique is used for cutting the part, the second is used for polishing and leveling the surface. There are also auxiliary methods of processing materials - erosion-chemical technology, wire, anodic-mechanical, electrical contact and others.

What equipment is used and what orders are made?

| Name | Quantity | Options |

| Electroerosive cutting machine A207.86M | 1 | 250*160*100mm |

The lowest roughness of the processed surface is Ra 1.25 µm, the accuracy of the product sample is according to GOST 20551

Even a simple listing of the equipment on which electroerosive processing of metals is carried out at Zubiks deserves to entrust us with the most complex work. These are cutting machines working using the electroerosion method, marked A207.79 and A207.86, electro-piercing EDM450 and even the 7740F electroerosive cutting machine with five coordinates.

Therefore, the range of work performed with their help is very wide:

- wire cutting, which provides unique possibilities for electroerosive cutting of workpieces and the production of complex slots;

- cutting of heavy-duty alloys, fast and without causing tool wear;

- cutting splines and keyways;

- processing of used surfaces of punches, dies, extruder dies, restoration of their efficiency;

- partial production of molds, processing of gear profiles, die making and many other skilled jobs.

Flaws

- Dielectric materials must not be processed. The electric arc, which creates high-temperature plasma, occurs due to the contact of the electrode with the metal surface of the workpiece. If the part is made of dielectric material (wood, concrete, plastic), then the cutting arc will not occur and the machine will be useless.

- High power consumption. An EDM machine requires a large amount of electricity to operate, which increases the cost of processing. During operation of the machine, constant parameters of the electric current (voltage, power, strength) must be maintained. Therefore, many installations are equipped with protective equipment that allows you to change machine parameters in the event of a power surge.

- Poor performance. Most machine models cut at low speeds (from 0.1 to 7-8 millimeters per second, depending on the method of metal processing). Therefore, EDM machines are not suitable for factories with high production loads.

- High price. EEO equipment is quite expensive, which reduces its versatility and availability. Most machines are produced by foreign companies (Japan, Germany, Poland), which also negatively affects pricing. In addition, you will have to pay auxiliary costs - for the purchase of protective fluid, for replacing used electrodes, for electricity consumption, and others.

Main components of EEE machines and their operation

Copying and stitching machine

A typical copying and stitching machine with a vertical layout, equipped with an electro-hydraulic drive system for working parts, consists of the following components:

- L-shaped bed, height adjustable.

- The working head in which the electrode-tool assembly is mounted.

- Drives for two-coordinate movement of the working head (on some standard sizes of machines there is also an orbital head, thanks to which the electrode tool can rotate).

- A work table on which the workpiece to be processed is fixed.

- A bath with a working fluid, which is equipped with a screw drive for its lifting and lowering.

- Electric motors: main drive, working tank drive and orbital head.

- Control systems.

A separate housing houses a stepper pulse generator, which is included in the overall electrical circuit of the machine. These devices must meet the following requirements:

- Possibly higher efficiency;

- Stabilize all parameters of the electrical discharge over time;

- Have the ability to maximize the operating pulse frequency;

- To provide such parameters of the electric discharge at which the wear of the electrode-tool, the productivity of the process and the quality of processing of the workpiece will be optimal.

Domestic pulse generators of the ShGI system are equipped with built-in regulators for the supply of the electrode-tool and short-circuit prevention units.

The feed units of the working head in machines that use a non-stationary electric discharge for EDM can be of three main types - solenoid, electromechanical and electrohydraulic. The first is used in low-power installations, the second - mainly for units producing electric spark cutting. The electrohydraulic drive is considered the most universal. Its disadvantages are slightly lower productivity at auxiliary passages and the need for additional space for hydraulic components responsible for cleaning and pumping the working fluid.

Electric arc machines

Electric arc machines consist of:

- Frame type beds.

- A working head with an electrode-tool and a control and tracking system for its movement during EEE.

- Pumping station for pumping working fluid under high pressure (this is necessary to improve the quality of EDM with a stationary arc discharge).

- A sealing chamber into which the workpiece is installed.

- Desktop.

- DC power supply.

The operating cycle of such equipment includes installation of the workpiece to be subjected to EDM on the table, subsequent placement of the sealing chamber, supply of the tool head with the tool electrode, and activation of the pump drive for supplying the working medium. After this, the power source is turned on, the arc discharge is excited and processing is carried out. The electrode-tool is fed automatically. Upon reaching the required voltage value on the arc, a breakdown of the interelectrode gap occurs, and the resulting arc column, compressed by the flow of the working medium, produces dimensional shaping. Erosion products are removed by a pumping unit through working holes in the electrode tool.

Processing methods

We list the main methods of electrical discharge machining:

- Creating holes. The plasma beam allows you to create very deep holes in a metal surface (from 20 to 40 diameters depending on the type of electrode). The depth of the hole can be increased by torsing the part, moving the electrode, or using non-standard auxiliary equipment. The average drilling speed is 0.1-1 millimeter per second.

- Cutting metal objects. Using a plasma beam, you can cut a workpiece into any number of parts. The cutting depth has practically no restrictions on depth - the standard depth is 20-40 diameters, but it can be increased through the use of non-standard electrodes and rotation of the workpiece. The average cutting speed is 0.1-0.5 millimeters per second.

- Cutting out parts. Using EDM technology, objects of any shape can be cut. This technology is widely used for cutting gemstones to create unusual jewelry. It is also used for the production of shaped cutters, dies, punches and other objects.

- Grinding, alloying. EDM technology can be performed to level rough surfaces, as well as to eliminate external defects. Grinding is carried out using a point method using an electrode, so EED alloying is not recommended for working with large surfaces. However, this technology can be used to work with parts of complex shapes and to eliminate defects on the surface of magnetic alloys. The average grinding speed is 4-5 square millimeters per second.

EDM technology can also be used to mark metals and create inscriptions on their surface. Any symbols can be used for marking - letters, numbers, special designations. De facto, marking is the creation of non-through holes, and a code can be applied to any area of a metal part. The average performance of EEO equipment is 4-10 millimeters per second, which is a good indicator for equipment of this class.

Types of EDM Equipment

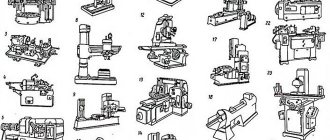

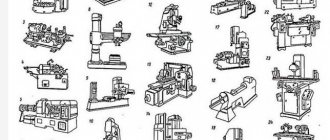

In industry, two types of erosion machines are used - wire cutting and piercing, the fundamental difference of which lies in technology.

Wire cutting machine

The tool used is a very thin wire, with a diameter of only 0.1-0.2 mm, made of a refractory material, usually tungsten or molybdenum. The wire is wound on drums and, when moving along the surface of the workpiece, cuts lines along a given contour.

The wire-cutting machine performs the functions of milling equipment. However, the accuracy is much higher than with traditional machining, including when working with particularly hard metals.

Electroerosive piercing machines

Stitching machines are available in both stationary and desktop versions. An electrode of a given shape serves as a working tool. A recess or hole in the workpiece copies the shape of the electrode. These machines process:

- steel of stainless, tool and hardened grades;

- titanium and other electrically conductive materials.

On such machines, deep holes with very small diameters or complex shapes are produced. Using the electroerosion method, you can produce very accurate copies of molds, stamps or other parts. The electrode, which in this case serves as a template, is made of a malleable material, such as graphite or copper. By changing the polarity of connecting the workpiece, you can get depressions or a convex relief with an imprint of the electrode on its surface.

One of the most labor-intensive operations is cutting threads in refractory and especially strong materials. In this case, the movement of the electrode inside the hole is controlled by a CNC machine.

Electroerosion is a modern high-tech method of metal processing. Electroerosive machines replace traditional mechanical ones where high precision, creation of surfaces or cavities of complex configurations, and work with workpieces made of especially strong metals, alloyed and hardened steels are required.

Machines for electroerosion of metals

We list the main models of machines that are presented in Russia:

- INTEGRAL 2 (AGIE). Produced by the Swiss company of the same name. Allows you to work with parts measuring no more than 80 x 60 x 25 centimeters. The main operating mode is electric spark erosion in a protective environment of a dielectric liquid. It has a built-in CNC panel, which allows you to control the technological features of the operation (ion flow power, processing accuracy, final level of roughness).

- AQ535 (SODICK). Produced by a Japanese company. Allows you to process workpieces whose dimensions are no more than 105 x 65 x 30 centimeters. EDM is performed using a cutting wire that can do all the basic operations (making holes, marking, grinding, cutting). The model is equipped with an advanced CNC panel and has a built-in system that saves electricity, which reduces the cost of processing.

- Model 4531. Produced in the USSR; new 4531 machines are no longer produced. However, on sale you can find many unused models, as well as used machines. The work uses electric spark processing of metal workpieces. The maximum dimensions of processed parts are 16 x 12 x 3 centimeters. The control is carried out mainly mechanically + there are several information panels that allow you to find out the technological features of the procedure.

Types of equipment used

As you know, there are a variety of methods and methods for treating metal surfaces, and this type is more effective than mechanical ones.

This is mainly due to the fact that the tool that is used for mechanical types of processing is much more expensive than the wire that is used in electrical discharge machining.

In cases where it is necessary to produce molds and parts with complex shapes, as well as in the production of certain materials to which high requirements for processing accuracy are applied, wire-cut electrical discharge units are used.

As a rule, this type of equipment is used to produce a variety of parts for aircraft, electronics, and even the space sector.

In the video below you can see how such processing is carried out using electrical discharge equipment.

For mass and serial production of parts using this method, in most cases, copying and piercing units are used.

Such machines make it possible to obtain fairly accurate through contours, as well as small holes, which is successfully used in the production of meshes, as well as stamps in the tool industry.

As a rule, equipment of this type is selected based on the assigned tasks, as well as financial return. It should also be noted that electrical discharge machining is classified as a complex and rather labor-intensive work process.

It cannot be done at home with your own hands. Only qualified and certified people who have relevant experience in this field are allowed to work on machines for this type of part processing.

When performing electrical discharge machining, it is necessary not only to observe safety precautions, but also to wear special clothing. Video:

Technology Basics

The features that electrical discharge machining has include the following:

- One of the electrodes is the workpiece, the other is the electrode-tool.

- The discharge is applied periodically, in the form of short pulses, since such an effect allows the electrical strength of the medium between the electrodes to be restored.

- Unipolar pulses are supplied in order to reduce wear on the instrument electrode used.

- An important point is how long the impulse lasts. With a short duration of the applied pulse, the wear of the anode increases significantly. However, with a long pulse duration, cathode wear increases significantly.

Scheme of electrical discharge processing method

Often in practice, the method of connecting to the positive and negative plus of the alternator is used.

Scheme 2

EDM of materials with different degrees of machinability

The erosive effect produced by the same discharge power can vary greatly depending on the material of the part. Electroerosionists use the term “electrical erosion machinability” to describe this phenomenon - the dependence of the efficiency of erosion on the characteristics of the metal being processed.

There are several parameters that determine the electrical erosion machinability of a material:

- to melt;

- heat capacity;

- thermal conductivity;

- to boil.

EEE process

The essence and application of the technique

The method is based on the effect of electric discharges in a dielectric medium on the part, resulting in the destruction of the metal or a change in its physical properties.

Application of the EEE method:

- When processing parts made of metals with complex physical and chemical properties;

- In the manufacture of parts with complex geometric parameters, with difficult machining;

- When alloying the surface to increase wear resistance and give parts the required qualities;

- Improving the characteristics of the top layer of the metal surface (hardening) due to oxidation of the material under the influence of an electric discharge;

- High-precision grinding of parts;

- Marking of products without harmful influence, which is present in mechanical branding.

High-precision grinding of parts

Different types of electrical discharge machining are used to perform different operations. Numerical control (CNC) devices are installed on industrial machines, which greatly simplifies the use of any type of processing.

Types of electrical discharge processing of material:

- Electric spark processing is used for cutting carbide materials, shaped cutting and for making holes in high-strength metals. Gives high accuracy, but the speed is low. Used in piercing machines.

- The electric contact processing method is based on local melting of metal by arc discharges with subsequent removal of waste material. The method has lower accuracy, but higher operating speed than the electric spark method. It is used when working with large parts made of cast iron, alloy steel, refractory and other metals.

- The electric pulse method is similar to the electric spark method, but arc discharges lasting up to 0.01 seconds are used. This gives high productivity with relatively good quality.

- The anodic-mechanical method is based on a combination of electrical and mechanical effects on the metal. The working tool is a disk, and the working medium is liquid glass or a substance with similar characteristics. A certain voltage is applied to the workpiece and the disk; during the discharge, the metal melts, and the slurry is removed mechanically by the disk.

Electrocontact processing method

In industry, machines are used that operate based on the method of electrical discharge machining of metal. They are classified according to several parameters: operating principle, control, presence of CNC, etc.

Types of machines operating on the EEO principle:

- Electroerosive cutting machine;

- Wire Erosion Machine;

- Electroerosive wire cutting machine;

- CNC wire EDM;

- Electroerosive piercing machine.

CNC Wire Erosion

Due to its multi-functionality, the EEO machine is necessary on the farm, and sometimes it is not at all replaceable. Everyone would like to have such a device in their garage. Unfortunately, buying such a factory-assembled machine is very expensive and often not possible. There is a way out of this situation - to assemble it yourself.