Classification

Mandrel pipe benders are divided into the following types:

- Semi-automatic.

- Automatic.

Semi-automatic devices have high productivity and are used by industrial enterprises. They allow you to carry out large volumes of work. They have a high cost, so they are rarely used for domestic purposes. Using a semi-automatic device, pipe bending is performed with high precision. The rest of the work is carried out by employees of the plant (operator or assistant operator) where the unit is used.

The automatic device has greater functionality and does all the work independently. The device forms a project, creates a program for its implementation, and then performs the necessary tasks. Manual devices do not have numerical control, so they are almost never used for this purpose. The operating principle of semi-automatic and automatic units is similar, but the functions differ depending on the design.

By design, devices are divided into devices having:

- crossbow equipment;

- hydraulic drive;

- electrical system;

- manual system;

- hand-made kit.

The device has a simple operating principle: after fixing the workpiece, the desired bend is ensured. The task is carried out under pressure. Impact patterns may vary depending on the model. A mandrel pipe bender accomplishes the task thanks to the presence of a special element. This element is mandrel.

Popular models of automatic pipe benders

Among devices in the lowest price category, automated pipe bending units of the Master3X line from the Baltic Machine-Building Company are popular. Installations of this series allow:

- Automatic preparation and adjustment of the working module for deformation;

- Feeding the initial workpiece and fixing it;

- Precise rotation and movement of the semi-finished product in all three coordinates, both at the initial moment and during the bending process;

- Programmable activation of the process lubrication supply system;

- Switching off with the nodes returning to their original position.

The equipment is very compact, but it still cannot fully implement CNC functions, since the Master3X pipe benders do not have graphic display units, as well as units for adapted operation control with changing physical and mechanical parameters of deformable materials.

Turkish automatic pipe benders from Cansa Makina have similar capabilities. They are designed for deforming pipes with a diameter of up to 80 mm (Master3X work with workpieces up to 50 mm); accordingly, they have a higher power drive, as well as increased dimensions.

The Arcor company (Germany) produces automatic pipe benders of the DBM series, equipped with a hydraulic drive. The installations deform pipes with a diameter of up to 120 mm; to this it is worth adding the traditionally high German quality of manufacturing of all parts and assemblies.

A classic example of a full-fledged CNC pipe bender is the DW CNC complexes produced by the TelHoo concern (a China-Taiwan joint venture). In fact, only the assembly of the installation is Chinese, and all the main units are supplied by Japanese, Italian and German manufacturers. This predetermines the reliable operation of the unit at a relatively affordable price and service.

Advantages

In comparison with their analogues, mandrel pipe bending tools have a number of advantages that ensure their popularity:

- performing high-quality and precise bending on thin-walled workpieces;

- low risk of damage to soft metal products;

- the presence of an internal stabilizer that protects the product from deformation.

A strong spring is used as a stabilizer. The polyurethane coating enhances the strength of the spring and improves its function. When using other types of devices, waviness or corrugation is formed. Even if the automatic mandrel tool creates deformation, it will not cause thickening or narrowing of the walls. The high operating speed achieved by pipe benders allows it to be used for serial processing of workpieces.

Why do you need a CNC mandrel pipe bender with automatic tool change?

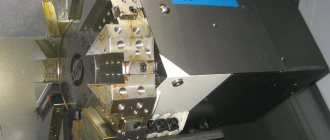

Conventional automatic mandrel pipe benders are designed for bending complex spatial parts, but in practice, complex spatial pipe parts usually have several radii, and this greatly complicated the matter, because the equipment had to be rearranged for each bend, and accordingly productivity decreased and accuracy was lost. To solve this problem, mandrel pipe benders were developed, where several sets of equipment are installed simultaneously, and it changes according to the program.

Advantages of an automatic mandrel pipe bender with automated change of equipment compared to a conventional one:

- productivity increases

: due to the fact that there is no need to change equipment or perform separate operations on several machines, time is reduced and therefore productivity; - accuracy increases

: accuracy increases due to the fact that all bends on the part are performed in one setup; - saving working space

: in order to increase productivity on conventional automatic mandrel pipe benders, they installed a whole line of machines that made bends each with its own radius, and a machine with automatic tool change replaces this entire line; - fewer workers

: this is also due to the fact that this machine replaces an entire line, therefore fewer workers are required.

Contents and cost

Devices with a mandrel design require careful handling and periodic cleaning. The main structural elements are complex mechanisms that require maintenance.

Each model of machine has limitations on the size of pipes it can be used to process. The unit is large in size, so it requires a spacious room.

The cost of the devices is quite high. This is due to the fact that they are intended to be used for large-scale work. The cheapest models are used for processing small-format pipes. The budget group of devices is represented by semi-automatic equipment. It is more difficult to acquire automatic machines due to their higher cost. They are used for industrial purposes.

Most popular models

The most popular due to their technical characteristics are the company’s models:

- MASTER (CE-51);

- Cansa Makina (CNC76, CNC51, CNC38);

- ARCOR (DBM 25T–DBM 120T).

The MASTER company produces semi-automatic mandrel pipe benders with numerical control. They allow you to rotate the workpiece in space for processing. It is possible to clamp the pipe during processing. During operation, the mandrel mechanism is automatically lubricated.

Cansa Makina specializes in the production of models that have an automatic operating principle. The devices are capable of processing workpieces of various diameters. The advantage of the units is the minimum error rate during operation.

ARCOR produces models that are characterized by high functionality and efficiency. The devices are capable of bending large-diameter pipes. They allow you to create products with different bending directions and several streams.

CNC pipe bender: semi-automatic and automatic models

Computer numerical control (or CNC) began to be installed on semi-automatic or automatic models of pipe benders relatively recently. With the use of these systems, pipe bending has become more precise and less time-consuming. CNC complexes are not installed on manual models of pipe bending tools.

A semi-automatic CNC pipe bending machine can be called the most common type of equipment (not counting manual pipe benders). This machine is called semi-automatic because a certain part of the operations is carried out by the software part of the equipment, while the remaining actions must be performed by the machine operator. The process of bending pipes is fully automated - the most difficult work that requires high precision and quality. But the operation of the machine requires constant monitoring.

Note! The use of a semi-automatic CNC pipe bender is justified for small enterprises that do not require very high production and productivity standards.

If average indicators are not enough, then the use of automatic machines with a program control system is recommended: they are much more functional. With their help, it is possible to create an individual project for executing an operation, scrolling it in “demo mode” before direct execution.

CNC pipe bender allows you to process pipes with the thinnest walls without deformation

A semi-automatic CNC pipe bender is also successfully used when it is necessary to bend thin-walled pipes: however, for this you should choose models equipped with a mandrel (a special stabilizing element in the form of a metal spring, sometimes coated with polyurethane). Mandrelless machines do a rather poor job of removing the corrugation of a thin-walled pipe that occurs as a result of bending. Also, with mandrelless machines there is a possibility of thin-walled pipes becoming oval during bending. Some ovality is also possible when using a mandrel pipe bender, however, the deviation from the norm will reach only a few percent, which is safe for further operation.

DIY pipe bender

A CNC pipe bending machine is an expensive piece of equipment available to large enterprises with a sufficient budget. But for home purposes, such a device can be made with your own hands. It will have less productivity than a professional unit. Such a device will be able to cope with the processing of workpieces made of soft metals of small diameter.

The most important element of the package is the massive frame on which the remaining parts of the unit will be located. After manufacturing the massive frame, the design is supplemented with:

- multi-strand bending rollers;

- eccentric;

- clamping blocks.

CNC Mandrel Bender Options with Automated Tool Changer

The automatic pipe bending machine with automatic tool changer has the same options as conventional pipe bending machines:

— kits for various profiles

: additional equipment can be ordered for the machine for various sizes and profile shapes

— laser measuring instrument

: allows you to quickly and accurately control products when setting up the machine and subsequently

— automatic hole punching unit

: a punch is built into the fixing clamp, the mandrel acts as a matrix; the punching is mandrelless, so the first wall is punched with slight deformation; one or both walls can break through

— workpiece cutting unit

: a knife is built into the fixing clamp, cutting the pipe in the right place; accordingly, it is possible to obtain several parts at once from one length of workpiece in a continuous cycle (the arrow points to the groove where the knife is located)