Malfunctions occur both in expensive German or American modifications of chainsaws, and in their cheap Chinese counterfeits. It’s nice when the power tool starts up smoothly: the saw warms up and gradually reaches the rated power declared by the manufacturer, which is provided throughout the entire operating cycle. Things are worse if everything happens the other way around: after pulling the gas cable, the unit begins to slip, runs jerkily after short pauses, stalls and restarts with the pusher.

There can be many reasons for this phenomenon, as well as scenarios for the development of events. Let us consider in detail each working situation and the breakdowns that preceded them.

What to do if the chainsaw does not idle?

Problems with idle speed are considered constant companions of chainsaws. There may be several prerequisites that could lead to stalling at the time of start-up and cranking of the chain when idling, the main ones being:

- air and gasoline filters are clogged;

- poor quality fuel mixture or improper preparation;

- problems with the ignition module;

- a carburetor whose settings no longer correspond to the load on the saw;

- motor elements are deformed or rusted.

A series of actions are performed sequentially:

- wash the fuel hose or replace it with a new one,

- Clean the air filter, which could be clogged with sawdust and dirt particles. Modern air filters are reusable, they can be washed with the addition of detergent, completely removing them from the saw body;

- check gasoline and motor oil, which may be of poor quality or simply not suitable for working with this saw;

- testing spark plugs and carburetor.

Eliminating one or more possible problems will usually restore the saw to its former strength.

Does your chainsaw stall at idle? There is an exit

If the saw starts to stall at idle, then there are a priori several reasons, and it will be easy to find out even for a novice owner if you follow the recommendations of our specialists and check everything competently and delicately. So, the reasons why a chainsaw stalls at idle may be the following:

- reduction in the capacity of gasoline and air filters;

- malfunctions in the ignition system, also referred to as its abnormal operation;

- spontaneous change in carb settings;

- elements of the fuel supply system are faulty;

- the muffler or exhaust ducts are clogged;

- the occurrence of defects on the piston, cylinder or other elements of the CPG, defects on the valve;

Before checking the insides of the saw to find out why the tool stalls at idle, you need to inspect all its external components for any deviations, which may include possible deformations, and also check for the presence of fuel in the tank. Let's consider each of these situations:

- We check and repair filters. If the fuel or air filter is clogged, the engine receives insufficient amounts of air or fuel, or does not receive one of the elements at all, and accordingly cannot operate fully. We remove the fuel line hose from the carb fitting and direct it into a working container. Click on “paging” several times and look at the result. With a clean fuel filter, gasoline flows evenly, clearly, without jerks and vice versa. To check the air filter, you need to remove it carefully so that sawdust and dirt do not get into the carb. After washing it, blowing it or replacing it with a new one, we analyze the result to see whether the problem was in two or one of the filters.

- We check the ignition system and the spark plug itself. Its poor condition can cause the saw to fail to operate at idle speed, if it stalls when you give it gas or even fails to start at all. So, the candle could have been filled with fuel; a spark does not occur due to a huge amount of carbon deposits or a burnt-out spark plug element; a spark does not occur if the gap between the electrodes is violated (too large or small); a dry spark plug will indicate a lack of gasoline in the piston cylinder; Incorrect carburetor adjustment and a clogged air filter can be determined by the presence of black carbon deposits on the spark plug and soot on its electrodes.

- Why, after checking the ignition system and filters, the saw continues to stall at idle - the cause can only be the carburetor. You need to find three adjustment screws, among which one is responsible for maximum speed, the second for minimum speed and idle speed (the screw is called “T”). It must be configured according to the recommendations, strictly according to the instructions for each individual device. If even adjusting the idle speed did not help, and the saw continues to stall at the same speed, proceed to disassembling and inspecting the whole crab. We describe how to do this in our articles.

- Malfunctions, breakdowns, clogging of the chainsaw muffler. The last option, which provokes situations at idle when the saw stalls. A muffler contaminated with sawdust and dirt, with adhering oils and exhaust gases, loses its throughput. If it is not cleaned and replaced in time, the engine will begin to “choke.” All elements associated with the muffler must be gently soaked, carefully cleaned and blown with compressed air, and installed in their place. At this moment, cover the engine with a rag to prevent dust from entering.

If your Husqvarna saw or Shtil power tool stalls at idle speed, we have presented you with all the existing testing options. It is also important to correctly assemble all the parts during disassembly in their original place, drain the gasoline, if any, replace it with a clean mixture and try to start the saw. Spare parts for chainsaws can always be ordered from the KosiKosa service.

Why doesn't the chainsaw gain momentum?

Starting up is a complex multi-level process in which almost all life support systems of the saw are involved. That is why the fact that the chain saw loses speed, turns on intermittently and feels confident only at idle should be considered from different angles.

The following factors could lead to this:

- a faulty motor - its service life could be exhausted, and the piston rings and cylinder could wear out, become deformed, or even succumb to corrosion;

- a faulty spark plug or the coil itself - as a result, the spark necessary to ignite the air-fuel mixture is not produced;

- unbalance of the carburetor screws, as well as a number of reasons that could cause it to fail.

Adjusting the chainsaw carburetor

Using a chainsaw greatly simplifies life even for amateurs, and in some professions it is almost irreplaceable.

But, like any relatively complex equipment, a chain saw requires regular maintenance. If it is performed untimely or of poor quality, this leads to various malfunctions. One of the most common causes of problems is the incorrect setting of the chain saw carburetor, which becomes confused due to the displacement of the adjusting screws under the influence of vibrations or as a result of unsuccessful attempts to adjust it. Adjustment of the chainsaw is required in the following cases:

- The factory settings of the chainsaw carburetor are off;

- the engine starts with effort and stalls almost instantly;

- debris particles entering the fuel distribution mechanism due to a malfunction of the air purification system;

- the exhaust is too thick, the fuel consumption is too high, the fuel does not burn completely in the cylinder;

- significant wear of the piston group (in this case, adjusting the chainsaw carburetor is a temporary measure).

The carburetor is designed to prepare the fuel mixture for supply to the engine. Violations of the proportions in the fuel mixture lead to malfunctions in the functioning of the engine.

The design of carburetors in different models of chain saws varies, but they all operate on the same principle. The air flow moves quickly through the channel. The speed of its movement is regulated using a damper that blocks the channel. The fuel supplied into the channel through the atomizer is mixed with air, after which the resulting air-fuel mixture enters the engine.

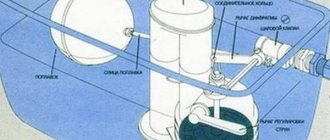

The carburetor always consists of the same set of parts, although it may vary slightly depending on the manufacturer. It consists of the following parts:

- The basis. It is a special tube that has an external resemblance to an aerodynamic design. Air flow passes through it. In the middle of the tube in the transverse direction there is a valve, the position of which can be changed. The more it is pushed into the passage, the less air enters the motor.

- Diffuser. This is the narrowed part of the pipe. With its help, an increase in the speed of air flow is ensured precisely in the part from which the fuel is supplied.

- Float chamber. This element is shaped like a tank. It is used to continuously maintain an optimal fuel level before entering the channel from which air is supplied.

- Channels for fuel supply. The fuel mixture is located in the float chamber, from where it enters the nozzle and then is fed into the atomizer.

In order for the operation of the tool to be efficient and smooth, the output to be maximum, and fuel consumption to be economical, timely adjustment of the chainsaw carburetor . Before performing this, check the cleanliness of the air and fuel filters. On most chainsaws, adjustment is made using three screws: high speed, low speed, idle.

Adjusting the carburetor must be done with the utmost care, since errors are fraught with very significant consequences, including engine failure.

Signs of a correct setting are the following:

- engine acceleration is fast and smooth;

- the chain remains motionless at idle;

- The engine produces a smooth sound when running, reminiscent of the sound of a four-stroke unit.

The carburetor adjustment of a Chinese chainsaw is done in the same way as for models produced by European manufacturers; in fact, Chinese analogues are copies of famous brand tools, but with some changes.

For this, the same screws H, L and T are used. The standard for carburetors of Chinese chain saws is the position of the screw L, in which it is loosened by one and a half turns compared to the fully clamped state. For screw H, the standard is one turn from the same position. Idle speed adjustment is performed on a warm engine.

On some models, only the idle speed is adjusted. However, owners of Chinese chain saws and service employees talk about the increased difficulty of adjusting the carburetor for tools produced by Chinese manufacturers. Even experienced craftsmen to adjust a Chinese chainsaw , unlike original tools.

The chainsaw does not develop speed: we test the device for malfunctions

The ignition module can be diagnosed for problems visually. To do this you need:

- turn out the spark plug;

- evaluate its appearance (it should not be filled with gasoline or contain a black coating);

- check the distance between the coil and magnets (up to 0.2 mm);

- if necessary, examine the spark plug block for spark supply using a working power cable.

If after checking no defects were found, you should proceed to checking the carburetor unit.

This working unit is one of the most vulnerable in modern chainsaws. New tools that go on sale from the factory have basic settings for low and high speeds, which must be reinstalled after running in and running in all the parts. Similar actions are performed if the saw does not develop traction corresponding to the maximum torque according to the instructions.

Try also growing Black Prince tomato in your garden.

The figure shows a typical three-jet adjustment circuit.

In this case, you need to reconfigure one of them - the “H” jet, which is responsible for the operation of the saw under load. To do this, it is enough to adjust the fuel supply with the engine running at the highest chain rotation speed, using the tachometer and the operating instructions.

Other chainsaw malfunctions

Many users encounter problems when the chainsaw does not slow down. The device reaches maximum power in a matter of seconds, which cannot be reduced.

This may be due to the fact that:

- the throttle valve does not function - its spring or traction element has weakened;

- the power switch does not switch well;

- The throttle shaft has lost its spin.

But the opposite situation can also happen - when the saw gains power uncontrollably. The reasons why the chainsaw itself gains momentum should be looked for in:

- carburetor - it needs to be cleaned or reconfigured;

- fuel supply system - gas filter, fuel hose;

- malfunctions of the cylinder-piston pipes or pipes connecting them to the carburetor.

There are quite a lot of breakdowns that manifest themselves through speeds that are atypical for a particular part of the operating cycle. But careful attention to the instrument will help to diagnose them in time and return it to normal operation.