02/18/2021 Author: VT-METALL

Issues discussed in the material:

- Laser and plasma cutting of metal: differences and similarities

- Advantages of plasma and laser cutting

- Cost of equipment and consumables for both types of cutting

- The quality of the result after plasma and laser cutting

When choosing which is better – laser and plasma cutting of metal, you must first take into account the differences and similarities of the two types. This is important both for selecting equipment for your own production and for ordering cutting on the outside. Understanding the strengths and weaknesses of each method will allow you to get quality products and stay within your budget.

Despite the fact that one can come across an opinion about the superiority of laser over plasma, it would be more correct to say that everything depends on the thickness and type of metal being cut. In one case you need to choose a laser, in another case plasma is suitable. In our article we will talk about all the features of these technologies and determine in what conditions and what is best to use.

Laser and plasma cutting of metal: differences and similarities

- Properties of laser cutting.

The laser installation consists of three main parts:

- working (active) medium – laser radiation source;

- optical resonator - a mirror that enhances the radiation of the installation;

- the energy source is a pumping system that creates conditions for the occurrence of electromagnetic radiation.

The metal is heated over a small surface area. The cutting process is carried out either at melting temperatures or during evaporation of the metal. The second option is used exclusively for cutting thin materials, since it is energy-consuming.

To facilitate work, one of the following gases is supplied to the cutting zone: helium, argon, nitrogen, air or oxygen. They perform the functions of supporting the metal combustion process, blowing it away from the melting zone, cooling adjacent surfaces, increasing depth and speed, and cutting.

According to the method of using the working environment, laser systems belong to one of three types:

- Solid state. The working fluid is a cylindrical rod, which consists of neodymium glass, yttrium-aluminum garnet or ruby, alloyed with ytterbium or neodymium. A gas-discharge flash lamp or semiconductor laser is used as an energy source.

- Gas. The working fluid is carbon dioxide, sometimes mixed with nitrogen and helium. Based on their design type, such laser devices are divided into slot-type installations and those with longitudinal or transverse pumping. Electrical discharges are applied to excite the gaseous medium.

- Gas-dynamic. The working fluid is carbon dioxide, heated to 1,000–3,000 °K (+726…+2,726 °C), which is excited using an auxiliary low-power laser.

- Features of plasma cutting.

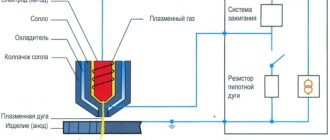

For plasma cutting, the following plasma-forming gases are used: a mixture of hydrogen and argon, compressed air, oxygen or nitrogen. Inside the plasma torch, to which cooling is required, the gas is heated to a temperature of +5,000...+30,000 °C and takes on the state of plasma: a mixture of free electrons, ions and neutral atoms. As a result, the gas has the ability to conduct electric current. Due to heating, its volume expands 50–100 times, and it flows out of the plasmatron at a significant speed. Plasma, acting on the metal, begins to melt it.

During plasma cutting, an electric arc appears between the cutter nozzle and the electrode, which is formed when the cutter is brought close to the metal. This is possible by using a DC power supply.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

There are devices of indirect or direct action. In the first case (plasma jet cutting), the arc is formed inside the cutter. This processing method is used for cutting materials that do not conduct electrical current. In the second (with plasma-arc cutting) it occurs between the material being cut and the cathode of the plasmatron.

Advantages of plasma and laser cutting

- Laser cutting.

With laser processing, the cut is more precise than with plasma. Thanks to the correct setting, it will not jump all over the surface of the metal sheet. But when cutting with plasma, fluctuations constantly occur, and the outlines of corners and cutouts are not entirely clear. This is especially critical for small parts or with complex cutout shapes. Therefore, for parts with high quality requirements and exact compliance with the project, it is important to use a laser, since it can clearly cut the metal where it is directed, without significant oscillatory movements.Unlike plasma cutting, laser cutting can produce narrower slots. To produce clearer holes when using plasma, their diameter must exceed the thickness of the sheet material by one and a half times, but at the same time be at least 4 mm. The use of lasers makes it possible to make holes with diameters equal to the thickness of the metal - from 1 mm. This significantly increases the potential for designing products and housings that use this cutting method in their reamers.

Laser cutting is characterized by minor thermal deformations. But if you write a program for processing without taking into account the elementary characteristics and properties of the metal used, then, theoretically, you can overheat the part even using this method. For example, using a laser you cannot make very frequent and small holes for ventilation - this can lead to overheating of the metal. With this method of cutting, the holes in the ventilation grilles must be made larger and less frequent. In other cases, the deformations caused by the laser are not so significant.

With plasma cutting, the heated zone is much wider, and deformations are more pronounced. Unlike plasma cutting of metals, such indicators of the laser method provide better results.

With the laser cutting option, no scale remains on thin sheet metal. This means that after cutting, the reamer is sent straight to bending, bypassing the stripping operation. This allows you to save working time on the production of parts, and, ultimately, the customer’s money.

Laser-made holes have more perpendicular edges. A major problem with plasma machines is the taper of the holes. Laser equipment, when processing metal up to 4 mm thick, leaves perpendicular walls, and with values above 4 mm, a slight bevel (approximately 0.5°), and the lower edge of the hole is slightly larger in diameter than the upper. At the same time, their shape is not distorted: both the lower and upper holes are perfectly round. And with plasma, as the thickness of the material increases, the holes begin to show ellipse.

Both types of cutting installations have high processing speed. Both methods are good here. Speed parameters decrease only with increasing part thickness.

But for metals with medium or high thickness, the use of a laser becomes ineffective. This is the main disadvantage of laser cutting, in contrast to plasma technology. With a thickness of 20 to 40 mm, the laser beam is used much less frequently, and with values from 40 mm and above, it is not used at all.

- Plasma cutting.

A larger range of choice of metal thickness for cutting is the main advantage of plasma cutting, in contrast to laser cutting. It is rational to use plasma for:

- cast iron up to 90 mm thick;

- copper with a maximum thickness of 80 mm;

- steel with a thickness of no more than 150 mm;

- aluminum with a thickness of less than 120 mm.

As already noted, high cutting speed is a common positive factor for both plasma and laser methods of cutting metals.

When choosing a plasma cutting method, you need to remember the taper of the holes. And if for a specific order such an error is an unacceptable factor, then it is better to choose laser processing. The deviation from the vertical of the walls of holes during plasma cutting can be from 3 to 10 degrees. For the laser method, as mentioned above, this parameter is no more than 0.5 degrees. When using plasma, the diameter of the lower hole is smaller than the top. With a metal thickness of 20 mm, the difference between the lower and upper cutting diameters can be more than 1 mm.

Increased accuracy, minimal cuts relative to the thickness of the metal, minor thermal deformations - all these are advantages of using laser cutting.

When using plasma, scale often remains. Of course, cleaning it after plasma cutting will not be difficult, but you will have to spend some time and effort on this, and this is a waste of man-hours and, accordingly, leads to an increase in production costs.

Advantages and disadvantages of both methods

| Plasma (recommended cutting thickness – within 0.8 – 120 mm) | Laser (recommended cutting thickness – up to 6 mm) |

| The holes at the bottom of the metal are larger in diameter compared to the holes at the top due to the peculiarities of cutting with a plasma torch | Smooth and straight cutting edges, high quality and ideal geometric shape with minimal taper |

| Wide cut | Narrow cut |

| Average service life of manufactured parts due to rougher cut edges than laser cut ones | Precision of work and durability of the resulting parts: no defects or geometric irregularities, narrow and barely visible cuts with small temperature zones are obtained, which increases the service life of the product. This is especially important when creating small figures with complex shapes and clear angles. The ability to heat a narrow zone of metal, which reduces the level of deformation during work. |

| Low cost of equipment, high cost of consumables | High cost of equipment, low cost of consumables |

| Fast working speed when processing thick steel. You can cut sheets of thickness: up to 150 mm, if it is carbon and alloy steel; up to 120 mm, if it is aluminum and alloys; up to 90 mm if it is cast iron; up to 80 mm if it is copper | Fast working speed when processing thin steel. No scale appears on the metal, so it can be sent to the next production stage without additional processing |

| Disadvantages: inability to use for sheets with a thickness of less than 0.8 mm, the appearance of scale after working with any type of steel due to short-term thermal firing, the presence of restrictions on the minimum hole size | Disadvantages: when processing sheets with a thickness of over 4 mm, a deviation of 0.50 appears, high rejects when working with sheets with a thickness of over 20-40 mm |

In terms of productivity, a plasma machine is more affected by the number of holes required per part than a laser machine. This increases operating costs and the cost of an hour of operation due to restrictions on starts and firmware for nozzles and electrodes, respectively.

Cost of equipment and consumables for both types of cutting

When choosing a plasma or laser method for cutting metal, you must take into account that the price of a portal plasma installation is 5-6 times less than a similar laser one. However, when comparing both methods, you should calculate not only the initial price, but also the costs of further maintenance.

This includes the cost of electricity, the use of auxiliary gases and the cost of consumables. When deciding on the choice of plasma or laser cutting, it is necessary to take into account that the estimated cost of operating a laser cutting machine includes:

- Gas prices:

- pure oxygen or air - for treating steels with a high carbon content;

- nitrogen – when using workpieces made of aluminum (or its alloys) and corrosion-resistant (stainless) steels and alloys.

- Energy consumption costs:

- energy consumption costs of the installation itself;

- the cost of electricity spent on the laser and cooler.

- Consumables, which include:

- internal and external optics;

- replacing worn nozzles;

- cleaning and replacing filters.

The intensity of operation of laser systems has a significant impact on the frequency of replacement of consumables: from once every several weeks or years.

Without information on the operating costs of a plasma processing installation, it would be difficult to answer the question of how plasma cutting differs from laser cutting. For this reason, we continue to study in more detail the costs of alternative types of equipment.

Plasma cutting uses air or oxygen. Electricity is spent only on creating plasma and powering the machine itself. If we talk about consumables, then you need the same amount of them as when using a laser. These include:

- protective screen;

- electrode;

- nozzle.

Reducing the cost of a plasma cutter can be achieved by using low-current nozzles and electrodes, but this will lead to a decrease in machine productivity, but will not affect the quality of the cut.

Considering the question of how many holes should be per workpiece in order to reduce the hourly cost of work, we can safely say that the advantage is on the side of the laser, since the electrodes and nozzles used in plasma installations are designed for a given number of starts and flashes.

The more holes that need to be made, the higher the operating costs of plasma equipment.

The quality of the result after plasma and laser cutting

Taking into account the quality parameters of the surfaces of parts after processing and making a comparative analysis of the cost of consumables, we come to the conclusion: when using thinner sheet materials, laser cutting is more effective, and when working with thicker workpieces, plasma cutting is more effective. It should be remembered that the maintenance costs of both types of cutting vary widely and mainly depend on the geometric parameters of the workpieces, the number of holes in them, and the type and thickness of the metal being cut.

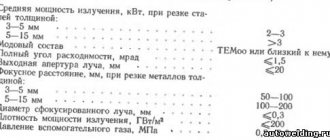

| Options | Laser cutting | Plasma cutting |

| Cutting width | Constant (0.2–0.375 mm) | Varies due to instability of the plasma arc (0.8–1.5 mm) |

| Cutting accuracy | Typically ±0.05 mm (0.2 - 0.375 mm) | Depends on the degree of wear of consumables ±0.1…±0.5 mm |

| Taper | Less than 1° | 3–10° |

| Minimum openings | In continuous mode, the diameter is approximately equal to the thickness of the material. For pulse mode, the minimum hole diameter can be one third of the material thickness | The minimum diameter of the holes is one and a half thickness of the material, but not less than 4 mm. Pronounced tendency towards ellipticity (increases with increasing material thickness) |

| Internal corners | High quality | Some corner rounding occurs and more material is removed from the bottom of the cut than from the top |

| Scale | Usually absent | As a rule, there is (small) |

| Burns | Invisible | Present on sharp outer edges of parts |

| Thermal impact | Very little | More than laser cutting |

| Metal cutting performance | Very high speed. For small thicknesses, usually with a noticeable decrease as thickness increases, prolonged burning of large thicknesses | Fast burn. Very high speed at small to medium thicknesses, usually with a sharp decrease as thickness increases |

The laser cutting method is more effective for steels up to 6 mm thick. In this case, high quality and accuracy are ensured at a relatively high cutting speed. Cutting edges on sheets 4 mm thick or less remain smooth and straight. Increasing thickness predisposes to the appearance of a bevel of approximately 0.5°. When laser cutting holes, the lower diameters are larger than the upper ones, but remain round and of good quality.

Plasma cutting of metal, in contrast to a laser machine, is economically more efficient when processing thicker-walled material. In addition, relatively good cutting quality is maintained. From a financial point of view, this type of processing is rational for cutting copper with a thickness of less than 80 mm, aluminum and alloys based on it with a workpiece thickness of no more than 120 mm, cast iron - no more than 90 mm, carbon and alloy steels with a thickness of up to 150 mm. For cutting sheet material with a thickness of 0.8 mm and thinner, the use of plasma is undesirable.

We can conclude: when processing thinner sheets, laser cutting has an advantage over plasma cutting. And when cutting thicker workpieces, primacy can be given to laser systems. It must be taken into account that the costs of servicing equipment of these types of cutting are different and mainly depend on the geometric parameters of the workpieces, the number of holes in them, the type and thickness of the metal being cut.

Summary table - comparison of metal cutting with laser and plasma

| Laser cutting | Plasma cutting | |

| Cutting width | Constant - from 0.2 to 0.375 millimeters | Variable due to arc instability - from 0.8 to 1.5 millimeters |

| Cutting accuracy | ±0.05 millimeters | From ±0.1 to ±0.5 millimeters depending on the wear of consumables |

| Taper | Less than 1 degree | From 3 to 10 degrees |

| Minimum openings | The diameter is approximately equal to the thickness of the metal | The diameter is approximately 1.5 times the thickness of the metal and should not be less than 4 millimeters. |

| Internal corners | Accurate | Slightly rounded |

| Scale | Almost never found | Light, but almost always present |

| Burns | Invisible | Visible on outer edges |

| Thermal impact | Minor | Increased compared to laser |