Process Features

To raise a wooden structure, it is recommended to prepare the base for supporting the jack. The supporting platform must provide not only stability, but also freely accept the pressure from above. The raw material used is board or timber. The support is laid on the subgrade or foundation to ensure uniform distribution of the impact over it. If laying is done on the ground, it must first be compacted well.

Sliding is prevented by securely fixing the jack head when it comes into contact with the house. The main condition is the evenness of the log in the place to which the lifting force will subsequently be applied. It is allowed to use a metal plate measuring 10*10 cm with a slightly concave shape in the center. It is she who is subsequently placed between the jack and the wooden house.

What jacks are suitable?

To raise the house you will need jacks identical to those used in car workshops. Their main feature is the ability to lift a lot of weight. The load on the lift is preliminarily calculated taking into account the mass of the structure and climatic conditions:

- the total mass of the house is calculated as the sum of the masses of the external and internal walls, floors and roof. The total volume is estimated by multiplying the volume of wooden structures by the density of the material used during their construction;

- the additional weight of all communication lines and devices is added, the disconnection of which is impossible during the work;

- heavy elements of furniture and decor are not taken into account. They are first taken out of the house;

- the final load is multiplied by 20%. This ensures that the jacks can definitely lift the house. Allowance is made for moisture, which the wood actively absorbs.

Important! When jacks lift a wooden house, they should not operate at their maximum capacity (maximum load). For this purpose, a reserve of 20% is made.

In order to raise a panel house made of wood, you will need any of the existing types of lifting mechanisms. The main thing is to ensure that the load-carrying capacity of the tool matches the weight of the building. Do not allow the mechanism to operate at maximum values.

Screw

They are distinguished by the simplicity and reliability of the mechanism. They are made in the form of a screw, along the thread of which the contact pad moves. The latter is considered the fundamental load-bearing part of the mechanism. The product is characterized by high load capacity, compactness and ease of maintenance. Capable of lifting the weight of a building up to 50 tons.

Screw

Hydraulic

The mechanism of operation of the device is based on the lifting force of the liquid. It promotes displacement of the piston when pressure is created by a specialized pumping lever element.

There are several types of hydraulic devices:

- bottle (2-100 t). The main disadvantage: small initial working height. If you are considering replacing the location of a house in a country house, a model up to 10 tons will do. The remaining models are used preferably by professionals.

Bottle

- rolling Load capacity is not higher than 10 tons. The best option for a country cottage. The cost is slightly higher than the first option considered;

Roll-up

- with low lift. Expensive option. Expanded functionality: ability to work in horizontal and vertical planes. It is allowed to raise the house on a slope. Load capacity does not exceed 25 tons.

Both types of jacks are acceptable for raising a house. In terms of reliability, they are approximately equivalent. The choice depends on the price category of a particular model, its load capacity and build quality. It is not recommended to use Chinese products. Many manufacturers in this country are not scrupulous enough when it comes to compliance with specified technical and operational characteristics.

Tools and accessories for work

To build the foundation of a brick house, you will need a set of certain tools.

First of all, jacks. Three types of lifts are used in construction:

Hydraulic jack diagram.

- screw;

- rack and pinion;

- hydraulic.

They differ in the principle of operation of the mechanism. The latter type of wall lifting is even preferable, because hydraulics provide a low lifting speed and a small working stroke. These qualities are important to raise the brick wall evenly, without distortions.

The lifting capacity of the jack depends on the weight of the building. Brick is heavier than wood, so this figure should be in the range from 20 to 30 tons. If we are talking about raising a small country house, a load capacity of 8 to 10 tons is enough.

In addition to lifts, during work you will need tools for concreting (scoop shovel, trowel, concrete mixer), hammer and crowbar. If the additional foundation requires reinforcement, then you will need a grinder and metal scissors.

To control the lifting process and avoid distortions in the structure, craftsmen advise using levels and plumb lines. More experienced ones resort to the help of levels, with the help of which they can observe deviations of the house from the norm horizontally and vertically. But the use of these devices requires certain knowledge, so it is better to entrust such work to a specialist.

How to raise a house with your own hands?

You can raise a wooden dwelling using a different number of lifting units:

- use of one lifting mechanism. Various points of the structure move in turn. The displacement in the vertical direction is strictly regulated - no more than 50 mm. Irreversible damage and deformation are prevented, as a result of distortion of door and window structures, the formation of cracks in the finishing façade material and damage to the integrity of the glass unit. The raised part of the house is fixed with wooden beams, and the lift moves further. Consistent work allows you to raise the structure to the same height;

- use of two lifts. The correct layout of the units is carried out to lift and move the house vertically. Both points do not need to be hung simultaneously. It is important to lift a certain section of the building one at a time, preventing the building from moving to the other side from the lifts and its severe deformation. The step-by-step instructions for performing the work are similar to the first method;

- The house can be raised using four lifting devices. Manipulations are characterized by synchronicity.

Preparatory operations

The installation option for the jack completely depends on the type of foundation structure. Tile and strip type bases require cutting niches in the shape of a rectangle. On a column-type and pile-type base, the mechanism is installed on wooden panels.

The location of the support should be smooth and even. Subsequently, a specialized metal tripod stand is installed on it. It is important to exclude the possibility of it slipping. The support allows you to adjust the structure in height.

Preparatory activities

Important! It is recommended to purchase special jack stands that are durable, stable and reliable.

Additionally, wooden plates with a width of at least 200 mm are purchased.

If a complete replacement of the foundation structure is planned, temporary support is required. It is created metal by welding corners and channels. This design is advisable until the new foundation reaches the required strength.

Lifting the house

Detailed instructions for performing house lifting operations:

- Work begins from the most sagging corner. Having retreated 1 m from the site, a hole is dug for mounting the platform and installing the jack. The soil must be dry and compacted.

- The lifting device is installed under the lower log. If it is intact and strong, a steel plate is mounted under the head. Otherwise, you need to cut a hole in the log for the jack pin, where the wood will be of better quality. Working with rotten and unreliable material is strictly prohibited. This is unsafe for the performer of the work.

- We are preparing to directly raise the angle. We resort to accuracy and attentiveness. It is not allowed to raise the house higher than 50 mm in one go. At the same time, the prepared supports and supports are wedged in. Provides relief from the weight on the jack.

Lifting

- The condition of the house is monitored. At that stage, complications may arise that are easier to eliminate at the moment.

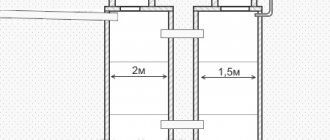

- If you plan to lift the house with two jacks, prepare to work with the second corner. A recess for the pallet is dug in the same way. Subsequently, a device for lifting the house is installed on it. The device is brought under the log of the lower crown. A metal plate is placed on the head and the structure is raised. Wooden blocks and dies are inserted under the lower crown.

- The lift is installed in the middle of the log. Similar manipulations are performed. The house rises slightly by 20-30 mm. The thrust elements are lined.

- A return is made to the first corner. They lift it, trying to level the frame, but not higher than 60 mm. Supports made from blocks are used. They try to envelop the entire side with supporting elements.

- The wooden house is inspected again.

- Lifting units are removed from reinforced areas. They are being prepared for lifting from the other side. The work is done in the same way.

- A return is made to the first two corner sections. The structure is raised until the frame is fully leveled. Correctness is checked with a water building level.

- Raising is performed alternately in any direction until it is completely level.

- Reliable supports are installed under the walls. Along the perimeter of the entire house.

Foundation restoration

When installing a new foundation for a wooden house, adhere to the following order:

- The existing trench is deepened and leveled to create a new foundation. Its depth should exceed the level of soil freezing, and its width should be greater than that of the previous base;

- Place a sand cushion about 10-20 cm high on the bottom;

- A reinforcement frame is formed, for which they use steel rods with a cross-section of about 8-12 mm - it all depends on the dimensions of the building and its weight. The release of reinforcement for its subsequent connection with a common reinforcement frame is impractical here;

- The formwork is installed with careful fixation of the structure along its entire length;

- First of all, fill the corner supports, preferably one time, after which they proceed to fill the rest of the tape. This approach will give the structure greater strength and solidity;

- During pouring, the concrete mixture is carefully compacted. This can be done using a steel rod or a special device;

- After pouring is completed, the concrete is given time to harden, after which it is covered with roofing felt, which acts as a waterproofing agent, and proceeds to the final stage of work.

The structure should be lowered with extreme care and caution, performing the operations in the reverse order of lifting and monitoring the condition of the walls and their load. As you can see, raising and replacing the old foundation is not as simple as it might initially seem

Although, if you have the proper desire and appropriate tools, you can cope with all operations on your own. The main thing is to follow the recommendations presented above and not to be too hasty.

As you can see, raising and replacing the old foundation is not as easy as it might initially seem. Although, if you have the proper desire and appropriate tools, you can cope with all operations on your own. The main thing is to follow the recommendations presented above and not to be too hasty.

Security measures

Whatever the reason for moving a house, the process is not safe. Especially if the work is supposed to be done manually. Before raising a structure, it is recommended to carefully study not only the technological process of the work, but also safe labor practices and precautions:

- During the preparatory process, the house is strengthened in all directions. The logs are fastened using boards; window and door structures can be protected from distortion using spacer beams;

- A specialized recess is prepared for installing the jack. It is exposed at the corner of the house;

- The lift is mounted only under a solid and wide surface. Experts advise pre-laying the boards;

- Initially, the condition of the lower crown logs is checked and their strength is monitored. Damaged areas are being strengthened. The technique used is to install metal beams;

- The possibility of damage to the logs can be minimized by placing a lining under the retractable rods of the plates. The place of support is made with a slight unevenness - a depression.

If you strictly follow the instructions and safe work practices, you can move the structure to the desired location efficiently and reliably.

Source

What structures can be lifted

For major repairs, only one-story buildings of the following types are raised: made of wooden beams;

from rounded and other logs; panel wooden houses. Structures made of timber or hardwood , such as larch and oak, last for quite a long time. There are still houses built before the revolution, which are over 100 years old and have retained their almost original appearance.

Modern wooden buildings are not so durable. The reason for this is the quality of the timber, which became especially susceptible to various diseases after the beginning of the “atomic era” and the ongoing testing of nuclear bombs.

In this regard, wooden structures must be thoroughly inspected to identify signs of rot and the appearance of fungus; the lower crowns of wooden houses are especially often affected by this.

Briefly about the main thing

Wooden houses are jacked up to replace the lower crown or repair the foundation.

Only one-story timber or frame-panel buildings can be lifted with a jack.

Based on some external signs, such as subsidence of the building or destruction of the lower crown, one can understand that the log house needs repair.

For houses located low to the ground, rolling or inflatable jacks are more suitable. In other cases, it is better to use a scissor mechanism.

Before raising the house and pouring the foundation, you need to disconnect all communications from it.

You need to start raising the house from the corners located on one wall.

After finishing the work, the jacks need to be removed one at a time from under the crown and replaced with supports.

If you are going to jack up the house, be sure to disconnect the bottom crown from the foundation.

Ratings 0

Signs of Problems

There are several such signs and they can be seen almost with the naked eye.

Namely: partial or complete violation of the foundation of the house; deepening the foundation into the ground; subsidence of the building in one of the corners; large distortion of windows and doors, as well as the tilt of the building. After inspection and identification of many additional works, a decision is made to raise the house. At the same time they create a plan according to which they purchase the necessary building materials and tools. In addition, the following activities are planned for major repairs:

- replacement of rotten building crowns;

- preventing further subsidence;

- alignment of the distortion of the entire box around the perimeter;

- treating wood with chemicals to prevent rotting;

- complete or partial replacement of the foundation.

Such grandiose work is carried out within 1 - 2 weeks , involving the entire family and several invited specialists.

Foundation repair using screw piles

The piles are connected to each other by channels and form a kind of lattice. Afterwards, the house can be lowered onto the resulting lattice.

It is this method of maintaining the foundation in normal condition that has gained the highest popularity. This is not strange, because it is quite simple and not expensive. At the same time, its efficiency is at its best.

During construction, some people forget that the foundation is the most important part of the house. As a result, during operation, various cracks, chips, and so on appear on it.

This is a sure sign that the foundation needs repairs.

It is in this case that you will need to raise the foundation using jacks. In recent years, some residents of our country have begun to prefer a foundation on screw piles to an ordinary one. This is due to its many advantages over ordinary concrete.

The technology for replacing the foundation with screw piles is quite simple. Moreover, it will seem simple to those people who are reading this article, because it has already described how it is necessary to raise a house with the help of jacks. In this case, this process is the main one. So, the installation technology is as follows:

Based on the characteristics of the soil on which the piles will be installed, their exact number is calculated

This is a very important matter, because the integrity of the future structure will directly depend on it; it's worth raising the house. This is done according to the principle described above

Then you need to mark the perimeter on the territory of which all the piles will be located. It is very important to calculate the location of each of them. Piles should be installed at the corners of the building, as well as along the perimeter of the load-bearing walls; Next you need to start screwing in all the piles in turn. This can be done manually, but you can use special equipment; All piles are connected to each other by channels. They should form some kind of lattice. This will increase the rigidity of the structure; only after this the house can be lowered onto the resulting grid.

Now we can state the fact that the renovation of the foundation has been completed and it will delight its owners for many years.

Preparing to lift the building

Before lifting the house, it is necessary to carry out actions to ensure ease of lifting and further repairs. This is done to protect against sudden and unexpected destruction of the structure. The following must be done:

- dismantle the outgoing sewer pipes;

- disconnect the power line;

- turn off the gas pipeline (if any);

- cut off the heating pipes from the boiler and disassemble the chimney;

- remove all furniture;

- remove all doors and windows from the boxes;

- reject or cut down interfering trees and bushes.