To create comfortable living conditions in a private house, a sewerage system is installed to ensure wastewater removal with further treatment and disposal.

Operating conditions of the sewer system

To correctly select the required sewage system, several main factors must be taken into account:

- the number of permanent residents in the house;

- average water consumption per day per resident;

- groundwater level depending on the season;

- the size of the plot and the area of land available for the construction of treatment facilities;

- amount of precipitation during the year;

- type of soil on the site.

Sewage installation options

The installation of a sewerage system in a country house involves the installation of pipelines through which wastewater is discharged to a storage tank located on the site.

Typically, designers recommend installing 2 types of sewage systems on a site:

- storm sewer system for a private home, ensuring the removal of rainfall, melt water and maintaining a given level of groundwater, preventing flooding of basements and cellars;

- a domestic sewer system for a private house, into which all wastewater generated as a result of the life activities of the residents of the house is collected.

It is possible to combine 2 types of sewage systems in one system with an increase in the volume of the storage tank depending on the number of residents living in the house.

Causes of blockage and solutions

Domestic sewerage is a very complex system, but it can also fail. It manifests itself in clogged pipes in any part of the network. This happens for a number of reasons:

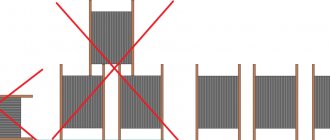

- Initially, the pipes were installed incorrectly, namely, bricks were placed under the joints of horizontally running pipes. As a result, the joint sank and the normal flow of wastewater stopped. This problem is eliminated by restoring the normal connection of the pipes. A normal, level concrete support is mounted under the joint.

- Subsidence of soil under horizontally laid pipes. In this case, blockage occurs in places where there is a strong bend in the previously straight pipe route. To eliminate the problem, the location of the uneven laying is determined and the normal soil level is restored under it.

- Fracture or roughness in the trays of collector wells. Small debris and feces get stuck on uneven surfaces, creating water blockages. The solution to the problem is to repair the tray or replace its damaged segment.

- Incorrect calculation of the slope of a horizontal pipe. If it is too small, the flow of water and fecal matter will be slow, resulting in congestion. To eliminate the problem, pipes or trays are shifted taking into account an inclination angle of at least 2 degrees.

Before repairing any section of the sewer, first remove the blockage using a long steel wire or a special cable. The damaged area must be covered. And only after this the repair work begins.

Construction of sewerage systems

The general house sewerage system includes the following elements:

- Storage device for (with or without treatment system) wastewater.

- External (external) sewerage pipeline system.

- Internal sewer system.

The storage system can be designed as:

- A cesspool (without a bottom or with a bottom), in which wastewater is filtered by purifying the wastewater as it passes through the ground and processing it with the help of microflora living in the reservoir. Crushed stone or screenings are used to fill the bottom. Designed for wastewater flow rates up to 1 cubic meter. meters.

- A sealed tank - made of steel or plastic and having a specified volume that allows the collection of wastewater for a certain period. The plastic tank is installed in a pre-dug pit and does not require additional sealing and is not subject to corrosion.

- A septic tank in which wastewater is treated and after a certain period of time the waste is removed by pumping using a special vehicle equipped with a tank. In some areas, a two-chamber septic tank system is used, designed to serve a larger number of residents. The first well is used as a sump, and the second for filtering wastewater. A septic tank is a container divided into 2-3 chambers, in which stage-by-stage wastewater treatment is carried out. The septic tank “Purflo” (France) produces high-quality wastewater treatment and is designed for 2-10 people.

- Local treatment plants are systems capable of removing up to 98% of solids from wastewater, converting them into fertilizers. Such stations are designed to process wastewater in volumes from 1 to 10 cubic meters. meters per day, which meets the needs of consumers ranging from 4 to 50 people. An example is the Biosepter-Super-filter installation (Russia). The station has a durable body made of durable steel 5 mm thick, designed to operate for 30 years and consisting of several compartments for step-by-step wastewater treatment. At the initial stage, fat-containing components are separated, and the largest fractions are settled. In the second chamber, medium-sized fractions are separated, and the third chamber is filtered using special filters and microbiological purification.

To pump fecal water, in addition to the gravity method, a special pump Wilo TMW30 EM -30 (Germany) can be used, capable of pumping up to 72 l/min, providing a pressure of up to 30 m and operating from a 220 V network with a power of 700 W.

Useful tips

When installing a small local sewer network, for example, in a private house or on a personal plot, you must follow all the recommendations for building a large city sewer system. That is, it is necessary to lay pipes correctly, maintain them on time, and the sump tank is best made in the form of a septic tank - a modern container for collecting sewage with beneficial bacteria in it.

These bacteria are able to clarify wastewater, making it homogeneous and odorless. Such liquid is then easier to remove with a special pump. A sewage system built for one house differs little from a large urban system, and therefore requires a serious engineering approach.

- Google +

- In contact with

- Telegram

- Classmates

- Viber

Rules for placing a septic tank when installing a sewer system

According to current standards, water consumption per person should be 200 liters of water per day. Then the installed storage device must have a volume that provides storage of 3 daily norms (600 liters per person) and is determined taking into account the number of residents living in the house.

Special requirements apply to the location of the storage device on the site, which must comply with:

- The drive should be mounted at the lowest point of the site.

- The distance from the drive must be at least:

- to the water supply source – 50 m;

- roadway – 5 m;

- reservoir (open) – 30 m;

- to a residential building – 5 m;

- to the neighboring area 2-4 m;

- the distance to fruit trees is from 3 to 4 m.

A little about the depth and slope of the pipeline

In order to correctly determine the depth of immersion of pipelines into the ground, it is necessary to use the recommendations given in SNiP 2.04.03-85, according to which the minimum depth should be determined by the experience of operating similar engineering systems in a given region.

In most of the territory of the Russian Federation, the following ratios are quite acceptable:

- With a pipeline diameter of 50mm, the minimum depth is about 300mm.

- When using large diameter pipes, the trench must have a depth of at least 700mm.

These ratios are fully consistent with the data obtained during the operation of existing storm sewers.

From a practical point of view, the simplest and most reliable way to determine the required trench depth is to contact professionals or neighbors who have already solved this problem and have verified in practice that the decision was correct.

To ensure the optimal slope of the sewer pipeline, the following factors should be taken into account:

- pipe diameter;

- specifics of wastewater disposal;

- the material from which sewer pipes are made.

If pipes with a diameter of 200 mm are used to install a sewer main, the optimal slope of the pipeline is considered to be 7 mm for each meter of the main. If a pipe with a diameter of 150 mm is used, it should be laid with a slope of no less than 8 mm/mp of the main line. If absolutely necessary, the slope can be reduced slightly by first reading the recommendations given in SNiP 2.04.03-85.

According to these recommendations, with a main pipeline diameter of 200 mm, the slope can be reduced to 5 mm/mp, and when using pipes with a diameter of 150 mm, the slope can be reduced to 7 mm/mp of the sewer main.

In other words, if necessary, you can reduce the slope of the highway by approximately 2 mm/mp. However, we should not forget that the maximum pipeline slope should be no more than 15 mm/m.

With a further increase in slope, the likelihood of blockages in the line increases. This is due to the fact that sand and small abrasive particles contained in the drains settle on the inner surface of the pipes and gradually form a kind of blockage.

Sewage system diagram

Before the start of construction work, a layout diagram of all elements is drawn up, indicating all points associated with the water supply and wastewater drainage system. Such a scheme allows you to correctly install the sewerage system, taking into account all sanitary requirements and avoid installation errors.

When drawing up the layout of the sewer system, the following must be taken into account:

- all drain points planned for placement in the building with a floor breakdown;

- the location of the central riser (pipes with a diameter of 110 mm), and the outlets from the washbasin or toilet should not exceed 1 m;

- the placement of the sewerage network pipeline should be carried out according to a scheme with separation of the drainage from washbasins and toilets;

- all pipelines of the sewer network must have a slope with a pipe diameter of 50 mm - 3%, and with a diameter of 110 mm - 2% and ensure the free flow of wastewater into the storage tank;

- location of the drain pipe;

- placement of the passage of an external sewerage pipeline with the installation of inspection wells (with a distance of 10-15 m).

Basic standards for the installation of sanitary sewage systems

The basic standards for the installation of household sewage systems were developed several decades ago, back during the existence of the USSR. These were guides such as:

- “Fundamentals of water legislation of the USSR and union republics”;

- “Rules for the protection of surface waters from pollution by wastewater”;

- “Rules for sanitary protection of coastal waters of the seas”, Ministry of Water Resources of the USSR, Ministry of Fisheries of the USSR and Ministry of Health of the USSR;

- “Regulations on water protection and coastal strips of small rivers in the country”;

- “Instructions on the procedure for approval and issuance of permits for special water use.”

When constructing sewer systems, the number of residents permanently residing in the city and the presence of industrial enterprises in it are taken into account. There should have been no residential areas or developed fields in the areas where wastewater treatment facilities were installed. The uninterrupted operation of the sewerage system is planned. High quality pipes and materials used to construct the system are required.

Selection of pipe material for sewerage

Before laying the pipeline, it is necessary to select the pipe material for internal and external wiring.

The most commonly used materials for the manufacture of sewer pipes are:

- cast iron;

- polypropylene;

- polyvinyl chloride

Cast iron pipes used for installation of the sewer system are produced in 2 versions:

- with bell;

- without bell.

and are resistant to temperature changes, corrosion, alkalis and acids. They have low cost and durability during operation.

Plastic pipes have a number of positive characteristics compared to other materials:

- long service life;

- high level of strength and flexibility;

- high resistance to corrosion;

- light weight, which significantly reduces labor costs;

- high degree of internal surface treatment, which prevents the formation of deposits;

- ease of installation of structures.

Polypropylene pipes are produced in several brands:

- PN 10 (designed for temperatures up to 45 * C);

- PN 16 (designed for operating temperatures up to 60 * C);

- PN 20 (designed for operating temperatures up to +100 *C).

Certain brands of polypropylene pipes are resistant to high temperatures and are mainly used for laying internal piping. The pipe has a structure consisting of 2 layers, outer - polypropylene, inner - polyethylene.

Polyvinyl chloride pipes are highly resistant to mechanical influences from the external environment, resistant to temperature changes, and open fire. Pipes painted orange are used for laying external pipelines, and gray ones are used for internal ones.

Types of storm drainage

Currently, there are several modifications of rainwater drainage, differing from each other in design, materials used, purpose and installation technology. The choice of any modification is most often determined by climatic conditions, terrain features and the material capabilities of the owner of the site.

Classification by type of accommodation

In the private sector, country houses and summer cottages, three main types of storm sewers are widespread:

- open;

- closed;

- mixed.

Let's consider the features and scope of each of these modifications.

Open type

This type of sewerage system is an extensive network of drainage trays located on the ground surface. Through these trays, rain and melt water enters the main drainage system of the site, where it is purified in filtering drainage wells and absorbed into the ground.

The installation of such a storm sewer requires minimal investment, is characterized by ease of installation work and efficient drainage. The presence of an open “storm drain” allows, at minimal cost, to provide reliable protection of foundations, basements, ground floors and paved paths from the harmful effects of moisture. In addition, open storm drainage allows you to create favorable conditions for growing plants and prevents waterlogging of the area.

Closed type

A closed sewer system includes an extensive network of underground communications, including funnels for collecting rain and melt water, pipelines, filter elements and storage drainage wells. Typically, the end point of a closed storm drain is a filter drainage well.

Closed rainwater drainage allows not only to effectively remove excess moisture outside the site, but also ensures high-quality wastewater treatment. Purified water can be used for irrigation or other domestic needs.

Mixed type

As the name implies, such a storm drainage system includes separate open and closed elements. Collection and transportation of wastewater to the central drainage main is carried out using trays located on the ground surface. Accumulation, filtration and disposal of wastewater outside the site occurs in the underground part of the sewer system.

The installation of a combined rainwater drainage system makes it possible to reduce the volume of earthworks, which speeds up the installation process and reduces the material costs associated with laying a drainage main.

Classification according to wastewater collection method

In terms of its design, rainwater drainage can be point or linear. Point storm drainage is characterized by the presence of several water collectors connected through pipelines to the main drainage main. As a rule, such receivers are located directly under the gutters. Most often, such systems are equipped with special protective and decorative grilles and traps of fine pollutants.

Installation of a linear system will require significantly more time and material resources. Such systems not only protect the underground part of the foundation of buildings and structures located on the site from the harmful effects of heavy rainfall and melting snow, but also ensure effective removal of moisture from the entire territory of the household.

Let us consider in detail point and linear rainwater drainage.

Spot

The point system is intended for draining water from individual areas and consists of the following main elements:

- water intakes;

- guide trays;

- settling tanks for fine pollutants;

- pipelines providing transportation of wastewater to a storage or filter well;

- storage or grouting tank.

When installing a point drainage system, it is advisable to install water intakes in places of greatest accumulation of moisture:

- in the lowlands;

- before entering the site;

- in front of the entrance doors;

- under sewer pipes fixed to the walls of the building.

Linear

The linear drainage system is more efficient and is installed in the following cases:

- the slope of the site exceeds 30;

- in the latitudes under consideration there is a large amount of precipitation in the form of rain and snow, and there is also a high probability of flooding of the area due to spills of nearby reservoirs or spring floods;

- If the property is located in a lowland or under the slope of any natural elevation.

Before proceeding with the installation of storm sewers, it is necessary to draw up a plan of the entire drainage main, with an exact indication of the location of trays, pipelines, inspection, storage and grouting wells. It is not advisable to start installation work without such a plan. In addition, the design of a storm drainage system has many subtleties, so it is better to entrust the preparation of design documentation to a specialist.

Drainage of large areas requires an extensive drainage line, the technical condition of which is monitored using inspection (inspection) wells, the distance between which depends on the diameter and slope of the pipeline. In addition, inspection wells allow for regular maintenance and cleaning of the system.

The main design parameters of rainwater drainage are regulated by SNiP (Building Norms and Rules). The most significant characteristics of a storm drainage system include:

- slope of the drainage main;

- pipeline laying depth;

- diameter of water pipes;

- materials used during installation.

What do you need to know when laying internal sewerage?

The installation of the internal system is carried out in 2 stages:

- internal sewerage;

- ventilation.

The central riser can be laid by installing pipes without additional insulation using boxes or in special niches. The central riser must be provided with inspection hatches necessary for cleaning in case of clogging of the system. The most suitable place for placing and installing a riser are toilets.

At the points of connection or branching of pipelines, tees, bends, crosses, manifolds, as well as special fittings in the form of clamps, ties, gaskets, and seals are used. The bends have a pipe inclination angle from 15* to 90* and different diameters. The connection of pipes of the external and internal systems is carried out using adapters having an angle of 90-130 *, which allows to reduce the noise of the processes taking place. The joints between the pipes are sealed using special gaskets or liners treated with a waterproof sealant.

Drain points are equipped with water seals to prevent odors from entering the premises from the sewerage system.

A ventilation system in the house is necessary to remove gases generated in the sewer network and bring fresh air into the premises. To remove accumulated gases, a drain pipe is used, which is connected to the central riser of the sewer network.

The installation of a drain pipe must meet certain requirements:

- the outlet on the roof of the vent pipe (usually 110 mm) should not freeze during periods of sub-zero temperatures;

- the height of the vent pipe protruding above the roof covering must exceed the height of other outlets (stove, ventilation, fireplace);

- the drain pipe must be located at a distance of at least 4 m from balconies and windows;

- The connection between the drain pipe and the ventilation outlet is prohibited.

- The general layout of the sewer and ventilation system depends on the area of the house, the number of floors of the building and the number of drainage points.

Fan pipelines are equipped with special vacuum valves that prevent the formation of a rarefied environment when draining water and pumping wastewater from the storage tank, which helps reduce the noise level of the system.

How the fecal sewage system works in Moscow

Modern fecal sewerage in Moscow is a complex engineering system, on the operation of which the environmental well-being of the entire city depends. It serves to drain household and municipal wastewater, which subsequently undergoes a full cleaning cycle. The main technical characteristics of the Moscow sewerage system are:

- the total length of pipelines is about 8179 km;

- total design capacity - 6.345 million m3/day;

- diameter of channels, pipes and collectors - from 12.5 cm to 4.5 m;

- the length of gravity pipelines is 227.8 km;

- length of pressure pipelines - 74.8 km;

- number of pumping stations - 49;

- number of treatment facilities - 17.

The terrain determines the direction of pipelines to the southern and southeastern parts of the city, and treated wastewater is discharged into the river. Moscow and its tributaries. Fecal wastewater is filtered at three treatment plants:

- Lyubertsy;

- Kuryanovskoe;

- Yuzhnobutovskoe.

Most engineering systems were designed in the second half of the last century. Today they are being reconstructed and improved - a targeted government program has been created for this purpose.

External sewage system

Installation of external sewerage is carried out through a special sleeve with a cross-section of 150 mm, installed in the side wall when pouring the foundation of the house. To prevent the flow of wastewater stored in the storage tank, the external pipeline is equipped with a special check valve that also prevents rodents from entering the house through the pipes.

To lay the pipeline according to the plan, a trench is laid with a depth below the soil freezing level with the laying of a sand cushion 15 cm high, which helps maintain the integrity of the pipeline during soil shifts. In the case of a high groundwater level, pipes are laid to a shallower depth with preliminary insulation of the pipes. After all installation operations of the external pipeline, the system is pressed and leaks are subsequently eliminated.

To clean the external sewerage pipeline, inspection hatches are installed, which are placed according to the rules:

- the inspection hatch is installed at the connection of the internal and external pipeline systems;

- when connecting an external pipeline to a wastewater storage tank;

- when changing the direction of the pipeline line;

- in places where additional pipeline connections are inserted.

The entire external sewage system must have a slope of 2% in relation to the storage tank. When using a special pump for pumping wastewater, installation is carried out in a horizontal plane.

What is sanitary sewerage

Household sewerage is a complex system of pipelines, sedimentation tanks and technical means for removing human waste products collected by primary devices - toilets, bathtubs, sinks. This system is designed to keep cities and small towns within sanitary standards in order to preserve the health of the population.

What is included in the maintenance of cleaning systems?

Visual inspection: open the lid and draw water from the sump into a glass container. The water should stand for 30 minutes. If 50% are dense particles, then you need to pump out a third of the sump.

If the particles make up a smaller volume, then you need to pump out a quarter of the volume of the sump.

Sewerage maintenance once a quarter:

- The installation turns off for 20 minutes;

- The station is turned on and the pipe is released from the pump (the clamp is removed, the plug is removed);

- The sludge is pumped out when the station is operating in the first mode;

- In the receiving chamber, the circuit breaker must be in the raised position;

- Fresh water is poured in in the volume that was pumped out;

- The coarse fraction filter is cleaned;

- The hair catcher is taken out and cleaned;

- The walls of the chamber are washed;

- Pumps are washed;

- The station is turned off and non-recyclable waste is removed;

- The injectors are cleaned with a needle.

The product pumped out of the reservoir serves as an excellent fertilizer; it is poured into compost.

Every six months: the membranes on the compressor are replaced.

Once a year: the compressor is checked and all components of the system are adjusted; the air filter is cleaned. Preventative work is being carried out.

Preparation for installation of external sewerage

As preparatory measures, a primary assessment of the soil is carried out: its composition and freezing depth, groundwater occurrence. Based on the data received, a project must be drawn up. The length of the outer part of the pipeline, its bends, and the location of the wells are indicated on the drawing. This will be useful in the future when carrying out repair and maintenance work.

After all the calculations, it is important to prepare the trench and lead the pipe out of the house. To do this, a hole is formed in the foundation low (15 cm below the ground level) and a steel sleeve is necessarily inserted into it. A pipe is brought out through it.

The trench is dug in accordance with the planned pattern. At the same time, maintain a bias towards the septic tank. The bottom of the trench is carefully compacted and covered with a layer of slightly damp sand. It also compacts well. If it is impossible to dig a trench for some reason (there is a building standing, there is a roadway, etc.), use the horizontal directional drilling method to lay the pipeline.