The abbreviation KGShP refers to a crank-type hot stamping press. The exceptionally high power of individual models of such equipment makes it the optimal choice for enterprises involved in the processing of scrap metal.

Hot stamping crank press with a nominal force of 14,000 tf. Used for hot stamping of crankshafts weighing up to 200 kg as part of a modern robotic line

The use of CGSP, in particular, makes it possible to successfully solve such a pressing problem for these enterprises as packaging scrap metals with low ductility (aluminum and titanium alloys, bronze, etc.). Meanwhile, purchasing a press of this type is an unaffordable luxury for the vast majority of such enterprises. The main area of application of CGShP, which are presented on the modern market in a wide variety of modifications, is to equip production facilities that produce their products in large, medium and small batches.

In the video below you can see the K8540 crank hot forging press in action.

Purpose

Hot stamping press is equipment used for forging. The process results in complex parts with projections and depressions. The equipment can produce:

- rods with flanges;

- retaining rings;

- glasses with a complex profile;

- disembarking pipe ends.

It is used for pressing scrap metal into bags that are convenient for storage and further processing. When packaging scrap, metal with low ductility is used. At large industrial enterprises, stamping presses are used for the production of serial and large-scale products. During processing, the material is heated.

K2019 image of single crank press

Photo of single crank press k2019

Photo of single crank press k2019

Photo of single crank press k2019

Design and principle of operation

The hot stamping press is designed for processing workpieces at temperatures up to 1200°C. At the same time, there are some features in the design of the equipment:

- For medium and low rated power, asynchronous electric motors are installed. At high power, the manufacturer uses synchronous units that develop a force of up to 31.5 MN.

- The rotational motion is transmitted through wedge-shaped belts.

- The main shaft that receives the movement is installed in bearing supports. On one side there is a flywheel, and on the other end there is a speed conversion mechanism for the eccentric shaft.

- On the eccentric shaft, on one side, band brakes are installed, and on the other, a clutch for engagement, which contains several friction discs.

- A brake and clutch control system is mounted on the press.

- The machine is equipped with guides for the slider.

- The open height is adjusted by a wedge that is installed on the table.

- The bed consists of several elements that are connected by heated pins.

- The fixed part of the press is mounted on the work table.

- The lubrication and monitoring system for equipment operation is installed by the manufacturer.

Principle of operation:

- The electric motor transmits movement to the flywheel and intermediate shaft.

- The clutch is activated when the set number of revolutions per minute is reached, air is supplied to it under pressure and the eccentric shaft is connected to the connecting rod.

- The brake located at the end of the main shaft is automatically released.

- The slider begins forward movement with return.

- The moving part of the die, thanks to the slider, performs the hot pressing operation.

- When the slider moves upward, the finished product is automatically ejected.

Devices for securing the workpiece and automating the process can be additionally added to the design.

Industrial equipment (Photo: Instagram / kubanzheldormash)

Presses KI-2126 KI-2326 KI-1426 single-crank open single-action presses with a force of 400 kn

Presses KI-2126 KI-2326 KI-1426 are designed to perform various operations of cold stamping of sheet material: cutting, punching, shallow drawing, etc. are widely used in any type of production: small-scale, serial, mass. have three main versions: tiltable, non-tiltable, with a mobile table and horn. The latter are designed for processing parts with a large closed die height, and are also equipped with a special table (horn) for processing parts with a closed contour

Design Features

: — The bed is cast, cast iron, box-shaped, subjected to aging to relieve internal stresses, high rigidity, maintaining precision parameters over a long service life — A rigidly interlocked clutch-brake ensures reliable stopping of the slider at TDC — Convenient adjustment of the optimal clearances between the working disks as they wear - Slider balancers, designed to eliminate the influence of the weight of the slider and the upper half of the die on the operation of the press and to prevent arbitrary lowering of the slider in emergency cases (broken connecting rod screw or studs) - Overload safety device - Wedging device for removing the press from the thrust - Central lubrication system main friction pairs - Electric locks for safe operation - Contactless control box - Motorized closed height adjustment

Equipment for a fee

: — Winding and unwinding devices — Pneumatic cushion — Device for feeding tape material — Pneumatic blower — Scissors for cutting tape waste — Assembly and lubricant recycling system

Technical characteristics of crank presses KI2126 KI2326 KI1426

| Options | Ab model | ||

| press KI-2126 | press KI-2326 | press KI-1426 | |

| Nominal force, kN | 400 | 400 | 400 |

| Slider stroke adjustable, maximum, mm | 90 | 90 | 90 |

| Slider stroke adjustable, smallest, mm | 10 | 10 | 10 |

| Slider stroke frequency, continuous, unregulated, min-1 | 160 | 160 | 160 |

| Slider stroke frequency, single, min-1 | 56 | 56 | 56 |

| Table dimensions, left to right, mm | 630 | 630 | 630 |

| Table dimensions, front to back, mm | 460 | 460 | 460 |

| Distance from the axis of the slider to the frame, mm | 250 | 250 | 250 |

| The greatest distance between the table and the slider in its lower position at the greatest stroke, mm | |||

| fixed table presses | 300 | 300 | |

| presses with mobile table | |||

| with the table in the upper position | 200 | ||

| with the table in the lower position | 500 | ||

| Clear distance between bed posts, mm | 280 | 280 | |

| Thickness of the die plate, mm | 80 | 80 | 80 |

| Dimensions of the bottom surface of the slider, from left to right, mm | 400 | 400 | 400 |

| Dimensions of the bottom surface of the slide, front-to-back, mm | 285 | 285 | 285 |

| Air pressure in the press network, MPa, not less | 0,35 | 0,35 | 0,35 |

| Air pressure in the factory network, MPa, not less | 0,8 | 0,8 | 0,8 |

| Compressed air consumption (in single stroke mode), liter/cycle | 0,9 | 0,9 | 0,9 |

| Dimensions of the hole in the slide for the stamp shank, diameter, mm | 50N9 | 50N9 | 50N9 |

| Dimensions of the hole in the slide for the stamp shank, depth, mm | 70 | 70 | 70 |

| The greatest distance between the axis of the hole for the horn and the slider in its lower position at the greatest stroke, mm | 259 | ||

| Maximum stroke of the ejector in the slide, mm | 35 | 35 | 35 |

| Angle of inclination of the bed, degrees | 30 | ||

| Drive electric motor power, kW pr PV=40% | 6,3 | 6,3 | 6,3 |

| Technological work, with continuous strokes, J | 400 | 400 | 400 |

| Technological work, with single strokes, J | 800 | 800 | 800 |

| Overall dimensions, mm | |||

| from left to right | 1400 | 1400 | 1400 |

| front to back | 1500 | 1720 | 1500 |

| height | 2700 | 2800 | 2870 |

| Weight, kg | 3450 | 3545 | 3970 |

Varieties

Classification by purpose:

- equipment for the manufacture of parts from sheet raw materials;

- press for long products;

- machines for cutting rods and metal sheets.

Depending on the structural structure, there are two types of presses:

- Simple action. The design of such stamps uses one working part. If necessary, they are equipped with an automatic workpiece feeding system.

- Multiple action. They contain several working parts and additional elements. The entire process is performed in strict sequence established by the manufacturer.

Information about the manufacturer of the single crank press K2019

The K2019 press was produced by the Kursk Forging and Pressing Equipment Plant , founded in 1943.

Currently, the K2019 single-crank press is produced by PRESSMASH SO LLC, Moscow

Machine tools produced by the Kursk Forging and Press Equipment Plant

- K2019

single-crank press, single action, open, non-tilting, 80 kN - KD2114

single-crank press, single action, open, non-tilting, 25 kN - KD2118

single-crank press, single-action, open, non-tilting, 63 kN - KD2318

single-crank single-action open tilting press 63 kN

Selection principles

When purchasing crank hot stamping presses, consider:

- the maximum force achieved by the working mechanism;

- number of slider movements per minute;

- maximum workpiece dimensions;

- electric motor power;

- dimensions of the machine, which must correspond to the room.

Advantages and disadvantages

Advantages:

- increased accuracy of finished products;

- increase in productivity relative to similar hammers by 35%;

- the use of prefabricated structures as a result of the processing technology;

- high reliability of all components;

- reducing the cost of manufacturing one product.

In addition to its advantages, the press also has disadvantages:

- no redistribution of metal along the axis of the part;

- increase in the number of streams;

- complexity of equipment design;

- parts after processing need additional cleaning from scale;

- high price.

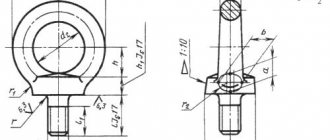

K2019 Dimensions of the crank press die plate

Dimensions of the crank press die plate K2019

Diagram of permissible forces of a single-crank press by 2019

Exploitation

When operating hot stamping equipment, it is recommended to observe the following rules:

- the press is equipped with a brake that stops the slide after the stamping operation is completed;

- it is forbidden to allow critical overloads, since the machine may fail;

- it is necessary to use a special device to eliminate jamming of the slider;

- It is not allowed to apply forces higher than nominal;

- it is necessary to install a movement blocking system on the equipment in case of malfunctions;

- the press is equipped with a shock absorber to prevent the slide from hitting the frame if the brake is not applied in a timely manner;

- a device is installed in the design to block the movement of the slider during repair and adjustment work.

Compliance with the requirements of safe operation will allow you to perform the stamping operation quickly and efficiently. In Russia, stamps are made in Voronezh at a machine tool plant. Also, many enterprises are engaged in major repairs of equipment and further sale to consumers. In addition to domestic manufacturers, hot forging presses are manufactured in Europe and Asia. The cost depends on the size and configuration of the equipment.

Presses KI-2128 KI-2328 KI-1428 single-crank open single-action presses with a force of 630 kn

Presses KI-2128 KI-2328 KI-1428 are designed to perform various cold stamping operations of sheet material: cutting, punching, shallow drawing, etc. are widely used in any type of production: small-scale, serial, mass. have three main versions: tiltable, non-tiltable, with a mobile table and horn. The latter are designed for processing parts with a large closed die height, and are also equipped with a special table (horn) for processing parts with a closed contour

Design Features:

— The bed is cast, cast iron, box-shaped, subjected to aging to relieve internal stresses, high rigidity, maintaining precision parameters over a long service life — A rigidly interlocked clutch-brake ensures reliable stopping of the slider at TDC — Convenient adjustment of the optimal clearances between the working disks as they wear out — Slider balancers are designed to eliminate the influence of the weight of the slider and the upper half of the die on the operation of the press and to prevent arbitrary lowering of the slider in emergency cases (breakage of the connecting rod screw or studs) — Overload protection — Wedging device for removing the press from the thrust — Central lubrication system for the main parts friction pairs - Electrical interlocks for safe operation - Contactless control box - Motorized closed height adjustment

Equipment for a fee

— Winding and unwinding devices — Pneumatic cushion — Device for feeding tape material — Pneumatic blower — Scissors for cutting tape waste — Assembly and lubricant recycling system

Technical characteristics of crank presses KI2128 KI2328 KI1428

| Options | Ab model | ||

| press KI-2128 | press KI-2328 | press KI-1428 | |

| Nominal force, kN | 630 | 630 | 630 |

| Slider stroke adjustable, maximum, mm | 100 | 100 | 100 |

| Slider stroke adjustable, smallest, mm | 10 | 10 | 10 |

| Slider stroke frequency, continuous, unregulated, min-1 | 140 | 140 | 140 |

| Slider stroke frequency, single, min-1 | 45 | 45 | 45 |

| Table dimensions, left to right, mm | 800 | 800 | 800 |

| Table dimensions, front to back, mm | 560 | 560 | 560 |

| Distance from the axis of the slider to the frame, mm | 300 | 300 | 300 |

| The greatest distance between the table and the slider in its lower position at the greatest stroke, mm | |||

| fixed table presses | 340 | 340 | 340 |

| presses with mobile table | |||

| with the table in the upper position | 240 | ||

| with the table in the lower position | 530 | ||

| Clear distance between bed posts, mm | 340 | 340 | |

| Thickness of the die plate, mm | 85 | 85 | 85 |

| Dimensions of the bottom surface of the slider, from left to right, mm | 450 | 450 | 450 |

| Dimensions of the bottom surface of the slide, front-to-back, mm | 310 | 310 | 310 |

| Air pressure in the press network, MPa, not less | 0,35 | 0,35 | 0,35 |

| Air pressure in the factory network, MPa, not less | 0,8 | 0,8 | 0,8 |

| Compressed air consumption (in single stroke mode), liter/cycle | 1,6 | 1,6 | 1,6 |

| Dimensions of the hole in the slide for the stamp shank, diameter, mm | 50N8 | 50N8 | 50N8 |

| Dimensions of the hole in the slide for the stamp shank, depth, mm | 75 | 75 | 75 |

| The greatest distance between the axis of the hole for the horn and the slider in its lower position at the greatest stroke, mm | 280 | ||

| Maximum stroke of the ejector in the slide, mm | 50 | 50 | 50 |

| Angle of inclination of the bed, degrees | 30 | ||

| Drive electric motor power, kW pr PV=40% | 8,5 | 8,5 | 8,5 |

| Technological work, with continuous strokes, J | 800 | 800 | 800 |

| Technological work, with single strokes, J | 1600 | 1600 | 1600 |

| Overall dimensions, mm | |||

| from left to right | 1530 | 1530 | 1530 |

| front to back | 1680 | 1830 | 1680 |

| height | 3000 | 3100 | 3150 |

| Weight, kg | 6275 | 6410 | 6790 |

Location of the main components of the K2019 single-crank press

Location of the main components of a single-crank press by 2019

- Bed K2019-11-001

- Drive K2019-21-001

- Eccentric shaft K2019-23-001

- Command apparatus - K2019-24-001

- Installation of clutch-brake K2019-26-001

- Slider K2019-31-001

- Air duct KE2118.01-41-001

- Drive guard K2019-71-001

- Command apparatus fencing - KE2114.01-72-001

- Work area fencing -

- Electrical equipment K2019-91-001

- Push-button control station KE2114.01-92-00

- Flywheel -

- Pneumatic blower

Kinematic diagram of single-crank press K2019

Kinematic diagram of the K2019 single-crank press

List of kinematic diagram elements

- Electric motor

- Drive pulley

- Drive flywheel

- Clutch-brake

- Eccentric shaft

- screw

- Eccentric bushing

- connecting rod

- Adjustment screw

- Crawler

- Ejector stop

- Ejector bar

- Air supply head

- Bearing

- Bearing

- Bearing

Location of controls for single crank press K2019

Location of controls for single crank press K2019

- Pedal

- Input switch

- Operating mode switch

- Counter

- Light signaling

- Local lighting switch

- Button "Stop continuous strokes"

- "General stop" button

- Button "Start electric motor"

- Buttons "Slider stroke" (Two-handed activation)

Technical characteristics of the K2019 press

Technical characteristics of the single crank press K2019

Technical characteristics of the single crank press K2019