Glass made of metal

Specialists from the California Institute of Technology have obtained a material that is unique in its properties - the strongest alloy to date - “metallic glass”. The uniqueness of the new alloy is that metallic glass is made of metal, but has the internal structure of glass. Today, scientists are figuring out what exactly gives the alloy such unusual properties and how they can be introduced into alloys made from less expensive materials.

The amorphous structure of glass, unlike the crystalline structure of metal, is not protected from the propagation of cracks, which explains the fragility of glass. Metal glasses also have the same disadvantage, which also break quite easily, forming shear bands that develop into cracks.

Alloy properties

Specialists from the Californian Institute noticed that the appearance of a large number of shear bands provides high resistance to the development of cracks, due to which the opposite effect is achieved: the material bends without collapsing. It is precisely this material, the energy of producing shear bands that is much less than the energy required to turn them into cracks, that they created. “By mixing five elements, we ensured that when cooled, the material “does not know” which structure to adopt and chooses an amorphous one,” explained study participant R. Ritchie.

Metal glass

The most durable alloy - metallic glass - consists of noble palladium, silicon, phosphorus, germanium with a small addition of silver (formula: Pd79Ag3.5P6Si9.5Ge2).

The new alloy showed itself in tests as a combination of mutually exclusive properties - strength and endurance at a level not previously seen in any other material. As a result, the new metallic glass combines the hardness of glass with the crack resistance of metals. Moreover, the level of rigidity and strength is within reach.

Use of material

For structural metal, the research carried out has significantly pushed back the limits of load tolerance. But, according to scientists’ forecasts, the most durable alloy may not be widely used, due to the rarity and high cost of its main component, palladium. However, developers have reported possible use of this material in medical implants (for example, for intramaxillary prostheses), as well as parts in the automotive or aerospace industries.

Our world is full of amazing facts that are interesting to many people. The properties of various metals are no exception. Among these elements, of which there are 94 in the world, there are the most ductile and malleable, and there are also those with high electrical conductivity or a high resistance coefficient. This article will talk about the hardest metals, as well as their unique properties.

Iridium ranks first in the list of metals that are distinguished by the greatest hardness. It was discovered at the beginning of the 19th century by the English chemist Smithson Tennant. Iridium has the following physical properties:

- has a silvery-white color;

- its melting point is 2466 o C;

- boiling point – 4428 o C;

- resistance – 5.3·10−8Ohm·m.

Because iridium is the hardest metal on the planet, it is difficult to process. But it is still used in various industrial fields. For example, it is used to make small balls that are used in pen nibs. Iridium is used to make components for space rockets, some parts for cars, and more.

Very little iridium occurs in nature. Findings of this metal are a kind of evidence that meteorites fell in the place where it was discovered. These cosmic bodies contain significant amounts of metal. Scientists believe that our planet is also rich in iridium, but its deposits are closer to the Earth's core.

The second position on our list goes to ruthenium. The discovery of this inert silvery metal belongs to the Russian chemist Karl Klaus, which was made in 1844. This element belongs to the platinum group. It is a rare metal. Scientists have been able to establish that there is approximately 5 thousand tons of ruthenium on the planet. It is possible to extract approximately 18 tons of metal per year.

Due to its limited quantity and high cost, ruthenium is rarely used in industry. It is used in the following cases:

- a small amount of it is added to titanium to improve corrosion properties;

- its alloy with platinum is used to make electrical contacts that are highly resistant;

- ruthenium is often used as a catalyst for chemical reactions.

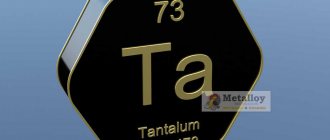

A metal called tantalum, discovered in 1802, takes third place on our list. It was discovered by the Swedish chemist A. G. Ekeberg. For a long time it was believed that tantalum is identical to niobium. But the German chemist Heinrich Rose managed to prove that these are two different elements. Scientist Werner Bolton from Germany was able to isolate tantalum in its pure form in 1922. This is a very rare metal. The largest deposits of tantalum ore were discovered in Western Australia.

Due to its unique properties, tantalum is a highly sought-after metal. It is used in various fields:

- in medicine, tantalum is used to make wire and other elements that can hold tissue together and even act as a bone substitute;

- alloys with this metal are resistant to aggressive environments, which is why they are used in the manufacture of aerospace equipment and electronics;

- tantalum is also used to create energy in nuclear reactors;

- the element is widely used in the chemical industry.

Chromium is one of the hardest metals. It was discovered in Russia in 1763 in a deposit in the Northern Urals. It has a bluish-white color, although there are cases where it is considered a black metal. Chrome cannot be called a rare metal. The following countries are rich in its deposits:

- Kazakhstan;

- Russia;

- Madagascar;

- Zimbabwe.

There are chromium deposits in other countries as well. This metal is widely used in various branches of metallurgy, science, mechanical engineering and others.

The fifth position in the list of the hardest metals goes to beryllium. Its discovery belongs to the chemist Louis Nicolas Vauquelin from France, which was made in 1798. This metal has a silvery-white color. Despite its hardness, beryllium is a brittle material, which makes it very difficult to process. It is used to create high-quality loudspeakers. It is used to create jet fuel and refractory materials. The metal is widely used in the creation of aerospace technology and laser systems. It is also used in nuclear energy and in the manufacture of X-ray equipment.

The list of the hardest metals also includes osmium. It is an element belonging to the platinum group, and its properties are similar to iridium. This refractory metal is resistant to aggressive environments, has a high density, and is difficult to process. It was discovered by the scientist Smithson Tennant from England in 1803. This metal is widely used in medicine. Elements of pacemakers are made from it, and it is also used to create the pulmonary valve. It is also widely used in the chemical industry and for military purposes.

The transition silver metal rhenium takes the seventh position on our list. The assumption about the existence of this element was made by D.I. Mendeleev in 1871, and chemists from Germany managed to discover it in 1925. Just 5 years after this, it was possible to establish the extraction of this rare, durable and refractory metal. At that time, it was possible to obtain 120 kg of rhenium per year. Now the amount of annual metal production has increased to 40 tons. It is used for the production of catalysts. It is also used to make electrical contacts that can self-clean.

Silver-gray tungsten is not only one of the hardest metals, it also leads in refractoriness. It can only be melted at a temperature of 3422 o C. Thanks to this property, it is used to create incandescent elements. Alloys made from this element have high strength and are often used for military purposes. Tungsten is also used to make surgical instruments. It is also used to make containers in which radioactive materials are stored.

One of the hardest metals is uranium. It was discovered in 1840 by the chemist Peligo. D.I. Mendeleev made a great contribution to the study of the properties of this metal. The radioactive properties of uranium were discovered by the scientist A. A. Becquerel in 1896. Then a chemist from France called the detected metal radiation Becquerel rays. Uranium is often found in nature. The countries with the largest deposits of uranium ore are Australia, Kazakhstan and Russia.

The final place in the top ten hardest metals goes to titanium. For the first time this element was obtained in its pure form by the chemist J. Ya. Berzelius from Sweden in 1825. Titanium is a lightweight silver-white metal that is highly durable and resistant to corrosion and mechanical stress. Titanium alloys are used in many branches of mechanical engineering, medicine and the chemical industry.

From childhood we know that the strongest metal is steel. We associate everything iron with it.

Iron man, iron lady, character of steel. When we pronounce these phrases, we mean incredible strength, strength, hardness.

For a long time, steel was the main material in production and armament. But steel is not metal. More precisely, it is not entirely pure metal. This is with carbon, in which other metal additives are present. By using additives, e.g. change its properties. After this, it is processed. Steelmaking is a whole science.

The strongest metal is obtained by introducing appropriate alloys into steel. This could be chromium, which imparts heat resistance, nickel, which makes the steel hard and elastic, etc.

In some areas, steel has begun to replace aluminum. Time passed, speeds increased. Aluminum couldn't stand it either. I had to turn to titanium.

Yes, yes, titanium is the strongest metal. To give steel high strength characteristics, titanium began to be added to it.

It was discovered in the 18th century. Due to its fragility, it was impossible to use. Over time, having obtained pure titanium, engineers and designers became interested in its high specific strength, low density, resistance to corrosion and high temperatures. Its physical strength exceeds the strength of iron several times.

Engineers began adding titanium to steel. The result is the most durable metal, which has found application in ultra-high temperature environments. At that time, no other alloy could withstand them.

If you imagine an airplane flying three times faster than you can imagine how the covering metal heats up. The sheet metal of the aircraft skin in such conditions heats up to +3000C.

Today, titanium is used unlimitedly in all areas of production. These are medicine, aircraft manufacturing, ship production.

It is clear that titanium will have to move in the near future.

Scientists from the USA, in the laboratories of the University of Texas in Austin, discovered the thinnest and most durable material on Earth. They called it graphene.

Imagine a plate whose thickness is equal to the thickness of one atom. But such a plate is stronger than diamond and conducts electric current a hundred times better than computer chips made of silicon.

Graphene is a material with damaging properties. It will soon leave the laboratory and rightfully take its place among the most durable materials in the Universe.

It is even impossible to imagine that a few grams of graphene would be enough to cover a football field. This is metal. Pipes made of such material can be laid manually without the use of lifting and transport mechanisms.

Graphene, like diamond, is the purest carbon. Its flexibility is amazing. This material bends easily, folds perfectly and rolls perfectly.

Manufacturers of touch screens, solar panels, cell phones, and, finally, super-fast computer chips have already begun to look at it.

When they talk about the strongest metals in the world

, I immediately remember a medieval knight with a sword at the ready and in armor made of the legendary Damascus steel. It is this that many rightly consider to be the hardest, most durable, resistant to mechanical or chemical influences. But steel is not pure metal; it consists of several components that have been processed to change the final properties of the finished product. Consequently, it cannot be called a substance with the highest hardness. What metal is the strongest on the planet?

Titanium

This unusually beautiful silver-white metal was discovered almost simultaneously at the end of the 18th century by two scientists - the Englishman W. Gregory and the German M. Klaproth. According to one version, titanium got its name in honor of the characters of ancient Greek myths, the mighty Titans; according to another, from Titania, the fairy queen from German mythology, because of its lightness. However, no use was found for it then.

Then in 1925, physicists in Holland were able to isolate pure titanium and discovered its many benefits. These are high indicators of manufacturability, specific strength and resistance to corrosion, very high strength at high temperatures. It also has high anti-corrosion resistance. These fantastic performance immediately attracted engineers and designers.

In 1940, the scientist Krol obtained pure titanium using the magnesium-thermal method, and since then this method has been the main one. The strongest metal on earth is mined in many places in the world - Russia, Ukraine, China, South Africa and others.

Titanium is twice as strong as iron in mechanical terms, and six times stronger than aluminum. Titanium alloys are currently the strongest in the world, and therefore have found application in the military (submarine, missile construction), shipbuilding and aviation industries (on supersonic aircraft).

This metal is also incredibly malleable, so it can be made into any shape - sheets, pipes, wire, tape. Titanium is widely used for the manufacture of medical prostheses (and it is biologically ideally compatible with the tissues of the human body), jewelry, sports equipment, etc.

It is also used in chemical production due to its anti-corrosion properties; this metal does not corrode in an aggressive environment. So, for testing purposes, a titanium plate was placed in sea water, and after 10 years it did not even rust!

Due to its high electrical resistance and non-magnetizing properties, it is widely used in radio electronics, for example, in structural parts of mobile phones. The use of titanium in the field of dentistry is very promising; its ability to fuse with human bone tissue is especially important, which gives strength and solidity in prosthetics. It is widely used in the manufacture of medical instruments.

How are the properties of metals determined?

To test metals for strength, chemical, physical and technological methods are used. Hardness determines how materials resist deformation. Resistant metal has greater strength and parts made from it wear out less. To determine hardness, a ball, diamond cone or pyramid is pressed into the metal. The hardness value is determined by the diameter of the imprint or the depth of indentation of the object. Stronger metal is less deformed and the depth of the imprint will be shallower.

But tensile samples are tested on tensile testing machines with a load that gradually increases during stretching. The standard can have a circle or square cross-section. To test the metal to withstand impact loads, impact tests are carried out. An incision is made in the middle of a specially made sample and placed opposite the impact device. Destruction must occur where the weak point is. When testing metals for strength, the structure of the material is examined using X-rays, ultrasound and powerful microscopes, and etching with chemicals is also used.

Technological tests include the simplest types of tests for destruction, ductility, forging, and welding. The extrusion test makes it possible to determine whether a sheet material is capable of cold forming. Using a ball, a hole is pressed into the metal until the first crack appears. The depth of the hole before fracture occurs will characterize the plasticity of the material. The bend test makes it possible to determine the ability of sheet material to take the desired shape. This test is used to evaluate the quality of welding seams. To assess the quality of the wire, a bend test is used. Pipes are tested for flattening and bending.

Uranus

The natural oxidizing properties of uranium were used in antiquity (1st century BC) in the production of yellow glaze in ceramic products. One of the most well-known durable metals in world practice, it is weakly radioactive and is used in the production of nuclear fuel. The 20th century was even called the “age of Uranus.” This metal has paramagnetic properties.

Uranium is 2.5 times heavier than iron, forms many chemical compounds; its alloys with elements such as tin, lead, aluminum, mercury, and iron are used in production.

No. 6 – Iridium

This metal was discovered simultaneously with the above-mentioned osmium, and its high concentration in the rock indicates its cosmic origin, that is, iridium and osmium fell to Earth along with meteorites. It is not used in its pure form, but is added to alloys, for example, to platinum, and makes products from it - be it jewelry or rocket parts - almost eternal. Iridium costs about $50 per gram.

Tungsten

This is not only the strongest metal in the world, but also a very rare one, which is not even mined anywhere, but was obtained chemically back in 1781 in Sweden. The most temperature-resistant metal in the world. Due to its high refractoriness, it lends itself well to forging, and it can be pulled into a thin thread.

Its best known use is as tungsten filament in light bulbs. Widely used for the production of special instruments (incisors, cutters, surgical) and in jewelry production. Due to its property of not transmitting radioactive rays, it is used to produce containers for storing nuclear waste. Tungsten deposits in Russia are located in Altai, Chukotka, and the North Caucasus.

Tantalum

Tantalum deserves bronze in the ranking, as it is one of the strongest metals in the world. It is a silvery metal with high hardness and atomic density. Due to the formation of an oxide film on its surface, it has a leaden tint.

The distinctive properties of tantalum are high strength, refractoriness, resistance to corrosion, and resistance to aggressive environments. The metal is a fairly ductile metal and can be easily machined. Today tantalum is successfully used:

- in the chemical industry;

- during the construction of nuclear reactors;

- in metallurgical production;

- when creating heat-resistant alloys.

Osmium

The heaviest element, for example, a kilogram of osmium, looks like a ball that easily fits in your hand. It belongs to the platinum group of metals and is several times more expensive than gold. It got its name because of the bad smell during a chemical reaction carried out by the English scientist S. Tennant in 1803.

Externally it looks very beautiful: shiny silver crystals with a blue and cyan tint. It is usually used as an additive to other metals in industry (high-strength ceramic-metal cutters, medical knife blades). Its non-magnetic and durable properties are used in the manufacture of high-precision instruments.

Mechanical properties of metals and alloys

The mechanical properties of metal materials include the following:

- Strength. It lies in the ability of a material to resist destruction under the influence of external forces. The type of strength depends on how external forces act. It is divided into: compression, tension, torsion, bending, creep, fatigue.

- Plastic. This is the ability of metals and their alloys to change shape under load without being destroyed, and to retain it after the end of the impact. The ductility of a metal material is determined by stretching it. The more elongation occurs, while the cross-section decreases, the more ductile the metal. Materials with good plasticity are perfectly processed by pressure: forging, pressing. Plasticity is characterized by two quantities: relative narrowing and elongation.

- Hardness. This quality of the metal lies in its ability to resist the penetration of a foreign body that has greater hardness into it, without resulting in residual deformations. Wear resistance and strength are the main characteristics of metals and alloys, which are closely related to hardness. Materials with such properties are used for the manufacture of tools used for metal processing: cutters, files, drills, taps. Often, the hardness of a material determines its wear resistance. Thus, hard steels wear out less during operation than softer grades.

- Impact strength. The peculiarity of alloys and metals is to resist the influence of loads accompanied by impact. This is one of the important characteristics of the material from which parts that experience impact loads are made during machine operation: wheel axles, crankshafts.

- Fatigue. This is the state of a metal that is under constant stress. Fatigue of the metal material occurs gradually and can result in the destruction of the product. The ability of metals to resist failure due to fatigue is called endurance. This property depends on the nature of the alloy or metal, the state of the surface, the nature of the processing, and operating conditions.

Beryllium

It was obtained by chemist Paul Lebeau at the end of the 19th century. At first, this metal was nicknamed “sweet” because of its candy-like taste. Then it turned out that it has other attractive and original properties, for example, it does not want to enter into any chemical reactions with other elements with rare exceptions (halogen).

The strongest metal in the world is at the same time hard, brittle, light, and also highly toxic. Its exceptional strength (for example, a wire with a diameter of 1 mm can support the weight of a person) is used in laser and space technology, and nuclear energy.

Which precious metal is better to invest in?

When an investor wants to invest money in precious metals conveniently and profitably, he has to discard the rare and difficult to sell rhodium, ruthenium, iridium and osmium. That leaves what I call the “big four”: gold, silver, platinum and palladium. To figure out which metal is better to invest in, first let’s compare their returns over a long period of time:

palladium immediately catches your eye . This metal has significantly pulled away from gold and the rest over the past few years. The high yield of palladium is its big plus, but pay attention to 2000 - palladium reached the 1700% yield mark and fell sharply, by 80%. The risks of investing in this metal are high, despite the fact that in the current realities it is a scarce metal that is in great demand in the automotive industry.

Gold was in second place, its chart is much calmer than that of palladium, the biggest price collapse happened in 1980 - then all precious metals suffered. In 2013, after the end of ten years of growth, the drawdown in profitability was 35%. It is in gold that countries prefer to keep their financial reserves, this says a lot.

In third place is platinum . This is not visible on the chart, but it has long been the most expensive precious metal. That all changed in 2015, when demand for platinum began to fall due to a scandal with diesel car manufacturers. In addition, due to stricter environmental requirements, platinum has been replaced by cheaper and more efficient palladium. In general, the platinum market is going through hard times, although there are prospects - palladium has become too expensive, and in some industries it can be easily replaced by platinum.

The precious metal with the worst result is silver . Despite this, silver loves to follow gold and works well as a substitute for it - the charts correlate by 90%. However, when markets are doing well and precious metals are in a bearish trend, silver falls much more than gold. In some ways, this is even a plus, because silver can provide higher returns in any direction of the trend. Bottom line, silver is not a great long-term investment, but buying/selling it at the right time can be much more profitable.

We looked at the potential profitability of four precious metals, but to complete the picture we need to compare investment risk indicators:

In all respects except profitability, gold confidently wins. Palladium and silver are the riskiest, but palladium is 3 times more profitable. Perhaps it is worth taking into account the differences in the structure of demand: silver is half an investment metal, palladium is completely industrial - the cycles of rising and falling prices do not coincide. Platinum's performance is average compared to other precious metals.

Obviously, gold is the best choice for long-term investment in precious metals. A metal briefcase also has a right to life, but not all of them fit well together.

Article on the topic: Rules for proper portfolio diversification

For example, gold and silver in a portfolio will behave the same due to high correlation, this will only increase risks. The best companion for gold is platinum or palladium, as they have high industrial demand and will rise for other reasons.

Well, we have figured out the features of four precious metals, now we can move on to specifics - which metal is more profitable to invest in right now and why.

The most resistant metal

Iridium is considered the most resistant metal - it cannot be dissolved in any acid. Due to its durability, this metal is used by the International Bureau of Weights and Measures - the kilogram standard is created from it. This iridium cylinder is necessary so that all countries have a common idea of exactly how much a kilogram should weigh. This is important because any deviation can cause malfunctions in planes and ships and, subsequently, a serious disaster.

Iridium is an indicator of how much a kilogram should weigh

Iridium is also used in making money. For example, the African country of Rwanda issued an iridium coin with a face value of 10 Rwandan francs. We can say that this is the most chemical-resistant coin. The only way to damage it is by throwing it into a vessel with fluorine, a strong oxidizing agent. But the destructive reaction will begin only when heated to 450 degrees Celsius.

The most liquid metal

Mercury is considered the most liquid metal and, at the same time, one of the most dangerous for the human body. It is almost always in a liquid state, because its melting point is -38 degrees Celsius. This is why this metal is used in thermometers - as the temperature increases, the liquid expands. Since the thermometer is made in the form of a glass tube, it can only expand in one direction. To prevent other conditions such as atmospheric pressure from affecting the thermometer readings, air is pumped out of the tube.

Despite its dangers, mercury is used even in everyday things

In the Middle Ages, it was believed that by mixing mercury, sulfur and the mysterious “philosopher’s stone”, pure gold could be obtained. Therefore, a lot of attention was paid to this metal. Since the Middle Ages, no one has been able to obtain gold from mercury, but scientists did it in 1947 - they placed 100 milligrams of mercury in a nuclear reactor and obtained 35 micrograms of gold. Here is the second amazing property of mercury - it can be turned into gold, but this is a very expensive process.

The lightest metal

The title of lightest metal rightfully goes to lithium. It is painted silver-white and is so soft that it can be easily cut with a knife. Since it is the lightest metal on the periodic table, when it enters water it floats to the surface.

And here it is - lithium

For many, this may be a revelation, but you can hold a device with lithium in your hand right now - this is your smartphone. Mobile devices use lithium batteries, which are compact but only last a few days on a single charge. Scientists are trying to improve the performance of lithium-ion batteries, but so far they have not succeeded.

Perhaps in the future, completely different batteries will be used instead of lithium-ion batteries. Which? Read in this material.

The rarest metal

Francium is the rarest metal. According to scientists' calculations, its concentration in the earth's crust is only 340 grams. It is possible to obtain more uranium artificially, but this requires starting nuclear reactions.

Francium is very rare and rarely used

Francium is very radioactive, so at the moment it is practically not used anywhere. However, sometimes scientists still use varieties of francium in the course of scientific research. There have also been attempts to diagnose cancer using technologies where francium was also involved.

If you are interested in science and technology news, subscribe to our Telegram channel. There you will find announcements of the latest news from our site!

The hardest metal

Titanium is considered the hardest and lightest metal on our planet. Due to its properties, it is actively used in aviation and shipbuilding - the material is excellent for the manufacture of aircraft and ship hulls. In addition, due to its strength and lightness, body armor is made from titanium. This metal is safe for the human body, therefore it is often used in medicine for the manufacture of instruments and even prostheses - artificial body parts.

Due to its outstanding properties, the word “titanium” is used to describe video cards and other electronics to emphasize their power.

When heated, titanium begins to absorb oxygen, chlorine, nitrogen and other gases. Thanks to this amazing property, the metal is used in various filters - passing various gases through titanium tubes heated to 600 degrees Celsius, you can clean them of impurities. In the same way, you can purify water from oxygen, which is especially useful in the food industry. It is believed that the oxygen contained in water degrades the quality of some products - at a minimum, it can shorten the shelf life of beer.