Metals are a type of materials that have been used by humans since ancient times. This group of substances is very numerous, but they all have common physical characteristics, which are commonly called metallic properties.

Hardness is common among them, but not decisive. Others are more specific, which even the softest metal has. These properties are determined by the features of their structure at the molecular level.

Properties of metals

Iron and its alloys (steel, cast iron), copper, aluminum... The use of these materials marked breakthroughs in scientific and technological progress at different stages of the development of civilization. Each of these metals has characteristics that give it unique practical value. Common features for them are high thermal and electrical conductivity, plasticity - the ability to maintain integrity during deformation, metallic luster.

A damask blade that cuts through iron armor, and the softest metal, on which traces remain from the slightest impact, have a similar internal structure. It is based on a crystal lattice, at the nodes of which there are atoms with a positive and neutral charge, between which there is an “electron gas” - particles that have left the outer shells of the atoms due to a weakening of the bond with the nucleus. A special metallic bond between positive ions located at the nodes of the crystal lattice is carried out due to the attractive forces arising in the “electron gas”. The hardness, density, and melting point of the metal depend on the con.

Purpose of soft metal

From a biological point of view, this metal does not have a special role. But ever since it was first discovered (in 1875), gallium has been used in microelectronics. It is also widely used in pharmaceutical production. Nowadays, gallium arsenide is used to create microwave circuits and infrared applications.

In addition to the fact that this metal is recognized as the softest, it is also expensive. For example, in 2005, for 1000 kilograms of this metal, buyers had to shell out a little more than one million dollars.

Criteria for evaluation

The answer to the question of which metal is the softest will always be a subject of discussion unless the evaluation criteria are agreed upon and the very concept of softness is defined. Opinions about this material characteristic will vary among specialists in different industries. A metallurgist may understand softness as increased malleability, a tendency to accept deformations from abrasive materials, etc.

It is important for materials scientists to be able to objectively compare different characteristics of substances. Softness should also have generally accepted evaluation criteria. The softest metal in the world must have generally recognized indicators proving its “record” characteristics. There are several techniques whose purpose is to measure the softness of various materials.

Measurement methods

Most certified methods for measuring hardness are based on the contact effect on the test material from a harder body called an indenter, measured using precision instruments. Depending on the type of indenter and the measurement methods, there are several main methods:

- Brinell method. The diameter of the imprint left by a metal ball when pressed into the surface of the test substance is determined.

- Rockwell method. The depth of indentation into the surface of the ball or diamond cone is measured.

— Vickers method. The area of the imprint left by the diamond tetrahedral pyramid is determined.

— Shore hardness. There are scales for very hard and very soft materials - the depth of immersion of a special needle or the height of rebound from the surface of a special striker is measured.

Mohs hardness scale

This scale for determining the relative hardness of minerals and metals was proposed at the beginning of the 19th century by the German Friedrich Mohs. It is based on the scratching method, where a harder sample leaves a mark on a softer one, and is very convenient for finding out which metal is the softest. In relation to 10 reference minerals, which are assigned a conditional hardness index, the place on the scale and a digital index are determined for the test substance. The softest reference mineral is talc. It has a Mohs hardness of 1, and the hardest, diamond, is 10.

Hardness is assessed on the Mohs scale according to the “softer - harder” principle. It is possible to determine exactly how many times, for example, aluminum, which has an index on the Mohs scale of 2.75, is softer than tungsten (6.0), only by having measurement results based on other methods. But to determine the softest metal in the periodic table, this table is quite enough.

The softest metal in the world

Metals are a type of materials that have been used by humans since ancient times. This group of substances is very numerous, but they all have common physical characteristics, which are commonly called metallic properties. Hardness is common among them, but not decisive. Others are more specific, which even the softest metal has. These properties are determined by the features of their structure at the molecular level.

Properties of metals

Iron and its alloys (steel, cast iron), copper, aluminum... The use of these materials marked breakthroughs in scientific and technological progress at different stages of the development of civilization. Each of these metals has characteristics that give it unique practical value. Common features for them are high thermal and electrical conductivity, plasticity - the ability to maintain integrity during deformation, metallic luster.

A damask blade that cuts through iron armor, and the softest metal, on which traces remain from the slightest impact, have a similar internal structure. It is based on a crystal lattice, at the nodes of which there are atoms with a positive and neutral charge, between which there is an “electron gas” - particles that have left the outer shells of the atoms due to a weakening of the bond with the nucleus. A special metallic bond between positive ions located at the nodes of the crystal lattice is carried out due to the attractive forces arising in the “electron gas”. The hardness, density, and melting point of the metal depend on the con.

Criteria for evaluation

The answer to the question of which metal is the softest will always be a subject of discussion unless the evaluation criteria are agreed upon and the very concept of softness is defined. Opinions about this material characteristic will vary among specialists in different industries. A metallurgist may understand softness as increased malleability, a tendency to accept deformations from abrasive materials, etc.

It is important for materials scientists to be able to objectively compare different characteristics of substances. Softness should also have generally accepted evaluation criteria. The softest metal in the world must have generally recognized indicators proving its “record” characteristics. There are several techniques whose purpose is to measure the softness of various materials.

Measurement methods

Most certified methods for measuring hardness are based on the contact effect on the test material from a harder body called an indenter, measured using precision instruments. Depending on the type of indenter and the measurement methods, there are several main methods:

- Brinell method. The diameter of the imprint left by a metal ball when pressed into the surface of the test substance is determined.

- Rockwell method. The depth of indentation into the surface of the ball or diamond cone is measured.

— Vickers method. The area of the imprint left by the diamond tetrahedral pyramid is determined.

— Shore hardness. There are scales for very hard and very soft materials - the depth of immersion of a special needle or the height of rebound from the surface of a special striker is measured.

Mohs hardness scale

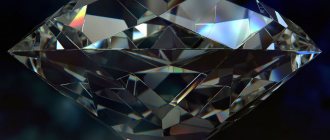

This scale for determining the relative hardness of minerals and metals was proposed at the beginning of the 19th century by the German Friedrich Mohs. It is based on the scratching method, where a harder sample leaves a mark on a softer one, and is very convenient for finding out which metal is the softest. In relation to 10 reference minerals, which are assigned a conditional hardness index, the place on the scale and a digital index are determined for the test substance. The softest reference mineral is talc. It has a Mohs hardness of 1, and the hardest, diamond, is 10.

Hardness is assessed on the Mohs scale according to the “softer - harder” principle. It is possible to determine exactly how many times, for example, aluminum, which has an index on the Mohs scale of 2.75, is softer than tungsten (6.0), only by having measurement results based on other methods. But to determine the softest metal in the periodic table, this table is quite enough.

The softest are alkali metals

From the Mohs mineralogical scale it is clear that the softest substances are those belonging to the alkali metals. Even mercury, familiar to many from the liquid from a thermometer, has a hardness index of 1.5. Softer than it are several substances that have similar physical, mechanical and chemical properties: lithium (0.6 on the Mohs scale), sodium (0.5), potassium (0.4), rubidium (0.3). The softest metal is cesium, which has a Mohs hardness rating of 0.2.

The physical and chemical properties of alkali metals are determined by their electronic configuration. It differs only slightly from the structure of inert gases. An electron located at the outer energy level has mobility, which determines high chemical activity. The softest metals are particularly volatile and difficult to mine and preserve unchanged. They are characterized by violent chemical interactions with air, water, and oxygen.

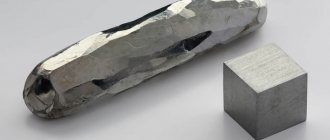

Item #55

The name “cesium” comes from the Latin caesius - “sky blue”: in the spectrum emitted by a highly heated substance, two bright blue stripes are visible in the infrared range. In its pure form, it reflects light well, looks like light gold and has a silvery-yellow color. Cesium is the softest metal in the world, the Brinell hardness index is 0.15 Mn/m2 (0.015 kgf/cm2). Melting point: +28.5°C, therefore, under normal conditions, at room temperature, cesium is in a semi-liquid state.

It is a rare, expensive and extremely reactive metal. In electronics, radio engineering and the high-tech chemical industry, cesium and alloys based on it are increasingly used and the need for it is constantly growing. Its chemical activity and ability to form compounds with the highest electrical conductivity are in demand. Cesium is an important component in the production of special optical devices, lamps with unique properties and other high-tech products. At the same time, softness is not its most sought-after quality.

4u-pro.ru

The softest are alkali metals

From the Mohs mineralogical scale it is clear that the softest substances are those belonging to the alkali metals. Even mercury, familiar to many from the liquid from a thermometer, has a hardness index of 1.5. Softer than it are several substances that have similar physical, mechanical and chemical properties: lithium (0.6 on the Mohs scale), sodium (0.5), potassium (0.4), rubidium (0.3). The softest metal is cesium, which has a Mohs hardness rating of 0.2.

The physical and chemical properties of alkali metals are determined by their electronic configuration. It differs only slightly from the structure of inert gases. An electron located at the outer energy level has mobility, which determines high chemical activity. The softest metals are particularly volatile and difficult to mine and preserve unchanged. They are characterized by violent chemical interactions with air, water, and oxygen.

The softest metal in the world

Education January 3, 2016

Metals are a type of materials that have been used by humans since ancient times. This group of substances is very numerous, but they all have common physical characteristics, which are commonly called metallic properties.

Hardness is common among them, but not decisive. Others are more specific, which even the softest metal has. These properties are determined by the features of their structure at the molecular level.

Properties of metals

Iron and its alloys (steel, cast iron), copper, aluminum... The use of these materials marked breakthroughs in scientific and technological progress at different stages of the development of civilization. Each of these metals has characteristics that give it unique practical value. Common features for them are high thermal and electrical conductivity, plasticity - the ability to maintain integrity during deformation, metallic luster.

A damask blade that cuts through iron armor, and the softest metal, on which traces remain from the slightest impact, have a similar internal structure. It is based on a crystal lattice, at the nodes of which there are atoms with a positive and neutral charge, between which there is an “electron gas” - particles that have left the outer shells of the atoms due to a weakening of the bond with the nucleus. A special metallic bond between positive ions located at the nodes of the crystal lattice is carried out due to the attractive forces arising in the “electron gas”. The hardness, density, and melting point of the metal depend on the con.

Criteria for evaluation

The answer to the question of which metal is the softest will always be a subject of discussion unless the evaluation criteria are agreed upon and the very concept of softness is defined. Opinions about this material characteristic will vary among specialists in different industries. A metallurgist may understand softness as increased malleability, a tendency to accept deformations from abrasive materials, etc.

It is important for materials scientists to be able to objectively compare different characteristics of substances. Softness should also have generally accepted evaluation criteria. The softest metal in the world must have generally recognized indicators proving its “record” characteristics. There are several techniques whose purpose is to measure the softness of various materials.

Video on the topic

Measurement methods

Most certified methods for measuring hardness are based on the contact effect on the test material from a harder body called an indenter, measured using precision instruments. Depending on the type of indenter and the measurement methods, there are several main methods:

- Brinell method. The diameter of the imprint left by a metal ball when pressed into the surface of the test substance is determined.

- Rockwell method. The depth of indentation into the surface of the ball or diamond cone is measured.

— Vickers method. The area of the imprint left by the diamond tetrahedral pyramid is determined.

— Shore hardness. There are scales for very hard and very soft materials - the depth of immersion of a special needle or the height of rebound from the surface of a special striker is measured.

Mohs hardness scale

This scale for determining the relative hardness of minerals and metals was proposed at the beginning of the 19th century by the German Friedrich Mohs. It is based on the scratching method, where a harder sample leaves a mark on a softer one, and is very convenient for finding out which metal is the softest. In relation to 10 reference minerals, which are assigned a conditional hardness index, the place on the scale and a digital index are determined for the test substance. The softest reference mineral is talc. It has a Mohs hardness of 1, and the hardest, diamond, is 10.

Hardness is assessed on the Mohs scale according to the “softer - harder” principle. It is possible to determine exactly how many times, for example, aluminum, which has an index on the Mohs scale of 2.75, is softer than tungsten (6.0), only by having measurement results based on other methods. But to determine the softest metal in the periodic table, this table is quite enough.

The softest are alkali metals

From the Mohs mineralogical scale it is clear that the softest substances are those belonging to the alkali metals. Even mercury, familiar to many from the liquid from a thermometer, has a hardness index of 1.5. Softer than it are several substances that have similar physical, mechanical and chemical properties: lithium (0.6 on the Mohs scale), sodium (0.5), potassium (0.4), rubidium (0.3). The softest metal is cesium, which has a Mohs hardness rating of 0.2.

The physical and chemical properties of alkali metals are determined by their electronic configuration. It differs only slightly from the structure of inert gases. An electron located at the outer energy level has mobility, which determines high chemical activity. The softest metals are particularly volatile and difficult to mine and preserve unchanged. They are characterized by violent chemical interactions with air, water, and oxygen.

Item #55

The name “cesium” comes from the Latin caesius - “sky blue”: in the spectrum emitted by a highly heated substance, two bright blue stripes are visible in the infrared range. In its pure form, it reflects light well, looks like light gold and has a silvery-yellow color. Cesium is the softest metal in the world, the Brinell hardness index is 0.15 Mn/m2 (0.015 kgf/cm2). Melting point: +28.5°C, therefore, under normal conditions, at room temperature, cesium is in a semi-liquid state.

It is a rare, expensive and extremely reactive metal. In electronics, radio engineering and the high-tech chemical industry, cesium and alloys based on it are increasingly used and the need for it is constantly growing. Its chemical activity and ability to form compounds with the highest electrical conductivity are in demand. Cesium is an important component in the production of special optical devices, lamps with unique properties and other high-tech products. At the same time, softness is not its most sought-after quality.

Source: fb.ru

monateka.com

Item #55

The name “cesium” comes from the Latin caesius - “sky blue”: in the spectrum emitted by a highly heated substance, two bright blue stripes are visible in the infrared range. In its pure form, it reflects light well, looks like light gold and has a silvery-yellow color. Cesium is the softest metal in the world, the Brinell hardness index is 0.15 Mn/m2 (0.015 kgf/cm2). Melting point: +28.5°C, therefore, under normal conditions, at room temperature, cesium is in a semi-liquid state.

It is a rare, expensive and extremely reactive metal. In electronics, radio engineering and the high-tech chemical industry, cesium and alloys based on it are increasingly used and the need for it is constantly growing. Its chemical activity and ability to form compounds with the highest electrical conductivity are in demand. Cesium is an important component in the production of special optical devices, lamps with unique properties and other high-tech products. At the same time, softness is not its most sought-after quality.

2QM.ru: The softest metal in the world

Metals are a type of materials that have been used by humans since ancient times. This group of substances is very numerous, but they all have common physical characteristics, which are commonly called metallic properties.

Hardness is common among them, but not decisive. Others are more specific, which even the softest metal has. These properties are determined by the features of their structure at the molecular level.

The content of the article

Properties of metals

Iron and its alloys (steel, cast iron), copper, aluminum... The use of these materials marked breakthroughs in scientific and technological progress at different stages of the development of civilization. Each of these metals has characteristics that give it unique practical value. Common features for them are high thermal and electrical conductivity, plasticity - the ability to maintain integrity during deformation, metallic luster.

A damask blade that cuts through iron armor, and the softest metal, on which traces remain from the slightest impact, have a similar internal structure. It is based on a crystal lattice, at the nodes of which there are atoms with a positive and neutral charge, between which there is an “electron gas” - particles that have left the outer shells of the atoms due to a weakening of the bond with the nucleus. A special metallic bond between positive ions located at the nodes of the crystal lattice is carried out due to the attractive forces arising in the “electron gas”. The hardness, density, and melting point of the metal depend on the con.

Criteria for evaluation

The answer to the question of which metal is the softest will always be a subject of discussion unless the evaluation criteria are agreed upon and the very concept of softness is defined. Opinions about this material characteristic will vary among specialists in different industries. A metallurgist may understand softness as increased malleability, a tendency to accept deformations from abrasive materials, etc.

It is important for materials scientists to be able to objectively compare different characteristics of substances. Softness should also have generally accepted evaluation criteria. The softest metal in the world must have generally recognized indicators proving its “record” characteristics. There are several techniques whose purpose is to measure the softness of various materials.

Measurement methods

Most certified methods for measuring hardness are based on the contact effect on the test material from a harder body called an indenter, measured using precision instruments. Depending on the type of indenter and the measurement methods, there are several main methods:

- Brinell method. The diameter of the imprint left by a metal ball when pressed into the surface of the test substance is determined.

- Rockwell method. The depth of indentation into the surface of the ball or diamond cone is measured.

— Vickers method. The area of the imprint left by the diamond tetrahedral pyramid is determined.

— Shore hardness. There are scales for very hard and very soft materials - the depth of immersion of a special needle or the height of rebound from the surface of a special striker is measured.

Mohs hardness scale

This scale for determining the relative hardness of minerals and metals was proposed at the beginning of the 19th century by the German Friedrich Mohs. It is based on the scratching method, where a harder sample leaves a mark on a softer one, and is very convenient for finding out which metal is the softest. In relation to 10 reference minerals, which are assigned a conditional hardness index, the place on the scale and a digital index are determined for the test substance. The softest reference mineral is talc. It has a Mohs hardness of 1, and the hardest, diamond, is 10.

Hardness is assessed on the Mohs scale according to the “softer - harder” principle. It is possible to determine exactly how many times, for example, aluminum, which has an index on the Mohs scale of 2.75, is softer than tungsten (6.0), only by having measurement results based on other methods. But to determine the softest metal in the periodic table, this table is quite enough.

The softest are alkali metals

From the Mohs mineralogical scale it is clear that the softest substances are those belonging to the alkali metals. Even mercury, familiar to many from the liquid from a thermometer, has a hardness index of 1.5. Softer than it are several substances that have similar physical, mechanical and chemical properties: lithium (0.6 on the Mohs scale), sodium (0.5), potassium (0.4), rubidium (0.3). The softest metal is cesium, which has a Mohs hardness rating of 0.2.

The physical and chemical properties of alkali metals are determined by their electronic configuration. It differs only slightly from the structure of inert gases. An electron located at the outer energy level has mobility, which determines high chemical activity. The softest metals are particularly volatile and difficult to mine and preserve unchanged. They are characterized by violent chemical interactions with air, water, and oxygen.

Item #55

The name “cesium” comes from the Latin caesius - “sky blue”: in the spectrum emitted by a highly heated substance, two bright blue stripes are visible in the infrared range. In its pure form, it reflects light well, looks like light gold and has a silvery-yellow color. Cesium is the softest metal in the world, the Brinell hardness index is 0.15 Mn/m2 (0.015 kgf/cm2). Melting point: +28.5°C, therefore, under normal conditions, at room temperature, cesium is in a semi-liquid state.

It is a rare, expensive and extremely reactive metal. In electronics, radio engineering and the high-tech chemical industry, cesium and alloys based on it are increasingly used and the need for it is constantly growing. Its chemical activity and ability to form compounds with the highest electrical conductivity are in demand. Cesium is an important component in the production of special optical devices, lamps with unique properties and other high-tech products. At the same time, softness is not its most sought-after quality.

2qm.ru